Documente Academic

Documente Profesional

Documente Cultură

Study Guide 2013

Încărcat de

Portia ShilengeDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Study Guide 2013

Încărcat de

Portia ShilengeDrepturi de autor:

Formate disponibile

FACULTY OF ENGINEERING AND THE BUILT ENVIRONMENT

DEPARTMENT OF CHEMICAL AND METALLURGICAL ENGINEERING

NAME OF COURSE PROCESS CONTROL III

NQF

LEVEL

NQF

CREDITS

QUALIFICATION & SAQA ID COURSE CODE

6 0.083

Diploma in ..

SAQA ID No.: ..

PCT301T

COMPILED BY M.L. MOROPENG

2013

STUDENT COURSE GUIDE

Page 2 of 22

COPYRIGHT : Tshwane University of Technology

Private Bag X680

PRETORIA

0001

All rights reserved. Apart from any reasonable quotations for the purposes

of research criticism or review as permitted under the Copyright Act, no part

of this book may be reproduced or transmitted in any form or by any means,

electronic or mechanical, including photocopy and recording, without

permission in writing from the publisher.

Printed and distributed by :

FACULTY OF ENGINEERING AND BUILT

ENVIRONMENT

Tshwane University of Technology

Private Bag X680

Pretoria

0001

Page 3 of 22

ORGANISATIONAL COMPONENT CONTENTS:

1. Welcome ................................................................................................................ 5

2. Staff ....................................................................................................................... 5

2.1 Contact Details ................................................................................................ 5

2.2 Staff availability ................................................................................................ 5

3. Requirements, resources and recommended material. ....................................... 5

3.1 Requirements for the course ............................................................................ 6

4. Code of conduct .................................................................................................. 8

4.1 Attendance ....................................................................................................... 8

4.2 Classroom behaviour ....................................................................................... 8

4.3 Responsibilities of students ............................................................................. 8

1. Overview of the course ....................................................................................... 9

1.1 Purpose of the course ...................................................................................... 9

1.2 Links to other subjects ..................................................................................... 9

1.3 Course outcomes ............................................................................................. 9

2. Assessment ...................................................................................................... 10

2.1 Assessment methods and criteria ................................................................. 10

2.2 Assessment rules .......................................................................................... 10

2.3 Marking system .............................................................................................. 10

2.4 Year mark ...................................................................................................... 10

2.5 Moderation.................................................................................................. 10

2.6 Promotion requirements................................................................................. 11

3. Course content and schedule of tests and assignments ................................... 11

3.1 Course structure and schedule of tests and assignments ............................. 11

3.2 Learning outcomes and assessment criteria.................................................. 13

Page 4 of 22

3.3 Generic outcomes and critical cross-field outcomes ...................................... 16

4. GLOSSARY OF TERMS ......................................................................................... 16

5. Assessment of record ............................................................................................. 16

5.1. Examples of tests .......................................................................................... 17

Page 5 of 22

SECTION A ORGANISATIONAL COMPONENT

1. WELCOME

Welcome to the Process Control III class. This is a one-semester subject, which provides an introduction in the

Process Control with particular application to Chemical Engineering field. It is offered via compulsory lectures

over 14 weeks. The course is structured in such a way as to provide a sound foundation for application of

process control principles in Chemical Engineering. We trust you will enjoy the course, and find it interesting

and informative. Good knowledge of physics, chemistry and mathematics is the requirement for the course.

2. STAFF

2.1 CONTACT DETAILS

NAME CAMPUS

ROOM

NO

TEL NO

CONSULTATION

TIMES

ACADEMIC

FUNCTION

Ms. ML

Moropeng

Pretoria 3-724

012-382-3516

moropengl@tut.ac.za

On appointment Lecturer

Mr MR

Futhana

External

Not available

Moderator

2.2 STAFF AVAILABILITY

If, after attending class and making every effort from your side to master content, you still have

problems with understanding key concepts or principles or their application, lecturer is available for

consultation (by appointment only, or in class but during office hours!).

