Documente Academic

Documente Profesional

Documente Cultură

Win AC

Încărcat de

Raj ChavanTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Win AC

Încărcat de

Raj ChavanDrepturi de autor:

Formate disponibile

PC-based Control Open, flexible and reliable

Product Brief February 2004

What benefits does SIMATIC WinAC offer?

SIMATIC WinAC is the PC-based control system from Siemens, and is available in two versions either as a Slot PLC with hardware support (PLC = Programmable Logic Controller) or as a software PLC. Thanks to the short innovation cycles and attractive price/performance ratio, PCs are used today not just in the office but increasingly in automation, for example, for HMI tasks and data processing. Frequently, the resources of these devices are not utilized to the full and their performance is constantly expanding. So why not use the PC for open-loop and closed-loop control too? Due to the ruggedness of Industrial PCs, this is not a problem. And the openness of the PC makes it easy to integrate all the necessary hardware and software components. Optimum system integration on the one hand and openness towards third-party components on the other is not a contradiction as far as Totally Integrated Automation is concerned. What could therefore be better than solving all tasks in one single unit, thus utilizing the advantages of PC-based technology within Totally Integrated Automation? With this setup, a SIMATIC S7 is integrated in the PC, and a cost-optimized complete solution is achieved where if desired all components can come from one source. Developers and users both profit from the experience and worldwide services of Siemens as the market leader, and the high quality of the SIMATIC products and systems. PC-based controllers are configured and programmed in the same manner as S7 controllers using the STEP 7 standard software. User programs can execute depending on customer requirements on a PLC or on a PC and existing S7 programs can be ported as PC-based solutions.

WinAC (Windows Automation Center) the PC-based control solution of Totally Integrated Automation offers decisive advantages: Open PC-based Control, Windows-based Utilization of SIMATIC know-how Easy integration of technology functions Open data interfaces to the Office world and other PC applications Maximum performance and use of the main memory of the PC Communication and diagnosis throughout every level WinAC variants to suit all requirements Open PC-based Control based on Windows SIMATIC WinAC supports control on the PC. WinAC the SIMATIC S7 in your PC is the ideal solution when in addition to control and visualization functions, tasks that generate a high volume of data and high-speed technology functions have to be implemented on a PC platform. SIMATIC WinAC is easy to combine with third-party components through the OPC (OLE for Process Control) standard interface and easy to integrate into the office world. SIMATIC WinAC hardware and software can be implemented on the SIMATIC PC and on most generally available PCs equipped with the Professional versions of Windows 2000/XP. In this case, the latest PC trends and operating system variants are supported. Utilization of SIMATIC know-how WinAC is programmed using the familiar SIMATIC programming tools - with STEP 7 or, if preferred, with the well-proven Engineering Tools such as the S7-SCL (high-level textual language) or S7-GRAPH (graphical configuration for sequence controls) languages standardized to IEC 61131-3. All the configuration information for a PC-based application is generated, managed and stored centrally. Centralized engineering is

then possible over Industrial Ethernet or over PROFIBUS as well as Engineering on Target, whereby STEP 7 is directly installed on the control PC. SIMATIC WinAC is code-compatible to SIMATIC S7-400, i.e. program blocks created for SIMATIC S7-300 and S7-400 can be reused in WinAC and vice-versa. So existing software investments are protected. In combination with familiar and well-proven configuration with STEP 7, you can use your accumulated SIMATIC know-how to the full with WinAC. Easy integration of technology functions SIMATIC WinAC also supports the easy integration of technology functions, e.g. for counting, positioning and closed-loop control tasks. For this purpose, on the one hand, intelligent function modules are available for SIMATIC ET 200 distributed I/O stations that are connected through PROFIBUS DP. On the other hand, various different SIMATIC software packages, such as Standard PID Control for general closedloop control tasks and Easy Motion Control with its function block library through to Standard PLCopen Motion Control for traversing linear and circular axes, provide solutions for simple technology tasks. Fig. 1 shows an example of a control setup with WinAC and several bus systems and network components.

Centralized engineering PC Server

Panel PC with WinAC

Programming device

Open data interfaces to the Office world and other PC applications As shown in Fig. 2, SIMATIC WinAC offers an open data interface to standard software of the Office world for vertical integration on the basis of OPC (OLE for Process Control). During visualization and data processing, the process data can be accessed simply via this open data interface by using symbols. The integral OPC server permits multi-vendor industrial communications with all OPC client applications, e.g. visualization systems from other vendors.

