Documente Academic

Documente Profesional

Documente Cultură

Estimate LEL and Flash

Încărcat de

nirmal_subudhiDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Estimate LEL and Flash

Încărcat de

nirmal_subudhiDrepturi de autor:

Formate disponibile

A Series To Learn Process safety

Estimating LEL and Flash

The lower explosive limit (LEL) is the minimum concentration of a vapor in air that will support a flame when ignited. The flash point is the lowest temperature of a liquid that produces sufficient vapor for an open flame to ignite in air. Gooding provides ways to estimate these two important safety-related properties. The methods make use of the following observed rules:

1. The LEL occurs at about 50% of the stoichiometric oxidation concentration at ambient temperature and pressure. 2. The flash point occurs at about the temperature at which the liquid has a vapor pressure equal to the LEL partial pressure. 3. It follows then, that knowing the stoichiometry and having a vapor pressure chart, one can determine the LEL and flash point. Also if either the LEL or flash point is known, a vapor pressure chart can be used to estimate the other.

Example: Estimate the LEL and flash point for ethanol The oxidation (combustion) equation is: C2H5OH + 3O2 = 2CO2 + 3H2O For 1 mol of ethanol we need: 3 mols of O2 or 3/0.21 = 14.28 mols of air. The stoichiometric concentration of ethanol in air is thus 1/15.28 = 0.0654mol fraction. The LEL is 50% of this or 0.0327 mol fraction. This matches the reported value of 3.3% by volume. The partial pressure of LEL ethanol is 0.0327 atm. The temperature that produces a vapor pressure of 0.0327atm is 11C, which is our predicted flash point. This is close to the reported 13C. The Gooding article presents graphs that show high accuracy for these methods Source : Gooding, Charles H., Estimating Flash Point and Lower Explosive Limit,

Chemical Engineering, December, 12, 1983.

Protesha Sinergy

A Series To Learn Process safety

Question : Flash point of a mixture is that temperature at which Pmix(T) reaches the LFL. Can anybody provide a simple correlation or demystify what my lecturer is trying to say? Would it be cheeky to ask for a simple example to shed some light on an extremely baffled student ?

Answer : The flash point is the lowest temperature at which a liquid gives off

enough vapour to form a flammable air-vapour mixture near its surface. The lower the flash point, the greater the fire hazard. The flash point is an approximate value and should not be taken as a sharp dividing line between safe and hazardous conditions. The flash point is determined by a variety of test methods which give different results. Two types of methods are abbreviated as OC (open cup) and CC (closed cup). Question : would you know of a way of calculating the flash point based on that data? (which are hydrocarbon mixtures) Flash point = 0.77(ASTM 5% in F - 150 F) The ASTM 5% refers to the 5 volume % temperature of the ASTM distillation of the petroleum product. The flash point occurs at about the temperature at which the liquid has a vapor pressure equal to the LFL partial pressure. For example, ethanol has a LFL of 3.3 volume%. The LFL partial pressure is therefore 0.033 atm. The temperature that produces a vapor pressure of 0.033 atm is 11C, which is the predicted flash point. This is close to the reported flash point of 13C (see for example NFPA 325). The Antoine equation to find temperature that produces LFL partial pressure.

Question : how you have got the partial pressure from the LFL;

Answer : This equation for estimating the flash point of petroleum products

is it just LFL/100 ? and would that be the same if my partial pressure values were in kPa?

Answer : The LFL partial pressure is LFL (in volume %)/100*atmospheric

pressure. So for the example of ethanol with LFL of 3.3 vol%, the LFL partial pressure is 3.3/100 * 1 atm = 0.033 atm or 3.3/100 * 1.013 bar = 0.0334 bar or 3.3/100 * 101.3 kPa = 3.34 kPa

Protesha Sinergy

S-ar putea să vă placă și

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationDe la EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationÎncă nu există evaluări

- Flammability LimitDocument8 paginiFlammability LimitnewbabyiluÎncă nu există evaluări

- Oxidation of Organic Compounds: Medium Effects in Radical ReactionsDe la EverandOxidation of Organic Compounds: Medium Effects in Radical ReactionsEvaluare: 4 din 5 stele4/5 (1)

- Fundamentals of Fires and ExplosionsDocument79 paginiFundamentals of Fires and Explosionsbhen08100% (1)

