Documente Academic

Documente Profesional

Documente Cultură

Cemb c205 Elect GB

Încărcat de

Andris PelsisTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Cemb c205 Elect GB

Încărcat de

Andris PelsisDrepturi de autor:

Formate disponibile

Special maintenance

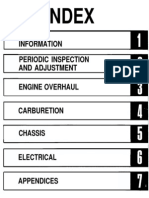

CONTENTS page

1 - CHECK OF THE RIM DISTANCE GAUGE ...................................................................................................................3 2 - ASSEMBLY OF THE PIEZO MEASURERS ..................................................................................................................4 3 - LOGIC TROUBLE SHOOTING SEQUENCE ................................................................................................................5 4 - TO CHECK MACHINE CALIBRATION .........................................................................................................................7 5 - WHEEL MEASUREMENT AND PRESETTINGS ON THE BALANCING MACHINE ...................................................7 6 - HOW TO CHECK FUNCTIONING AND ACCURACY...................................................................................................8

M 0194 GB - 1

M 0194 GB - 2

1 - CHECK OF THE RIM DISTANCE GAUGE

Check that the ruler used for measuring the DISTANCE of the wheels reads 26.5 cm as measurement of the distance from the adapter plane. If the graduated scale is changed, position it with the line indicating 26.5 at the xed index limit (reading point) when the gauge tip coincides with the adapter plane.

Fig. 1

Reading point :26.5 cm

Adapter plane

M 0194 GB - 3

2 - ASSEMBLY OF THE PIEZO MEASURERS

Problems of excessive compensation and out-of-phase sometimes depend on a fault in the piezo measurers. To replace them, proceed as follows: Fig. 2 1. Remove the weight shelf. 2. Remove nuts 1 and 2 with relative cup springs and washers. 3. Back-off screws 3, 4 and 5 then disassemble the various parts. 4. Reassemble the various parts without tightening the nuts being careful to follow the correct sequence. N.B. Mount the piezo units in accordance with the position of the coloured wires shown in the drawing. yellow 5. Keeping the spindle perfectly aligned, tighten nut 5 blue with a spanner, and nuts 3 and 4 by hand (by half a turn yellow with the spanner if necessary). white 6. Ret the washers, cup springs and nuts 1 and 2. Tighten the nuts fully in order to fully regain the elasticity of the cup springs, then loosen them by half a turn. This will automatically ensure correct loading on the piezo (a torque wrench can be used set to 400 kg. cm.). 7. Cover the piezo units with a generous layer of silicone. (N.B. For correct operation, insulation of the piezo crystals should be greater than 50 Mohm). 8. Reassemble the various parts. 9. Again carry out the automatic calibration.

M 0194 GB - 4

3 - LOGIC TROUBLE SHOOTING SEQUENCE

Is the fuse on the power supply board in a good state?

NO

Replace the power supply board

YES Replace the fuse and switch on

YES Is the fuse working? NO Disconnect CN1 on the computer board. Again replace the fuse and switch on.

Is the fuse working? YES Replace the computer board

NO

Is there a voltage of 8.5 Vac across points 1 - 3 and the earth 2 on CN3 (computer)?

NO

Check that on the CN2 the imput voltage (12/24 V DC) is available and that there is no damage in the wiring. If everything is OK, replace the power supply board.

YES

M 0194 GB - 5

Is the position sensor working? (see special testing sequence)

NO

YES

Replace the position sensor board. N.B. Do not remove the mounting brackets.

Replace the computer board

M 0194 GB - 6

4 - TO CHECK MACHINE CALIBRATION

1) Mount an iron wheel of average size and accurately preset the Distance/Diameter/Width measurements. 2) Perform 10 consecutive spins and determine the repeatability error (normally 1 g; 2 g acceptable). 3) Balance the wheel as best as possible. 4) Apply 100 g on the Outside; the following should be true: F.E. = 100 5 F.I. 5 gr Position of weight on F.E. = 6 o'clock 5) Remove the 100 g weight from the Outside (F.E.) and apply it on the Inside (F.I.); the following should be true: F.I. = 100 5 F.E. 5 gr Position of weight on F.I. = 6 o'clock

