Documente Academic

Documente Profesional

Documente Cultură

Cu, Ni AA

Încărcat de

Lalo RuizDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Cu, Ni AA

Încărcat de

Lalo RuizDrepturi de autor:

Formate disponibile

9.1.07 AOAC Official Method 971.

20 Copper and Nickel in Tea

Atomic Absorption Spectrophotometric Method First Action 1971 Final Action 1976

Caution: See Appendix B, safety notes on AAS, wet oxidation, nitric acid, and perchloric acid.

A. Principle

minimum readings, respectively, and 0.40 is factor to convert range of 6 values to s. Beginning with solution containing 0 Cu, aspirate each matrix standard solution and record A. If value for 10 g/mL solution differs from average of the 6 values used to calculate s by >0.01 (av er age of the 6 val ues), re peat mea sure ments. If these determinations indicate drift, determine cause (e.g., deposits in burner or clogged capillary), correct it, and repeat calibration. Repeat for Ni solutions. Plot A against g metal/mL.

E. Determination

Materials are wet ashed and after dilution Cu and Ni are determined by AA at 232.0 nm (Ni) and 324.7 nm (Cu). Matrix of standard solutions is matched to that of test solution to avoid interference from Na and K.

B. Apparatus

Atomic absorption spectrophotometer.Measuring content or change of content of 0.05 g Ni or Cu/mL in aqueous solution.

C. Preparation of Standard Solutions

(a) Copper standard solution.1000 g/mL. Dissolve 1.000 g 99.99% Cu in 20 mL HNO3, cool, and dilute to 1 L with H2O. (b) Nickel standard solution.1000 g/mL. Dissolve 1.000 g 99.99% Ni in 20 mL HNO3, cool, and dilute to 1 L with H2O. (c) Matrix standard solutions.Prepare solutions containing 0, 0.2, 0.4, 0.8, 1.6, 2.0, 4.0, 8.0, and 10 g Ni and Cu/mL and major metal matrix components: (1) For 3 g tea test portion.To contain 180 g Ca, 100 g Mg, and 40 g Al/mL with final concentration of 8% (v/v) HClO4. (2) For 6 g instant tea test portion.To contain 7000 g K, 70 g Na, 700 g Mg, and 130 g Ca/mL with final HNO3 concentration of (1 + 9).

D. Preparation of Calibration Curve

Select test portion weight to give solution containing 0.05 but 10 g Ni/mL, usually 3 g for teas and 6 g for instant teas. (a) Wet ashing.Accurately weigh test portion into 400 mL beaker, add 100 mL HNO3, and swirl. Cover, and let react 10 min; then place on hot plate. Evaporate to near dryness and cool. Add 50 mL HNO3, and for tea, add 10 mL HClO4. Continue evaporation to obtain clear solution. Transfer to 50 mL volumetric flask and dilute to volume with H2O. (Insoluble KClO4 which settles to bottom of flask does not interfere.) Prepare reagent blank containing same amounts of acids taken from same lots, evaporated as above. (b) Photometry.Aspirate test and blank solutions, and record A. Measure A of matrix standard solution containing 10 g/mL. If this value differs from value of average of the 6 values used to calculate s by >2s, repeat measurement. If these values indicate drift, determine cause, correct it, and repeat calibration and test and blank readings. (c) Calculations.Correct readings of test solution for blank. Convert corrected A to g/mL from calibration curve. Concentration (mg/kg) Ni (or Cu) = CV W

Let instrument stabilize. Optimize conditions for Cu or Ni according to manufacturers instructions. Aspirate 10 g/mL standard enough times to establish that A reading is not drifting. Record 6 readings and calculate standard deviation (s) = (x y) 0.40, where x and y are maximum and

where C = g metal/mL from curve, V = final volume test solution (50), and W = g test portion. References: JAOAC 53, 531(1970); 54, 658(1971). CAS-7440-50-8 (copper) CAS-7440-02-0 (nickel)