N

Drive ET 200S distributed I/O station ET 200X distributed I/O station Operator Panel

Fig. 1: Example of a control setup with SIMATIC WinAC on Ethernet and PROFIBUS

A component of WinAC is now the SIMATIC NET OPC server which offers a significantly improved performance compared to the previous WinAC solution. Therefore a uniform OPC solution is now available for SIMATIC. SIMATIC WinCC and ProTool/Pro can be linked in through a SIMATIC interface in order to utilize comprehensive diagnostic functions and a common database. PG/OP communication supports the connection of SIMATIC programming devices and Operator Panels. Furthermore, SIMATIC WinAC also permits simple horizontal integration of technological applications, e.g. barcode reader, image processing, data acquisition, numerical control. A supplementary product is available for this (ODK, Open Development Kit), and permits access to all hardware and software components of the PC by incorporation of C++ programs into the WinAC control program, thus allowing high flexibility.

Vertical integration

SIMATIC ProTool/ Pro

SIMATIC WinCC

3rd party Visualization

Data Exchange

SIMATIC Interface

OPEN Interface

ODK

Technology

WinAC Software-PLC, Slot-PLC

Horizontal integration

Fig. 2: WinAC provides open data interfaces for vertical and horizontal integration of other applications

What benefits does SIMATIC WinAC offer?

Maximum performance and use of the main memory of the PC With SIMATIC WinAC, your PC-based automation solution can profit from the high performance of modern PCs. High processor clock frequencies result in a high-performance WinAC solution. Through utilizing the main memory of the PC, no size restrictions apply to your WinAC user programs. Communication and diagnosis throughout every level SIMATIC WinAC offers the complete functional scope of S7 communication with S7 controls and other WinAC stations over the MPI, PROFIBUS and Industrial Ethernet networks. With S7 communication, any data ranges can be transmitted and received. WinAC stations are handled here in the same manner as other S7 CPUs. By supporting several independent PROFIBUS connections (e.g. CP 5613) as well as the activation and deactivation of PROFIBUS slaves, an extremely flexible network concept can be implemented. PROFIBUS DP V1 support enables intelligent field devices with complex functions to be integrated. Direct access from a central control room beyond SIMATIC WinAC and network limits to all DP slaves and their components is particularly possible for diagnostics purposes even with remote diagnostics using Teleservice (Fig. 3). This powerful routing function indicates the status of the individual modules of the distributed slaves, i.e. faults can already be diagnosed exactly in the control room.

Control room PC

WinAC, e.g. Slot PLC

ET 200S distributed I/O station

ET 200M distributed I/O station

ET 200X distributed I/O station

Fig. 3: For diagnostic purposes, direct access is possible from the control desk through WinAC to the I/O level of the I/O devices

Simple operation An improved authorization model permits differentiation between plant owners, programmers and machine operators. Only simple PC user privileges, and not administrator privileges, are required to operate machines. This guarantees protection against unauthorized access, and may also reduce down times resulting from maloperations.

WinAC Slot PLC For increased availability and operational reliability

SIMATIC WinAC is available in two different versions as a Slot PLC or Software PLC: The WinAC Slot PLCs are used in PC-based solutions in which a higher degree of availability and operational reliability are required (Fig. 4). The WinAC Software PLCs are appropriate for PC-based applications whenever high flexibility and openness are required for integrating different tasks on a PC, e.g. data processing tasks (Fig. 5).

Fig. 4: WinAC Slot PLCs 412, 416 and power supply extension board

WinAC Slot PLCs for increased availability and operational reliability The WinAC Slot PLCs are based on the high-performance S7-400 CPUs in terms of performance and command set and enable a controller to be implemented that is independent of Windows. The Slot PLCs are subject to a restart controlled by discrete commands and after an interruption, the user program is resumed directly at the point of interruption. In combination with an optional power supply (PS Extension Board) and an external 24 V power supply, the user program of the Slot PLC can be processed completely independently of the PC. Battery backup ensures that all data memory areas are retentive. Thanks to this rugged and deterministic response, applications that demand enhanced availability and operational reliability can be implemented. The Slot PLCs have one integrated MPI/DP and one DP interface, for example, for communication with other CPUs and for interfacing to distributed I/O. In addition, the Slot PLCs support isochrone mode which can be used to implement highspeed, time-dependent applications at decentralized locations. Programs can be archived and dearchived using the hard disk of the PC. The WinAC panel on the PC offers the display and operating functions of the Slot PLC comparable with those of an S7-CPU (Fig. 6). WinAC Slot is available in two different versions: WinAC Slot 412 is based on the CPU 412 with 128 KB memory for code and 128 KB memory for data WinAC Slot 416 is based on the CPU 416 with 1.6 MB memory for code and 1.6 MB memory for data