6) If the values are out-of-tolerance, proceed to self-calibration and repeats points 3), 4) 5). (N.B. F.I. = inside; F.E. = outside)

5 - WHEEL MEASUREMENT AND PRESETTING ON THE BALANCING MACHINE

The ever increasing need for more accurate calibration and use of the ALU functions means that it is important to establish how to measure the rims and how the balancing machine interprets the preset data. Hence a description is now given of how to modify the preset dimensions automatically in order to obtain the distances of the correction planes which are dened as through planes for the centres of gravity of the corrective weights. Consider a typical rim: size "l", given as width by the rim manufacturer, differs from the measurement of the distance between the correction planes for the rim thickness and physical dimensions of the counterweight, whose centre of gravity is located at distance "h" from the resting point of the rim edge. The balancing machine automatically corrects the measurement preset by adding 2 x h = 6 mm to the measurement. Measurement "b" made with the gauge is generally more accurate even if very similar to the measurement "l" known to the rim user. The two measurements differ only by the thickness of the sheet metal, usually about 2 mm per side. Such insignicant distance means that an accurate calibration can be obtained regardless of whether the inner rim width "l" or outer width "b" is preset. It is a good rule to add inch to the value given by the rim manufacturer. As regards the ALU functions, the machine performs the following approximations in addition to the systematic correction regarding the centre of gravity of the counterweight as seen above.

ALU 1 a = a preset + " b = b preset - 1 " d = d preset - 1" ALU 2 a = a preset + " b = distance of adapter surface - " -a dI = d preset - 1" dE = d preset - 2 " ALU 3 a = a preset b = distance of adapter surface - " -a dI = d preset dE = d preset - 2 "

I

12/13 mm piano appoggio

I

N.B.:

I = INSIDE E = OUTSIDE

4 E ALU a = a preset b = b preset - 3/4" dI = d preset dE = d preset - 1"

N.B. Functions ALU1/2/3/4 can only be selected when the balancing machine is set to car mode.

M 0194 GB - 7

6 - HOW TO CHECK FUNCTIONING AND ACCURACY

Further to some notices informing us of defects and unaccuracies not clearly traceable, we are explaining hereunder the procedure how to check functioning and accuracy to help us to detect problems.

FIRST CHECKS

Accurate wiping of adapter and cones Spring cover sliding Shaft end blocking

CALIBRATION BALANCING MACHINE (see SELF-CALIBRATION)

Use ta iron wheel 6" / 14" ( 1" ) Set accurate measures, in manual mode if necessary Make self-calibration

CHECKING MACHINE CALIBRATION (see TO CHECK MACHINE CALIBRATION)

Make 10 spins without loosening the wheel and detect MAX oscillations F.I. (Inner side)= F.E. (Outer side)= (tolerance 2) Put 100 gr. on FE rst and then on FI using an accurately balanced wheel) Detect rates F.I.= F.E.= POS.E.= F.I.= F.E.= POS.I= (tolerance 3%)

CHECKING THE ADAPTER

Turn a ne balanced wheel upside down (180) and detect unbalance rates ERR.MAX= This check-out in particular must be made with a sample wheel whose max unbalance errors due to centering are well known (generally lower than 10 gr. for iron wheels).

M 0194 GB - 8

S-ar putea să vă placă și

- GORBEL Freestanding Motorized Jib Crane - ManualDocument18 paginiGORBEL Freestanding Motorized Jib Crane - Manualaiyubi2Încă nu există evaluări

- Installation - Ring Gear Installation ManualDocument31 paginiInstallation - Ring Gear Installation ManualManuel Ortiz86% (7)

- Omega RG-2500Document27 paginiOmega RG-2500Haidar AlifÎncă nu există evaluări

- Service Manual: VCR Mechanism UnitDocument34 paginiService Manual: VCR Mechanism UnitcobrabrÎncă nu există evaluări

- 2003 Nissan Altima 2.5 Serivce Manual PBDocument8 pagini2003 Nissan Altima 2.5 Serivce Manual PBAndy DellingerÎncă nu există evaluări

