Documente Academic

Documente Profesional

Documente Cultură

AN4303

Încărcat de

haas84Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

AN4303

Încărcat de

haas84Drepturi de autor:

Formate disponibile

Maxim > Design Support > Technical Documents > Application Notes > Automatic Test Equipment (ATE)

> APP 4303

Keywords: cable loss, automatic test equipment, ATE, parametric measurement unit, PMU, pin electronics, PE, cable compensation, drive-compare-load, DCL, dielectric loss, skin effect, return path loss, connector, relay, high, low frequencies, copper, conductor APPLICATION NOTE 4303

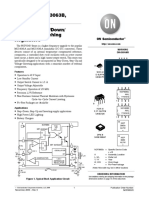

Impact of Cable Losses

By:Bernard Hyland, Senior Member of Technical Staff Sep 29, 2008 Abstract:There are many test companies that design, build, and ship large-pin-count automatic test equipment (ATE). These testers have complex integrated circuits that drive each pin of the tester. A tester could have as many as 4096 pins. Figure 1 shows that, at each pin, there is usually a driver, comparator, load, and sometimes even a parametric measurement unit (PMU). These electronics are attached to a cable, which is then connected to the pin. To keep costs down, a vendor may choose to use low-quality cables. All cables, especially low-quality ones, suffer from signal losses that reduce the ultimate performance of the tester.

Page 1 of 8

Figure 1. Typical tester setup for one device under test (DUT) pin.

Defining Cable Loss

In a typical coaxial cable ( Figure 2 ), there are two main components of cable loss: skin-effect loss and dielectric loss.

Figure 2. Typical coaxial cable.

Skin-Effect Loss

At high frequencies, the signal tends to propagate along the surface of the inner conductor (shown in

Page 2 of 8

Figure 2). This is known as skin-effect loss. This skin depth () is defined as:

where is the frequency in rad/s, is the conductor's magnetic permeability in H/m, and is the conductor's resistance in ohmmeters. The skin-effect loss causes the resistance per unit length, R l , and the inductance per unit length, L l , to increase with the square root of the frequency. The resistance per unit length is calculated as:

where w is the width of the conductor. For a circular wire of radius r, the width is 2 r. The return path resistance also needs to be added, but it is normally much less then the forward path and can be ignored.

Dielectric Loss

The dielectric insulator, shown in Figure 2, also contributes to frequency-dependent cable losses. The dielectric constant () is defined as:

where ' is the real component of the dielectric constant, and tan represents the imaginary, or loss tangent, dissipation factor of the dielectric. Because the dielectric insulator affects capacitance, the capacitance per unit length (Cl ) changes to C l (1 + jtan) .

Total Cable Loss

Including skin-effect and dielectric losses, the ideal cable per unit length model can be changed to include these losses, as shown in Figure 3 .

Figure 3. Simplified cable model. From Figure 3, we define the propagation constant as jk = ZK, where Z is the distributed series impedance, and Y is the distributed parallel admittance. In this case:

By using a Taylor expansion approximation and further simplifying, the following term can be extracted:

Page 3 of 8

where ZO is the line's characteristic impedance, r is the relative dielectric constant, and c is the speed of light. Finally, what we are really after is the cable gain, H(f) = e -jkl , where l is the length of the line. Using the findings from above, we arrive at:

where:

and

The simplistic conclusion that we want to see from the above calculations is: 1. Skin effect losses ( 1) dominate at low frequencies ( Figure 4 ) 2. Dielectric losses ( 2) dominate at high frequencies (Figure 4) In real cables, H(f) varies somewhat from the approximations above. However, it is accurate enough for most ATE work, where the attenuation increases by 6dB at the most.

Figure 4. Representation of skin-effect (inner conductor), dielectric, and return-path (outer conductor) losses. Figure 4 provides a basic representation of losses for the typical coaxial cable shown in Figure 2, which has a characteristic impedance of 50, an inner copper conductor, and an outer conductor made of braided steel. Each cable will have its own unique losses, but will still show the same trend seen in Figure 4.

Summary of Cable Losses

It is not the intent of this application note to offer a rigorous mathematical approach to the derivations of cable lossesthis can be obtained from various scholastic sources. However, what was demonstrated in the equations is summarized in Figure 4. From the above analysis we obtain the following important points: 1. All cables have losses, and these losses will ultimately limit the performance of a system. The amount of the loss depends on the quality of the cable and its specifications.

