Documente Academic

Documente Profesional

Documente Cultură

45 Dynamic

Încărcat de

Tejaswi J DamerlaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

45 Dynamic

Încărcat de

Tejaswi J DamerlaDrepturi de autor:

Formate disponibile

ISSN (Print) : 2320 3765 ISSN (Online): 2278 8875

International Journal of Advanced Research in Electrical, Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 2, Issue 8, August 2013

DYNAMIC D-Q AXIS MODELING OF THREE-PHASE ASYNCHRONOUS MACHINE USING MATLAB

Shakuntla Boora1, S.K Agarwal2, K.S Sandhu3

Assistant professor, Dept. of EE, YMCAUST, Faridabad, India1 Professor and Head, Dept. of EE, YMCAUST, Faridabad, India2 Professor and Head, Dept. of EE, National Institute of Technology, Kurukshetra, India3 ABSTRACT: This paper presents a dynamic d-q axis model of three- phase asynchronous motor in synchronously rotating frame. The systems of differential equations representing the dynamic state behaviours of the machine as developed are implemented in MATLAB/SIMULINK. The effects of the stepped sequence of mechanical loading on the motor output variables namely: three-phase stator currents (ia, ib and ic), electromechanical torque and rotor speed, d-q stator and rotor currents (iqs, ids, iqr and idr), d-q voltages (vqs and vds) are examined. The results obtained clearly show the elegance of the d-q axis transformation theory in machine modelling and the inherent limitations of the directon-line starting of 3-hp and 2250-hp asynchronous motors. Keywords: dynamic modelling, asynchronous machine, synchronous reference frame, MATLAB/SIMULINK . I.INTRODUCTION The use of asynchronous motors particularly squirrel-cage rotor has increased tremendously since the day of its invention. They are being used as actuators in various industrial processes, robotics, house appliances (generally singlephase) and other similar applications. The reason for its day by day increasing popularity can be primarily attributed to its robust construction, simplicity in design and cost effectiveness, reliability, high efficiency and good self-starting capability [1-4]. The analysis of asynchronous motor is carried out in steady state whereby the machine is modelled as a second order electromechanical system. Dynamic model describes the transient as well as the steady state behavior of the asynchronous machine. The model can be used to simulate the asynchronous motor drives and evaluate their transient performances including that of using the scalar control technique. This model is also essential when developing high performance control techniques for the aynchronous motor drives such as vector control or direct control (DTC) drives. During start-up and other severe motoring operations, the asynchronous motor draws large currents, produce voltage dips, oscillatory torques and can even generate harmonics in the power system [5]. It is therefore important to be able to model the asynchronous machine in order to predict these phenomena. Various models have been developed and the qd axis model for the study of transient behaviour has been well tested and proven to be reliable and accurate [5, 6]. It has been shown that the speed of rotation of the d-q axis can be arbitrary although there are three preferred speeds or reference frames as follows [5]: (a) The stationary reference frame when the d-q axes do not rotate. (b) The rotor reference frame when the d-q axes rotate at rotor speed. (c) The synchronously rotating reference frame when the d-q axes rotate at synchronous speed. It is preferable to study multimachine system and stability analysis of controller design where the motor output equations must be linerized about an operating point in synchronously rotating frame [7]. In this frame, the steady state variables are constant and do not vary sinusoidally with time. In this paper, asynchronous machine model is described in the synchronously rotating frame [8] and also the effects of the stepped sequence of mechanical loading on the motor output variables are observed.

Copyright to IJAREEIE

www.ijareeie.com

3942

ISSN (Print) : 2320 3765 ISSN (Online): 2278 8875

International Journal of Advanced Research in Electrical, Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 2, Issue 8, August 2013

II. ASYNCHRONOUS MACHINE MODEL The asynchronous machine d-q or dynamic equivalent circuit is shown in fig. 1. The modelling equations in flux linkage form may be rearranged into the following form

(b) Fig.1 Dynamic d - q equivalent circuits of machine (a) qe-axes, (b) de axes circuit

dFqs dt dFds dt dFqr dt dFdr dt

e e

= b vqs = b vds = b = b

e b e b

Fds Fqs Fdr + Fqr +

Rs X ls Rs X ls Rr X lr Rr X lr

Fqs Fmq Fds Fmd Fqr Fmq Fdr Fmd

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10) (11) (12)

e r b e r b F qs x ls F ds x ls

Fmq = Xml Fmd = Xml

+ +

F qr x lr F dr x lr

= = = = Te =

1 X ls 1 X lr 1 X ls 1 X lr 3 p 2 2

Fqs Fmq Fqr Fmq Fds Fmd Fdr Fmd

1 b 2 P

Fds iqs Fqs ids

dw r dt

Te TL = J

Copyright to IJAREEIE

www.ijareeie.com

3943

ISSN (Print) : 2320 3765 ISSN (Online): 2278 8875

International Journal of Advanced Research in Electrical, Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 2, Issue 8, August 2013