Battery backup Status display Start and stop of the controller

Status and error display of the CPU

Memory Reset

Fig. 6: The user interface of the WinAC Slot PLC corresponds to the display and operating elements of an S7 CPU

Fig. 5: The WinAC software PLCs for high flexibility and openness

The new version of WinAC Slot offers even more performance and improved convenience: Up to four Slot PLCs can be used in one PC. Furthermore, a Software PLC can be combined with up to three Slot PLCs. An automation solution can therefore be of more compact design with fewer PCs, reducing space requirements and hardware costs. Firmware updating is carried out using a file instead of with a memory card as previously. Downloading of firmware from any PC storage medium (hard disk, USB stick, CD-ROM) in the installed state simplifies and accelerates maintenance and servicing.

Software PLC WinAC Basis For higher flexibility and openness

The SIMATIC WinAC Software PLCs are available in two different versions:

Onboard DP Interface (SIMATIC PC) or CP 5611 DP-Interface DP Master 32 Slaves Or CP 5613 - DP Interface DP Master 125 Slaves PG/OP communication

WinAC Basis WinAC RTX (real-time capability)

WinAC Basis the economical solution WinAC Basis is the economical solution for data-intensive and extensive PC tasks in combination with processes for which a deterministic response does not have to be guaranteed. A typical cycle time of 2 to 3 ms is achieved; this cycle time jitter results from the necessary operating system functions. Application examples include line and cell controllers in which different equipment units and machines are coordinated and an interface for data processing is required. WinAC Basis is a standard Windows application whose performance can be adapted to requirements by means of the processor and the Windows priority. WinAC Basis can use all the main memory of the PC and offers program backup on the hard disk. With the help of system functions (SFC 82 - 84), non-cyclic data such as production parameters and recipe data can be saved long-term on the hard disk of the PC. In combination with an uninterruptible power supply (UPS), all data can also be stored retentively. I/O interfacing over PROFIBUS DP is performed at up to 12 Mbit/s over the integrated DP interface of the SIMATIC PCs or over communications processors (CP 5611/5613). In this case, up to four PROFIBUS lines with up to 500 slaves can be operated (Fig. 7). The new version of WinAC Basis contains an optimized runtime system with an average increase in performance of around 100%. This noticeably reduces the cycle time, and significantly increases the data throughput.

PC

CP 5613 (PCI) onboard DP-Interface

Fig. 7: WinAC Basis can operate up to four independent PROFIBUS lines for interfacing to the I/O

WinAC PN - the PROFInet option package for WinAC Basis Instead of being a separate WinAC version, WinAC PN is now available as an option package for WinAC Basis. This package can be used to simply update an existing system to PROFInet functionalities for Component based Automation. WinAC PN uses the PROFInet V2.0 standard which offers an improved real-time communications response. Component based Automation permits the modular design of plants and machines by application of distributed intelligence, e.g. programmable field devices, drives and I/O stations. This significantly reduces the cost for configuration and commissioning.

Software PLC WinAC RTX For real-time and deterministic response

Real-time response means that

the response to process events takes place within a specific time which can be useful, for example, when "bad" parts are to be rejected during quality assurance. It can also be specified which priority the control program should have in comparison to the Windows application that is executing simultaneously (Fig. 8). Deterministic response means that the control program will be executed in a specified cycle and, if necessary, Windows applications that are executing simultaneously will be interrupted - this is necessary for drive controls. The time that remains until the end of the cycle time after executing the control program is then available for Windows (Fig. 9).

Fig. 8: User interface for determining the priorities for the control program and the Windows applications

WinAC RTX offers the same functional scope as WinAC Basis and also contains a real-time extension for Windows 2000/XP (Real Time eXtension of the company VenturCom). This real-time extension supports both a real-time response and a deterministic response.

This can be used to implement PCbased and machine tasks such as demanding closed-loop control and Motion Control tasks. No operating system know-how is necessary.