- Incineration of Municipal Waste: Specialized Seminars on Incinerator Emissions of Heavy Metals and Particulates, Copenhagen, 18–19 September 1985 and Emission of Trace Organics from Municipal Solid Waste Incinerators, Copenhagen, 20–22 January 1987De la EverandIncineration of Municipal Waste: Specialized Seminars on Incinerator Emissions of Heavy Metals and Particulates, Copenhagen, 18–19 September 1985 and Emission of Trace Organics from Municipal Solid Waste Incinerators, Copenhagen, 20–22 January 1987Robert B. DeanÎncă nu există evaluări

- Flammability Limit: Kebakaran Dan Ledakan Teknik Kesehatan Dan Keselamatan KerjaDocument34 paginiFlammability Limit: Kebakaran Dan Ledakan Teknik Kesehatan Dan Keselamatan Kerja20-124 EkkiÎncă nu există evaluări

- Nuclear Waste Cleanup Technologies and OpportunitiesDe la EverandNuclear Waste Cleanup Technologies and OpportunitiesÎncă nu există evaluări

- Flash Point TutorialDocument8 paginiFlash Point TutorialS. GreenÎncă nu există evaluări

- SIA Guidance Note 47 Flammable Solvents The Hazard of Static ElectricityDocument12 paginiSIA Guidance Note 47 Flammable Solvents The Hazard of Static ElectricityAli AbbasovÎncă nu există evaluări

- Flash Point TemperatureDocument3 paginiFlash Point Temperaturemissa ltqtcbm5Încă nu există evaluări

- Flash Calc 1flash Calc 1Document9 paginiFlash Calc 1flash Calc 1Mohamed MamdouhÎncă nu există evaluări

- Appendix A - General Thermodynamic FormulasDocument7 paginiAppendix A - General Thermodynamic Formulaskim haksongÎncă nu există evaluări

- Chapter 1 Solubility Parameters - An IntroductionDocument26 paginiChapter 1 Solubility Parameters - An IntroductionDuygu İnceÎncă nu există evaluări

- Odor Thresholds and Irritation Levels of Several Chemical SubstancesDocument10 paginiOdor Thresholds and Irritation Levels of Several Chemical SubstancesIgnacio Quero EcheverriaÎncă nu există evaluări

- Don't Gamble With Physical Properties PDFDocument12 paginiDon't Gamble With Physical Properties PDFInés BeltránÎncă nu există evaluări

- Chemistry in The Service of Man (Alexander Findlay, 1947)Document420 paginiChemistry in The Service of Man (Alexander Findlay, 1947)mimakos100% (2)

- Prediction of Minimum Flash Point Behaviour For Binary MixturesDocument9 paginiPrediction of Minimum Flash Point Behaviour For Binary Mixturesmurdanetap957Încă nu există evaluări

- Fuels and Chemicals - Auto Ignition TemperaturesDocument5 paginiFuels and Chemicals - Auto Ignition TemperaturesyoesseoyÎncă nu există evaluări

- The Fundamentals of Fire ExtinguishmentDocument0 paginiThe Fundamentals of Fire ExtinguishmentjohnzepolÎncă nu există evaluări

- Activity Coefficients in Polymer SolutionsDocument10 paginiActivity Coefficients in Polymer Solutionsmappemaq100% (1)

- Improved Coward Explosive Triangle For Determining Explosibility of Mixture GasDocument7 paginiImproved Coward Explosive Triangle For Determining Explosibility of Mixture GassunilsinghmÎncă nu există evaluări

- A Review of Barker's Activity Coefficient Method and VLE Data ReductionDocument7 paginiA Review of Barker's Activity Coefficient Method and VLE Data Reductionmurdanetap957Încă nu există evaluări

- Preventing ExplosionDocument4 paginiPreventing ExplosionBtbayr BaatadÎncă nu există evaluări

- Aluminum Hydroxide MSDSDocument9 paginiAluminum Hydroxide MSDSSeyit AvcuÎncă nu există evaluări

- Thermodynamics of Polymer Blends PDFDocument5 paginiThermodynamics of Polymer Blends PDFpedroÎncă nu există evaluări

- Hitec Solar SaltDocument3 paginiHitec Solar Saltlmf_pachecoÎncă nu există evaluări