2005 AOAC INTERNATIONAL

S-ar putea să vă placă și

- GU Moisture Analyzer enDocument44 paginiGU Moisture Analyzer enLalo RuizÎncă nu există evaluări

- ReadmeDocument13 paginiReadmeLalo RuizÎncă nu există evaluări

- 01-0202-00 System 5000 Methods ManualDocument75 pagini01-0202-00 System 5000 Methods ManualLalo RuizÎncă nu există evaluări

- Bascula Humedad MB23 PDFDocument59 paginiBascula Humedad MB23 PDFLalo RuizÎncă nu există evaluări

- MANUAL UV Winlab SoftwareDocument41 paginiMANUAL UV Winlab SoftwareLalo RuizÎncă nu există evaluări

- Dterminacion de Carbon de ElastomerosDocument2 paginiDterminacion de Carbon de ElastomerosLalo RuizÎncă nu există evaluări

- Friction, Wear and Lubrication: TribometersDocument12 paginiFriction, Wear and Lubrication: TribometersWellington AnaluisaÎncă nu există evaluări

- Friction, Wear and Lubrication: TribometersDocument12 paginiFriction, Wear and Lubrication: TribometersWellington AnaluisaÎncă nu există evaluări

- Tribology BrochureDocument4 paginiTribology BrochureLalo RuizÎncă nu există evaluări

- Catalogo Tyler AzulDocument26 paginiCatalogo Tyler AzulLalo RuizÎncă nu există evaluări

- Cleaning DSC Pans ProcedureDocument2 paginiCleaning DSC Pans ProcedureLalo RuizÎncă nu există evaluări

- Presentación Teórica MS-MSDocument72 paginiPresentación Teórica MS-MSLalo RuizÎncă nu există evaluări

- GU Moisture Analyzer enDocument44 paginiGU Moisture Analyzer enLalo RuizÎncă nu există evaluări

- Metodo FIAS Enva100Document20 paginiMetodo FIAS Enva100Lalo Ruiz100% (1)

- Manuel UV WinlabDocument1.046 paginiManuel UV WinlabClem100% (2)

- CD en Alimentos Por AADocument1 paginăCD en Alimentos Por AALalo RuizÎncă nu există evaluări

- MANUAL UV Winlab SoftwareDocument41 paginiMANUAL UV Winlab SoftwareLalo RuizÎncă nu există evaluări

- Soporte Universal FiasDocument11 paginiSoporte Universal FiasLalo RuizÎncă nu există evaluări

- ReadmeDocument13 paginiReadmeLalo RuizÎncă nu există evaluări

- Manual Usuario Fias Mhs15Document142 paginiManual Usuario Fias Mhs15Lalo RuizÎncă nu există evaluări

- ReadmeDocument13 paginiReadmeLalo RuizÎncă nu există evaluări

- Arsenico Por Generador de HidrurosDocument14 paginiArsenico Por Generador de HidrurosHernan Santiago Effio LaraÎncă nu există evaluări

- Arsenico Por Generador de HidrurosDocument14 paginiArsenico Por Generador de HidrurosHernan Santiago Effio LaraÎncă nu există evaluări

- Arsenico Por Generador de HidrurosDocument14 paginiArsenico Por Generador de HidrurosHernan Santiago Effio LaraÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- PreciControl HbA1c Norm.05975115001.V4.EnDocument2 paginiPreciControl HbA1c Norm.05975115001.V4.EnARIF AHAMMED PÎncă nu există evaluări

- Introduction To MetrologyDocument55 paginiIntroduction To Metrologypatel ketan92% (36)

- Thermo Chloride Ise ManualDocument39 paginiThermo Chloride Ise Manualwiroch6kayanhaÎncă nu există evaluări

- HSE-P-06 Monitoring and Measurement Issue 2.1Document4 paginiHSE-P-06 Monitoring and Measurement Issue 2.1eng20072007Încă nu există evaluări

- Nomenclature in Evaluation of Analytical MethodsDocument25 paginiNomenclature in Evaluation of Analytical Methodsjljimenez1969100% (1)