WinAC RTX also supports isochrone mode that can be used to implement high-speed, time-dependent applications such as closed-loop controls even with distributed I/O. Interfacing to PROFIBUS DP slaves is possible using the CP 5613. The new version of WinAC RTX contains an optimized runtime system with an average increase in performance of around 100%. This noticeably reduces the cycle time, and significantly increases the data throughput.

Output tO

Input tI

Program cycle tOB1 Minimum cycle time tMCT

Windows and other Windows applications

Output tO

Input tI

Program Cycle tOB1

Execution time

Cycle time

Fig. 9: Deterministic response of WinAC RTX thanks to a constant cycle time with a reserve for Windows following execution of the control program

Open Development Kit WinAC Option for integrating special tasks

PC-based solutions generally also include technological tasks such as image processing, data acquisition or numerical control. The new WinAC option Open Development Kit (ODK) permits flexible use of all PC resources by the control program via three different interfaces in order to upgrade the performance of the PLC functionality. All operating system functions and system resources of Windows are available to the programmer, and thus also access to external hardware and software components. The new ODK version integrates the functions of the previous supplementary packages ODK (old version for the Software PLCs) and T-Kit (for the Slot PLCs) in one single development package. Software developments can therefore be repeatedly applied since such software can now be used on all WinAC PLCs. Furthermore, the new ODK version is compatible with the previous versions, enabling existing applications to be used further.

ODK applications are developed using a standard development environment for C/C++ programming, e.g. the Microsoft Visual Developers Studio. The application development engineer thus uses a standard environment tailored to Windows applications. No C++ programming knowledge is required when incorporating such applications into the control program of WinAC. The ODK applications can be used like normal system functions in the STEP 7 program. Development engineers of C++ applications can receive support from the WinAC Competence Center:

www.siemens.com/pcbasedautomation/cc

Windows

WinAC Soft PLC

C/C++

CCX

FB

Fig. 11: The Custom Code Extension Interface (CCX) permits the calling of C/C++ programs from the control program of the WinAC Software PLC

WinAC ODK provides three interfaces for the following applications: Custom Code Extension Interface (CCX) for calling separate C/C++ programs from the control program of WinAC Shared Memory Extension Interface (SMX) for fast data exchange of WinAC with Windows applications Controller Management Interface (CMI) for integration of the WinAC panel functionality in a Windows application The table shows which interfaces are available for which WinAC versions:

Interface WinAC Soft Custom Code Extension Interface (CCX) Shared Memory Extension Interface (SMX) Controller Management Interface (CMI) Slot

Fig. 10: User interface of application wizard with class library C++ program

Windows 2000/XP

WinAC Slot PLC WinAC Software PLC

Examples of SMX application: Interfacing of motion control systems Interfacing of systems for data acquisition and analysis Transmission and saving of large quantities of production and quality data Direct high-performance incorporation of a job database Controller Management Interface (CMI) ODK can be used to integrate the function of the WinAC panel into a Windows application (Fig. 13). The CMI provides the following functions of the WinAC panel for the application: LED statuses Start and Stop of the PLC Downloading of programs Application examples: Integration of the WinAC Panels into an HMI application Remote control of the PLC Implementation of specific user privileges

Application

SMX

DP Master

Distributed I/O

Drive

Fig. 12: The Shared Memory Extension Interface (SMX) permits data exchange between Slot or Software PLC and Microsoft applications

Custom Code Extension Interface (CCX) ODK includes an application wizard and a class library for simple programming in Microsoft Visual C++ (Fig. 10). The C++ program which executes outside WinAC is called from the PLC program via the CCX using two system functions (SFC 65_000, SFC 65_001) (Fig. 11). The C program can be executed in three different manners: Synchronous, i.e. processed as part of the PLC cycle Asynchronous, i.e. started by the PLC program, and terminated in the background Continuous, i.e. processed parallel to the PLC program This permits many different applications to be implemented. Examples include: Interfacing of fieldbus cards to WinAC

Direct access to the Windows file

system

Implementation of special com

munications protocols Complex calculations for control of foil quality

Integration of robot control software in WinAC

Shared Memory Extension Interface (SMX) Via SMX, ODK supports the development of applications which require data exchange between Windows applications, e.g. Visual C++ and the WinAC PLCs, as necessary e.g. with control or image processing tasks. This data exchange takes place particularly rapidly via a dual-port RAM (DPR) or shared memory which are accessed both by the external C++ program and the PLC program (Fig. 12). ODK contains libraries for reading and writing this DPR according to the polling method. As far as the WinAC PLC is concerned, the DPR represents a 4-kB large I/O range which is accessed using load/transfer commands.