- Balancing Machine ManualDocument20 paginiBalancing Machine Manualashley_hance6036Încă nu există evaluări

- Parking Brake SystemDocument7 paginiParking Brake SystemThomas A. EDISSONÎncă nu există evaluări

- C2600 Operating InstructionsDocument12 paginiC2600 Operating InstructionsEduardo PérezÎncă nu există evaluări

- 2 & 3 Wheeler Lab ManualDocument36 pagini2 & 3 Wheeler Lab ManualKarthi100% (1)

- Road Wheels & Tires: SectionDocument6 paginiRoad Wheels & Tires: Sectionfrank1220uÎncă nu există evaluări

- Er 82Document2 paginiEr 82Dibyendu ChakrabortyÎncă nu există evaluări

- Manual de Operacion y Mantenimiento HSM-Shaft Manual (Ing) PDFDocument16 paginiManual de Operacion y Mantenimiento HSM-Shaft Manual (Ing) PDFJorge A VilalÎncă nu există evaluări

- Bearing InspectionDocument20 paginiBearing InspectionMoustapha SeyeÎncă nu există evaluări

- H-3860D - Man - 0816 DesgasteDocument8 paginiH-3860D - Man - 0816 Desgastealvaro almendarezÎncă nu există evaluări

- 7HB (A, B, C, D, E, X) Assembly-Disassembly ManualDocument33 pagini7HB (A, B, C, D, E, X) Assembly-Disassembly ManualYavuz Ercanli100% (1)

- Parking Brake System: SectionDocument8 paginiParking Brake System: Sectiontipo3331Încă nu există evaluări

- Yamaha XS650 XS 650 Service Repair ManualDocument213 paginiYamaha XS650 XS 650 Service Repair Manualandy miller100% (4)

- TT Bearing Insp Proc v3Document7 paginiTT Bearing Insp Proc v3Rino AdityaÎncă nu există evaluări

- BI-DIRECTIONAL TOOL TURRETS INSTRUCTION MANUAL</TITLEDocument31 paginiBI-DIRECTIONAL TOOL TURRETS INSTRUCTION MANUAL</TITLEchidambaram kasi100% (17)

- ZF 4HP14 Automatic Transmission Repair Manual PDFDocument122 paginiZF 4HP14 Automatic Transmission Repair Manual PDFRajkumar100% (5)

- CC 16Document19 paginiCC 16Malisa BrownÎncă nu există evaluări

- 1 PDFDocument41 pagini1 PDFChan Peng SwanÎncă nu există evaluări

- Corona Piñon de MolinosDocument31 paginiCorona Piñon de Molinosstoneblind100% (1)

- Installation and Operation: General MountingDocument9 paginiInstallation and Operation: General MountingLarry JorgensonÎncă nu există evaluări

- Generator Testing Manual For Rotor & ExciterDocument20 paginiGenerator Testing Manual For Rotor & ExciterRakesh KumarÎncă nu există evaluări

- Axis & Ball Screw Inspection GuideDocument15 paginiAxis & Ball Screw Inspection GuidePham LongÎncă nu există evaluări

- Alp MN-756 75518Document12 paginiAlp MN-756 75518eddie0fongÎncă nu există evaluări

- Vaga WL103 Manual enDocument12 paginiVaga WL103 Manual enНебојша РадићÎncă nu există evaluări

- M-S-215 Static Cone PenetrometerDocument4 paginiM-S-215 Static Cone PenetrometerJunpieter GultomÎncă nu există evaluări

- Clinton MODEL AS-870 / 870LCD: Service ManualDocument20 paginiClinton MODEL AS-870 / 870LCD: Service ManualnachcratchÎncă nu există evaluări

- 2GR-FE Engine MechanicalDocument156 pagini2GR-FE Engine MechanicalLuks Fernandez100% (7)

- SL-ES-221-Ver03 Shovel Hoist Drum Gear Alignment ProcedureDocument60 paginiSL-ES-221-Ver03 Shovel Hoist Drum Gear Alignment ProcedurePedro Leyton CortesÎncă nu există evaluări

- Afbc Vol-IiiDocument133 paginiAfbc Vol-IiiVijay Raj100% (1)