3. REQUIREMENTS, RESOURCES AND RECOMMENDED MATERIAL.

Page 6 of 22

3.1 REQUIREMENTS FOR THE COURSE

3.1.1 PRESCRIBED RESOURCES

The following tables indicate what literature and other resources are essential for successful

completion of this course. You are strongly advised to acquire all the prescribed resources.

PRESCRIBED LITERATURE

CATEGORY AUTHOR NAME PUBLISHER ISBN NO

TEXTBOOK Svrcek W.Y.,

Mahoney D.P.,

Young B.R.

A Real-Time Approach to

Process Control. 2

nd

edition

John Wiley &

Sons, 2006

0-470-02534-

4

TEXTBOOK Serbog D.E, Edgar

T.F, and

Mellichamp D.A.

Process Dynamics and

Control. 2

nd

edition

John Wiley &

Sons,, 2004

0-471-00077-

9

TEXTBOOK Norman H.

Ceaglske

Automatic Process Control

for Chemical Engineers

John Wiley &

Sons,, 1956

COMPULSARY LITERATURE

NOTES Moropeng M.L. PROCESS CONTROL III 2013

Lecture notes discussed in

classes

myTUTor

OTHER PRESCRIBED RESOURCES

CATEGORY DESCRIPTION WHERE TO FIND COST LEVY

CALCULATOR ANY SCIENTIFIC

CALCULATOR

ANY GOOD BOOKSHOP

3.1.2 RECOMMENDED RESOURCES

Page 7 of 22

The following recommend resources will enhance your understanding and knowledge in this course,

and you are encouraged to use the following additional resources.

RECOMMENDED RESOURCES

CATEGORY AUTHOR NAME PUBLISHER ISBN NO

BOOKS C. D. Johnson Process Control Instrumentation

Technology, 7

th

ed

Prentice Hall 2003 0-13-048731-7

D.O. Desa Instrumentation Fundamentals for

Process Control

Taylor Francis 2001 1-56032-901-7

D.M. Considine Process/industrial instruments

and controls handbook, 5

th

ed.

McGraw-Hill 2002 0-07-012582-1

B.G. Liptak Instrument Engineers Handbook.

Volume One: Process

Measurement and Analysis, 4

th

ed.

CRC Press 2002 0849310830

G. Stephanopoulos Chemical Process Control:

Introduction to Theory and

Practice

Prentice Hall PTR

1985

9780471175391

T.E. Marlin PROCESS CONTROL: Designing

Processes and Control Systems for

Dynamic PerformanceAnalysis, 2

nd

ed.

McGraw-Hill 2000 0-07-039362-1

J. B. Riggs, M. N. Karim Chemical and Bio-process Control

3

rd

ed.

Ferret Publishing

2006

0-9669601-4-9

RECOMMENDED ELECTRONIC MATERIAL & WEBSITES

WEBSITES 1. Interactive Applets illustrating DP cell operation, Introduction to PC, controller

tuning:

http://www.chbe.gatech.edu/lee/control_modules/applet/Start/AppletsPC.html

2. Process Control Interactive Learning Modules:

http://www.pc-education.mcmaster.ca/course.htm

3. Instrumentation: http://instrumentation.co.za

4. Journals: http://www.sciencedirect.com

5. Course notes and learning resources from University of Newcastle upon Tune:

http://lorien.ncl.ac.uk/ming/Dept/Swot/connotes.htm

Page 8 of 22

6. Control Engineering Virtual Library:

http://www-control.eng.cam.ac.uk/extras/Virtual_Library/Control_VL.html

4. CODE OF CONDUCT

Please take note of the following regulations. These regulations are in addition to the standard rules

and regulations as determined by the TUT. Please familiarise yourself with the TUT rules and

regulations as set out in the student diaries received on registration.

4.1 ATTENDANCE

Regular attendance of the Process Control lectures is of primary importance. It is the learners

responsibility to sign the register each week. A minimum attendance of 80% is mandatory for all

courses including Process control III, in a 14 week, for classes that have not been attended and for

which you have not furnished a valid doctors letter or other proof of extenuating circumstances,

amounts to 20% absenteeism. This level of absenteeism will lead to exclusion from the final

moderation at the end of the year, which means that you will fail the course and will have to repeat it

the following year.