Windows Application RUN-P RUN STOP

WinAC Panel

CMI

WinAC

Fig. 13: The CMI integrates the function of the WinAC panel into a Windows application

Technical specifications of WinAC

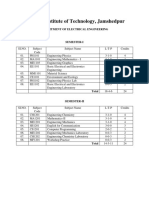

PC-based Control Software-PLC WinAC Basis V4.1 Basic features Main memory (integrated) WinAC RTX V4.1 WinAC Slot 412 V3.4 128 KB code + 128 KB data 4/4 KB 4 KB 256/256 All data 256 FB, 256 FC, 512 DB 0.200 s 0.200 s 0.600 s PC independent Up to four Slot PLCs 2 2 2048 FB, 2048 FC, 4095 DB 0.080 s 0.080 s 0.480 s PC independent Slot-PLC WinAC Slot 416 V3.4 1.6 MB code + 1.6 MB data 10/10 KB 16 KB 512/512

Usable PC memory 16/16 KByte 2 KByte 512/512 All data

Number of inputs/outputs Bit memories S7 counters/S7 timers Memory Card insertable

Usable PC memory (non-paged memory) 16/16 KB 2 KB 512/512

Retentive Without UPS and PS Extension Board With UPS With PS Extension Board and battery Number of function blocks

Only limited by the available PC memory

Command execution times Bit operations Integer operations Floating point operations Reference platform Deterministic Multi-processor mode Total No. of DP connections Integrated CP5611/ integr. interface to SIMATIC PC, max. CP5613 max. Communication functions PG/OP communication S7-communic. as server S7-communic. as client PROFInet Process data access OPC HMI through SIMATIC interface SIMATIC ProTool/Pro SIMATIC WinCC/WinCC flexible Technology SIMATIC FM 2) Easy Motion Control C/C++ Interface PLC programming software Operating system Windows NT 4.0 WS Windows 2000 Professional Windows XP Professional Order No. group

1 2

0.013 s 0.025 s 0.025 s Pentium 2.4 GHz 4 1 4 1)

0.013 s 0.025 s 0.025 s Pentium 2.4 GHz 4 4

1 Software PLC and up to 3 Slot PLCs

N N

FM 350/351/352/ 353/354/355 , with ODK STEP 7 V5.2 and higher, Engineering Tools (optional) >= SP3 >= SP1 6ES7671-0CC... 6ES7671-0RC... 6ES7673-2CC... 6ES7673-6CC...

10

) With WinAC PN option package for Component based Automation ) Notes on the FM modules: FM 350 - Counter module, FM 351 - Controlled positioning in rapid traverse and creep feed modes FM 352 - Electronic cam controller, FM 353 - Positioning with stepping motors FM 354 - Positioning with servo motors, FM 355 - Universal closed-loop control module

Software PLC on the Multi Panel Embedded Control

In addition to the WinAC variants described above, Embedded Control with WinAC MP is a software PLC that executes under Windows CE on the multifunctional platform SIMATIC MP 370.

This combination is particularly suitable for control tasks that require extremely rugged hardware.

The following table shows the most important features for differentiation. You can find further information in the Product Brief "Embedded Control with WinAC MP" (6ZB53701BK0.-....).

PC-based Control Productivity improvements thanks to

Embedded Control Cost savings due to

Flexible integration of control, visualization,

data processing and technology on a single platform Scalable solutions in hardware and software Open interfaces Utilization of the performance of the PC platform

Control and visualization on a single platform Ready to use, ready to operate components No additional hardware or software components are

necessary

Compact design Implementation directly at the machine

Compact, rugged, easy to use

Control with SIMATIC programming languages Deterministic response Retentive Operation without a fan and hard disk

Open, flexible, technologically advanced

Control with SIMATIC programming languages Deterministic response Retentive SIMATIC NET OPC Server with Data Access Alarms & Events Visualization with Pro Tool WinCC Third-party systems Technology SIMATIC FM (through ET 200) Standard libraries, EasyMotion Open Development Kit Communication over MPI PROFIBUS Industrial Ethernet

Visualization with Pro Tool

Technology SIMATIC FM (through ET 200) Standard libraries, EasyMotion Communication over PROFIBUS Industrial Ethernet

11

PC-based Automation Competence Center Our Competence Center offers you a complex spectrum of targeted services ranging from workshops and feasibility analyses through to the performance of specific development tasks under contract.