- Procedimiento Alineaci N Tambor Hoist SL-ES-221-Ver03Document60 paginiProcedimiento Alineaci N Tambor Hoist SL-ES-221-Ver03Miguel_Angel_R_2722Încă nu există evaluări

- Cat EyeDocument2 paginiCat EyejaklaudiuszÎncă nu există evaluări

- TM 10 6670 277 13 and PDocument45 paginiTM 10 6670 277 13 and PlegasuÎncă nu există evaluări

- 4100 Digital: Wheel Balancer Operators ManualDocument22 pagini4100 Digital: Wheel Balancer Operators Manualdionisio emilio reyes jimenezÎncă nu există evaluări

- 4100 Digital: Wheel Balancer Operators ManualDocument22 pagini4100 Digital: Wheel Balancer Operators ManualASIFÎncă nu există evaluări

- WE4.000 Rev.2 Gunite ASA Pocket GuideDocument8 paginiWE4.000 Rev.2 Gunite ASA Pocket GuidePrathmeshÎncă nu există evaluări

- Operatiion & Maintenance Instructions Sharpe Mixers - Side Entry With SealDocument16 paginiOperatiion & Maintenance Instructions Sharpe Mixers - Side Entry With Sealrongweius100% (1)

- C-12 Industrial Engine BDL00001-UP (SEBP3252 - 59) - Reglages SoupapesDocument4 paginiC-12 Industrial Engine BDL00001-UP (SEBP3252 - 59) - Reglages SoupapesDamien LEGRANDÎncă nu există evaluări

- Dynamic Balancing ExpDocument10 paginiDynamic Balancing ExpSand Man Out100% (1)

- Sgs3468ahd PDFDocument62 paginiSgs3468ahd PDFDilan BvlyÎncă nu există evaluări

- Precision-9 IG EN 988-10984-002Document8 paginiPrecision-9 IG EN 988-10984-002akhilÎncă nu există evaluări

- PSHL PressureMatic Operation and Service Manual PDFDocument15 paginiPSHL PressureMatic Operation and Service Manual PDFmareveyÎncă nu există evaluări

- Operation Manual: (Wheel Balancer)Document13 paginiOperation Manual: (Wheel Balancer)hector castellanos rÎncă nu există evaluări

- Front Suspension: SectionDocument16 paginiFront Suspension: SectionOmar RodriguezÎncă nu există evaluări

- Operation Manual: (Wheel Balancer)Document13 paginiOperation Manual: (Wheel Balancer)hector castellanos rÎncă nu există evaluări

- EC 120 Adjustment Using The STEADYControl Adjustment Equipment - Cabin Antivibrators (AMM 53-37-00, 5-2)Document16 paginiEC 120 Adjustment Using The STEADYControl Adjustment Equipment - Cabin Antivibrators (AMM 53-37-00, 5-2)Latest RumorÎncă nu există evaluări

- Ccs3000 User ManualDocument21 paginiCcs3000 User ManualYUNES KORGÎncă nu există evaluări

- Manual AlmenGageDocument12 paginiManual AlmenGagerodrigoÎncă nu există evaluări

- Training BHSDocument222 paginiTraining BHSmurali03692% (13)

- si0206Document3 paginisi0206jentleproÎncă nu există evaluări

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDe la EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementÎncă nu există evaluări

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003De la EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Evaluare: 5 din 5 stele5/5 (1)

- Machine Design Elements and AssembliesDe la EverandMachine Design Elements and AssembliesEvaluare: 3.5 din 5 stele3.5/5 (2)

- How to Rebuild & Modify Rochester Quadrajet CarburetorsDe la EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsEvaluare: 5 din 5 stele5/5 (2)

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesDe la EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesEvaluare: 5 din 5 stele5/5 (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe la EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitÎncă nu există evaluări

- Physical Education For Class - 11thDocument19 paginiPhysical Education For Class - 11thdjjagu908Încă nu există evaluări

- The Human Element is Critical in Personal SellingDocument18 paginiThe Human Element is Critical in Personal SellingArsalan AhmedÎncă nu există evaluări