Page 4 of 8

2. The losses that do occur are: a. Skin-effect losses, which dominate at low frequencies b. Dielectric losses, which dominate at high frequencies c. Return-path losses, which are insignificant and can be ignored for most cases d. Losses through connectors, relays, and other connections made to the output nodes or the DUT

Cable Loss vs. Cable Cost

Figure 5 shows the cable loss for typical cables, while Table 1 compares the cost of some cables relative to their losses.

Figure 5. Cable losses for a variety of cables. Table 1. Typical Cost per Foot for Various Flexible Coaxial Cables from One Selected Manufacturer Cable Loss at 900MHz (dB/m) Cost per Meter ($) RG174 RG142 RG400/U RG232/U R393/U RG58/U RG8X RG8 Notes

Page 5 of 8

0.75 0.382 0.3492 0.4589 0.296 0.531 0.25 0.14

1.3 14.6 15.11 10.4 22.7 1.46 1.14 1.79 14.3

RG58 low loss 0.3691

1. The cost multiplier of a good quality cable compared to that of a low-quality cable is as high as twenty to one (Figure 5, Table 1). 2. ATE manufacturers prefer low-cost cables, but may suffer system performance degradation that is related to such cables. 3. Pin electronics without cable compensation cannot correct for cable losses. 4. Substituting high-cost, very wideband, power-hungry pin drivers only provides marginal improvements over lower cost, lower bandwidth, lower powered pin drivers when using lossy cables. 5. Using 4096 cables in a single tester means that, for each meter in length, the cost of the cable assembly could run from $5325 to $92,979 (Table 1). 6. By transferring cable compensation to the pin electronics, the savings on the 4096 pin tester examples could possibly be as high as $92,979 - $5325, or $87,654, per tester. 7. The cost values in these notes are based on the information in Table 1, and could vary significantly depending on the ATE manufacturer. However, these numbers highlight the large cost associated with the cable assemblies and, therefore, why it is important for ATE manufacturers to find alternative solutions that allow the use of lower cost cables. 8. The cables listed in Table 1 are flexible cables. The best cables are the semirigid and rigid cables. These cables cost approximately $30 per foot, which is a factor of 3 or more over the best of the flexible cables. These would be cost prohibitive to any tester manufacturer, and hence are not used. 9. As tester frequencies increase, the need for cable compensation becomes imperative. High-end testers are already approaching speeds of > 1Gbps.

Performance Degradations Due to Cable Loss

For testers that run in the 200Mbps range, cable loss may not be a big concern. However, for testers running at 500Mbps and higher, the performance of the full signal path, electronics, cable, and pin must be analyzed very carefully to ensure that full performance is measured correctly at the pin. The following performance specifications are the most important for a high-speed tester: 1. DC accuracy of the waveform levels 2. Rise and fall times 3. Maximum toggle rate 4. Minimum pulse-width capability 5. Propagation accuracy and matching relative to each edge 6. Propagation skews, such as propagation vs. minimum pulse width, amplitude, and common mode All of the aforementioned performance characteristics are impacted by the choice of the cable. As the toggle rates increase, cable losses begin to dominate and limit the performance of the tester, regardless of the driver's bandwidth for driving the cable. The plots in Figures 6 and 7 represent and highlight these problems.

Figure 6. Step response of short/high-quality cable.

Page 6 of 8

Figure 7. Step response of longer/low-quality cable. Figures 6 and 7 illustrate waveforms that most engineers have already seen and know about. However, the following is noteworthy: 1. t0 represents 50% of the waveform's amplitude. As a rule of thumb, the 10% to 90% rise time is about 28.6 x t0. These two waveforms show a significant degradation in the rise times for these two cable lengths. 2. The bandwidth-limiting rolloff nature of the curve impacts the maximum toggle rate, minimum pulse widths, and bandwidth. So, the degradation in the signal path is obvious from these plots. 3. The signal degradation has nothing to do with the actual driver. In this case, we are feeding a step response of infinite bandwidth, and it is the cable that is creating the slowdowns in rise times. 4. For higher speeds and longer cables, this problem gets worse. 5. All cables, no matter what length or quality, display the characteristics in Figures 6 and 7 to some degree. 6. It is imperative to find a solution for cable losses so as to allow the full bandwidth of the driver, otherwise the increase in cost for higher quality cables adds little to no value to the application. 7. Designing cable compensation into the electronics solves these cable loss issues.

