Documente Academic

Documente Profesional

Documente Cultură

Us 20130249277

Încărcat de

david19775891Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Us 20130249277

Încărcat de

david19775891Drepturi de autor:

Formate disponibile

US 20130249277A1

(19) United States (12) Patent Application Publication (10) Pub. N0.: US 2013/0249277 A1

PARK et a].

(54) VEHICLE OPERATING SYSTEM AND

METHOD OF CONTROLLING THE SAME

(43) Pub. Date:

(52) US. Cl.

Sep. 26, 2013

USPC ......................................................... .. 307/91

(76) Inventors: Seong-Joon PARK, Yongin-si (KR); Ri-A JU, Yongin-si (KR)

(57)

ABSTRACT

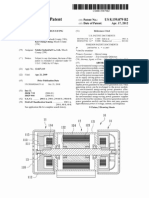

A Vehicle operating system and a method of controlling the

Vehicle operating system, the Vehicle operating system

(21) App1.No.: 13/612,926

(22) Filed:

(30)

including an electric poWer generation module that is con?g ured to generate electric poWer; a battery, the battery being

Sep. 13, 2012

Foreign Application Priority Data

(KR) ...................... .. 10-2012-0030235

chargeable by using the electric poWer generated by the elec tric poWer generation module; a battery management system that controls the chargeable battery; and a cooler that is con ?gured to cool the battery, Wherein the battery management

System is Con?gured to Cut Off the electric power Supplied to

Mar. 23, 2012

the battery When the battery is fully charged, and When the

Publication Classi?cation battery management system cuts off the electric poWer sup plied to the battery, the cooler is con?gured to consume the

(51) Int. Cl. B60L 1/00

(2006.01)

electric poWer generated by the electric poWer generation module.

150

CONTROLLER

130

MATN

P1

1 20

T00 P3 LJ

33

LF 102

ELECTRTC

POWER

SWITCHING

START MOTOR

131 1 32

110

ELECTRIC LOAD

T40

5M3

GENERATTON

MODULE

,

BATTERY

101

F N

CONTROLLER

P4

P2

AT

-E

Patent Application Publication

Sep. 26, 2013 Sheet 1 0f 8

US 2013/0249277 A1

03

9E5?8wi

02

R 22

94O : 5N? 825

.QE H

2592@086i2

N? :2 52/2

9: 2: 25

538

53203$5628

Q2

m? 3 E 5

:75 08

HT!

ma _||_

:E

295

Patent Application Publication

Sep. 26, 2013 Sheet 2 0f 8

US 2013/0249277 A1

FIG. 2

100

P3 LJ P1

_________________________________ _ -4192-

103

I04 5

PROTECTION CIRCUIT

BATTERY

CONTROLLER

BATTERY

I ____________________ ..J

i

101

P4 |--|

P2

FIG. 3

_.

Patent Application Publication

Sep. 26, 2013 Sheet 3 0f 8

US 2013/0249277 A1

\lz.viA

:2 NM: Q: x: tom com H/

2: Q z

.Urm w

m

+ m2 2:

2aEmtg6/z2EitE/

$Z3Q285E

ON"

258d 5692

Patent Application Publication

Sep. 26, 2013 Sheet 4 0f 8

US 2013/0249277 A1

mm?

02

com

mm?

C2

um

.wwm m

mi.|.

_

2: .

x: Q:

cow

@2Q3E0H8

02

ERV w5tz8i/E

EZjQO S 526

Patent Application Publication

Sep. 26, 2013 Sheet 5 0f 8

US 2013/0249277 A1

? 8 Q R

mm: 2: x: Q:

U :8 M/ m9 2: . 8m

.UE @

Ag

82>UV E$56<a2m t5/E

5 E 2 3 j O 9 0 Z 8 Q @231068%

8*

M259

Patent Application Publication

Sep. 26, 2013 Sheet 6 0f 8

US 2013/0249277 A1

FIG. '7

IS ELECTRIC POWER GENERATED BY ELECTRIC POWER GENERATION MODULE?

S102

START TO CHARGE BATTERY

S103

MEASURE CHARGE AMOUNT OF BATTERY

S108

END CHARGING BATTERY

S109

S104

CHARGE AMOUNT >

REFERENCE VALUE?

TRANSMIT SIGNAL REGARDING FULL CHARGE STATE FROM BATTERY CONTROLLER TO FAN CONTROLLER SIIO

TRANSMIT SIGNAL REGARDING

BATTERY CONTROLLER TO FAN CONTROLLER

S106

CONSUME, BY FAN, ALL ELECTRIC POWER

POWER GENERATION MODULE

S111 IS ELECTRIC POWER GENERATED BY ELECTRIC POWER GENERATION MODULE?

START TO DRIVE FAN BY FAN CONTROLLER

S107

FULL CHARGE?

Patent Application Publication

Sep. 26, 2013 Sheet 8 0f 8

US 2013/0249277 A1

FIG. 9

IS ELECTRIC POWER GENERATED BY ELECTRIC POWER GENERATION MODULE?

YES S202 S209 START TO CHARGE BATTERY

ENO CHARGING BATTERY

S203

MEASURE CHARGE AMOUNT OF BATTERY

S204 CHARGE AMOUNT > REFERENCE VALUE?

S210 TRANSMIT SIGNAL REGARDING FULL CHARGE STATE FROM BATTERY CONTROLLER TO FAN CONTROLLER S211 OIRECT OPERATION OF EAN CONTROLLER BY MAIN CONTROLLER

YES

S205

TRANSMIT SIGNAL REGAROING

CHARGE STATE FROM BATTERY

CONTROLLER TO FAN CONTROLLER 5206

DIRECT OPERATION OF FAN CONTROLLER BY MAIN CONTROLLER

8212

CONSUMEI BY FAN, ALL ELECTRIC POWER GENERATEO BY ELECTRIC POWER GENERATION MODULE

S213 IS ELECTRIC POWER GENERATED BY ELECTRIC POWER GENERATION MODULE?

S207

START TO DRIVE FAN BY FAN CONTROLLER YES

S208

NO

FULL CHARGE?

YES

US 2013/0249277 A1

Sep. 26, 2013

VEHICLE OPERATING SYSTEM AND METHOD OF CONTROLLING THE SAME CROSS-REFERENCE TO RELATED APPLICATION

tem and may be con?gured to generate a control signal for

starting driving of the cooler When the charge state is greater

than a reference value.

[0001]

Korean Patent Application No. 10-2012-0030235,

?led on Mar. 23, 2012, in the Korean Intellectual Property

[0014] The cooler may include a fan that cools the battery, and a fan controller that controls driving of the fan, and the fan controller may be con?gured to adjust a rotating speed of the fan based on the control signal.

O?ice, and entitled, Vehicle Operating System and Method of Controlling Same, is incorporated by reference herein in its entirety.

BACKGROUND

[0015] Charging the battery and driving the cooler may be simultaneously performed by using the electric poWer gener ated by the electric poWer generation module, When the

charge state of the battery is greater than the reference value

and the battery is not yet fully charged.

[0016] The data related to the charge state of the battery may be data indicating a voltage of the battery.

[0017] The main controller may estimate a temperature of

[0002] [0003]

1. Field Embodiments relate to a vehicle operating system

and a method of controlling the same.

[0004]

[0005]

2. Description of the Related Art

Unlike primary batteries that are unable to be

the battery from the data indicating the voltage of the battery

and controls the cooler based on the estimated temperature.

recharged, secondary batteries may be recharged. Secondary

batteries may be used in a single battery form and in a battery module form (in Which a plurality of batteries are connected to each other and bound in one unit) according to types of external devices to Which the secondary batteries are to be

[0018]

The battery management system may directly trans

mit data indicating a charge state of the battery to the cooler. [0019] The cooler may include a fan that cools the battery, and a fan controller that controls driving of the fan, and the fan controller may be con?gured to adjust a rotating speed of the

fan based on the data.

applied.

[0006] A lead battery has been used as a poWer supply for

starting engines of vehicles. Recently, an ldle Stop & Go (ISG) system to improve gas mileage has been considered. A poWer supply that supports the ISG system, e.g., an idling stop device, may have a poWer characteristic for outputting high poWer for starting an engine.