- Causes and Diagnosis of Iron Deficiency and Iron Deficiency Anemia in AdultsDocument88 paginiCauses and Diagnosis of Iron Deficiency and Iron Deficiency Anemia in AdultsGissell LópezÎncă nu există evaluări

- 600 2 Sub-Zero Built-In Series Refrigerator Service ManualDocument188 pagini600 2 Sub-Zero Built-In Series Refrigerator Service Manual911servicetechÎncă nu există evaluări

- Primer To Using Stampplot® Pro Standard User LicensedDocument21 paginiPrimer To Using Stampplot® Pro Standard User LicensedSandy Rachman AdrianÎncă nu există evaluări

- Performance AppraisalsDocument73 paginiPerformance AppraisalsSaif HassanÎncă nu există evaluări

- Personal Weaknesses ListDocument3 paginiPersonal Weaknesses ListKinga SzászÎncă nu există evaluări

- 5 - Econ - Advanced Economic Theory (Eng)Document1 pagină5 - Econ - Advanced Economic Theory (Eng)David JackÎncă nu există evaluări

- Louis Theroux PowerpointDocument6 paginiLouis Theroux Powerpointapi-330762792Încă nu există evaluări

- Contemporary Philippine Arts From The RegionsDocument29 paginiContemporary Philippine Arts From The RegionsDina Ilagan50% (2)

- Dreams and Destiny Adventure HookDocument5 paginiDreams and Destiny Adventure HookgravediggeresÎncă nu există evaluări

- Origin and Development of Law of Sea PDFDocument135 paginiOrigin and Development of Law of Sea PDFkimmiahujaÎncă nu există evaluări

- Kung Fu MedicinesDocument9 paginiKung Fu MedicinesDavid HewittÎncă nu există evaluări

- Financial MarketsDocument323 paginiFinancial MarketsSetu Ahuja100% (2)

- Philhis Handouts Week 1Document5 paginiPhilhis Handouts Week 1Jeen JeenÎncă nu există evaluări

- ANTENATAL ASSESSMENT Form 13Document4 paginiANTENATAL ASSESSMENT Form 13Kaku ManishaÎncă nu există evaluări

- Narasimha EngDocument33 paginiNarasimha EngSachin SinghÎncă nu există evaluări

- Tle-Bpp 8-Q1-M18Document14 paginiTle-Bpp 8-Q1-M18Michelle LlanesÎncă nu există evaluări

- Research Online Research OnlineDocument11 paginiResearch Online Research OnlineMunib HussainÎncă nu există evaluări

- Chapter 9 MafinDocument36 paginiChapter 9 MafinReymilyn SanchezÎncă nu există evaluări

- What Music Really Means To ChildrenDocument5 paginiWhat Music Really Means To ChildrenMara Sofia ValenteÎncă nu există evaluări

- People v. Cresencia ReyesDocument7 paginiPeople v. Cresencia ReyesAnggling DecolongonÎncă nu există evaluări

- The Research TeamDocument4 paginiThe Research Teamapi-272078177Încă nu există evaluări

- Policy Guidelines On Classroom Assessment K12Document88 paginiPolicy Guidelines On Classroom Assessment K12Jardo de la PeñaÎncă nu există evaluări

- Acute Care Handbook For Physical Therapists 5Th Edition Full ChapterDocument41 paginiAcute Care Handbook For Physical Therapists 5Th Edition Full Chaptergloria.goodwin463100% (20)

- Elementary Hebrew Gram 00 GreeDocument216 paginiElementary Hebrew Gram 00 GreeRobert CampoÎncă nu există evaluări

- Prayer BuddyDocument42 paginiPrayer BuddyJoribelle AranteÎncă nu există evaluări

- Intrinsic Resistance and Unusual Phenotypes Tables v3.2 20200225Document12 paginiIntrinsic Resistance and Unusual Phenotypes Tables v3.2 20200225Roy MontoyaÎncă nu există evaluări

- Untitled DocumentDocument2 paginiUntitled DocumentClaudia WinÎncă nu există evaluări

- My Manifesto - Huma 1100Document2 paginiMy Manifesto - Huma 1100api-490833029Încă nu există evaluări