4.2 CLASSROOM BEHAVIOUR

Students are required to arrive on time for lectures. If more then 15 minutes late, dont enter the

classroom.

4.2.1. USAGE OF CELL PHONES IN CLASSES

Use of cell phones in the class: put your cell phone in silent mode. No sending SMS, or talking on cell

phone is allowed. In case of emergent incoming call, please go out of the class.

4.3 RESPONSIBILITIES OF STUDENTS

It is your responsibility to make a success of learning in this course. You are encouraged to attend all

classes, write all assessments 1 to 6 and hand in your assignments/projects on the set due dates.

Assessment 6 is compulsory, even if a student received zero score for the task(s) because of non

compliance or late submission. Non-submission of assessment 6 will imply failing the subject and will

have to repeat it the following year. You are most welcome to consult with the lecturer if you feel you

are struggling with any learning concept in this course. Please make sure to make an appointment in

advance!

Page 9 of 22

SECTION B LEARNING COMPONENT

1. OVERVIEW OF THE COURSE

This course is designed to give students the foundation of chemical engineering process

instrumentation and process control. The mathematical methods , overview of methodology for the

formulation and solution of energy balance, applied to chemical process systems. Introduces students

to the chemical engineering professional and the fundamentals operation of chemical process

equipment. It also provides students with the basic principles of chemical engineering energy balance

as well as calculation techniques to solve energy balance problem for chemical process system and

equipment.

1.1 PURPOSE OF THE COURSE

The purpose of this course is to introduce the student to the process instrumentation and process

control methods required to obtain a chemical product of a desired quality and quantity in an efficient

and economic manner, while maintaining safety. The student will understand the physical principles

used for the design and operation of the sensors, final control elements and controllers. The student

will learn how to regulate the process variables by tuning the controller. The major themes of the

course are control systems, process instrumentation and typical control modes. .

1.2 LINKS TO OTHER SUBJECTS

Good knowledge of physics, chemistry and mathematics is the requirement for the course. The

Process Control III course will help you in creating a foundation for process control IV, in B.Tech. level.

The students must have knowledge of mathematics II and other related subjects, such drawing skills

and computer skills.

1.3 COURSE OUTCOMES

The learning schedule, as set out in section A, and ways in which you will be guided to master the

content, will enable you to achieve the learning outcomes, as detailed under 3. After completion of

the course you are expected to:

1. Know the types of industrial instrumentation used to measure T,P,LL and F.

2. Learn the basics of chemical process control.

3. Understand fully the various types of industrial controllers and their characteristics.

4. Understand the effects of feedback and feed-forward control on a process.

5. Understand fully the various types of industrial control valves and their characteristics.

Page 10 of 22

6. Be able to effectively tune a single loop PID controller.

7. Understand the jargon of process control.

2. ASSESSMENT

2.1 ASSESSMENT METHODS AND CRITERIA

Assessment of this course will include 6 assessments, five (5) of which will be in the form of a formal

written tests. The 6

th

assessment is a VETO (compulsory) assessment which may includes the

assignments, E-learning , practicals, and project(s) . The various assessment methods therefore will

focus on criteria that will enable the lecturer(s) to determine whether you have achieved the learning

outcomes. The assessment criteria relevant to each learning outcome are detailed in section 3.

2.2 ASSESSMENT RULES

The faculty guidelines regarding the continuous assessment practice apply. You are advised to

familiarise yourself with these rules, as they are applied stringently. All assignments/homework

deadlines should be adhered to, failure to do will results in subtraction of marks. The application of

general rules regarding tests/assignments missed due to illness or other circumstances will apply,

students will submit a doctors note and the lecture will make allowances.

2.3 MARKING SYSTEM

The assessment will comprise of the following, five assessments, two assignments, project and a

practical work. Marks are assigned as indicated under 2.4.