SUMMARY [0007] Embodiments are directed to a vehicle operating system and a method of controlling the same.

[0020] The fan controller may be con?gured to rotate the fan to consume all the electric poWer generated by the electric poWer generation module When the fan controller receives data indicating a full charge state from the battery manage ment system.

[0021] Driving of the cooler may begin When the charge

state is greater than a reference value.

[0022] Charging the battery and driving the cooler may be simultaneously performed by using the electric poWer gener ated by the electric poWer generation module, When the

charge state of the battery is greater than the reference value

[0008] The embodiments may be realiZed by providing a vehicle operating system including an electric poWer genera tion module that is con?gured to generate electric poWer; a

battery, the battery being chargeable by using the electric

poWer generated by the electric poWer generation module; a battery management system that controls the chargeable bat

tery; and a cooler that is con?gured to cool the battery, Wherein the battery management system is con?gured to cut off the electric poWer supplied to the battery When the battery

and the battery is not yet fully charged. [0023] The data indicating the charge state of the battery may be data indicating a voltage of the battery.

[0024] The cooler may be con?gured to estimate a tempera ture of the battery from the data indicating the voltage of the

battery and may be con?gured to control the cooler based on the estimated temperature.

[0025]

The embodiments may also be realiZed by providing

is fully charged, and When the battery management system

cuts off the electric poWer supplied to the battery, the cooler is con?gured to consume the electric poWer generated by the electric poWer generation module. [0009] The vehicle operating system may further include a

main controller that receives data related to a charge state of

a method of controlling a vehicle operating system, the

method including charging a battery by using electric poWer generated by an electric poWer generation module; determin ing a charge state of the battery; determining Whether the battery is fully charged; cutting off the electric poWer sup plied to the battery When the battery is fully charged; and

consuming at least some of the electric poWer generated by the electric poWer generation module via a cooler that cools

the battery from the battery management system and that

controls the cooler based on the received data.

[0010]

When the main controller receives data indicating a

the battery When the charge state of the battery is greater than

a reference value.

full charge state from the battery management system, the

main controller may be con?gured to generate a control sig nal for controlling the cooler based on the received data. [0011] The cooler may include a fan that cools the battery, and a fan controller that controls driving of the fan, and the fan controller may be con?gured to adjust a rotating speed of the fan based on the control signal. [0012] The fan controller may be con?gured to rotate the fan to consume all the electric poWer generated by the electric

[0026]

When the battery is fully charged, the cooler may

consume all the electric poWer generated by the electric

poWer generation module. [0027] Determining the charge state of the battery may include measuring a voltage of the battery, and When the charge state of the battery is greater than the reference value,

a controller may allocate an amount of electric poWer used to

poWer generation module.

[0013] The main controller may receive data related to the

charge the battery and another amount of electric poWer used by the cooler from among the electric poWer generated by the electric poWer generation module based on the voltage of the

charge state of the battery from the battery management sys

battery.

US 2013/0249277 A1

Sep. 26, 2013

BRIEF DESCRIPTION OF THE DRAWINGS

[0028] Features will become apparent to those of ordinary skill in the art by describing in detail exemplary embodiments

with reference to the attached drawings in which: [0029] FIG. 1 illustrates a block diagram of a vehicle oper

132, and the main controller 150, to be described in greater detail below. The battery pack 100 may include a battery 101

and the BMS 102.

[0042]

The battery 101 may be a rechargeable secondary

battery and may be con?gured with one or more serial-con

ating system according to an embodiment; [0030] FIG. 2 illustrates a block diagram of a battery pack in the vehicle operating system of FIG. 1, according to an

nected and/or parallel-connected battery cells. For example,

the battery 101 may be a lithium ion battery. [0043] The battery pack 100 may be applied to a power supply for starting an engine in an Idle Stop & Go (ISG) system in which an ISG function is implemented to improve

embodiment;

[0031] FIG. 3 illustrates a graph showing an amount of a

current generated by an electric power generation module according to an embodiment; [0032] FIGS. 4 to 6 illustrate operational states of the vehicle operating system of FIG. 1, according to an embodi ment;

[0033] FIG. 7 illustrates a ?owchart of a method of control

gas mileage. In response to frequently repeated stopping and restarting of the engine in the ISG system, charging and discharging of the battery pack 100 may also be repeated.

[0044] For a lead battery in one type of ISG system, when

ling the vehicle operating system of FIG. 1, according to an

embodiment;

[0034] FIG. 8 illustrates a block diagram of a vehicle oper

ating system according to an embodiment; and

[0035] FIG. 9 illustrates a ?owchart illustrating a method of

controlling the vehicle operating system of FIG. 8, according

to an embodiment.

a charge and discharge operation is frequently repeated, a life span of the lead battery may be reduced, and a charge and discharge characteristic thereof may be deteriorated. For example, due to the repetition of charging and discharging, a charging amount may be reduced, an engines starting per formance may be lowered, and a replacement cycle of the lead battery may be shortened. [0045] According to an embodiment, the battery pack 100

may include a lithium ion battery maintaining a relatively

DETAILED DESCRIPTION

[0036]

Example embodiments will now be described more

constant charge and discharge characteristic and having less aging deterioration compared with the lead battery. Thus, the battery pack 100 may be appropriately applied to the ISG

system in which stop and restart of the engine are repeated. In

fully hereinafter with reference to the accompanying draw

ings; however, they may be embodied in different forms and

should not be construed as limited to the embodiments set

forth herein. Rather, these embodiments are provided so that

this disclosure will be thorough and complete, and will fully

convey the scope of the invention to those skilled in the art. [0037] As used herein, the term and/ or may include any

and all combinations of one or more of the associated listed

addition, a weight of the battery pack 100 may relatively lower than that of the lead battery having the same charge capacity. Thus, a gas mileage improvement effect may be expected. Also, the battery pack 100 may realiZe the same charge capacity and have a smaller siZe than the lead battery.

Thus, a loading space may be saved. [0046] In an implementation, the battery 101 may include various kinds of batteries. The battery 101 may have a lower rated voltage than an output voltage of the electric power generation module 120. For example, a Nickel-Metal Hydride (NiMH) battery or a nickel-cadmium battery may be used as the battery 101.

items. Expressions such as at least one of, when preceding a list of elements, modify the entire list of elements and do not modify the individual elements of the list.

[0038]

The terminology used in the application is used only

to describe speci?c embodiments and does not have any intention to limit the embodiments. An expression in the

[0047] According to the present embodiment, the battery

pack 100 may include the BMS 102. A lithium ion battery may have a better charge and discharge characteristic but may

singular includes an expression in the plural unless they are clearly different from each other in a context. In the applica

tion, it should be understood that terms, such as include and have, are used to indicate the existence of implemented

have lower stability than a lead battery. Thus, the battery pack

100 may include the BMS 102 so that the battery 101 may be

feature, number, step, operation, element, part, or a combina tion of them without excluding in advance the possibility of

existence or addition of one or more other features, numbers,

stably charged or discharged. For example, the BMS 102 may control the battery 101 to be charged and discharged so that over-charging or over-discharging of the battery 101 may be

reduced and/or prevented. For example, the BMS 102 may cut

steps, operations, elements, parts, or combinations of them.

[0039] FIG. 1 illustrates a block diagram of a vehicle oper ating system according to an embodiment. A vehicle to which the vehicle operating system is applied 1 may include, e.g., an

automobile or an electric bicycle.

off electric power supplied to the battery 101 when the battery

101 is fully charged.

