Documente Academic

Documente Profesional

Documente Cultură

Construction

Încărcat de

Ulfathbary AB0 evaluări0% au considerat acest document util (0 voturi)

71 vizualizări0 paginiJoints in Concrete Slab

Drepturi de autor

© Attribution Non-Commercial (BY-NC)

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentJoints in Concrete Slab

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

71 vizualizări0 paginiConstruction

Încărcat de

Ulfathbary ABJoints in Concrete Slab

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 0

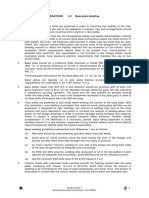

CIP 6 - Joints in Concrete Slabs on Grade

WHAT are Joints?

WHY are Joints Constructed?

Concrete expands and shrinks with changes in mois-

ture and temperature. The overall tendency is to shrink

and this can cause cracking at an early age. Irregular

cracks are unsightly and difficult to maintain but gen-

erally do not affect the integrity of concrete. Joints are

simply pre-planned cracks. Joints in concrete slabs can

be created by forming, tooling, sawing, and placement

of joint formers.

Some forms of joints are:

a. Contraction joints are intended to create weak-

ened planes in the concrete and regulate the loca-

tion where cracks, resulting from dimensional

changes, will occur.

b. Isolation or expansion joints separate or isolate

slabs from other parts of the structure, such as walls,

footings, or columns; and driveways and patios from

sidewalks, garage slabs, stairs, lightpoles and other

points of restraint. They permit independent verti-

cal and horizontal movement between adjoining parts

of the structure and help minimize cracking when

such movements are restrained.

c. Construction joints are surfaces where two suc-

cessive placements of concrete meet. They are typi-

cally placed at the end of a days work but may be

required when concrete placement is stopped for

longer than the initial setting time of concrete. In

slabs they may be designed to permit movement

and/or to transfer load. The location of construction

joints should be planned. It may be desirable to

achieve bond and continue reinforcement through a

construction joint.

Cracks in concrete cannot be prevented entirely, but

they can be controlled and minimized by properly de-

signed joints. Concrete cracks because:

a. Concrete is weak in tension and, therefore, if its

natural tendency to shrink is restrained, tensile

stresses that exceed its tensile strength can develop,

resulting in cracking.

b. At early ages, before the concrete dries out, most

cracking is caused by temperature changes or by

the slight contraction that takes place as the con-

crete sets and hardens. Later, as the concrete dries,

it will shrink further and either additional cracks may

form or preexisting cracks may become wider.

Joints provide relief from the tensile stresses, are easy

to maintain and are less objectionable than uncontrolled

or irregular cracks.

How to Construct Joints?

Joints must be carefully designed and properly con-

structed if uncontrolled cracking of concrete flatwork

is to be avoided. The following recommended prac-

tices should be observed:

a. The maximum joint spacing should be 24 to 36 times

the thickness of the slab. For example, in a 4-inch

[100 mm] thick slab the joint spacing should be about

Saw cut Tooled

Wall or Column

Expansion joint material

Slab on grade

Column

Contraction joints

intersect at diagonals

of the square

Form openings

which

will be filled after

floor has hardened

Concrete cracks below joints

Slab isolated from footing

Keyed

Doweled

Contraction Joints

Isolation Joints

Construction Joints

1979, 1989 AND 1998

Follow These Rules for Proper Jointing

1. Plan exact location of all joints, including timing of contraction joint sawing before construction.

2. Provide isolation joints between slabs and columns, walls and footings, and at junctions of driveways with

walks, curbs or other obstructions.

3. Provide contraction joints and joint filling materials as outlined in specifications.

References

1. Joints in Concrete Construction, ACI 224.3R, American

Concrete Institute, Farmington Hills, MI.

2. Guide for Concrete Floor and Slab Construction, ACI

302.1R, American Concrete Institute, Farmington Hills,

MI.

3. Slabs on Grade, ACI Concrete Craftsman Series CCS-1,

American Concrete Institute, Farmington Hills, Ml.

4. Joint Planning Primer, Concrete Construction, August

1997.

