Documente Academic

Documente Profesional

Documente Cultură

Item - 39 - Radial Drilling Machine-F

Încărcat de

prasad_kcpDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Item - 39 - Radial Drilling Machine-F

Încărcat de

prasad_kcpDrepturi de autor:

Formate disponibile

ITEM No-39

TECHNICAL SPECIFICATION No.Chhapra/WMP/MRS/01 RADIAL DRILLING MACHINE

5.0 5.0.1

SCOPE The specification covers the supply and putting into beneficial use of the above Radial rilling !achine "ith all electrical e#uip$ent and other accessories "hich "ill be supplied "ith the $achine. Ge era! De"#r$p%$o Radial standard "ill be dra"ing location rilling $achine co$plete "ith all e#uip$ent including $otor. The $achine erected at % one in !RS & location to no. R'TES()P(!(!RS(01 and one in PCS % to dra"ing no. R'TES()P(!(PCS(01.

5.1.0 5.1.1

5.1.*

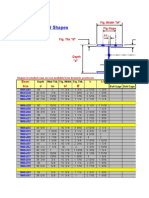

The tenderers are advised to visit Rail )heel +actory, -elahan.a, in their o"n interest for detailed study of the application of the drilling operation. They "ill see. clarifications, if any advance before sub$itting the offer. /ob Re#uire$ent The $achine shall be suitable and fully e#uipped for perfor$ing drilling, tapping and trepanning operations on various ferrous and non&ferrous $etals. +or drilling operation on graphite $ould blan. as per rg no0 C(T1(*(1, the tenderer shall also supply three 234 nos of trepanning tool as per rgno0 C(T1(*(1. TEC5'6C71 7T70 8eneral0 rilling(Trepanning Capacity rilling(Capacity rilling(Capacity <oring capacity <oring capacity rilling depth

5.*.0 5.*.1

5.*.*

5.3.0 5.3.1 5.3.* 5.3.1 5.3.3 5.3.; 5.3.5 5.3.:

0 190$$ . 050$$insteel 0:0$$ in cast iron 0=0$$ in steel 0110$$ ' cast iron 03*5$$

Tender No.2007/Workshop Projects (CWP)/GT-2

5.3.> 5.3.9 5.3.= 5.;.0 5.;.1 5.;.* 5.;.3 5.;.; 5.;.5 5.;.: 5.;.> 5.;.9 5.5.0 5.5.1 5.5.* 5.5.3 5.5.; 5.5.5 5.5.: 5.5.> 5.5.9 5.5.= 5.:.0 5.:.1 5.:.1 5.:.* 5.:.3 5.:.;

Taper spindle nose soc.et 0!.T.5 Spindle speeds0 01*(;0&1>00rp$ Spindle feeds 0:(0.1*to1.*5$$(rev rill Pressure 01:50.gs rill po"er 0;.5?" 7r$ Elevating !otor Po"er 03.0?" !a@ . rilling Radius 0*350 $$ !a@ .drill 5ead Traverse 01900$$ ia$eter of colu$n sleeve 0;00$$ !a@i$u$ distance base plate to spindle01:;5$$ !ini$u$ distance base plate to spindle 0390$$ )or.ing surface of the base plate 01ength*330$$ 0"idth1000$$ ST76 7R A SPEC'71 EBC'P!E6TS0 set

Electrical co$plete "ith "iring Set of tools for operation and another service for !aintenance of the $achine +oundation bolts($ounting pads )or. table capable of holing heavy Dobs. !achine la$p "ith **0(*;E transfor$er. Electro %5ydraulic 1oc.ing $echanis$. Set of sleeves 2+ro$ !T5 to !T14. rill rifts. Operation ad $aintenance $anual.

5.:.5 5.:.;

ES'86 +E7TCRES0 The $achine shall incorporate the design feature as under 0& 't shall be of rigid construction, suitable for light centering The gears, splines, spindles shall be $ade of alloy steel, hardened and precision ground. 7nti&+rication bearings shall be used for supporting all rotating parts li.e spindles etc., for prolonged accuracy. The original built&in accuracy of the $achine shall be capable of being $aintained conveniently and econo$ically by suitable adDust$ents and bac.&lash o scre"ed spindles etc. The $achine shall be provided "ith fine feed hand "heel. 1ubrication to all bearings, gears and slides shall be fro$ centraliFed po"er driven pu$p "ith