[0048] The BMS 102 may communicate with the main controller 150 through a third terminal P3 to transmit and receive various kinds of data, e.g., a charge state and a tem perature, to and from the main controller 150. In addition, the BMS 102 may transmit data regarding a charge state of the battery 101 to the fan controller 132 through a fourth terminal P4. A con?guration of the BMS 102 will be described in detail below with reference to FIG. 2. [0049] The start motor 110 may operate when a vehicle is to

[0040]

Referring to FIG. 1, the vehicle operating system 1

may include a battery pack 100, a start motor 110, an electric power generation module 120, a cooler 130, and a main controller 150. An electric load 140 may be connected to the

vehicle operating system 1. [0041] The battery pack 100 may store electric energy by receiving a current generated by the electric power generation

module 120 and may supply a driving current to the start

motor 110. The battery pack 100 may also supply stored

electric power as operating power for control units, e.g., a

Battery Management System (BMS) 102, a fan controller

start operating and may provide an initial rotation dynamic force for rotating a driving axis of an engine (not shown). For example, the start motor 110 may drive the engine by receiv ing electric power from the battery pack 100 through a ?rst

US 2013/0249277 A1

Sep. 26, 2013

terminal P1 and a second terminal P2, and rotating the driving

axis When the engine starts or When the engine restarts after an

exchange various kinds of data and a control signal With the

idle stop of the engine. [0050] The electric power generation module 120 may be connected to the driving axis of the engine and may operate during operation of the engine to convert a rotation dynamic

force to electric poWer. For example, the electric poWer gen eration module 120 may generate electric poWer during operation of the engine and may be, e.g., an alternator. The electric poWer generation module 120 may include a Direct Current (DC) or Alternating Current (AC) generator and a recti?er. In an implementation, the electric poWer generation module 120 may generate electric poWer having a voltage of about 15 V DC, e.g., about 14.4 to 14.8 V DC. The electric

battery pack 100, to monitor a state of the battery pack 100, and to control an operation of the battery pack 100. [0057] FIG. 2 illustrates a block diagram of the battery pack in the vehicle operating system of FIG. 1, according to an

embodiment.

[0058] As described above, the battery pack 100 may

include the battery 101, the BMS 102, and the ?rst to fourth

terminals P1 to P4. The BMS 102 may include a battery controller 103 and a protection circuit 104. [0059] The battery controller 103 may monitor a state of the battery 101 and may transmit a monitoring result to the main

poWer generation module 120 may supply the generated elec tric poWer to desired components, e.g., the battery pack 100,

the cooler 130, and/or the electric load 140. [0051] The cooler 130 may loWer a temperature of the

battery pack 100 by detecting a temperature increase (accord ing to charging and discharging of the battery pack 100) and

cooling the battery pack 100. The cooler 130 may include a fan 131 (for receiving electric poWer and generating air ?oW from a rotation dynamic force) and the fan controller 132 (for controlling driving of the fan 131). In an implementation, the

cooler 130 may further include a sWitching unit 133 (for controlling a How of current through the fan 131). [0052] The fan 131 may be con?gured so that the air ?oW

controller 150. For example, the battery controller 103 may detect a plurality of types of data, such as a voltage applied to the battery 101, a current ?oWing through the battery 101, a temperature of the battery 101, and a charge state of the battery 101. The battery controller 103 may individually detect the data or may acquire each of the types of data by estimating the data from another one of the plurality of types of data. For example, the battery controller 103 may measure

a voltage of the battery 101 to estimate the charge state or

temperature of the battery 101. [0060] The battery controller 103 may transmit the plural ity of types of detected data to the main controller 150 through the third terminal P3. Then, the battery controller 103 may

receive data or a control signal from the main controller 150 and may operate according to the received data or control

generated by the fan 131 directly reaches the battery pack 100 or the battery 101 of the battery pack 100, thereby directly

cooling the battery pack 100. In an implementation, the fan

131 may be con?gured so that the air ?oW arrives at the

signal.

[0061] In addition, the battery controller 103 may transmit data indicating the charge state of the battery 1 01 from among the plurality of types of detected data to the fan controller 132 through the fourth terminal P4. The data indicating the charge state of the battery 101 may be voltage data of the battery 101,

used to estimate SOC.

battery pack 100 or the battery 101 of the battery pack 100

through a duct.

[0053] According to the present embodiment, the fan con troller 132 may receive data regarding a charge state of the battery 101 from the BMS 102. The fan controller 132 may drive the fan 131 based on the received data. For example, an operation of the fan controller 132 may proceed as described beloW.

[0062] The protection circuit 104 may control a How of current toWards or to the battery 101 under control of the battery controller 103. For example, When an over current

[0054]

When the charge state of the battery 101 is equal to

?oWs through the battery 101, or When the battery 101 is over-charged, the battery controller 103 may control the pro

tection circuit 104 to cut off a path of the current and, accord ing to the control, the protection circuit 104 may turn off a sWitching device included therein to cut off the How of the

current.

or less than a reference value, e. g., 90%, the fan controller 132

may cut off the electric poWer supplied to the fan 131 by turning off the sWitching unit 133. When the charge state of the battery 101 is greater than the reference value, the fan controller 132 may supply the electric poWer to the fan 131 by turning on the sWitching unit 133. In this case, the fan con troller 132 may adjust a rotating speed of the fan 131 based on the charge state of the battery 101. When the battery 101 is in

a full charge state, the fan controller 132 may turn on the

[0063]

FIG. 3 illustrates a graph shoWing an amount of a

current generated by the electric poWer generation module

according to an embodiment. A horiZontal axis indicates a time (t), and a vertical axis indicates an amount of current (I).

[0064]

Referring to FIG. 3, When the electric poWer gen

sWitching unit 133 and control the rotating speed of the fan

131 so that all electric poWer generated by the electric poWer generation module 120 is consumed by or directed to the fan 131. [0055] The electric load 140 may be a component for con

eration module 120 generates electric poWer, a current ?oWs

suming electric poWer stored in the battery pack 100. The

electric load 140 may include various kinds of electronic devices, e.g., a navigation device, an audio device, a light, a vehicle black box, and/or a burglarproof or security device.

through the battery pack 100. As an amount of the current increases, a charge amount of the battery 101 may also increase, and the battery 101 may be in a full charge state at time t1. HoWever, the electric poWer generation module 120 may continuously generate electric poWer to apply the current

to the battery pack 100 (a slashed part after t1). Accordingly,

if electric poWer Were to be continuously supplied to the

The number and types of components forming the electric

load 140 may vary according to the vehicle. [0056] The main controller 150 may control general opera

battery 101, the battery 101 may be in an over-charge stage, and thus, deterioration, i.e., damage to the battery 101, may

occur.

tions of the vehicle operating system 1 in Which the battery

pack 100 is installed. The main controller 150 may be con

[0065] FIGS. 4 to 6 illustrate operational states of the vehicle operating system of FIG. 1, according to an embodi

ment. FIG. 4 illustrates a case Where the battery 101 is not yet

nected to the battery pack 1 00 through the third terminal P3 to

fully charged.

US 2013/0249277 A1

Sep. 26, 2013

[0066]

Referring to FIG. 4, the electric power generation

the battery 101, Which has been received from the battery

controller 103. In the instant case, the charge amount of the

module 120 may generate electric power and, accordingly, a current I1 may be generated. The generated current I1 may ?oW toWard the battery pack 100 and the cooler 130. [0067] The battery controller 103 may detect a charge state of the battery 101, may determine that the battery 101 needs to be charged, may generate a control signal Son (for turning on the sWitching device of the protection circuit 104), and may apply the control signal Son to the sWitching device. Accordingly, the sWitching device may be in a turn-on state, and a current 12 may be applied to the battery 101 to charge the battery 101. For example, When the charge state of the battery 101 is equal to or less than about 90%, the battery controller 103 may turn on the sWitching device to charge the

battery 101 may be greater than the reference value. Thus, the voltage of the battery 101 may also be greater than a reference voltage. Accordingly, it may be estimated that the tempera ture of the battery 101 is high. Thus, When the data Sv regard ing a voltage of the battery 101 (Which has been received from the battery controller 103) is greater than the reference value, the fan controller 132 may determine that the battery 101 needs to be cooled. Accordingly, the fan controller 132 may

drive the fan 131. [0077] In this case, the fan controller 132 may determine a

battery 101. [0068] In addition, the battery controller 103 may directly

transmit data regarding a charge state of the battery 101 (i.e., data Sv regarding a voltage of the battery 101) to the fan

controller 132. The fan controller 132 may determine that the battery 101 does not need to be cooled, based on the received data Sv. Thus, the fan controller 132 may apply a control signal Soff to the sWitching unit 133 so that the sWitching unit 133 is in a tum-off state, to thereby cut off a current 13 applied to the fan 131.

grade of cooling based on the temperature of the battery 101. Thus, the fan controller 132 may generate a control signal Sd by determining a suitable rotating speed of the fan 131 based

on the data Sv regarding a voltage of the battery 101 and may

drive the fan 131 by applying the generated control signal Sd

to the fan 131. For example, an amount of a current applied to

the fan 131 may be adjusted to thereby adjust the rotating

speed of the fan 131. Accordingly, an amount of electric poWer used to charge the battery pack 100 and an amount of electric poWer used by the cooler 130 may be determined or allocated from among the electric poWer generated by the electric poWer generation module 120. [0078] FIG. 6 illustrates a case Where the battery 101 is

[0069] Accordingly, I1:I2, and I3:0. For example, the bat

tery 101 may be charged, and the cooler 130 may not operate. [0070] The fan controller 132 may estimate a temperature of the battery 101 based on the data regarding a charge state of

fully charged.