2.4 YEAR MARK

The final mark will be calculated as follows:

Overall mark is 100%

Assessment 1* (18%) + Assessment 2*(18%) + Assessment 3*(18%) + Assessment 4*(18%) +

Assessment 5*(18%) + Assessment 6*(10%) = 100%.

Assessment 6 = ave (Assignment+ project+ practical) *(10%)

If you have queries about your mark, you must immediately consult your course lecturer (contact details are given above),

before final publication of results. Once the marks are entered on TUTs mainframe computer, the mark cannot be

changed.

2.5 MODERATION

Exam paper will be checked by external moderator.

Page 11 of 22

2.6 PROMOTION REQUIREMENTS

This is a continuous assessment subject and a student must obtain a minimum weighted average

marks (for ALL five assessments, and VETO assessment (assignments, projects, and E-Learning

assessments) of 50% et-least in order to pass this course. A student shall achieve a distinction when

the accumulated total equals or exceeds 75%. As a continuous assessment subject, Main,

Supplementary or Exit examination opportunities do not apply.

3. COURSE CONTENT AND SCHEDULE OF TESTS AND ASSIGNMENTS

This course comprises both a theory and application component. Your mastery of that theory is

assessed at regular intervals. More importantly, the application of theory is assessed through

assignments/projects.

The following outline provides an overview of the content to be covered in this course and the ways in

which your progress will be assessed.

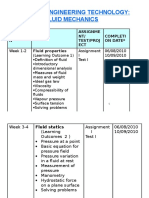

3.1 COURSE STRUCTURE AND SCHEDULE OF TESTS AND ASSIGNMENTS

DURATION THEME

ASSIGNMENT/

TEST/PROJECT

COMPLETION DATE*

Week 2-3

CONTROL THEORY

Incentives for Process Control; Control

Loops and Variables

- Incentives for Process Control

- Logic Flow Diagram for a Control

Loop

- Physical Diagram for a Control

Loop

- Feedback and feed forward

control

January-February

2012

Week 3

Process and Instrumentation Diagram

& Process parameters measurements

- Pressure measurement

- Level measurement

- Temperature measurement

- Flow rate measurement

Assignment 01

february 2012

Page 12 of 22

Class test 1

Week 4

Dynamic behavior of control loop

systems

- Block diagram

representation

- Transfer functions

- Response of simple control

systems

July -August 2013

Week 5-6

Laplace transformation

- Table of Laplace

Transformation

- Laplace Transformation for

ODEs

- The inverse Laplace

Transformation of an ODE.

- Laplace Transformation to

solve partial fractions..

Semester test 1 August 2013

Week 7-8

Dynamic modeling (Fundamentals of

Single-Input Single-Output System )

- Derive mathematical model

of all elements of control

- Obtain process dynamic

response curve (step function

input)

- P-I-D control modes

September 2013

Week 9-10

Dynamic behavior of first-Order and

Second-Order Processes.

- Response of first - order process.

- The first-order response to a

forcing function.

- Graphical representation of the

first order response.

- Important cases of a second-

order response.

- The second-order response to a

Assignment 2

Class test 2

September -October

2013

Page 13 of 22

forcing function

Week 11

Process Controllers

- On/off controllers

- List and discuss process controller

modes

- Features of PID controllers

October 2013

Week 12

Stability

- General stability criterior

- Method of tuning (Ziegler-

Nichols)

- Tuning of PI and PID controller

- Open loop tuning

- Closed loop tuning

Semester test 2 November 2013

Week 13

Control Valve Operation

- Select control valve type

- Size control valve

Class test 3

December 2013

Week 14

SICK/MAKEUP TEST:

(All Learning

Outcomes )

December 2013

*Please note that test dates may be moved on short notice where circumstances require such change. Also,

take particular note of the rules regarding tests and assignments in section B, 2.6

(List the topics or themes covered and remember to cross reference the learning outcomes. )

3.2 LEARNING OUTCOMES AND ASSESSMENT CRITERI A

The following tables clearly indicate what you have to achieve (the learning outcomes) and how you

will be assessed (assessment criteria) to determine whether you have achieved the required

knowledge and competences:

Page 14 of 22

LEARNING OUTCOME 1:

Identify process variables

Assessment criteria Assessment method

1.1 The process control Incentives are explained.

1.2. Process variables are identified.

1.3. Control objectives are identified.

1.4. Process variables are classified as controlled

variables, manipulated variables and disturbances.