Tender No.2007/Workshop Projects (CWP)/GT-2

slight glass for indication of pressure and flo" of lubricant along "ith filters. 5.:.5 5.:.: 5.:.> Controls shall be through push buttons conveniently approachable by the operator. The elevation of ar$ shall be by po"er. The $achine should be capable of cla$ping electro hydraulically the drill head to the ar$, the ar$ to this sleeve and he sleeve to the colu$ns. The change tools during operation there should be an arrange$ent "hereby "ithout using center, only ar$ to sleeve cla$ping is relieved auto$atically to recla$p after traverse. The $achine should be provided "ith a depth stop, "hich shall be set fro$ a vernier scale on a large depth chart. 7uto$atic disengage$ent of po"er feed "hen re#uired depth of drilling s reached. CentraliFed arrange$ent head for pre&setting. of controls on spindle

5.:.9.

5.:.= 5.:.10

Overload safety protection in the $echanical drive syste$ to safeguard driving parts against overloading. There should be positive protection of all ele$ents by $eans of a $echanis$ in the fed drive. Radically located steel balls trans$it tor#ue pressed on to a notched plate. The balls ride the notches "ith the slightest overload. 7rrange$ents for easy re$oval elevating scre" ad nut. and asse$bly of

5.:.11 5.:.1* 5.:.13 5.:.1;

Electrical li$it s"itches on colu$ns should be provided in both directions. Proper guards shall be provided for all $oving parts. The design of the $achine shall be suitable for operations in an at$osphere containing graphite dust.

Tender No.2007/Workshop Projects (CWP)/GT-2

5.:.15 5.:.1:

rill head guide hardened strips.

"ays

shall

be

fitted

"ith

The specification for graphite $ould is sho"n in 766EGCRE&7 for reference. The electrical e#uip$ent should be placed inside the 7R!. E1ECTR'C71S0 The $achine should be #uipped for independent electric drive "ith push button controls. The electric syste$ should confor$ to HStandard specification for 7C $otors and Control 8earI as per details enclosed in 7ppendi@%7. The schedule of particulars indicated in 7ppendi@&< $ust be sub$itted "ith the tender "ith all particulars duly filled in.

5.:.1> 5.>

Tender No.2007/Workshop Projects (CWP)/GT-2

7PPE6 'G%7 ST76 7R SPEC'+'C7T'O6S +OR 71ER67T'68 CCRRE6T !OTORS 76 CO6TRO1 8E7R 1. Scope This specification applies to all types of 7C $otors for driving independent line shafting of individual $achine tools in )or.shops. Each $otor shall be supplied "ith all necessary au@iliaries for the efficient perfor$ance of the duty re#uired. *. ST76 7R SPEC'+'C7T'O6

7ll 7C $ediu$ voltage $otors shall fully confor$ to 'S0 3*5 or its latest revision for all essential design and test features of the $achines. 3. P7RT'CC17RS O+ E1ECTR'C SCPP1The $otors and s"itchgear supplied shall be suitable for operation on ;15 Eolts 7C. 3 phase 50 cycles, ; "ire syste$ "ith neutral solidly earthed. !otors of 1 5P and above shall be "ound for 3 phase supply. !otors of fractional horse&po"er 2under one 5P4 $ay be "ound for ;15 volts three phase of *30 volts single phase supply. ;. T-PE 7ll $otor "ill be designed for safe and continuous operation for a voltage variation of J 5K "ithout over te$perature of $otor "inding or $agnetic circuit. Each $otor shall be of the totally enclosed fan cooled type unless other"ise specified and fitted "ith ball or roller bearings of standard $a.e readily available. )here roller bearings are provided, a suitable location collar or bearing shall also be provided. 7ll ball and roller bearings shall be accurately fitted and provided "ith $oisture proof and dust proof housing. 5. T-PE O+ )'6 '68 7ny of the follo"ing types $ay be offered depending upon the duty and 5P re#uired.