For a squirrel cage asynchronous machine vqr and vdr in (3) and (4) are set to zero. An asynchronous machine model can be represented with five differential equations. To solve these equations, they have to be rearranged in the state space form. The state space form can be achieved by inserting (5) and (6) in (1-4) and collecting the similar terms together so that each state derivative is a function of only other state variables and motor inputs. Then, the equations (1-4 and 12) of a squirrel-cage asynchronous motor in state-space become

dFqs dt dFds dt dFqr dt dFdr dt dw r dt

= b vqs = b vds + = b = b =

P 2 J

e b e b

Fds + Fqs +

Rs X ls Rs X ls Rr X lr

x ml x lr x ml x lr

Fqr + Fdr + Fqs +

x ml x ls x ml x ls

1 Fqs 1 Fds 1 Fqr

(13) (14) (15) (16) (17)

w e w r b

Fdr +

Rr X lr

x ml x ls

x ml x lr

w e w r b

Fqr +

x ml x ls

Fds +

x ml x lr

1 Fdr

Te TL

III. SIMULINK IMPLEMENTATION The inputs of a squirrel cage asynchronous machine are the three-phase voltages, their fundamental frequency and the load torque. On the other hand the outputs are the three-phase currents, the electrical torque and the rotor speed. The Asynchronous machine model consists of five major blocks: A. O-n conversion block

2 1 3 2 3 1 3 1 3 1 3 2 3

van vbn = vcn

3 1 3 1 3

vao vbo vco

(18)

B. Unit vector calculation block e = we dt (19)

C. Abc-syn conversion block van s 1 0 0 vqs v 1 1 = 0 bn s vds 3 3 vcn vqs vds

s s = vqs cose vds sine s s = vqs sine + vds cose

(20)

(21)

D. Asynchronous Machine q-d model block Equations (5-10) and equations (13-17) E. Syn-abc conversion block is qs s ids = vqs cose + vds sine = vqs sine + vds cose 1

1 2 1 2

(22)

ia ib = ic

0

3 2 3

is qs is ds

(23)

Copyright to IJAREEIE

www.ijareeie.com

3944

ISSN (Print) : 2320 3765 ISSN (Online): 2278 8875

International Journal of Advanced Research in Electrical, Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 2, Issue 8, August 2013

Fig. 2 The complete asynchronous machine simulink model IV. SIMULATION RESULTS Two asynchronous motors: 3hp and 2250hp were tested in this simulated model [Appendix-I]. The results of the simulation are given for the first asynchronous motor: The 3hp machine is relatively high-slip machine; that is, rated torque is developed at a speed considerably less than synchronous speed [fig.3]. At stall, the input impedance of the asynchronous motor is essentially the stator resistance and leakage reactance in series with the rotor resistance and leakage reactance. Consequently with the rated applied voltage, the starting current is large, in some cases in the order of 10 times the rated value. This is observed in figure 4(a) and figures 8(a) and is a major limitation of the direct-on-line starting of the motor. It is therefore, recommended that reduced voltage starting methods such as star/delta, autotransformer and soft start methods be employed to reduce the excess starting current. It is observed in figure 4(c) that the rotor accelerates from stall with zero mechanical load torque and since friction and windage losses are not taken into account, the machine accelerates to synchronous speed. It can be seen from figure 4, that the machine has reached steady state at about 0.4 second. The application of 11.87 N-m mechanical loads at 0.5 seconds as illustrated in figure 4(b), results in sharp drop in the motor speed i.e. from 377 rad/sec to 361.2 rad/sec of figure 4(c) and an increase in the electromechanical torque upto 11.87 N-m in sympathy with the applied mechanical loading. It is also observed from figure 5 that the stator q-axes voltage (vqs) = 179.6V = Vm (magnitude of supply voltage) and stator d-axis voltage (vds) = 0. It implies that the stator d-q voltages are DC quantities throughout the complete simulation time of 1.5 second. It is observed from figure 6 that the stator currents are DC quantities in the steady state at 0.4sec. The application of 11.87 N-m mechanical loads at 0.5 seconds as illustrated in figure 6, results in slight increase in DC currents. After removal of load at 0.9 sec, the stator d-q currents again appear as DC quantities.

Copyright to IJAREEIE

www.ijareeie.com

3945

ISSN (Print) : 2320 3765 ISSN (Online): 2278 8875

International Journal of Advanced Research in Electrical, Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 2, Issue 8, August 2013

Fig.3 Torque-speed characteristics during free acceleration: 3-hp Asynchronous motor

Fig. 4 Simulated results for (a) Stator currents (b) electromagnetic torque and (c) rotor speed when TL is stepped from TL=0 to TL=11.87N-m and then stepped down from T L=11.87N-m to TL=0.