- Kinetics of Surface ReactionsDocument24 paginiKinetics of Surface ReactionsShehRoz KhanÎncă nu există evaluări

- Weber ThermodynamicsDocument337 paginiWeber ThermodynamicsnonecoÎncă nu există evaluări

- Hydrogenation Methods Paul N Rylander 1985Document202 paginiHydrogenation Methods Paul N Rylander 1985I-Sun Deep Mohan TeaÎncă nu există evaluări

- Unifac PDFDocument13 paginiUnifac PDFBalmore ZambranoÎncă nu există evaluări

- Experiment 4 Dynamic Response of Temperature Measuring Devices (Transient Heat Transfer)Document6 paginiExperiment 4 Dynamic Response of Temperature Measuring Devices (Transient Heat Transfer)praful2604Încă nu există evaluări

- Prediction of Hansen Solubility Parameters With A NewDocument18 paginiPrediction of Hansen Solubility Parameters With A NewJonatas LopesÎncă nu există evaluări

- CHE 318 Prof Bayawa NotesDocument143 paginiCHE 318 Prof Bayawa NotesDavid JohnÎncă nu există evaluări

- Fuel Production From Pyrolysis of Natural and Synthetic RubbersDocument8 paginiFuel Production From Pyrolysis of Natural and Synthetic RubbersMary Grace VelitarioÎncă nu există evaluări

- ,MMNBGDocument6 pagini,MMNBGAnonymous FW5PVUp100% (1)

- NIST-JANAF Thermochemical TablesDocument39 paginiNIST-JANAF Thermochemical TablesVelzaeroÎncă nu există evaluări

- Heat and Mass Transfer PropertiesDocument63 paginiHeat and Mass Transfer Propertieskaushita banerjeeÎncă nu există evaluări

- ISS2009 BookDocument226 paginiISS2009 BookramoradoÎncă nu există evaluări

- Appendix C11 Values of Hansen Solubility Parameters For Solvents Soils and Polymers 2014 Cleaning With SolventsDocument5 paginiAppendix C11 Values of Hansen Solubility Parameters For Solvents Soils and Polymers 2014 Cleaning With SolventsMenee Love U TooÎncă nu există evaluări

- Anodic Protection - Eng. Onel IsraelDocument11 paginiAnodic Protection - Eng. Onel IsraelOnel Israel Badro100% (2)

- Soluble Silicates 00 VailDocument456 paginiSoluble Silicates 00 VailSiddhartha PachisiaÎncă nu există evaluări

- Mass Transfer QuizzesDocument10 paginiMass Transfer QuizzesNate JamesÎncă nu există evaluări

- Melamine Formaldehyde Curing Studies andDocument7 paginiMelamine Formaldehyde Curing Studies andtahera aqeelÎncă nu există evaluări

- Firing Petcoke - Vanadium AspectDocument21 paginiFiring Petcoke - Vanadium AspectAnand Gupta100% (1)

- TA Chemicals Guide en LRDocument24 paginiTA Chemicals Guide en LRYehor HorbatkoÎncă nu există evaluări

- A New Procedure To Estimate BLEVE OverpressureDocument16 paginiA New Procedure To Estimate BLEVE OverpressureJuan R. Uribe PichiriloÎncă nu există evaluări

- QB PDFDocument18 paginiQB PDFShivani0% (1)

- Flash Points of Aqueous Solutions PDFDocument18 paginiFlash Points of Aqueous Solutions PDFChitikala RajeshÎncă nu există evaluări

- The Entanglement Concept in Polymer RheolgyDocument179 paginiThe Entanglement Concept in Polymer RheolgysachinbobadeÎncă nu există evaluări

- Octane Number PDFDocument9 paginiOctane Number PDFLê Ngọc Huyền80% (5)

- Keane-Technical Methods of Chemical Analysis Vol 3 PT 1 1908Document582 paginiKeane-Technical Methods of Chemical Analysis Vol 3 PT 1 1908RonLaytonÎncă nu există evaluări

- 1-2 Hydrocarbons Ignition and FlammabilityDocument40 pagini1-2 Hydrocarbons Ignition and Flammabilityronachaif3191Încă nu există evaluări

- Thermodynamics and Its ApplicationsDocument30 paginiThermodynamics and Its ApplicationspoletoÎncă nu există evaluări