5. Bruce A. Suprenant, Sawcutting Joints in Concrete, Con-

crete Construction, January 1995.

10 feet [3 m]. It is further recommended that joint

spacing be limited to a maximum of 15 feet [4.5 m].

b. All panels should be square or nearly so. The length

should not exceed 1.5 times the width. Avoid

L-shaped panels.

c. For contraction joints, the joint groove should have

a minimum depth of

1

/4 the thickness of the slab,

but not less than 1 inch [25 mm]. Timing of

jointing operations depends on the method used:

Preformed plastic or hard board joint strips are

inserted into the concrete surface to the

required depth before finishing.

Tooled joints must be run early in the finishing

process and rerun later to ensure groove bond

has not occurred.

Early-entry dry-cut joints are generally run 1 to

4 hours after completion of finishing, depending

on the concretes setting characteristics. These

joints are typically not as deep as those ob-

tained by the conventional saw-cut process,

but should be a minimum of 1 inch [25 mm] in

depth.

Conventional saw-cut joints should be run

within 4 to 12 hours after the concrete has

been finished.

d. Raveling during saw cutting is affected by the

strength of the concrete and aggregate character-

istics. If the joint edges ravel during sawing, it must

be delayed. However, if delayed too long, sawing

can become difficult and uncontrolled cracking may

occur.

e. Use premolded joint filler such as asphalt-impreg-

nated fiber sheeting, compressible foam strips, or

similar materials for isolation joints to separate slabs

from building walls or footings. At least 2 inches

[50 mm] of sand over the top of a footing will also

prevent bond to the footing.

f. To isolate columns from slabs, form circular or

square openings, which will not be filled until after

the floor has hardened. Slab contraction joints should

intersect at the openings for columns. If square open-

ings are used around columns, the square should be

turned at 45 degrees so the contraction joints inter-

sect at the diagonals of the square.

g. If the slab contains wire mesh, cut out alternate

wires, or preferably discontinue the mesh, across

contraction joints. Note that wire mesh will not pre-

vent cracking. Mesh tends to keep the cracks and

joints tightly closed.

h. Construction joints key the two edges of the slab

together either to provide transfer of loads or to help

prevent curling or warping of the two adjacent edges.

Galvanized metal keys are sometimes used for in-

terior slabs, however, a beveled 1 by 2 inch [25 by

50 mm] strip, nailed to bulkheads or form boards,

can be used in slabs that are at least 5 inches [125

mm] thick to form a key which will resist vertical

loads and movements. Keyed joints are not recom-

mended for industrial floors. Metal dowels should

be used in slabs that will carry heavy loads. Dowels

must be carefully lined up and parallel or they may

induce restraint and cause random cracking at the

end of the dowel.

i. Joints in industrial floors subject to heavy traffic re-

quire special attention to avoid spalling of joint edges.

Such joints should be filled with a material capable

of supporting joint edges. Manufacturers recom-

mendations and performance records should be

checked before use.

S-ar putea să vă placă și

- Cracks in ConcreteDocument4 paginiCracks in ConcreteAhmed Daahir AdenÎncă nu există evaluări

- Civil Equaltion PDFDocument2 paginiCivil Equaltion PDFBalaji_Rajaman_2280Încă nu există evaluări

- Mastermesh Perforated MetalDocument8 paginiMastermesh Perforated MetalnovadistributorsÎncă nu există evaluări

- Rules of Thumb by RowingengineerDocument6 paginiRules of Thumb by RowingengineerOyens EstoyeÎncă nu există evaluări

- History of Shear Design PresentationDocument42 paginiHistory of Shear Design PresentationMuhammad AbdullahÎncă nu există evaluări

- OneSteel Design Booklet DB1.1 - Design of Simply Supported Composite BeamsDocument54 paginiOneSteel Design Booklet DB1.1 - Design of Simply Supported Composite Beamsdirk.price635Încă nu există evaluări

- Concrete BleedingDocument2 paginiConcrete BleedingBatepola BacÎncă nu există evaluări

- Stuctural JHW Sms 100 CDDocument44 paginiStuctural JHW Sms 100 CDAkmalÎncă nu există evaluări