Conclusion

Cables used in a high-speed tester can impact the overall performance of the tester and will ultimately limit its performance. Due to the high cost that can be associated with these cables, low-cost cables, which have high losses, are normally used in these high-speed systems. As the speeds of these testers approach 1Gbps and higher, you can no longer ignore these losses. Replacing the drivers with higher bandwidth drivers does not compensate the loss caused by these cables, and hence the cables will limit the performance of the system. It is necessary to find a solution to these cable losses to allow testers with bandwidths greater than 1Gbps to perform at their full potential. Fortunately, there is a solution, and that is to design cable compensation into the electronics. Related Parts MAX9957 MAX9959 MAX9979 Fast Dual Driver for ATE with Waveform Shaping 25V Span, 800mA Device Power Supply (DPS) Dual 1.1Gbps Pin Electronics with Integrated PMU and Level-Setting DACs Free Samples Free Samples

More Information

Page 7 of 8

For Technical Support:http://www.maximintegrated.com/support For Samples:http://www.maximintegrated.com/samples Other Questions and Comments:http://www.maximintegrated.com/contact Application Note 4303: http://www.maximintegrated.com/an4303 APPLICATION NOTE 4303, AN4303, AN 4303, APP4303, Appnote4303, Appnote 4303 Copyright by Maxim Integrated Products Additional Legal Notices:http://www.maximintegrated.com/legal

Page 8 of 8

S-ar putea să vă placă și

- IPDocument16 paginiIPEry PriyonoÎncă nu există evaluări

- Meaoptical RFDocument7 paginiMeaoptical RFhaas84Încă nu există evaluări

- SSS DetectionMethod JungInKimDocument5 paginiSSS DetectionMethod JungInKimhaas84Încă nu există evaluări

- 5965 2898eDocument14 pagini5965 2898ehaas84Încă nu există evaluări

- 3a0Document32 pagini3a0haas84Încă nu există evaluări

- OFDMDocument15 paginiOFDMAvinash RaghooÎncă nu există evaluări

- New Farebox Benefits New Farebox Tips: Thank You For Riding VTA!Document2 paginiNew Farebox Benefits New Farebox Tips: Thank You For Riding VTA!haas84Încă nu există evaluări

- Armstrong Ofdm PDFDocument41 paginiArmstrong Ofdm PDFTuñoque Effio ArturoÎncă nu există evaluări

- Plugin-Introduction Orthogonal Frequency Division MultiplexDocument66 paginiPlugin-Introduction Orthogonal Frequency Division MultiplexanandanandnewÎncă nu există evaluări

- AN4338Document9 paginiAN4338haas84Încă nu există evaluări

- Introducing LTE AdvancedDocument36 paginiIntroducing LTE Advancedish_945Încă nu există evaluări

- MIT6 088IAP10 Lec01Document30 paginiMIT6 088IAP10 Lec01haas84Încă nu există evaluări

- Ts 8950 GW Data SheetDocument4 paginiTs 8950 GW Data Sheethaas84Încă nu există evaluări

- Setcom S COREDocument8 paginiSetcom S COREhaas84Încă nu există evaluări

- Setcom S COREDocument8 paginiSetcom S COREhaas84Încă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Audit MCQ & BlanksDocument16 paginiAudit MCQ & BlanksYogesh Karlekar100% (10)

- DIY FM Spy Microphone CircuitDocument8 paginiDIY FM Spy Microphone CircuitJorge OrtizÎncă nu există evaluări

- Automatic Rain Detector PDFDocument19 paginiAutomatic Rain Detector PDFPrashanthÎncă nu există evaluări

- RLC Circuit With Cobra4 Xpert-Link: Difficulty Level Group Size Preparation Time Execution TimeDocument16 paginiRLC Circuit With Cobra4 Xpert-Link: Difficulty Level Group Size Preparation Time Execution TimeLahcen SoussiÎncă nu există evaluări

- Hiten Parmar: Physics byDocument5 paginiHiten Parmar: Physics byMia JohnÎncă nu există evaluări