Test/home assignment

LEARNING OUTCOME 2

Explain various types of control systems

Assessment criteria Assessment method

2.1 The differences between open and closed loop are

explained

2.2 Elements of closed loop control system are

identified

2.3 Functions of elements of closed control loop are

explained

2.6 The difference between a feedback and feed

forward control systems are explained

2.7 The effect of disturbances on the control system are

discussed

Test/home assignment

LEARNING OUTCOME 3

Demonstrate the ability to tune a controller

Page 15 of 22

3.1 Control modes are identified

3.2 Functions of control modes are discussed

3.3 Correct controller parameters are determined

Test/home assignment

LEARNING OUTCOME 4

Demonstrate the ability to select and size a valve.

Assessment criteria Assessment method

5.1 General operation of control valve is explained.

5.2 Types of control valves and purpose of their usage

are explained.

5.3 Valve characteristic are explained.

5.4 Valve coefficient is determined.

5.5 Control valve selected for specific application

Test/home assignment/lab

LEARNING OUTCOME 5

Demonstrate understanding of advanced control modes (cascade, ratio, override) and ability to select a and apply

control mode for given process

7.1 Cascade control is explained and applied

7.2 Ratio control is explained and applied

7.3 Override control is explained and applied

Test/home assignment/lab

LEARNING OUTCOME 6:

Understand Incentives for Process Control

9.1 Explain why do we need Process Control

Test/home assignment

LEARNING OUTCOME 7:

Derive mathematical models of unit operations

10.1 Apply principles of mass and energy conservation

Test/home assignment/lab

Page 16 of 22

3.3 GENERIC OUTCOMES AND CRITICAL CROSS-FIELD OUTCOMES

4. GLOSSARY OF TERMS

Refer to the lecture notes and text book

5. ASSESSMENT OF RECORD

to derive mathematical models of all elements in the

process control loop (process, sensor, actuator)

10.2 Analyze dynamics of a unit operation (process)

LEARNING OUTCOME 8

Apply and analyze typical control loops

Assessment criteria Assessment method

11.1 Select controllers and tune control loops for typical

applications:

Flow control loops

Level control loops

Pressure control loops

Temperature control loops

Composition control loops

Test/home assignment/lab

LEARNING OUTCOME 9

Tuning process control loops

12.1 Apply process reaction curve method to find PID

controller parameters

12.2 Apply Internal model control tuning rules

12.3 Apply auto-tune variation technique

Test/home assignment/lab

Page 17 of 22

The following tests and examination are attached to serve as example of the implementation of the

assessment criteria and assessment method.

5.1. EXAMPLES OF TESTS

Question 1

The feedback system shown in the figure 1, below has the transfer function of the forward path

as

( )

(

+ a s s

K

and the transfer function of the feedback path as | | 1 .

Figure 1: Feedback system

Determine the following:

a. Decay ratio

b. Settling time

c. Period of oscillation

Question 2

Consider a process with the transfer function,

( )( )( ) 5 3 1

1

) (

+ + +

=

s s s

s G , that is to be placed

under PID control. Determine the stability of the process using Ziegler Nichols method.

Question 3

+

( )

|

|

.

|

\

|

+ a s s

1

( ) K

1

Page 18 of 22

3.1. A proportional controller is used to control the height of water in tank where the water

level can vary from 0-9m. The controller is to fully close a valve when the water rises to

5.5m and fully open when the water falls to 4.5m. If the required level is 5 m, compute the

proportional band and the controller gain (transfer function).