- Detailing Considerations Design Guide 7 - bk745 PDFDocument5 paginiDetailing Considerations Design Guide 7 - bk745 PDFFunkÎncă nu există evaluări

- FB Hotel Tower and Convention Center Structural Drawings: Oudie SsociatesDocument36 paginiFB Hotel Tower and Convention Center Structural Drawings: Oudie Ssociatesabet hilarioÎncă nu există evaluări

- Anchor 201 - Evaluation of Factors That Affect Bond StressDocument27 paginiAnchor 201 - Evaluation of Factors That Affect Bond StressPatrice AudetÎncă nu există evaluări

- Analysis of Large Bracing Connections Designs For Heavy ConstructionDocument25 paginiAnalysis of Large Bracing Connections Designs For Heavy Constructiondaniel.j.mccarthyÎncă nu există evaluări

- Introduction-Design-Guide 2Document16 paginiIntroduction-Design-Guide 2Sutha100% (1)

- IDEA-Connection-Theoretical-Manual EN Ver 8 2Document65 paginiIDEA-Connection-Theoretical-Manual EN Ver 8 2Massimo LatourÎncă nu există evaluări

- Steel GirderDocument26 paginiSteel GirderChan Nov100% (1)

- Zeds & Cees: Users GuideDocument40 paginiZeds & Cees: Users GuideTee Bun PinÎncă nu există evaluări

- Understanding Adhesive Anchor Installation and Inspection Final With FiguresDocument11 paginiUnderstanding Adhesive Anchor Installation and Inspection Final With FiguresAhmad Novan SugiartoÎncă nu există evaluări

- Rigid Pavement: Joints & ReinforcementDocument7 paginiRigid Pavement: Joints & ReinforcementTeCkMunÎncă nu există evaluări

- LIMCON Design GuideDocument9 paginiLIMCON Design GuideMatthew JohnstonÎncă nu există evaluări

- CIA Z11 Presentation 2022Document14 paginiCIA Z11 Presentation 2022John Van RooyenÎncă nu există evaluări

- Vapor Retarders Under Slabs On GradeDocument2 paginiVapor Retarders Under Slabs On GradeaaÎncă nu există evaluări

- Anchorage of Wood Shear Walls To Concrete For Tension and Shear PDFDocument6 paginiAnchorage of Wood Shear Walls To Concrete For Tension and Shear PDFIonFlorentaÎncă nu există evaluări

- Cracks and Shrinkage On ConcreteDocument3 paginiCracks and Shrinkage On ConcreteCaryl Louise ObcianaÎncă nu există evaluări

- A Nonlinear Model For Gusset Plate Connections Engineering StructuresDocument13 paginiA Nonlinear Model For Gusset Plate Connections Engineering StructuresHenry Jesús RíosÎncă nu există evaluări

- CIA Concrete 2017 Paper - Cracking in Residential PavingDocument10 paginiCIA Concrete 2017 Paper - Cracking in Residential Pavingsaagar8Încă nu există evaluări

- Structural For TenderDocument18 paginiStructural For Tenderrimshabatoool72Încă nu există evaluări

- Post Installed RebarDocument38 paginiPost Installed RebarSingDollarÎncă nu există evaluări

- Types of CracksDocument14 paginiTypes of Cracksasl halÎncă nu există evaluări

- TB Manual 7 Dec19Document44 paginiTB Manual 7 Dec19Brett RobertsÎncă nu există evaluări

- Microstran Fundamentals TRNC01483 1 0001Document69 paginiMicrostran Fundamentals TRNC01483 1 0001Cris BandaÎncă nu există evaluări

- Chapter 5 Staircase Types, Analysis and DesignDocument15 paginiChapter 5 Staircase Types, Analysis and Designzeru32611720% (1)

- Sample HOA Architectural ApplicationDocument5 paginiSample HOA Architectural ApplicationRichard BondÎncă nu există evaluări

- UWS CompositeBeam ShearConnectionDocument15 paginiUWS CompositeBeam ShearConnectionMuhammad AsroriÎncă nu există evaluări