- Physical Properties of Liquids and GasesDocument8 paginiPhysical Properties of Liquids and GasesGustavoSierraÎncă nu există evaluări

- Determination of Azithromycin by Ion-Pair HPLC With UV DetectionDocument5 paginiDetermination of Azithromycin by Ion-Pair HPLC With UV DetectionandresdelrojoÎncă nu există evaluări

- Fundamental of Exergy Analysis PDFDocument21 paginiFundamental of Exergy Analysis PDFpainternetmx1100% (1)

- IjoiijDocument347 paginiIjoiijpi.314153.4Încă nu există evaluări

- Supercritical Fluid ExtractionDocument12 paginiSupercritical Fluid ExtractionSata AjjamÎncă nu există evaluări

- Activity Coefficients of Strong Electrolytes in Aqueous SolutionsDocument6 paginiActivity Coefficients of Strong Electrolytes in Aqueous SolutionsL Sergio Quiroz CastilloÎncă nu există evaluări

- Compressor Dynamics 4Document1 paginăCompressor Dynamics 4nirmal_subudhiÎncă nu există evaluări

- Compressor Dynamics 1Document1 paginăCompressor Dynamics 1nirmal_subudhiÎncă nu există evaluări

- Compressor Dynamics 3Document1 paginăCompressor Dynamics 3nirmal_subudhiÎncă nu există evaluări

- Class 6-1Document1 paginăClass 6-1nirmal_subudhiÎncă nu există evaluări

- Compressor Dynamics 2Document1 paginăCompressor Dynamics 2nirmal_subudhiÎncă nu există evaluări

- Dispersion Model 2: Dr. AA Department of Chemical Engineering University Teknology MalaysiaDocument44 paginiDispersion Model 2: Dr. AA Department of Chemical Engineering University Teknology Malaysianirmal_subudhi100% (1)

- Hydrocarbon Processing: Deep Water FLNGDocument1 paginăHydrocarbon Processing: Deep Water FLNGnirmal_subudhiÎncă nu există evaluări

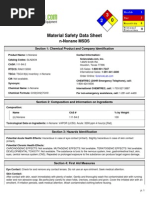

- Material Safety Data Sheet: 1. Chemical Product and Company IdentificationDocument7 paginiMaterial Safety Data Sheet: 1. Chemical Product and Company Identificationnirmal_subudhiÎncă nu există evaluări

- Process View VBA Tutorial: User'S ManualDocument1 paginăProcess View VBA Tutorial: User'S Manualnirmal_subudhiÎncă nu există evaluări

- M MercaptanDocument7 paginiM Mercaptannirmal_subudhiÎncă nu există evaluări

- Msds DodecaneDocument6 paginiMsds Dodecanenirmal_subudhiÎncă nu există evaluări

- Msds HeptadecaneDocument5 paginiMsds Heptadecanenirmal_subudhiÎncă nu există evaluări

- Msds HexadecaneDocument5 paginiMsds Hexadecanenirmal_subudhiÎncă nu există evaluări

- MSDS N EicosaneDocument3 paginiMSDS N Eicosanenirmal_subudhiÎncă nu există evaluări

- Msds UndecaneDocument5 paginiMsds Undecanenirmal_subudhiÎncă nu există evaluări

- Msds TetradecaneDocument5 paginiMsds Tetradecanenirmal_subudhiÎncă nu există evaluări

- Msds TolueneDocument6 paginiMsds Toluenenirmal_subudhi100% (1)

- Msds NonaneDocument5 paginiMsds Nonanenirmal_subudhiÎncă nu există evaluări

- Msds HeptaneDocument6 paginiMsds Heptanenirmal_subudhiÎncă nu există evaluări

- Msds PentadecaneDocument5 paginiMsds Pentadecanenirmal_subudhiÎncă nu există evaluări

- Msds N ButaneDocument6 paginiMsds N Butanenirmal_subudhiÎncă nu există evaluări

- Msds EthaneDocument7 paginiMsds Ethanenirmal_subudhiÎncă nu există evaluări

- Msds N PentaneDocument6 paginiMsds N Pentanenirmal_subudhiÎncă nu există evaluări