Tender No.2007/Workshop Projects (CWP)/GT-2

i4I S#uirrel CageI 'nduction !otors upto 15 5P ii4I5igh Tor#ue S#uirrel CageI 'nduction !otors upto *5 5P. iii4ISlip % RingI 'nduction !otors above *5 5P. 6OTE0 HSynchronousI !otors or HSynchronous 'nductionI !otors $ay be offered for po"er factor correction "here indicated. :. S'LE 76 SPEE

Shall be as indicated or necessary for driving the $achine tools. >. !ET5O O+ R'EE

Shall be as indicated or necessary for driving the $achine tools. 9. R7T'68 Shall be continuous or as necessary for driving the $achine tools. =. '6SC17T'O6 Class M<N insulation or Class MEN insulation te$perature rise as per standard specification corrected for ;5oC a$bient te$perature. "ith duly

The insulation used shall be suitable for a $oist tropical cli$ate. The "indings shall be specially i$pregnated to "ithstand such a cli$ate. 10. E++'C'E6C- 76 PO)ER +7CTOR

8uaranteed efficiency and po"er factor at full O and P loads shall be specified by tenderers. 11. TER!'671 7RR768E!E6T Shall be suitable for conduit "iring upto ;0 5P $otors and P1-STS Cable entry for $otors above ;0 5P. 1*. ES'86 +E7TCRES

The other essential design features shall be as follo"s0&

Tender No.2007/Workshop Projects (CWP)/GT-2

i4 Slip Ring $otors shall have continuously rated Rings. 7$ply di$ensioned to give long and trouble service.

Slip free

ii4 The ter$inal bo@es shall be properly insulated and of a$ply siFe for ter$inating alu$inu$ conductor cables. iii4 <all and roller bearings shall be provided "ith proper greasing nipples. iv4 )herever bra.es are provided, it is preferable that double shaft e@tension is provided, so that the bra.e pulley is not the sa$e as the co$plying face. v4 7ll $otors shall be braced to "ithstand the starting and accelerating forces. vi4 To facilitate starting arrange$ent "here re#uired at site the $oor "ill have all si@ ter$inal points of the stator "inding brought out at the ter$inal bo@. 13. CO6TRO1 8E7R0 The e#uip$ent for each $otor shall co$ply "ith <.S. specification 6o. 59>&1=;0 and to 'S0 9** or its latest edition on ay subse#uent a$end$ents thereto e@cept "here $odified therein. 8enerally spea.ing the type of control gear shall be as indicated belo"0& i4 !otors upto 5 5P ii4 !otor above 5 5P upto 15 5P(*5 5P iii4 Slip ring $otors above 15 5P iv4 Synchronous or synchronous 'nduction !otors 6OTE0 14 'n the case of ite$s 2iii4 and 2iv4 above, the starter control $ay be air brea. upto 100 a$ps capacity. 7bove 10 a$ps, oil brea.ers to be used e@cept for auto$atic control. H irect&onI Starter 2air brea.4 HStar elta or 7uto Transfor$erI Starter 27ir <rea.4 1i#uid type of $etallic Resistance type 2air Cooled or oil i$$ersed4 Suitable $a.erNs standards

Tender No.2007/Workshop Projects (CWP)/GT-2

*4 Control gear $ay be auto$atic "ith push button control or hand operated as specified and "hen not specified, as per $a.erNs standards. 34 The entire gear shall be totally enclosed iron clad type arranged for floor $ounting or $ounted on the $achines the$selves. 7ll inter connections bet"een the control gear, $otor and all au@iliary s"itches on the $achine shall be in $etallic conduit, fir$ly fi@ed on to the fra$e. 7n inter loc.ed, isolating s"itch shall be provided on the $ain controller for safety purposes. ;4 The control gear shall incorporate full over load protection o all the 3 phases, no volt release and single phasing prevention even for fractional 5P $otors also the necessary interloc.s bet"een stator and rotor control "here necessary. 1;. CO!P1'76CE )'T5 T5E 17)0 The "hole of the e#uip$ents shall co$ply "ith re#uire$ent of the 'ndian Electricity 7ct and Rules. 15. SP7RES Separate prices for spares re#uired for nor$al running $aintenance of the Plan for * years shall be #uoted and detailed prices shall be given. 1:. SC5E C1ES The tenderer is re#uired to fill up 7ppendi@&< and sub$it along "ith the offer. 1>. TEST S5EETS Certified copies of test triplicate in due course. 19. R7)'68S sheets shall be sub$itted in the

Si@ 2:4 sets for ferro prints of dra"ings sho"ing overall di$ensions and holding do"n bolt centers of the $otors and s"itchgear under supply and detailed diagra$ of electric connection shall be sub$itted to the Engineer. +ull particulars regarding the "eight, siFe, nu$ber of turns and the $aterial of insulation of the stator and