- Civil Design Help - Foundation For Rotating Equipment PDFDocument31 paginiCivil Design Help - Foundation For Rotating Equipment PDFoluomo1Încă nu există evaluări

- "Hybrid" Light Steel Panel and Modular Systems PDFDocument11 pagini"Hybrid" Light Steel Panel and Modular Systems PDFTito MuñozÎncă nu există evaluări

- Effect of Cracking On Corrosion of Steel in Concrete PDFDocument12 paginiEffect of Cracking On Corrosion of Steel in Concrete PDFSteve NolaÎncă nu există evaluări

- Galvanized Slip-Critical ConnectionsDocument2 paginiGalvanized Slip-Critical Connectionsaams_sÎncă nu există evaluări

- 2.1 BCHD Peer Review Structural Engineering Fee Proposal SIGNEDDocument9 pagini2.1 BCHD Peer Review Structural Engineering Fee Proposal SIGNEDRueleo MaoÎncă nu există evaluări

- Collapse analysis of externally prestressed structuresDe la EverandCollapse analysis of externally prestressed structuresÎncă nu există evaluări

- Installation Manual E-Brick en LoresDocument80 paginiInstallation Manual E-Brick en LoresvideoramirezÎncă nu există evaluări

- Metric Threaded Inserts: Design GuideDocument26 paginiMetric Threaded Inserts: Design GuideKesavan DhuraiÎncă nu există evaluări

- Chapter 1: Shed Basics: PurposeDocument4 paginiChapter 1: Shed Basics: PurposeHedi Ben MohamedÎncă nu există evaluări

- RTA - Pavement Details - CRCPDocument17 paginiRTA - Pavement Details - CRCPbraackwÎncă nu există evaluări

- CompB IDocument31 paginiCompB IEngibearÎncă nu există evaluări

- MetStructures Technical ManualDocument76 paginiMetStructures Technical ManualananditÎncă nu există evaluări

- Jumbo ShapesDocument12 paginiJumbo ShapesamokhtaÎncă nu există evaluări

- 02 Concrete in Practice 01-42Document86 pagini02 Concrete in Practice 01-42Hishmat Ezz AlarabÎncă nu există evaluări

- Unclear Grouting Concepts For Industrial Structures and EquipmentDocument8 paginiUnclear Grouting Concepts For Industrial Structures and EquipmentRajesh Kumar PandeyaÎncă nu există evaluări

- Technical Manual 4th Edition PDFDocument44 paginiTechnical Manual 4th Edition PDFJohn FarrowÎncă nu există evaluări

- Composite Beam ChartsDocument8 paginiComposite Beam ChartsAnonymous 1sJXK1DKZÎncă nu există evaluări

- DDA 3164 BEAM Shear Deflection and CrackDocument20 paginiDDA 3164 BEAM Shear Deflection and CrackZayyan RomjonÎncă nu există evaluări

- CIP 6 Joints in Concrete Slaabs On Grade PDFDocument2 paginiCIP 6 Joints in Concrete Slaabs On Grade PDFAli ParvezÎncă nu există evaluări

- Cracking Joint No RestrictionDocument2 paginiCracking Joint No RestrictionThanh Khiet UngÎncă nu există evaluări

- Joints in Concrete Slabs On GradeDocument2 paginiJoints in Concrete Slabs On GradeaaÎncă nu există evaluări

- CIP 6 - Joints in Concrete Slabs On GradeDocument2 paginiCIP 6 - Joints in Concrete Slabs On GradeBalaji_Rajaman_2280Încă nu există evaluări

- Construction Joints:: Expansion JointDocument5 paginiConstruction Joints:: Expansion JointSathya MurthyÎncă nu există evaluări

- URBAN DESIGN unit-IVDocument16 paginiURBAN DESIGN unit-IVmrunalini KolaÎncă nu există evaluări

- Expansion and Construction JointsDocument46 paginiExpansion and Construction Jointscricket review100% (1)

- Concrete JointsDocument5 paginiConcrete JointsDenzel OwuorÎncă nu există evaluări