- Msds OctaneDocument5 paginiMsds Octanenirmal_subudhiÎncă nu există evaluări

- Msds IsobutaneDocument6 paginiMsds Isobutanenirmal_subudhiÎncă nu există evaluări

- Hkum Termo 1 Sistem Terbuka PDFDocument75 paginiHkum Termo 1 Sistem Terbuka PDFrizky andrianÎncă nu există evaluări

- QHD1-Gears Pumps Cataloque v1.0 NZDocument28 paginiQHD1-Gears Pumps Cataloque v1.0 NZevgenyÎncă nu există evaluări

- FLOW MEASUREMENT - Course NotesDocument38 paginiFLOW MEASUREMENT - Course Notespawan deepÎncă nu există evaluări

- Ujian Rumah - TK4101 - SMT I 2015-2016Document2 paginiUjian Rumah - TK4101 - SMT I 2015-2016Jeffry PoerjotoÎncă nu există evaluări

- DS1353 SV Series Marine FM-200Document20 paginiDS1353 SV Series Marine FM-200kidmuÎncă nu există evaluări

- Briquette BurnerDocument5 paginiBriquette BurnerInternational Journal of Research in Engineering and TechnologyÎncă nu există evaluări

- High Pressure Accessories Catalog: Edition January 2008 V.03Document122 paginiHigh Pressure Accessories Catalog: Edition January 2008 V.03marcxl2808Încă nu există evaluări

- Adsorption Isotherms and Its TypesDocument10 paginiAdsorption Isotherms and Its Typeskritika negi100% (2)

- Lecture Guide 3 Conduction-through-a-Homogenous-Cylinder-WallDocument8 paginiLecture Guide 3 Conduction-through-a-Homogenous-Cylinder-WallCllyan ReyesÎncă nu există evaluări

- Obl MBMC Engels Manual PDFDocument24 paginiObl MBMC Engels Manual PDFJose Eduardo MoralesÎncă nu există evaluări

- Sru5 168 HDDocument1 paginăSru5 168 HDvicenteÎncă nu există evaluări

- Midterm Exam - HydraulicDocument4 paginiMidterm Exam - HydraulicIVÁN ARAYA100% (2)

- Hydraulic and Pneumatic Power SystemsDocument4 paginiHydraulic and Pneumatic Power Systemsajrio1785Încă nu există evaluări

- Medical Oxygen Generator: Design Document For 3 NM /H Medical Oxygen Generation SystemDocument46 paginiMedical Oxygen Generator: Design Document For 3 NM /H Medical Oxygen Generation SystemMendoud SofianeÎncă nu există evaluări

- VariableFlow 110411 PDFDocument8 paginiVariableFlow 110411 PDFbilal almelegyÎncă nu există evaluări

- 99992025 (1)Document3 pagini99992025 (1)ankit singhÎncă nu există evaluări

- Causes of Water HammerDocument6 paginiCauses of Water HammeraqhammamÎncă nu există evaluări

- College of Arts and Sciences Department of Mathematics and Physics Hand-Out On Fluid MechanicsDocument6 paginiCollege of Arts and Sciences Department of Mathematics and Physics Hand-Out On Fluid MechanicsBry RamosÎncă nu există evaluări

- Error Code Quick Guide Autoclave RunyesDocument4 paginiError Code Quick Guide Autoclave RunyesSinda MazouniÎncă nu există evaluări

- Complicated Rate Equations PPT VERDocument1 paginăComplicated Rate Equations PPT VERnabillaÎncă nu există evaluări

- Pe312-Natural Gas Engineering S&DDocument33 paginiPe312-Natural Gas Engineering S&DMalugu JohnÎncă nu există evaluări

- Refrigeration Efficiency GuideDocument0 paginiRefrigeration Efficiency GuideÁlvaro Martinez PérezÎncă nu există evaluări

- Age 10802Document162 paginiAge 10802vinoratheeshÎncă nu există evaluări

- The Defining Series - Jet Pumps - SLB PDFDocument8 paginiThe Defining Series - Jet Pumps - SLB PDFnoha azamaliÎncă nu există evaluări

- Flow in Packed BedsDocument8 paginiFlow in Packed BedsGerry Lou QuilesÎncă nu există evaluări

- ULTISEP Element Specification Sheet - GCA5536K10VDocument2 paginiULTISEP Element Specification Sheet - GCA5536K10Vaditya sigitÎncă nu există evaluări