[0079] Referring to FIG. 6, the electric poWer generation module 120 may generate electric poWer and, accordingly, the current I1 may be generated. The generated current I1 may ?oW toWard the battery pack 100 and the cooler 130. [0080] The battery controller 103 may detect a charge state of the battery 101, may determine that the battery 101 is fully charged, may generate a control signal Soff (for turning off the sWitching device of the protection circuit 104), and may apply the control signal Soff to the sWitching device. Thus,

the sWitching device may be in a tum-off state, and a current

the battery 101, Which has been received from the battery

controller 103, e.g., the data Sv regarding a voltage of the

battery 101. As the voltage of the battery 101 increases, the battery may be charged for a long time. Accordingly, it may be estimated that the temperature of the battery 101 increases. Thus, When the data Sv regarding a voltage of the battery 101 (Which has been received from the battery controller 103) is

equal to or less than the reference value, the fan controller 132 may determine that the battery 101 does not need to be cooled. Thus, the fan controller 132 may not drive the fan 131.

[0071] FIG. 5 illustrates a case Where a charge amount is

12 applied to the battery may be cut off, thereby ending the

charging.

[0081] The battery controller 103 may directly transmit data regarding a charge state of the battery 101 (i.e., the data Sv regarding a voltage of the battery 101) to the fan controller 132. The fan controller 132 may determine that the battery

101 needs to be cooled based on the received data Sv. Thus, the fan controller 132 may apply the current 13 to the fan 131 so that the sWitching unit 133 is continuously in a turn-on state to continuously rotate the fan 131.

greater than the reference value.

[0072] Referring to FIG. 5, the electric poWer generation module 120 may generate electric poWer and, accordingly,

the current I1 may be generated. The generated current I1 may

?oW through the battery pack 100 and the cooler 130.

[0073] The battery controller 103 may detect a charge state of the battery 101, may determine that a charge amount is greater than the reference value, may continuously turn on the

[0082] Accordingly, I1:I3, and I2:0. For example, charg

ing of the battery 101 may be prevented, and only the cooler

130 may operate. [0083] The fan controller 132 may estimate a temperature of the battery 101 based on the data Sv regarding a voltage of

sWitching device of the protection circuit 104, and may alloW charging of the battery 101 by alloWing the current 12 to be applied to the battery 101. [0074] The battery controller 103 may directly transmit data regarding a charge state of the battery 101 (i.e., the data Sv regarding a voltage of the battery 101) to the fan controller

132. The fan controller 132 may determine that the battery 101 needs to be cooled based on the received data Sv. Thus, the fan controller 132 may apply the control signal Son to the sWitching unit 133 so that the sWitching unit 133 is in a turn-on state to apply the current 13 to the fan 131, thereby driving the fan 131.

the battery 101, Which has been received from the battery

controller 103. In the instant case, the battery 101 may be

fully charged. Thus, the voltage of the battery 101 may be greater than the reference voltage and, accordingly, it may be estimated that the temperature of the battery 101 is high. When the data Sv regarding a voltage of the battery 101 (Which has been received from the battery controller 103) is

greater than the reference value, the fan controller 132 may determine that the battery 101 needs to be cooled and, accord ingly, the fan controller 132 may drive the fan 131. [0084] In this case, the temperature of the battery 101 may be maximiZed due to a full charge state of the battery 101. Thus, the fan 131 may operate at a maximum. In addition, if

[0075] Accordingly, I1:I2+I3, I2#0, and I3 #0. For example, the battery 101 may be charged and, simulta neously, the cooler 130 may be operated.

[0076] The fan controller 132 may estimate a temperature of the battery 101 based on the data Sv regarding a voltage of

US 2013/0249277 Al

Sep. 26, 2013

the electric power were to be supplied to the battery 101 to

[0094]

In operation S111, whether the electric power gen

further charge the battery 101, the battery 101 may be dete

riorated. Accordingly, the fan controller 132 may rotate the fan 131 to consume all available electric power generated by the electric power generation module 120.

[0085]

Although the battery controller 103 may transmit

the data Sv regarding a voltage of the battery 101 to the fan controller 132 (so that the fan controller 132 may determine the temperature of the battery 101 based on the received data Sv and may control driving/not driving and a rotating speed of the fan 131), the present embodiment is not limited thereto.

eration module 120 continues to generate the electric power may be determined. If it is determined that the electric power generation module 120 continues to generate the electric power, the method may proceed back to operation S103. If it is determined that the electric power generation module 120 is not generating the electric power, the method may end.

[0095] As described above, in the vehicle operating system 1 according to the present embodiment, if the battery 101 is fully charged, electric power supplied to the battery 101 may

be cut off, so that charging may not be further performed. The vehicle operating system 1 may be controlled so that all the

For example, the vehicle operating system may be con?gured

so that the battery controller 103 determines the temperature of the battery 101 based on the voltage of the battery 101 and applies a control signal for controlling the cooler 130 to the

fan controller 132 based on a result of the determination. [0086] FIG. 7 illustrates a ?owchart of a method of control

electric power generated by the electric power generation

module 120 is consumed by the fan 131. Accordingly, a decrease in performance, such as deterioration of the battery

101, may be reduced and/or prevented, and stability of the

battery pack 100 may be improved by cooling the battery 101.

[0096] In addition, the fan controller 132 may estimate the temperature of the battery 101 (based on the voltage of the

ling the vehicle operating system of FIG. 1, according to an

embodiment.

[0087]

Referring to FIG. 7, in operation S101, the main

battery 101), and adjust driving/not driving and a rotating

speed of the fan 131 based on the estimated temperature. Accordingly, the temperature of the battery 1 01 may not need

controller 150 or the BMS 102 may determine whether the

electric power generation module 120 is generating electric power. If the electric power generation module 120 is gener ating electric power, charging of the battery 101 may be started in operation S102. [0088] In operation S103, the battery controller 103 may

detect a charge state of the battery 101 and may measure a

to be separately measured, thereby omitting a con?guration

or element for measuring the temperature of the battery 101.

[0097] FIG. 8 illustrates a block diagram of a vehicle oper

charge amount based on the detected charge state of the

battery 101. In operation S104, whether the measured charge

amount is greater than the reference value may be deter mined. If it is determined that the measured charge amount is equal to or less than the reference value, the method may

proceed back to operation S103. [0089] If it is determined that the measured charge amount is greater than the reference value, the battery controller 103

may transmit a signal regarding the charge state to the fan

ating systemIaccording to an embodiment. In the present embodiment, a difference from the vehicle operating system 1 of FIG. 1 is mainly described. [0098] Referring to FIG. 8, a BMS 202 may transmit data regarding a charge state of a battery 201, e. g., data regarding a voltage of the battery 201, to a main controller 250. [0099] The main controller 250 may transmit a control signal for directing driving/not driving of a fan 231 to a fan controller 232 based on the received data. For example, the

main controller 250 may direct an operation of the fan con troller 232. [0100] The fan controller 232 may drive the fan 231 based on the direction of the main controller 250. The direction of the main controller 250 may include driving/not driving and a

controller 132 in operation S105. For example, the battery

controller 103 may transmit data regarding a charge state of

the battery 101 (e.g., data regarding a voltage of the battery

101) to the fan controller 132. [0090] In operation S106, the fan controller 132 may esti mate that a temperature of the battery 101 is high (based on

rotating speed of the fan 231. Alternatively, the main control ler 250 may receive the data regarding a voltage of the battery

201 or temperature data (based on the data regarding a voltage

the received data regarding a voltage of the battery 101), may

determine that the fan 131 needs to operate, and may start to drive the fan 131.

of the battery 201) from the BMS 202, and the fan controller

232 may determine driving/not driving and the rotating speed

of the fan 231 based on data received from the main controller 250.