- Static & Dynamic Characteristics of Measurement SystemDocument62 paginiStatic & Dynamic Characteristics of Measurement SystemabhishekÎncă nu există evaluări

- Catalogo Odournet 2014-10-31Document29 paginiCatalogo Odournet 2014-10-31Aimee WoodÎncă nu există evaluări

- lb565 eDocument4 paginilb565 eMohan RajÎncă nu există evaluări

- USM Go (Issue 6)Document310 paginiUSM Go (Issue 6)pjhollowÎncă nu există evaluări

- Hospital Commissioning Checklists: Structural & Operational StandardsDocument50 paginiHospital Commissioning Checklists: Structural & Operational Standardsmohamed radwan100% (1)

- SGF-GMP Self Assessment Questionnaire enDocument22 paginiSGF-GMP Self Assessment Questionnaire enOzlem Mep100% (1)

- APIC CEFIC Auditing Guide August 2016 - Annex 2Document50 paginiAPIC CEFIC Auditing Guide August 2016 - Annex 2Ngoc Sang HuynhÎncă nu există evaluări

- GE Bolt Mike III User Manual2016051922133 PDFDocument2 paginiGE Bolt Mike III User Manual2016051922133 PDFBrenno GonçalvesÎncă nu există evaluări

- AMX-4+ CALIBRATION Pdf-WordDocument62 paginiAMX-4+ CALIBRATION Pdf-WordHoang100% (9)

- EGE Pressure SensorsDocument8 paginiEGE Pressure SensorsYing Kei ChanÎncă nu există evaluări

- Ac7114-5 - Rev - 0 Audit Criteria For Nondestructive Testing Facility Eddy Current SurveyDocument15 paginiAc7114-5 - Rev - 0 Audit Criteria For Nondestructive Testing Facility Eddy Current SurveyskluxÎncă nu există evaluări

- LR-G200 Rebar Scanner PDFDocument65 paginiLR-G200 Rebar Scanner PDFJohn Carlo AmodiaÎncă nu există evaluări

- SGE Syringes CATALOG PDFDocument94 paginiSGE Syringes CATALOG PDFbokedÎncă nu există evaluări

- Level Gauge HydrastepDocument15 paginiLevel Gauge HydrastepashrafmuhÎncă nu există evaluări

- Tangazo La Kazi TBS, April 2014Document12 paginiTangazo La Kazi TBS, April 2014Rashid BumarwaÎncă nu există evaluări

- 0708 Control of Manitoring and Measuring DevicesDocument4 pagini0708 Control of Manitoring and Measuring DevicesSundara Rajan RamakrishnanÎncă nu există evaluări

- Cqi 9Document39 paginiCqi 9korray1100% (1)

- Forging Audit ChecklistDocument15 paginiForging Audit ChecklistAnkurÎncă nu există evaluări

- MetraSCAN 3D-R User Manual ENDocument482 paginiMetraSCAN 3D-R User Manual ENIgor VegaÎncă nu există evaluări

- Equipment Maintenance and Measuring Equipment ProcedureDocument2 paginiEquipment Maintenance and Measuring Equipment ProcedureRaja Mani100% (1)

- Asker CDocument2 paginiAsker CNguyễn Minh Đức100% (1)

- Amca 230-12Document23 paginiAmca 230-12Jeff Anderson Collins50% (2)

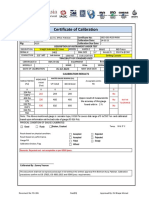

- Calibration Certificate of Weight IndicatorDocument1 paginăCalibration Certificate of Weight IndicatorHaseeb ManzoorÎncă nu există evaluări

- Proflow Manual enDocument51 paginiProflow Manual enAkin GucluÎncă nu există evaluări

- Calibrating Robot Revolution Counters FlexPendantDocument2 paginiCalibrating Robot Revolution Counters FlexPendantjoquispeÎncă nu există evaluări