NAFTA: pcbased@sea.siemens.com Northern Europe: CCCologne@siemens.com

Southern Europe: CCMilano@siemens.it Asia: pcba@pek1.siemens.com.cn

Further info can be found in the SIMATIC Guide Technical Documentation: Order further documents concerning SIMATIC at: To get in touch with your contact person near you, visit: With the A&D Mall you can order electronically using the Internet:

www.siemens.com/simatic-tech-doku-portal

www.siemens.com/simatic/printmaterial

www.siemens.com/automation/partner

www.siemens.com/automation/mall

Siemens AG Automation and Drives Postfach 4848, D-90327 Nrnberg Federal Republic of Germany

www.siemens.com/winac

Order No.: 6ZB5310-0KP02-0BA3 Printed in the Federal Republic of Gemany 26100/401403 KB 0304 6. MAN En

Siemens AG 2004 Subject to change without prior notice. All names marked with in this Product Brief are registered trademarks of Siemens AG.

The information provided in this brochure contains descriptions or characteristics of performance which in case of actual use do not always apply as described or which may change as a result of further development of the products. An

obligation to provide the respective characteristics shall only exist if expressly agreed in the terms of contract. Availability and technical specifications are subject to change without notice. .

S-ar putea să vă placă și

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Cs01304den 0112Document2 paginiCs01304den 0112Raj ChavanÎncă nu există evaluări

- Why Has 4-20 Ma Gained So Much Acceptance and Survived So Long?Document2 paginiWhy Has 4-20 Ma Gained So Much Acceptance and Survived So Long?Raj ChavanÎncă nu există evaluări

- Proline Prosonic Flow 93W: Technical InformationDocument32 paginiProline Prosonic Flow 93W: Technical InformationRaj ChavanÎncă nu există evaluări

- What Does NAMUR NE 43 Do ForDocument1 paginăWhat Does NAMUR NE 43 Do ForRaj ChavanÎncă nu există evaluări

- Instrumentation Cables: BS 5308, Part 1 BS 5308, Part 2 and Gen. To BS 5308, Part 1Document88 paginiInstrumentation Cables: BS 5308, Part 1 BS 5308, Part 2 and Gen. To BS 5308, Part 1Raj ChavanÎncă nu există evaluări

- Friedmann05.book Page V Tuesday, June 13, 2006 11:31 AMDocument3 paginiFriedmann05.book Page V Tuesday, June 13, 2006 11:31 AMRaj ChavanÎncă nu există evaluări

- Unit 8:: Including Risks in Cost EstimationsDocument7 paginiUnit 8:: Including Risks in Cost EstimationsRaj ChavanÎncă nu există evaluări

- Surge Protec IIDocument14 paginiSurge Protec IIRaj ChavanÎncă nu există evaluări

- Appendix C:: Glossary of Economic TermsDocument2 paginiAppendix C:: Glossary of Economic TermsRaj ChavanÎncă nu există evaluări

- Unit 14: Economics of AutomationDocument7 paginiUnit 14: Economics of AutomationRaj ChavanÎncă nu există evaluări

- Preface: Comments About This VolumeDocument1 paginăPreface: Comments About This VolumeRaj ChavanÎncă nu există evaluări

- Unit 4: Benefit EstimationDocument12 paginiUnit 4: Benefit EstimationRaj ChavanÎncă nu există evaluări

- Appendix B:: Solutions To All ExercisesDocument13 paginiAppendix B:: Solutions To All ExercisesRaj ChavanÎncă nu există evaluări

- Unit 11: Strategies For Risk MinimizationDocument5 paginiUnit 11: Strategies For Risk MinimizationRaj ChavanÎncă nu există evaluări

- Unit 1: Introduction and OverviewDocument3 paginiUnit 1: Introduction and OverviewRaj ChavanÎncă nu există evaluări

- Unit 7: Ammonia Plant Control-A Detailed ExampleDocument7 paginiUnit 7: Ammonia Plant Control-A Detailed ExampleRaj ChavanÎncă nu există evaluări

- 1813 IndxDocument3 pagini1813 IndxRaj ChavanÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Five things to do before you go Agile: Arne Åhlander 安儒宣Document28 paginiFive things to do before you go Agile: Arne Åhlander 安儒宣Arne ÅhlanderÎncă nu există evaluări