Tender No.2007/Workshop Projects (CWP)/GT-2

rotor "indings of the $otor as "ell as M6o voltN and over load coils etc of the Control 8ear shall be furnished. )here ball or roller bearings are used, $a.e and reference nu$ber of bearings shall be #uoted preferably of the dra"ings. Triplicate copies of the foundation dra"ings and erection instructions etc "here re#uired, shall be supplied in advance to enable preli$inary arrange$ents to be $ade for the erection of the e#uip$ent at site. Operation and $aintenance instructions shall also be furnished "here re#uired. 1=. 8C7R76TEE C17CSE +or a period of t"elve $onths fro$ the date of erection of he plant at site, the contractor shall be responsible for any defects "hich $ay develop under nor$al "or.ing conditions arising fro$ faulty $aterial, design or "or.$anship, but not other"ise and shall re$edy such defects "hen called upon to do entirely free of cost to the ad$inistration. 7ny such replace$ent shall also be subDect to a si$ilar guarantee. *0. EE'7T'O6S

eviations fro$ any of he above clauses shall be clearly pointed out in a letter "hich $ust acco$pany the tender. Clauses not so co$$ented upon "ill be ta.en as having $et "ith the approval of the supplier, and "ill, therefore, be binding on hi$.

Tender No.2007/Workshop Projects (CWP)/GT-2

"

7PPE6 'G%< 2Schedule of particulars and guaranteed perfor$ance to be filled by the contractor and are binding on hi$4 Sl.6o. 7. !OTORS0 1. *. 3. ;. 5. !a.e Type of "inding Type of enclosure Eoltage 6o.of Phases 2single or 3 phase4 :. 5.P. of !otor offered. Particulars Re$ar.s

Rated output a4 in ?) b4 in 5P

>. 5.P. of $otor re#uired 9. Speed ' R.P.!. =. Rating continuous or inter$ittent 10. Te$perature rise 11. Over load capacity 7t *5KQQQQQQQ..5rs. 50KQQQQQQQ..5rs. 1*. 13. 1;. 15. 1:. 1>. 19. 1=. *0. Reversible or irreversible !ethod of drive Type, $a.e and nu$ber of <earingsQQQQQQQQQQQQ.. i4 .E. ii4 6. .E. Class of insulation !aterial of insulation of Stator slot !aterial of insulation of Stator "indings !aterial of insulation of Rotor slot !aterial of insulation of rotor "indings )inding data Stator0 Rotor0 Starting current in A of full load current

*1.

Tender No.2007/Workshop Projects (CWP)/GT-2

10

**. *3. *;. *5. *:. *>. *9. *=.

Starting tor#ue in A of full load tor#ue Starting tor#ue inK of full load tor#ue Pull out tor#ue in K of full load tor#ue +ull load current of rotor 2in case of slip ring $otor4 Open circuit voltage rotor Efficiency at full load O H P H Po"er factor at full load O H P H Ter$inal arrange$ent

<. CO6TRO1 8E7R0 30. 31. 3*. 33. 3;. !a.e Type 7ir brea. or oil brea. 6or$al rating in 7$ps Protective evices0 a4 Type A 6o. of overload release b4 Range A 6o. of adDust$ent settings c4 Ti$e 1ag d4 's single phasing preventedR e4 6o. volt release provided

35. Push&button control provided for MStartN and MStopN etc. 3:. 'nstrue$ents provided 3>. Te$perature rise of coils 39. Class of insulation and full particulars of the coils siFe of "ire etc. 3=. 's control gear located on he fra$e of the $achineR 'f so, interconnecting bet"een $oor and control gear includedR ;0. 's an isolating s"itch fitted to the control gearR ;1. Ter$inal arrange$ent Signature of the Tenderer ateSSSSSSSSSSSSSSSS Place0SSSSSSSSSSSSSSS

Tender No.2007/Workshop Projects (CWP)/GT-2

11

1'ST O+ Sl no 1 * 3 ; 5

R7)'68S ra"ing no R'TES()P(!(!RS(01 R'TES()P(!(PCS(01 C(T1&1(1* C(T1&1(13 sheet&* 'nsert for C(T1&1(13 sheet&3

escription 1ayout of !ould Repair Shop 1ayout of Plant Care Shop rill /ig Trepanning guide Carbide Circular Trepanning Tool

Tender No.2007/Workshop Projects (CWP)/GT-2

12

S-ar putea să vă placă și

- Agitator DesignDocument7 paginiAgitator DesignTint Tiger100% (4)

- Rectangular Tank CalculationDocument28 paginiRectangular Tank CalculationHiếu Nguyên78% (32)

- Agent List - All CountriesDocument294 paginiAgent List - All Countriesg4goharÎncă nu există evaluări