- Forma Scientific Freezers ManualDocument38 paginiForma Scientific Freezers ManualEzsilvasilva SilvaÎncă nu există evaluări

- Bicmos Technology Improvements For Microwave ApplicationDocument4 paginiBicmos Technology Improvements For Microwave ApplicationkhnnaaÎncă nu există evaluări

- 25 Watt MosFet Audio AmplifierDocument3 pagini25 Watt MosFet Audio Amplifiermcm200Încă nu există evaluări

- PIC18F248Document402 paginiPIC18F248Ioannis PerperisÎncă nu există evaluări

- Rme April 2019 Exam 3 Key PDFDocument7 paginiRme April 2019 Exam 3 Key PDFJevan CalaqueÎncă nu există evaluări

- Comprehensive Objective Physics For Iit Jee Neet Competitive Exams Volume 2 II Narinder Kumar CompressDocument852 paginiComprehensive Objective Physics For Iit Jee Neet Competitive Exams Volume 2 II Narinder Kumar Compress0852altafÎncă nu există evaluări

- Philips Semiconductors TDA5144 Brushless DC Motor Drive Circuit SpecDocument17 paginiPhilips Semiconductors TDA5144 Brushless DC Motor Drive Circuit SpecJairoÎncă nu există evaluări

- STA543SADocument23 paginiSTA543SAbrainerkeeperÎncă nu există evaluări

- Digital Substation TestsDocument10 paginiDigital Substation Testsraghavendran raghuÎncă nu există evaluări

- User's ManualDocument24 paginiUser's ManualMARKO021Încă nu există evaluări

- Biodata To MIDIDocument18 paginiBiodata To MIDIJoão Carlos PintoÎncă nu există evaluări

- 4-Channel Integrated LCD SupplyDocument20 pagini4-Channel Integrated LCD SupplyDelta PratamaÎncă nu există evaluări

- Charge Redistribution A/D Converter Uses Weighted CapacitorsDocument9 paginiCharge Redistribution A/D Converter Uses Weighted CapacitorsHarijot Singh BindraÎncă nu există evaluări

- How To Calculate Eft by Mott-Schottky1Document4 paginiHow To Calculate Eft by Mott-Schottky1José Augusto LucenaÎncă nu există evaluări

- Analysis and Design A Series-Parallel Resonant Converter: Ashoka K. S - BhatDocument11 paginiAnalysis and Design A Series-Parallel Resonant Converter: Ashoka K. S - BhatChAmirShokatGujjarÎncă nu există evaluări

- Commander SK Technical Manual Data PDFDocument122 paginiCommander SK Technical Manual Data PDFPhong Nguyen100% (1)

- LM386 Audio Amplifier ReportDocument7 paginiLM386 Audio Amplifier ReportDhruvesh AsnaniÎncă nu există evaluări

- NCP3063, NCP3063B, NCV3063 1.5 A, Step-Up/Down/ Inverting Switching RegulatorsDocument19 paginiNCP3063, NCP3063B, NCV3063 1.5 A, Step-Up/Down/ Inverting Switching RegulatorschawkigenieÎncă nu există evaluări

- AC inspection checklist titleDocument1 paginăAC inspection checklist titlezahid_497Încă nu există evaluări

- Technical Documentation for Power Factor Regulator BLR-CXDocument40 paginiTechnical Documentation for Power Factor Regulator BLR-CXtcrajarupeshÎncă nu există evaluări

- EcoDial 3.36Document92 paginiEcoDial 3.36tatianaÎncă nu există evaluări

- Ultrathin Graphene-Protein Supercapacitors Miniaturized BioelectronicsDocument12 paginiUltrathin Graphene-Protein Supercapacitors Miniaturized BioelectronicsRavi SuryaÎncă nu există evaluări

- MX2 Multi Function Manual en 201010Document463 paginiMX2 Multi Function Manual en 201010gori-rÎncă nu există evaluări

- Wireless World 1948 09Document42 paginiWireless World 1948 09Jan PranÎncă nu există evaluări

- Application Note: AN100-1 May, 2007 Sanjay HavanurDocument3 paginiApplication Note: AN100-1 May, 2007 Sanjay HavanurIonel ConduraruÎncă nu există evaluări