3.2. Consider the proportional - mode level - control system. Valve is linear, with a flow scale

factor of 10 m

3

/h per percent controller output. The controller output is nominally 50%

with a constant of K

c

= 10% /%. A load change occurs when flow through valve F

out

changes from 500 m

3

/h to 600 m

3

/h. Calculate the new controller output and offset error.

1. What do you understand about the following?

a) Manipulated variable

b) Controlled variable

c) Measured variable

d) Set point

e) Process

2. The process is given by the equation

M G L G X

s m s L ) ( ) (

+ =

Draw the block diagram representation of the process, and construct the feedback

loop, showing all the essential elements (process, measurements, evaluation and

control) of process control.

3. What is Laplace transformation, by definition?

x(t)

Controller

LT

F

in

F

out

Page 19 of 22

4. Solve the given equations using Laplace transformation. The initial conditions are

zero.

a)

t

e y

dt

y d

2

2

2

2

= + (10)

b) 0 6 11 6

2

2

3

3

= + + + y

dt

dy

dt

y d

dt

y d

(10)

c) 1 2

2

2

= + + x

dt

dx

dt

x d

(10)

5. Using Laplace technique, determine the response (at time (t) =10 min) of the

process when the input is subjected to the unit step.

a)

8 6

40 22 4

) (

) (

2

2

+ +

+ +

=

s s

s s

s R

s C

(10)

6. A process of unknown transfer function is subjected to a unit impulse input. The

output of the process is measured accurately and is found to be represented by

the function.

t e t Y

t

3 1 ) ( =

,

Determine the original ordinary differential order (ODE) of this process.

Consider the figure 1 below,

Fig: 1 a man in the shower.

Page 20 of 22

1. Identify the following

1.1. Two process variables

1.2. The two disturbances

1.3. Three manipulated variables

1.4. Three measured variable

2. Draw the feedback and a feed forward control loops for the blending

process in figure 2 and discuss the advantages and disadvantages of both

control loops.

Fig: 2 a blending process.

QUESTION 3

Pure A

W

2

X

2

=1

Mixture (A,B)

W

1

X

1

W

X

Page 21 of 22

Determine the overall transfer functions of the following system, if the elements

have the transfer functions as given. (Use blocks diagram algebra).

QUESTION 4

4.1. Define Laplace transformation.

4.2. Find the response at time (t =1)

( )

( )

3

1

4

) (

+

+

=

s

s

s Y

C

o

C

i

Page 22 of 22

4.3. Determine y (t) when subjected to a unit step input , all initial conditions

equals to zero.

4.4.

) 4 4 (

3

) (

) (

2

+ +

+

=

s s

s

s X

s Y

1 6 11 6

2

2

3

3

= + + + y

dt

dy

dt

y d

dt

y d

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Suitable Pumps For GasolineDocument5 paginiSuitable Pumps For GasolinePortia ShilengeÎncă nu există evaluări

- UOP Reforming Solutions For .Improved Profits PaperDocument32 paginiUOP Reforming Solutions For .Improved Profits PaperstevemetroÎncă nu există evaluări

- Non Newtonian FluidsDocument12 paginiNon Newtonian FluidsPortia ShilengeÎncă nu există evaluări

- Solved Problems Samples in Fluid Flow PDFDocument10 paginiSolved Problems Samples in Fluid Flow PDFRichard Obinna100% (1)

- Presentations Oil Refinery ProcessesDocument36 paginiPresentations Oil Refinery ProcessesGururaj SreepatharaoÎncă nu există evaluări

- 7 Flow of Compressible FluidsDocument27 pagini7 Flow of Compressible FluidsPortia ShilengeÎncă nu există evaluări

- 2011-03 Head Losses Calculations PDFDocument44 pagini2011-03 Head Losses Calculations PDFAnastasia Monica KhunniegalshottestÎncă nu există evaluări

- 12 Chapter3 Section4 Oil Refining Industry Page193 220Document26 pagini12 Chapter3 Section4 Oil Refining Industry Page193 220Muhammad FarooqÎncă nu există evaluări

- Caracteristicas Normas ASME B31Document3 paginiCaracteristicas Normas ASME B31darthneoÎncă nu există evaluări