- Section Properties IPE HEAB UBC AnglesDocument6 paginiSection Properties IPE HEAB UBC Anglesprasad_kcpÎncă nu există evaluări

- Contrast and Latitude Comparisons: Source 1 Source 2Document3 paginiContrast and Latitude Comparisons: Source 1 Source 2prasad_kcpÎncă nu există evaluări

- Welding Codes and How They Re UsedDocument5 paginiWelding Codes and How They Re Usedprasad_kcpÎncă nu există evaluări

- Information Brochure Rtl2Document6 paginiInformation Brochure Rtl2prasad_kcpÎncă nu există evaluări

- Section Properties IPE HEAB UBC AnglesDocument6 paginiSection Properties IPE HEAB UBC Anglesprasad_kcpÎncă nu există evaluări

- GT BrochureDocument4 paginiGT Brochureprasad_kcpÎncă nu există evaluări

- Casti CourseDocument43 paginiCasti CoursekazumiyutoriÎncă nu există evaluări

- Calculation M I of SectionsDocument4 paginiCalculation M I of Sectionsprasad_kcpÎncă nu există evaluări

- SteelBook Dimns Areas WeightsDocument241 paginiSteelBook Dimns Areas Weightsprasad_kcpÎncă nu există evaluări

- PQR GMAW IN06C (Total)Document8 paginiPQR GMAW IN06C (Total)Wellington S. FrançaÎncă nu există evaluări

- Radiography CalculationsDocument2 paginiRadiography Calculationsshahgardez100% (2)

- PV Elite Manual PDFDocument39 paginiPV Elite Manual PDFDarshJhaÎncă nu există evaluări

- Guidelines For Seeking Employment in Uae: UAE Standard Time: GMT +4 Hours/IST (-) 1.5 HoursDocument3 paginiGuidelines For Seeking Employment in Uae: UAE Standard Time: GMT +4 Hours/IST (-) 1.5 HoursSherrine JibiÎncă nu există evaluări

- Radiographic Depth Determinitation - Rigid Method: Distance From Film (D)Document2 paginiRadiographic Depth Determinitation - Rigid Method: Distance From Film (D)prasad_kcpÎncă nu există evaluări

- Contrast and Latitude Comparisons: Source 1 Source 2Document3 paginiContrast and Latitude Comparisons: Source 1 Source 2prasad_kcpÎncă nu există evaluări

- WPS PQR Checklist 2014Document2 paginiWPS PQR Checklist 2014Sebastian Rajesh100% (1)

- Perhitungan Matematis Untuk Rim and Face Alignment Method Mathematic Calculation For Rim and Face Alignment MethodDocument6 paginiPerhitungan Matematis Untuk Rim and Face Alignment Method Mathematic Calculation For Rim and Face Alignment Methodprasad_kcpÎncă nu există evaluări

- Eritech Handbook LP Iec 62305 Lt30373Document92 paginiEritech Handbook LP Iec 62305 Lt30373ranjithkpvcÎncă nu există evaluări

- Radiographic Depth Determinitation - Rigid Method: Distance From Film (D)Document2 paginiRadiographic Depth Determinitation - Rigid Method: Distance From Film (D)prasad_kcpÎncă nu există evaluări

- Jobs in Middle East PDFDocument3 paginiJobs in Middle East PDFprasad_kcpÎncă nu există evaluări

- Welding Procedure - Job Knowledge 39Document3 paginiWelding Procedure - Job Knowledge 39prasad_kcpÎncă nu există evaluări

- The Indian Institute of Metals DirectoryDocument9 paginiThe Indian Institute of Metals Directoryprasad_kcpÎncă nu există evaluări

- GT BrochureDocument4 paginiGT Brochureprasad_kcpÎncă nu există evaluări

- Spec - WeldingDocument6 paginiSpec - Weldingprasad_kcpÎncă nu există evaluări

- Biometric Chennai Campus StudentsDocument50 paginiBiometric Chennai Campus Studentsprasad_kcpÎncă nu există evaluări

- ASNT Standards ListDocument3 paginiASNT Standards Listprasad_kcpÎncă nu există evaluări

- Total Depreciation : (At Any Time During The Year)Document10 paginiTotal Depreciation : (At Any Time During The Year)prasad_kcpÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Lewatit VP OC 1600 LDocument3 paginiLewatit VP OC 1600 Lphucuong2410Încă nu există evaluări

- I Forgot My Password: LoginDocument6 paginiI Forgot My Password: LoginMithun ShinghaÎncă nu există evaluări