[0091] In operation S107, the battery controller 103 may determine whether the battery 101 is fully charged. If it is determined that the battery 101 is not fully charged, the

method may proceed back to operation S103 to repeat the above-described operations. If it is determined that the bat tery 101 is fully charged, the battery controller 103 may turn off the switching device of the protection circuit 104 to end

[0101]

As described above, in the present embodiment, the

BMS 202, the fan controller 232, and the main controller 250 may be related to the data regarding a voltage of the battery 201 and the temperature estimation based on the data regard ing a voltage of the battery 201.

[0102] FIG. 9 illustrates a ?owchart of a method of control

charging of the battery 101 in operation S108. [0092] In operation S109, the battery controller 103 may

transmit a signal regarding a full charge state of the battery 101 to the fan controller 132. For example, the battery con troller 103 may transmit data regarding a voltage of the bat tery 101 to the fan controller 132. [0093] The fan controller 132 may estimate that the battery 101 is fully charged and the temperature of the battery 101 is suf?ciently high based on the received data. Accordingly, in operation S110, the fan controller 132 may increase a rotating

speed of the fan 131 to consume all available electric power

ling the vehicle operating system of FIG. 8, according to an

embodiment.

[0103]

Referring to FIG. 9, in operation S201, the main

controller 250 or the BMS 202 may determine whether the

electric power generation module 220 is generating electric

power. If the electric power generation module 220 is gener

ating electric power, charging of the battery 201 may begin in operation S202.

[0104] In operation S203, the BMS 202 may detect a charge

state of the battery 201 and may measure a charge amount based on the detected charge state of the battery 201. In

generated by the electric power generation module 120.

operation S204, whether the measured charge amount is

US 2013/0249277 A1

Sep. 26, 2013

greater than the reference value may be determined. If it is determined that the measured charge amount is equal to or less than the reference value, the method may proceed back to

the poWer supply robustly maintains a charge and discharge

characteristic and guarantees a long life span even With fre

quent starting. Nonetheless, the charge and discharge charac

teristic of lead batteries may not be su?icient due to deterio

operation S203.

[0105] If it is determined that the measured charge amount is greater than the reference value, the BMS 202 may transmit a signal regarding the charge state to the main controller 250 in operation S205. For example, the BMS 202 may transmit data regarding a charge state of the battery 201, e.g., data regarding a voltage of the battery 201, to the main controller 250. In operation S206, the main controller 250 may transmit a control signal for directing driving/not driving of the fan 23 1

to the fan controller 232 based on the received data. For

ration When used in the ISG system, thereby reducing life

spans of the lead batteries.

[0113] The embodiments provide a vehicle operating sys tem capable of properly charging a battery pack in a con?gu

ration in Which charge current is supplied from an electric poWer generation module of a vehicle to the battery pack.

example, the main controller 250 may direct an operation of the fan controller 232.

[0114] As described above, according to the embodiments, electric poWer generated after a battery pack is fully charged may be e?iciently used, thereby providing a vehicle operating system capable of increasing stability and a life span of the

battery pack.

[0115] For conciseness of the speci?cation, disclosure of conventional electronic con?gurations, control systems, soft

Ware, and other functional aspects of the systems may be omitted. In addition, connections or connection members of lines betWeen components shoWn in the draWings illustrate

functional connections and/or physical or circuit connec tions, and the connections or connection members may be

[0106] In operation S207, the BMS 202 may determine Whether the battery 201 is fully charged. If it is determined that battery 201 is not fully charged, the method may proceed

back to operation S203 to repeat the above-described opera

tions. If it is determined that the battery 101 is fully charged,

the BMS 202 may turn off the sWitching device of the pro tection circuit 204 to end charging of the battery 201 in

operation S209.

[0107] In operation S210, the BMS 202 may transmit a signal regarding a full charge state of the battery 201 to the main controller 250. For example, the BMS 202 may transmit data regarding a voltage of the battery 201 to the main con troller 250. In operation 211, the main controller 250 may

direct an operation of the fan controller 232 based on the received data. [0108] The fan controller 232 may estimate Whether the

represented by replaceable or additional various functional connections, physical connections, or circuit connections in

an actual apparatus.

[0116]

For steps forming the methods according to the

embodiments, if an order is not clearly disclosed or, if there is no disclosure opposed to the clear order, the steps may be

performed in a proper order. The embodiments are not nec

essarily limited to the disclosed order of the steps. The use of all illustrations or illustrative teams (for example, and so

battery 201 is fully charged and Whether the temperature of

the battery 201 is suf?ciently high, based on the received data. Accordingly, in operation S212, the fan controller 232 may

increase a rotating speed of the fan 231 to consume all the

forth, etc.) herein is simply to describe the embodiments in

detail, and the scope of the embodiments is not limited due to the illustrations or illustrative terms unless they are limited by

electric poWer generated by the electric poWer generation

module 220.

claims. In addition, it Will be understood by those of ordinary skill in the art that various modi?cations, combinations, and changes may be formed according to design conditions and

factors Within the scope of the attached claims or the equiva lents.

[0109]

In operation S213, Whether the electric poWer gen

eration module 220 continues to generate the electric poWer may be determined. If it is determined that the electric poWer generation module 220 continues to generate the electric poWer, the method may proceed back to operation S203. If it is determined that the electric poWer generation module 220 is not generating the electric poWer, the method may end.

[0117]

Example embodiments have been disclosed herein,

and although speci?c terms are employed, they are used and are to be interpreted in a generic and descriptive sense only

and not for purpose of limitation. In some instances, as Would be apparent to one of ordinary skill in the art as of the ?ling of

[0110] As described above, in the vehicle operating system 2 according to the present embodiment, if the battery 201 is fully charged, electric poWer supplied to the battery 201 may

be cut off so that charging is not further performed. The vehicle operating system 2 may be controlled so that all the

the present application, features, characteristics, and/or ele

ments described in connection With a particular embodiment may be used singly or in combination With features, charac

electric poWer generated by the electric poWer generation

module 220 is consumed by the fan 231. Accordingly, a decrease in performance, such as deterioration of the battery

201, may be reduced and/or prevented, and stability of the

battery pack 200 may be improved by cooling the battery 201.

[0111] In addition, the fan controller 232 may estimate the temperature of the battery 201 (based on the voltage of the battery 201), and may adjust driving/not driving and a rotat ing speed of the fan 231 based on the estimated temperature. Accordingly, the temperature of the battery 201 may not need

teristics, and/or elements described in connection With other embodiments unless otherWise speci?cally indicated. Accordingly, it Will be understood by those of skill in the art that various changes in form and details may be made Without departing from the spirit and scope of the present invention as set forth in the folloWing claims. What is claimed is:

1. A vehicle operating system, comprising:

an electric poWer generation module that is con?gured to generate electric poWer;

a battery, the battery being chargeable by using the electric poWer generated by the electric poWer generation mod

to be separately measured, thereby omitting a con?guration

or separate element for measuring the temperature of the

ule;

a battery management system that controls the chargeable

battery 201.

[0112] By Way of summation and revieW, a desirable char acteristic of a poWer supply supporting an ISG Would be that

battery; and

a cooler that is con?gured to cool the battery, Wherein:

US 2013/0249277 Al

Sep. 26, 2013

the battery management system is con?gured to cut off the electric power supplied to the battery When the

battery is fully charged, and

When the battery management system cuts off the elec tric power supplied to the battery, the cooler is con ?gured to consume the electric poWer generated by the electric poWer generation module. 2. The vehicle operating system as claimed in claim 1,

further comprising a main controller that receives data related to a charge state of the battery from the battery management

system and that controls the cooler based on the received data. 3. The vehicle operating system as claimed in claim 2, Wherein, When the main controller receives data indicating a

12. The vehicle operating system as claimed in claim 11, Wherein: the cooler includes: a fan that cools the battery, and a fan controller that controls driving of the fan, and

the fan controller is con?gured to adjust a rotating speed of

the fan based on the data.

full charge state from the battery management system, the

main controller is con?gured to generate a control signal for controlling the cooler based on the received data. 4. The vehicle operating system as claimed in claim 3, Wherein: the cooler includes: a fan that cools the battery, and a fan controller that controls driving of the fan, and the fan controller is con?gured to adjust a rotating speed of the fan based on the control signal. 5. The vehicle operating system as claimed in claim 4, Wherein the fan controller is con?gured to rotate the fan to consume all the electric poWer generated by the electric

13. The vehicle operating system as claimed in claim 12, Wherein the fan controller is con?gured to rotate the fan to consume all the electric poWer generated by the electric poWer generation module When the fan controller receives data indicating a full charge state from the battery manage ment system. 14. The vehicle operating system as claimed in claim 11, Wherein driving of the cooler begins When the charge state is

greater than a reference value.