- Flatbed Input DevicesDocument21 paginiFlatbed Input DevicesJaydeep PatelÎncă nu există evaluări

- Xerox Phaser 6250 Parts ServiceDocument467 paginiXerox Phaser 6250 Parts ServiceBen Midi AbbaneÎncă nu există evaluări

- Communication Engineering 1Document11 paginiCommunication Engineering 1Azza24 Azize24Încă nu există evaluări

- Harmeet KaurDocument1 paginăHarmeet KaurSakshamÎncă nu există evaluări

- Green University of Bangladesh: Faculty of Science and EngineeringDocument4 paginiGreen University of Bangladesh: Faculty of Science and EngineeringHaytham KenwayÎncă nu există evaluări

- CEM Presentation - Nov 2020 3Document45 paginiCEM Presentation - Nov 2020 3betifeleke1Încă nu există evaluări

- Itu-T: Test Methods For Installed Single-Mode Optical Fibre Cable LinksDocument34 paginiItu-T: Test Methods For Installed Single-Mode Optical Fibre Cable LinksJose ValenzuelaÎncă nu există evaluări

- Morphing Into The Flock: A Phenomenological Study of Native Students Immersed in The Online Learning PlatformsDocument129 paginiMorphing Into The Flock: A Phenomenological Study of Native Students Immersed in The Online Learning PlatformsLigaya Joyce MontebonÎncă nu există evaluări

- Symbol Table Symbol Table:: Possible Implementations TechniquesDocument7 paginiSymbol Table Symbol Table:: Possible Implementations TechniquesMilad AkbariÎncă nu există evaluări

- Metalink Notes For Oracle Apps Dba'sDocument4 paginiMetalink Notes For Oracle Apps Dba'snizamÎncă nu există evaluări

- Boiling Heat Transfer GuntDocument39 paginiBoiling Heat Transfer GuntAlyan YousafÎncă nu există evaluări

- Acs BD Schematic Most CurrentDocument8 paginiAcs BD Schematic Most CurrentgregfortkampÎncă nu există evaluări

- Women SafetyDocument6 paginiWomen Safetyanon_318625233Încă nu există evaluări

- Elektor Mag Summer 2023Document33 paginiElektor Mag Summer 2023Ludo Bagman100% (3)

- tr-8s CheatsheetDocument4 paginitr-8s CheatsheetJesús Miguel de la Morena PeinadoÎncă nu există evaluări

- Design Patterns LabDocument29 paginiDesign Patterns Labssambangi555Încă nu există evaluări

- Design of JFET Bias Circuits: ExperimentDocument11 paginiDesign of JFET Bias Circuits: ExperimentShang Divina EbradaÎncă nu există evaluări

- Space Shuttle Main Engine DrawingsDocument2 paginiSpace Shuttle Main Engine DrawingsMade in the wombÎncă nu există evaluări

- ZB MG-ZigBee Network Layer Technical OverviewDocument26 paginiZB MG-ZigBee Network Layer Technical Overviewuraza20014154Încă nu există evaluări

- How To Make An Electronic DrumDocument28 paginiHow To Make An Electronic Drumchivas1111Încă nu există evaluări

- Rate ContractDocument18 paginiRate ContractManoj RayÎncă nu există evaluări

- Affiliate Marketing - Fastest Way To Make Money OnlineDocument56 paginiAffiliate Marketing - Fastest Way To Make Money OnlineJiten Kh50% (4)

- Investigatory ProjectDocument3 paginiInvestigatory ProjectJenny Eyen Nicole0% (1)

- What's MADIDocument2 paginiWhat's MADIXristos SourgelosÎncă nu există evaluări

- Electrical BtechDocument27 paginiElectrical BtechNikhil AnandÎncă nu există evaluări

- 0901 GtsatDocument3 pagini0901 GtsatAlexander WieseÎncă nu există evaluări

- Guia Aplicacion Relay DriverDocument9 paginiGuia Aplicacion Relay DriverJulio javier Díaz GaravitoÎncă nu există evaluări

- DB 01.01.03.02 Pump M189 2Document2 paginiDB 01.01.03.02 Pump M189 2PRAMOD KUMARÎncă nu există evaluări

- The Implementation of Disney Using The ITIL ToolDocument8 paginiThe Implementation of Disney Using The ITIL Tooliness bslimaneÎncă nu există evaluări