- ECO2SA W2E Facility Draft Scoping Report For PPP 30 May 2012Document99 paginiECO2SA W2E Facility Draft Scoping Report For PPP 30 May 2012Portia ShilengeÎncă nu există evaluări

- Fluid Mechanics PresentationDocument158 paginiFluid Mechanics PresentationPortia ShilengeÎncă nu există evaluări

- Fluid Mechanics PresentationDocument158 paginiFluid Mechanics PresentationPortia ShilengeÎncă nu există evaluări

- 4 Flow MeasurementsDocument19 pagini4 Flow MeasurementsPortia ShilengeÎncă nu există evaluări

- Lecture 6Document42 paginiLecture 6Anonymous 9R53UyÎncă nu există evaluări

- Conservation Laws: Control-Volume Approach: M Total Mass (KG) of A Within The System at Any TimeDocument8 paginiConservation Laws: Control-Volume Approach: M Total Mass (KG) of A Within The System at Any TimePortia ShilengeÎncă nu există evaluări

- Cive1400 200304 PDFDocument17 paginiCive1400 200304 PDFMohd Nazri SalimÎncă nu există evaluări

- Chapter 11Document36 paginiChapter 11Hamza FayyazÎncă nu există evaluări

- Cive1400 2000 01 - v2Document14 paginiCive1400 2000 01 - v2naefmubarakÎncă nu există evaluări

- Milestones Achieved: Viscous Flow in Pipes ??Document74 paginiMilestones Achieved: Viscous Flow in Pipes ??Portia ShilengeÎncă nu există evaluări

- Assignment 1-2013Document3 paginiAssignment 1-2013Portia ShilengeÎncă nu există evaluări

- Fluid PropertiesDocument32 paginiFluid Propertiesjmartinezmo100% (1)

- Experiment Report: Characterizing Resonant Series RLC Circuits Using LabviewDocument15 paginiExperiment Report: Characterizing Resonant Series RLC Circuits Using LabviewPortia ShilengeÎncă nu există evaluări

- Laminar Flow and Frictional Pressure DropDocument35 paginiLaminar Flow and Frictional Pressure DropsyedmuhammadtariqueÎncă nu există evaluări

- 2016 Heat and Mass Transfer Practical ManualDocument8 pagini2016 Heat and Mass Transfer Practical ManualPortia ShilengeÎncă nu există evaluări

- Optimization of Ball Mill Lifter Profiles and Determination of Top Ball SizeDocument15 paginiOptimization of Ball Mill Lifter Profiles and Determination of Top Ball SizePortia ShilengeÎncă nu există evaluări

- Chapter 11Document36 paginiChapter 11Hamza FayyazÎncă nu există evaluări

- 2014 Nua301t Assessment 1 - MemoDocument4 pagini2014 Nua301t Assessment 1 - MemoPortia ShilengeÎncă nu există evaluări

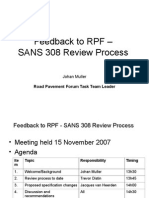

- 15 Johan MullerDocument22 pagini15 Johan MullerPortia ShilengeÎncă nu există evaluări

- p2 Cyclone Eff ProjctDocument12 paginip2 Cyclone Eff ProjctPortia ShilengeÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- 11 Chapter3Document45 pagini11 Chapter3Eloisa May LanuzaÎncă nu există evaluări

- Final Lesson Plan InvertebratesDocument4 paginiFinal Lesson Plan Invertebratesapi-301992134100% (2)

- Student Interest InventoryDocument9 paginiStudent Interest Inventoryapi-448791207Încă nu există evaluări

- Adekolavit 020111Document18 paginiAdekolavit 020111butidontwanttoÎncă nu există evaluări

- B.SC Physics Sem 5 6Document31 paginiB.SC Physics Sem 5 6vikasbhavsarÎncă nu există evaluări

- Improving Listening and Speaking Skills by Usinganimation Videos and Discussion MethodDocument7 paginiImproving Listening and Speaking Skills by Usinganimation Videos and Discussion MethodQuinnzaÎncă nu există evaluări