- 27 of The Best Ever Sex Positions To Play DirtyDocument1 pagină27 of The Best Ever Sex Positions To Play DirtyFrankie CulbertsonÎncă nu există evaluări

- Service: Audi A6 2011 Audi A7 Sportback 2011Document160 paginiService: Audi A6 2011 Audi A7 Sportback 2011Javier SerranoÎncă nu există evaluări

- Vacuum Pump Manual (English)Document12 paginiVacuum Pump Manual (English)nguyen lam An100% (1)

- Slides Iso 17021 Be LacDocument117 paginiSlides Iso 17021 Be Lacjorge.s1943Încă nu există evaluări

- Review For 9I1 Semester 2Document33 paginiReview For 9I1 Semester 2NGUYEN SARAHÎncă nu există evaluări

- Training Manual W Appendix 3-20-14 RsDocument193 paginiTraining Manual W Appendix 3-20-14 RsZakir Ullah100% (5)

- TPS6 LecturePowerPoint 11.1 DT 043018Document62 paginiTPS6 LecturePowerPoint 11.1 DT 043018Isabelle TorresÎncă nu există evaluări

- Mario Resume (Updated)Document2 paginiMario Resume (Updated)frontnisÎncă nu există evaluări

- CHAPTER 7development StrategiesDocument29 paginiCHAPTER 7development StrategiesOngHongTeckÎncă nu există evaluări

- William Gilpin On Picturesque TravelDocument7 paginiWilliam Gilpin On Picturesque Travelcordia ghoshÎncă nu există evaluări

- Research On Water Distribution NetworkDocument9 paginiResearch On Water Distribution NetworkVikas PathakÎncă nu există evaluări

- List of ISRO-DRDO JobsDocument2 paginiList of ISRO-DRDO Jobsjobkey.inÎncă nu există evaluări

- Crema Coffee Garage - Understanding Caffeine Content of Popular Brewing Methods Within The Australian Coffee Consumer MarketDocument33 paginiCrema Coffee Garage - Understanding Caffeine Content of Popular Brewing Methods Within The Australian Coffee Consumer MarketTDLemonNhÎncă nu există evaluări

- Magnesium Alloy Anodes For Cathodic ProtectionDocument2 paginiMagnesium Alloy Anodes For Cathodic Protectiongautam100% (1)

- Maximum Mark: 50: Cambridge International ExaminationsDocument12 paginiMaximum Mark: 50: Cambridge International ExaminationsCanio100% (1)

- A1 Paper4 TangDocument22 paginiA1 Paper4 Tangkelly2999123Încă nu există evaluări

- Fracture Mechanics HandbookDocument27 paginiFracture Mechanics Handbooksathya86online0% (1)

- How TikTok Reads Your Mind - The New York TimesDocument8 paginiHow TikTok Reads Your Mind - The New York Timesjoe smithÎncă nu există evaluări

- MEM - Project Pump and TurbineDocument22 paginiMEM - Project Pump and TurbineAbhi ChavanÎncă nu există evaluări

- Reading - Zeeshan UsmaniDocument25 paginiReading - Zeeshan UsmaniHanif AbbasÎncă nu există evaluări

- Measurement Techniques Concerning Droplet Size Distribution of Electrosprayed WaterDocument3 paginiMeasurement Techniques Concerning Droplet Size Distribution of Electrosprayed Waterratninp9368Încă nu există evaluări

- Speaking Topics b1Document3 paginiSpeaking Topics b1Do HoaÎncă nu există evaluări

- Globalisation Shobhit NirwanDocument12 paginiGlobalisation Shobhit NirwankrshraichandÎncă nu există evaluări

- An Introduction To Software DevelopmentDocument19 paginiAn Introduction To Software Developmentsanjeewani wimalarathneÎncă nu există evaluări

- Agriculture DisciplineDocument3 paginiAgriculture DisciplineUmair FaheemÎncă nu există evaluări

- Retool Your Linux Skills For Commercial UNIXDocument19 paginiRetool Your Linux Skills For Commercial UNIXPauloÎncă nu există evaluări

- GE Oil & Gas Emails Discuss Earthing Cable SpecificationsDocument6 paginiGE Oil & Gas Emails Discuss Earthing Cable Specificationsvinsensius rasaÎncă nu există evaluări

- Life Orientation September 2022 EngDocument9 paginiLife Orientation September 2022 EngTondaniÎncă nu există evaluări