15. The vehicle operating system as claimed in claim 14, Wherein charging the battery and driving the cooler are simul

taneously performed by using the electric poWer generated by

the electric poWer generation module, When the charge state of the battery is greater than the reference value and the

battery is not yet fully charged.

16. The vehicle operating system as claimed in claim 11, Wherein the data indicating the charge state of the battery is data indicating a voltage of the battery. 17. The vehicle operating system as claimed in claim 16,

Wherein the cooler is con?gured to estimate a temperature of

poWer generation module.

6. The vehicle operating system as claimed in claim 2, Wherein the main controller receives data related to the charge

the battery from the data indicating the voltage of the battery

and is con?gured to control the cooler based on the estimated

state of the battery from the battery management system and is con?gured to generate a control signal for starting driving

of the cooler When the charge state is greater than a reference value. 7. The vehicle operating system as claimed in claim 6, Wherein: the cooler includes: a fan that cools the battery, and a fan controller that controls driving of the fan, and

temperature.

18.A method of controlling a vehicle operating system, the

method comprising: charging a battery by using electric poWer generated by an electric poWer generation module;

determining a charge state of the battery;

determining Whether the battery is fully charged;

cutting off the electric poWer supplied to the battery When

the fan controller is con?gured to adjust a rotating speed of

the fan based on the control signal. 8. The vehicle operating system as claimed in claim 6,

the battery is fully charged; and

consuming at least some of the electric poWer generated by the electric poWer generation module via a cooler that

Wherein charging the battery and driving the cooler are simul

cools the battery.

19. The method as claimed in claim 18, Wherein, When the

taneously performed by using the electric poWer generated by

the electric poWer generation module, When the charge state of the battery is greater than the reference value and the

battery is not yet fully charged.

9. The vehicle operating system as claimed in claim 2, Wherein the data related to the charge state of the battery is

battery is fully charged, the cooler consumes all the electric poWer generated by the electric poWer generation module.

20. The method as claimed in claim 18, Wherein:

data indicating a voltage of the battery.

10. The vehicle operating system as claimed in claim 9, Wherein the main controller estimates a temperature of the

determining the charge state of the battery includes mea suring a voltage of the battery, and When the charge state of the battery is greater than the

reference value, a controller allocates an amount of elec

battery from the data indicating the voltage of the battery and

controls the cooler based on the estimated temperature.

11. The vehicle operating system as claimed in claim 1,

Wherein the battery management system directly transmits

data indicating a charge state of the battery to the cooler.

tric poWer used to charge the battery and another amount of electric poWer used by the cooler from among the electric poWer generated by the electric poWer genera tion module based on the voltage of the battery.

* * * * *

S-ar putea să vă placă și

- Modeling of Photovoltaic Systems Using MATLAB: Simplified Green CodesDe la EverandModeling of Photovoltaic Systems Using MATLAB: Simplified Green CodesÎncă nu există evaluări

- Starter GeneratorDocument15 paginiStarter GeneratorchodekiranÎncă nu există evaluări

- United States Patent: ShkondinDocument16 paginiUnited States Patent: ShkondinAngel DiosdadoÎncă nu există evaluări

- Us 20130292944Document11 paginiUs 20130292944Victor Von DoomÎncă nu există evaluări

- Steam Turbine Governor Design Based On Pole Placement TechniqueDocument5 paginiSteam Turbine Governor Design Based On Pole Placement TechniqueHanifCornflakezÎncă nu există evaluări

- Patent Application Publication (10) Pub. No.: US 2010/0288571 A1Document29 paginiPatent Application Publication (10) Pub. No.: US 2010/0288571 A1KrozeÎncă nu există evaluări

- Kinetic Energy Recovery SystemDocument13 paginiKinetic Energy Recovery SystemJainul PatelÎncă nu există evaluări

- PV Battery Wind-Turbine Public-Grid Hybrid Poker Supply For Telecom. - Equipment System Management ControlDocument9 paginiPV Battery Wind-Turbine Public-Grid Hybrid Poker Supply For Telecom. - Equipment System Management ControlJubari FikriÎncă nu există evaluări

- United States Patent: Hamdan Et A) - (10) Patent N0.: (45) Date of PatentDocument11 paginiUnited States Patent: Hamdan Et A) - (10) Patent N0.: (45) Date of PatentAnggara T NugrahaÎncă nu există evaluări

- SCR 50kW Fast ChargerDocument6 paginiSCR 50kW Fast ChargerDeepak GehlotÎncă nu există evaluări

- EP3633754A1Document17 paginiEP3633754A1laoshiLANDLÎncă nu există evaluări

- Wind Generation System For Charging BatteriesDocument6 paginiWind Generation System For Charging BatteriesAmit RanjanÎncă nu există evaluări

- Wind Speed and Rotor Position Sensorless Control For Direct-Drive PMG Wind TurbinesDocument9 paginiWind Speed and Rotor Position Sensorless Control For Direct-Drive PMG Wind TurbinesRaj KumarÎncă nu există evaluări

- A Managment Strategy For Solar Panel-Battery-Super Capacitor Hybrid Energy System in Solar CarDocument6 paginiA Managment Strategy For Solar Panel-Battery-Super Capacitor Hybrid Energy System in Solar CarMarcelo Millapan100% (1)

- New Control Strategies of A Small Size Wind Generation System For Battery ChargingDocument6 paginiNew Control Strategies of A Small Size Wind Generation System For Battery ChargingZellagui EnergyÎncă nu există evaluări

- Electric Power Systems Research: Yutaka Ota, Haruhito Taniguchi, Jumpei Baba, Akihiko YokoyamaDocument7 paginiElectric Power Systems Research: Yutaka Ota, Haruhito Taniguchi, Jumpei Baba, Akihiko YokoyamaMichael Zontche BernardÎncă nu există evaluări

- Constant Voltage Control On DC Bus of PV System With Flywheel Energy Storage Source PDFDocument6 paginiConstant Voltage Control On DC Bus of PV System With Flywheel Energy Storage Source PDFjcvmanalelÎncă nu există evaluări

- ! A Simple Maximum Power Point Tracking Based Control Strategy Applied To ADocument18 pagini! A Simple Maximum Power Point Tracking Based Control Strategy Applied To ABorislav BrnjadaÎncă nu există evaluări

- Dynamic Modeling of Variable Speed Centrifugal Pump Utilizing MATLAB / SIMULINKDocument7 paginiDynamic Modeling of Variable Speed Centrifugal Pump Utilizing MATLAB / SIMULINKInternational Journal of Science and Engineering InvestigationsÎncă nu există evaluări

- 02-An Intelligent Maximum Power Extraction Algorithm For Inverter-Based Variable Speed Wind Turbine SystemsDocument8 pagini02-An Intelligent Maximum Power Extraction Algorithm For Inverter-Based Variable Speed Wind Turbine Systemsömer Haşim YörükÎncă nu există evaluări

- United States: (12) Patent Application Publication (10) Pub. No.: US 2013/0313948 A1Document28 paginiUnited States: (12) Patent Application Publication (10) Pub. No.: US 2013/0313948 A1salvor00Încă nu există evaluări

- Dvanced Ngineering: Abstract: This Paper Deals With The Design of Kinetic Energy Recovery Systems (KERS) byDocument12 paginiDvanced Ngineering: Abstract: This Paper Deals With The Design of Kinetic Energy Recovery Systems (KERS) bypaulsonp_2Încă nu există evaluări