- Content Magnets 3717Document5 paginiContent Magnets 3717api-351279190Încă nu există evaluări

- The Professional Pricing Society (PPS) Brings Pricing Expertise To BerlinDocument2 paginiThe Professional Pricing Society (PPS) Brings Pricing Expertise To BerlinMary Joy Dela MasaÎncă nu există evaluări

- Essay Proposal Guidelines ResearchDocument2 paginiEssay Proposal Guidelines ResearchcrsarinÎncă nu există evaluări

- Teacher as Curricularist: Understanding the Key Roles(39Document50 paginiTeacher as Curricularist: Understanding the Key Roles(39jerick lanojanÎncă nu există evaluări

- Personal Growth and Professional DevelopmentDocument38 paginiPersonal Growth and Professional DevelopmentJackylyn Libay100% (1)

- The Role of Parents in Enhancing Discipline Among Students in Public Day Secondary Schools in Ngong Divison Kajiado North KenyaDocument10 paginiThe Role of Parents in Enhancing Discipline Among Students in Public Day Secondary Schools in Ngong Divison Kajiado North KenyaInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Homework's Effect on Student AchievementDocument11 paginiHomework's Effect on Student AchievementBrayan AcostaÎncă nu există evaluări

- Challenges 4, Module 9 Lesson 4 Bosnian Culture BankDocument2 paginiChallenges 4, Module 9 Lesson 4 Bosnian Culture BankHodžić NisvetaÎncă nu există evaluări

- Lesson Plan: Venn Diagrams (2 Periods)Document5 paginiLesson Plan: Venn Diagrams (2 Periods)api-307769664Încă nu există evaluări

- Prov502 Conference ReviewDocument4 paginiProv502 Conference Reviewapi-253983131Încă nu există evaluări

- Anatomy of An IEP UnderstoodDocument5 paginiAnatomy of An IEP UnderstoodGenevieve GuzmanÎncă nu există evaluări

- Assignment Module 2Document11 paginiAssignment Module 2Laraib jabeenÎncă nu există evaluări

- Senior Management Course Academic GuidelinesDocument17 paginiSenior Management Course Academic GuidelinesAnwarulhaq ShahÎncă nu există evaluări

- Types of Education Formal, Non-Formal, Informal Role of Various Agencies in Education.Document5 paginiTypes of Education Formal, Non-Formal, Informal Role of Various Agencies in Education.Bio FormicsÎncă nu există evaluări

- 50th 6-29-16 BookDocument60 pagini50th 6-29-16 BookJim LeiphartÎncă nu există evaluări

- Effect of Caption Meaning On Memory For Nonsense Figures PDFDocument9 paginiEffect of Caption Meaning On Memory For Nonsense Figures PDFIcaroÎncă nu există evaluări

- MBBS Prospectus 2017-18fDocument58 paginiMBBS Prospectus 2017-18fInaamullah MalikÎncă nu există evaluări

- Son RiseDocument2 paginiSon RiseAngela BatistaÎncă nu există evaluări

- NLP Leadership SkillsDocument12 paginiNLP Leadership SkillsCassandra ChanÎncă nu există evaluări

- NED University Master's in Supply Chain ManagementDocument35 paginiNED University Master's in Supply Chain Managementshoaib2769504Încă nu există evaluări

- English4 q3 Mod7 AnalyzeaStoryintermsofitsElementsDocument16 paginiEnglish4 q3 Mod7 AnalyzeaStoryintermsofitsElementsJeana Rick GallanoÎncă nu există evaluări

- Preschool Observation - Online Class-3Document6 paginiPreschool Observation - Online Class-3Mèo Mun100% (1)

- Curriculum Design EssayDocument8 paginiCurriculum Design EssayGrey ResterÎncă nu există evaluări

- Product-oriented learning focuses on student competenciesDocument4 paginiProduct-oriented learning focuses on student competenciesKri S ELÎncă nu există evaluări