- Condition Precedent and NoticesDocument1 paginăCondition Precedent and NoticesmutyokaÎncă nu există evaluări

- S00-01 - Mansa Choppies - Foundation Plan - 14022019 PDFDocument1 paginăS00-01 - Mansa Choppies - Foundation Plan - 14022019 PDFmutyokaÎncă nu există evaluări

- ZCCM V VedantaDocument20 paginiZCCM V Vedantamutyoka0% (1)

- House Design MasterDocument12 paginiHouse Design MastermutyokaÎncă nu există evaluări

- SSB02 Concept Design 2010-03-12Document60 paginiSSB02 Concept Design 2010-03-12georgeispasoiuÎncă nu există evaluări

- Standard Roof BOQ TemplateDocument1 paginăStandard Roof BOQ TemplatemutyokaÎncă nu există evaluări

- S00 - Roma Park - First Floor Scheme PDFDocument1 paginăS00 - Roma Park - First Floor Scheme PDFmutyokaÎncă nu există evaluări

- MR Musyani Final-Layout1 PDFDocument1 paginăMR Musyani Final-Layout1 PDFmutyokaÎncă nu există evaluări

- R00-02 - Floor Slabs ReinforcementDocument1 paginăR00-02 - Floor Slabs ReinforcementmutyokaÎncă nu există evaluări

- Delay and Disruption PDFDocument7 paginiDelay and Disruption PDFmutyokaÎncă nu există evaluări

- Pump Basket Fabrication Details: Project Information and StatusDocument1 paginăPump Basket Fabrication Details: Project Information and StatusmutyokaÎncă nu există evaluări

- PumpsDocument2 paginiPumpsmutyokaÎncă nu există evaluări

- Floor Slabs BarschdDocument1 paginăFloor Slabs BarschdmutyokaÎncă nu există evaluări

- S00-02 - SSFFGA - Suspended FloorsDocument1 paginăS00-02 - SSFFGA - Suspended FloorsmutyokaÎncă nu există evaluări

- BOZ Maximum Annual Lending RateDocument1 paginăBOZ Maximum Annual Lending RatemutyokaÎncă nu există evaluări

- Boz Annual Report 2016Document162 paginiBoz Annual Report 2016mutyokaÎncă nu există evaluări

- GuestDocument1 paginăGuestmutyokaÎncă nu există evaluări

- Foundation Bases BSC PDFDocument1 paginăFoundation Bases BSC PDFmutyokaÎncă nu există evaluări

- Sadc Traffic Signs - Volume 3Document241 paginiSadc Traffic Signs - Volume 3Amigowzz Hood67% (3)

- PumpsDocument2 paginiPumpsmutyokaÎncă nu există evaluări

- Guest Wing 1Document1 paginăGuest Wing 1mutyokaÎncă nu există evaluări

- Canteen Truss Prokon OutputDocument97 paginiCanteen Truss Prokon OutputmutyokaÎncă nu există evaluări

- Interim Measures and Emergency Arbitrator ProceedingsDocument26 paginiInterim Measures and Emergency Arbitrator ProceedingsmutyokaÎncă nu există evaluări

- Block Work 387799Document44 paginiBlock Work 387799skrai4uÎncă nu există evaluări

- Construction Specialties ExpansionDocument36 paginiConstruction Specialties ExpansionmutyokaÎncă nu există evaluări

- Digital Brochure Ndole BayDocument4 paginiDigital Brochure Ndole BaymutyokaÎncă nu există evaluări

- Tank Farm & Cold, Hot Water Tank Base ReinforcementDocument1 paginăTank Farm & Cold, Hot Water Tank Base ReinforcementmutyokaÎncă nu există evaluări

- Argelith Lieferprogramm GBDocument24 paginiArgelith Lieferprogramm GBmutyokaÎncă nu există evaluări

- Sketch 1. FoundationDocument1 paginăSketch 1. FoundationmutyokaÎncă nu există evaluări

- House Sketch Design 04-A1 LayoutDocument1 paginăHouse Sketch Design 04-A1 LayoutmutyokaÎncă nu există evaluări