- Ieee2008 2Document14 paginiIeee2008 2pnlinh28Încă nu există evaluări

- Device For Attaching An Electric Battery To The Chassis of A Motor VehicleDocument14 paginiDevice For Attaching An Electric Battery To The Chassis of A Motor VehicleTUNCAY GUMUSÎncă nu există evaluări

- Jurnal Mesin ListrikDocument5 paginiJurnal Mesin ListrikRonald RandyÎncă nu există evaluări

- The More Electric AircraftDocument7 paginiThe More Electric AircraftSivanagaraju GangavarapuÎncă nu există evaluări

- Module 13.5 ShahzadDocument57 paginiModule 13.5 ShahzadSKÎncă nu există evaluări

- Pinaki Mitra Ganesh K. Venayagamoorthy: Intelligent Coordinated Control of A Wind Farm and Distributed SmartparksDocument8 paginiPinaki Mitra Ganesh K. Venayagamoorthy: Intelligent Coordinated Control of A Wind Farm and Distributed SmartparksscribsunilÎncă nu există evaluări

- US20130076078A1Document8 paginiUS20130076078A1Andres TorresÎncă nu există evaluări

- Tai Lieuj Do An 4Document10 paginiTai Lieuj Do An 4HùngÎncă nu există evaluări

- Regenerative Braking of Series-Wound Brushed DC Electric Motors For Electric VehiclesDocument6 paginiRegenerative Braking of Series-Wound Brushed DC Electric Motors For Electric Vehiclesbeastlt12Încă nu există evaluări

- 9 FCFD 509891 Ea 2 C 89 FDocument5 pagini9 FCFD 509891 Ea 2 C 89 FshaheerdurraniÎncă nu există evaluări

- Multiple Model Predictive Control For WindDocument10 paginiMultiple Model Predictive Control For WindrsowmiyaÎncă nu există evaluări

- US20050183901A1Document7 paginiUS20050183901A1raaspoy2007Încă nu există evaluări

- Overview of Different Wind Generator Systems and Their ComparisonsDocument16 paginiOverview of Different Wind Generator Systems and Their ComparisonsAnonymous zfmlsb2GjAÎncă nu există evaluări

- Battery Voltage Stability Effects On Small Wind Turbine Energy CaptureDocument12 paginiBattery Voltage Stability Effects On Small Wind Turbine Energy Captureashishkumar14Încă nu există evaluări

- Chapter 3 - APU, Ext Power & RATDocument53 paginiChapter 3 - APU, Ext Power & RATHafeez Yusuf100% (1)

- AGN 002 - Customer TrainingDocument7 paginiAGN 002 - Customer TrainingariwibowoÎncă nu există evaluări

- Power and Battery Plant CoordinationDocument6 paginiPower and Battery Plant Coordinationdeepthik27Încă nu există evaluări

- Power Management of An Isolated Hybrid AC/DC Micro-Grid With Fuzzy Control of Battery BanksDocument10 paginiPower Management of An Isolated Hybrid AC/DC Micro-Grid With Fuzzy Control of Battery BanksShivaLalÎncă nu există evaluări

- Conference FinalDocument25 paginiConference FinalDr.Gopinath ChidambaramÎncă nu există evaluări

- Aerospace Flywheel DevelopmentDocument4 paginiAerospace Flywheel DevelopmentSuyambu LingamÎncă nu există evaluări

- HannettCombustion Turbine Dynamic Model Validation From TestsGas TurbineDocument7 paginiHannettCombustion Turbine Dynamic Model Validation From TestsGas TurbineWalter Ruiz PorrasÎncă nu există evaluări

- ADVISOR-Based Model of A Battery and An Ultra-Capacitor Energy Source For Hybrid Electric VehiclesDocument7 paginiADVISOR-Based Model of A Battery and An Ultra-Capacitor Energy Source For Hybrid Electric VehiclesKarthik KumarÎncă nu există evaluări

- United States: (12) Patent Application Publication (10) Pub. No.: US 2013/0180199 A1Document16 paginiUnited States: (12) Patent Application Publication (10) Pub. No.: US 2013/0180199 A1lsd15251525Încă nu există evaluări

- Cjee 2023 0020Document12 paginiCjee 2023 0020Dr O H GuptaÎncă nu există evaluări

- Seminar Presentation BLDCDocument27 paginiSeminar Presentation BLDCJustin Jennings100% (1)

- Control and Operation of A Vertical Axis Wind Turbine: SCADA Systems For Wind FarmsDocument7 paginiControl and Operation of A Vertical Axis Wind Turbine: SCADA Systems For Wind FarmsSalem SobhyÎncă nu există evaluări

- Hybrid Excavator Power System Controller Design Based On Fuzzy ControlDocument10 paginiHybrid Excavator Power System Controller Design Based On Fuzzy ControlKhalied HafeezÎncă nu există evaluări

- Ulllted States Patent (10) Patent N0.: US 8,159,079 B2Document9 paginiUlllted States Patent (10) Patent N0.: US 8,159,079 B2Victor Von DoomÎncă nu există evaluări

- Actuation SystemDocument11 paginiActuation SystemNavendu GuptaÎncă nu există evaluări

- Doubly-Fed Wind Turbine Mathematical Model and Simulation: 2014 International Symposium On Computer, Consumer and ControlDocument3 paginiDoubly-Fed Wind Turbine Mathematical Model and Simulation: 2014 International Symposium On Computer, Consumer and ControlSandeepKumarÎncă nu există evaluări

- Design of A Solar Power Management System For An Experimental UavDocument11 paginiDesign of A Solar Power Management System For An Experimental UavArulmani MurugesanÎncă nu există evaluări

- Batteries and FlywheelsDocument21 paginiBatteries and FlywheelssturrockÎncă nu există evaluări

- Flywheel Electric GeneratorDocument16 paginiFlywheel Electric GeneratoravalosheÎncă nu există evaluări

- Shymgen System - Optimizing The Performance of Shaft Generator and Drive Train On Fishing VesselsDocument6 paginiShymgen System - Optimizing The Performance of Shaft Generator and Drive Train On Fishing VesselsADRIANSF1Încă nu există evaluări

- KEYWORD: - Solar Charging Station, DC Voltage Regulation, ChopperDocument6 paginiKEYWORD: - Solar Charging Station, DC Voltage Regulation, Choppermd amirÎncă nu există evaluări

- Engine Starting TV2-117 TurboshaftDocument6 paginiEngine Starting TV2-117 Turboshafttmt IngÎncă nu există evaluări

- EP06025874NWA1Document19 paginiEP06025874NWA1raaspoy2007Încă nu există evaluări

- PSR s670 enDocument108 paginiPSR s670 endavid19775891100% (1)

- InstallationGuide en Yamaha Expansion Manager en Ig v240 E0Document5 paginiInstallationGuide en Yamaha Expansion Manager en Ig v240 E0Jose MartosÎncă nu există evaluări

- LG Aircondiotioner Catalog2015Document20 paginiLG Aircondiotioner Catalog2015david19775891Încă nu există evaluări

- Yamaha Expansion Manager en Om v230 f0Document25 paginiYamaha Expansion Manager en Om v230 f0david19775891Încă nu există evaluări

- Gamer! Lee Miller: Dec. 26, 1944. - H - Null-Er Des. 139,861 'Document2 paginiGamer! Lee Miller: Dec. 26, 1944. - H - Null-Er Des. 139,861 'david19775891Încă nu există evaluări

- Us 20130019216Document62 paginiUs 20130019216david19775891Încă nu există evaluări

- PH.D Engg OrdinancesDocument13 paginiPH.D Engg Ordinancesdavid19775891Încă nu există evaluări

- Us 20130218893Document16 paginiUs 20130218893david19775891Încă nu există evaluări

- Che-Torah Tape/10W) Po-Feng 33333333? 3% 13/5882 5152??Document16 paginiChe-Torah Tape/10W) Po-Feng 33333333? 3% 13/5882 5152??david19775891Încă nu există evaluări

- Us 8332143Document12 paginiUs 8332143david19775891Încă nu există evaluări

- Us 20130159882Document35 paginiUs 20130159882david19775891Încă nu există evaluări