- CH 18Document11 paginiCH 18jay mishraÎncă nu există evaluări

- PW 100Document1 paginăPW 100Anh Đại MaiÎncă nu există evaluări

- Hydraulic Report - Fire Water For Transforme - 0Document1 paginăHydraulic Report - Fire Water For Transforme - 0Aob AprilÎncă nu există evaluări

- Filtro RFM ON 185 V D 10 E 1.x (Hydac)Document2 paginiFiltro RFM ON 185 V D 10 E 1.x (Hydac)OARIASCOÎncă nu există evaluări

- The Laws of Thermodynamics: A Very Short IntroductionDe la EverandThe Laws of Thermodynamics: A Very Short IntroductionEvaluare: 4.5 din 5 stele4.5/5 (10)

- Process Plant Equipment: Operation, Control, and ReliabilityDe la EverandProcess Plant Equipment: Operation, Control, and ReliabilityEvaluare: 5 din 5 stele5/5 (1)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionDe la EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionEvaluare: 4.5 din 5 stele4.5/5 (3)

- Sodium Bicarbonate: Nature's Unique First Aid RemedyDe la EverandSodium Bicarbonate: Nature's Unique First Aid RemedyEvaluare: 5 din 5 stele5/5 (21)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedDe la EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedEvaluare: 5 din 5 stele5/5 (1)

- Laminar Flow Forced Convection in Ducts: A Source Book for Compact Heat Exchanger Analytical DataDe la EverandLaminar Flow Forced Convection in Ducts: A Source Book for Compact Heat Exchanger Analytical DataÎncă nu există evaluări

- Bulk Material Handling: Practical Guidance for Mechanical EngineersDe la EverandBulk Material Handling: Practical Guidance for Mechanical EngineersEvaluare: 5 din 5 stele5/5 (1)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisDe la EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisEvaluare: 4 din 5 stele4/5 (2)

- Basic Digital Signal Processing: Butterworths Basic SeriesDe la EverandBasic Digital Signal Processing: Butterworths Basic SeriesEvaluare: 5 din 5 stele5/5 (1)

- Chasing the Demon: A Secret History of the Quest for the Sound Barrier, and the Band of American Aces Who Conquered ItDe la EverandChasing the Demon: A Secret History of the Quest for the Sound Barrier, and the Band of American Aces Who Conquered ItEvaluare: 4 din 5 stele4/5 (25)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseDe la EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseEvaluare: 4.5 din 5 stele4.5/5 (51)

- Machinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionDe la EverandMachinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionÎncă nu există evaluări

- Cyber-Physical Systems: Foundations, Principles and ApplicationsDe la EverandCyber-Physical Systems: Foundations, Principles and ApplicationsHoubing H. SongÎncă nu există evaluări

- Pilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CDe la EverandPilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CÎncă nu există evaluări

- Gas Turbines: A Handbook of Air, Land and Sea ApplicationsDe la EverandGas Turbines: A Handbook of Air, Land and Sea ApplicationsEvaluare: 4 din 5 stele4/5 (9)

- Safety Theory and Control Technology of High-Speed Train OperationDe la EverandSafety Theory and Control Technology of High-Speed Train OperationEvaluare: 5 din 5 stele5/5 (2)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ADe la EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AÎncă nu există evaluări

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideDe la Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideEvaluare: 3.5 din 5 stele3.5/5 (7)

- Guidelines for Chemical Process Quantitative Risk AnalysisDe la EverandGuidelines for Chemical Process Quantitative Risk AnalysisEvaluare: 5 din 5 stele5/5 (1)

- An Applied Guide to Water and Effluent Treatment Plant DesignDe la EverandAn Applied Guide to Water and Effluent Treatment Plant DesignEvaluare: 5 din 5 stele5/5 (4)

- Electrical (Generator and Electrical Plant): Modern Power Station PracticeDe la EverandElectrical (Generator and Electrical Plant): Modern Power Station PracticeEvaluare: 4 din 5 stele4/5 (9)

- Piping Engineering Leadership for Process Plant ProjectsDe la EverandPiping Engineering Leadership for Process Plant ProjectsEvaluare: 5 din 5 stele5/5 (1)