- United States Patent: Muras Et Al. (10) Patent N0.: (45) Date of PatentDocument11 paginiUnited States Patent: Muras Et Al. (10) Patent N0.: (45) Date of Patentdavid19775891Încă nu există evaluări

- United States Patent: Shah-HosseiniDocument28 paginiUnited States Patent: Shah-Hosseinidavid19775891Încă nu există evaluări

- Us 8601537Document45 paginiUs 8601537david19775891Încă nu există evaluări

- United States: (12) Patent Application Publication (10) Pub. No.: US 2013/0013586 A1Document13 paginiUnited States: (12) Patent Application Publication (10) Pub. No.: US 2013/0013586 A1david19775891Încă nu există evaluări

- 305 / Create Statistical Data: Test/Refine ModelDocument32 pagini305 / Create Statistical Data: Test/Refine Modeldavid19775891Încă nu există evaluări

- Us 20120245970Document67 paginiUs 20120245970david19775891Încă nu există evaluări

- United States: (12) Patent Application Publication (10) Pub. No.: US 2013/0311283 A1Document28 paginiUnited States: (12) Patent Application Publication (10) Pub. No.: US 2013/0311283 A1david19775891Încă nu există evaluări

- United States Patent: (12) (10) Patent N0.: US 8,250,105 B2 Bollinger Et Al. (45) Date of Patent: Aug. 21, 2012Document41 paginiUnited States Patent: (12) (10) Patent N0.: US 8,250,105 B2 Bollinger Et Al. (45) Date of Patent: Aug. 21, 2012david19775891Încă nu există evaluări

- Us 8356047Document14 paginiUs 8356047david19775891Încă nu există evaluări

- United States Patent: Prahlad Et A1. (10) Patent N0.: (45) Date of PatentDocument34 paginiUnited States Patent: Prahlad Et A1. (10) Patent N0.: (45) Date of Patentdavid19775891Încă nu există evaluări

- Us 20130124440Document30 paginiUs 20130124440david19775891Încă nu există evaluări

- Us 8306997Document15 paginiUs 8306997david19775891Încă nu există evaluări

- European Patent Application: Method and Computer Program For Statistical and Data-Mining Processing of Large Data SetsDocument16 paginiEuropean Patent Application: Method and Computer Program For Statistical and Data-Mining Processing of Large Data Setsdavid19775891Încă nu există evaluări

- Ulllted States Patent (10) Patent N0.: US 8,315,981 B2Document34 paginiUlllted States Patent (10) Patent N0.: US 8,315,981 B2david19775891Încă nu există evaluări

- Us 20130182895Document39 paginiUs 20130182895david19775891Încă nu există evaluări

- United States: (12) Patent Application Publication (10) Pub. No.: US 2013/0318015 A1Document26 paginiUnited States: (12) Patent Application Publication (10) Pub. No.: US 2013/0318015 A1david19775891Încă nu există evaluări

- Us 8280899Document14 paginiUs 8280899david19775891Încă nu există evaluări

- Us 20130198093Document25 paginiUs 20130198093david19775891Încă nu există evaluări

- IND056 X 02Document1 paginăIND056 X 02david19775891Încă nu există evaluări

- SmarishDocument18 paginiSmarishShivaprasad SVÎncă nu există evaluări

- ME Con-1 Mock-1Document15 paginiME Con-1 Mock-1vidya chakitwarÎncă nu există evaluări

- Smart Gloves Based Gesture VocalizerDocument3 paginiSmart Gloves Based Gesture VocalizerKarthik DmÎncă nu există evaluări

- Bosch Lambda Sensor LSU 1 & 4.9Document10 paginiBosch Lambda Sensor LSU 1 & 4.9Al CaracasÎncă nu există evaluări

- Modern Recording DEC/JAN 1976 Vol. 1 No. 2Document76 paginiModern Recording DEC/JAN 1976 Vol. 1 No. 2harleyrider777100% (1)

- Gas Engine Site Specific Technical DataDocument4 paginiGas Engine Site Specific Technical Datavlcmstne04Încă nu există evaluări

- Elvis Presley y El FBI. Documentos Desclasificados.Document25 paginiElvis Presley y El FBI. Documentos Desclasificados.Diario 26Încă nu există evaluări

- Abb Relays Catalouge PDFDocument180 paginiAbb Relays Catalouge PDFABDUL GHAFOORÎncă nu există evaluări

- Portable Document Format Reference Manual - Version 1.1Document298 paginiPortable Document Format Reference Manual - Version 1.1Akihito Hashimoto100% (1)

- Lptop Toshiba Schematic l100Document27 paginiLptop Toshiba Schematic l100Swati BaslaÎncă nu există evaluări

- CIDX Project Charter RFID 2007-01-18Document3 paginiCIDX Project Charter RFID 2007-01-18api-3731318Încă nu există evaluări

- VHF and UHF Narrowbanding - Your Complete Guide To Meet The DeadlineDocument109 paginiVHF and UHF Narrowbanding - Your Complete Guide To Meet The DeadlineTopcom Toki-VokiÎncă nu există evaluări

- Factors Affecting Four Wheeler Industries in IndiaDocument54 paginiFactors Affecting Four Wheeler Industries in IndiaRitesh Vaishnav100% (2)

- Precision Estimates For AASHTO TestDocument139 paginiPrecision Estimates For AASHTO TestFred Jumbas Jr.Încă nu există evaluări

- IDBI/VMG/RFQ/2019-20/052: Page 1 of 3Document3 paginiIDBI/VMG/RFQ/2019-20/052: Page 1 of 3Tender 247Încă nu există evaluări

- 120 2013 Final StudyGuide 1Document5 pagini120 2013 Final StudyGuide 1Anonymous zN7CjfgnEÎncă nu există evaluări

- 06 Earth - Quake - Tips PDFDocument55 pagini06 Earth - Quake - Tips PDFMaheshbabu CheetakoruÎncă nu există evaluări

- University of Hyderabad Post Graduate Diploma in Business Management (PGDBM) I Term Assignment (2016) Dbm-416: Quantitative and Research MethodsDocument4 paginiUniversity of Hyderabad Post Graduate Diploma in Business Management (PGDBM) I Term Assignment (2016) Dbm-416: Quantitative and Research Methodsrao_nari8305Încă nu există evaluări

- ANSI-ASME B16.5 Blind Flange 150lbDocument1 paginăANSI-ASME B16.5 Blind Flange 150lbVishal MistryÎncă nu există evaluări

- 09slide 4Document29 pagini09slide 4Muhanad Al-khalisyÎncă nu există evaluări

- (Accelerated Learning) PhotoReading Tips 6Document11 pagini(Accelerated Learning) PhotoReading Tips 6chlsc100% (1)

- STIHL TS410, TS420 Spare PartsDocument11 paginiSTIHL TS410, TS420 Spare PartsMarinko PetrovićÎncă nu există evaluări

- School of Maritime Studies Vels University Thalambur: Fire Nozzle AimDocument2 paginiSchool of Maritime Studies Vels University Thalambur: Fire Nozzle AimAayush AgrawalÎncă nu există evaluări

- CH 07Document24 paginiCH 07Manan ChandaranaÎncă nu există evaluări

- As 60947.4.1-2004 Low-Voltage Switchgear and Controlgear Contactors and Motor-Starters - Electromechanical CoDocument12 paginiAs 60947.4.1-2004 Low-Voltage Switchgear and Controlgear Contactors and Motor-Starters - Electromechanical CoSAI Global - APACÎncă nu există evaluări

- Lecture04 MOS Small Sig 6upDocument6 paginiLecture04 MOS Small Sig 6upjs9999Încă nu există evaluări

- Porsche 918 Spyder DrivetrainDocument13 paginiPorsche 918 Spyder DrivetrainclevercogÎncă nu există evaluări

- ASSIGNMENT Operating SystemDocument15 paginiASSIGNMENT Operating SystemkaranÎncă nu există evaluări

- Some Observations and Experience With Pile Integrity Testing at Various Projects For EssarDocument5 paginiSome Observations and Experience With Pile Integrity Testing at Various Projects For EssarKausik DewanÎncă nu există evaluări

- Romi DM 03 Persiapan Mar2016Document82 paginiRomi DM 03 Persiapan Mar2016Tri Indah SariÎncă nu există evaluări