Copyright to IJAREEIE

www.ijareeie.com

3946

ISSN (Print) : 2320 3765 ISSN (Online): 2278 8875

International Journal of Advanced Research in Electrical, Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 2, Issue 8, August 2013

Fig.5 Simulated results for stator d-q voltages when TL is stepped from TL=0 to TL=11.87N-m and then stepped down from TL=11.87N-m to TL=0.

Fig.6 Simulated results for d-q stator and rotor currents when TL is stepped from TL=0 to TL=11.87N-m and then stepped down from TL=11.87N-m to TL=0. The results of simulation are also given for the other asynchronous motor: The 2250- hp machine is low slip machine; that is, rated torque is developed at synchronous speed as shown in figure 7. It is observed in figure 8(c) that the rotor accelerates from stall with zero mechanical load torque and since friction and windage losses are not taken into account, the machine accelerates to synchronous speed. It can be seen from figure 8, that the machine has reached steady state at about 2.8 second. The application of 8900 N-m mechanical load at 3

Copyright to IJAREEIE www.ijareeie.com 3947

ISSN (Print) : 2320 3765 ISSN (Online): 2278 8875

International Journal of Advanced Research in Electrical, Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 2, Issue 8, August 2013

seconds as illustrated in figure 8(b), results in the same motor speed as synchronous speed of figure 8(c) and an increase in the electromechanical torque in sympathy with the applied mechanical loading. It is also observed from figure 9 that the stator q-axes voltage (vqs) = 1877.7V = Vm (magnitude of supply voltage) and stator d-axes voltage (vds) = 0. It implies that the stator q-d voltages are DC quantities. It is observed from figure 10 that the stator currents are DC quantities in the steady state at 2.9 sec. The application of 8900 N-m mechanical loads at 3 seconds as illustrated in figure 8, results in very slight increase in currents. After removal of load at 4sec, the stator q-d currents again appear as DC quantities.

Fig.7 Torque-speed characteristics during free acceleration: 2250-hp Asynchronous motor

Fig.8 Simulated results for (a) Stator currents, (b) electromagnetic torque and (c) rotor speed when TL is stepped from TL=0 to TL=8900N-m and then stepped down from T L=8900vN-m to TL=0.

Copyright to IJAREEIE

www.ijareeie.com

3948

ISSN (Print) : 2320 3765 ISSN (Online): 2278 8875

International Journal of Advanced Research in Electrical, Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 2, Issue 8, August 2013

Fig. 9 Simulated results for d-q voltages when TL is stepped from TL=0 to TL=8900 N-m and then stepped down from TL=8900 N-m to TL=0.

Fig. 10: Simulated results for d-q stator and rotor currents when TL is stepped from TL=0 to TL=8900N-m and then stepped down from TL=8900 N-m to TL=0.

Copyright to IJAREEIE

www.ijareeie.com

3949

ISSN (Print) : 2320 3765 ISSN (Online): 2278 8875

International Journal of Advanced Research in Electrical, Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 2, Issue 8, August 2013

All the simulations are running under the same condition as below: Motor type: 3-hp and 2250-hp squirrel cage asynchronous motor Simulation time: 1.5 seconds and 5 seconds Solver type: ode45 (Demand-Prince) Relative tolerance: 1e-3 V. CONCLUSIONS For the analysis of dynamic behavior of the asynchronous machine, study of reference frames is essential. This paper has demonstrated the elegance of MATLAB/SIMULINK in the dynamic modeling and simulation of a 3-hp and 2250hp asynchronous motor driving a mechanical load. The simulated motor is symmetrical and windage and friction losses are assumed negligible for ease of analysis. The results obtained clearly show the elegance of d-q axis transformation theory in machine modeling, inherent limitations of the direct-on-line starting of asynchronous motors and effect of mechanical loading on various motor output variables. APPENDIX-I

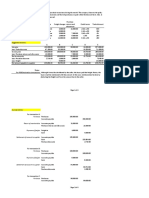

MACHINE-I DATA Rated Power Rated Line to Line Voltage Rated Frequency Number of poles, P Stator Resistance, Rs Stator Leakage Reactance, Xls Rotor Resistance, Rr Rotor Leakage reactance, Xlr Moment of inertia, J Magnetizing reactance, Xm MACHINE- II DATA Rated Power Rated Line to Line Voltage Rated Frequency Number of poles, P Stator Resistance, Rs Stator Leakage Reactance, Xls Rotor Resistance, Rr Rotor Leakage reactance, Xlr Moment of inertia, J Magnetizing reactance, Xm 2250HP 2300V 60Hz 4 0.029 ohm 0.226 ohm 0.022 ohm 0.226 ohm 63.87 Kg-m2 13.04 ohm 3 HP 220V 60Hz 4 0.435 ohm 0.754 ohm 0.816 ohm 0.754 ohm 0.089 Kg-m2 26.13 ohm

NOMENCLATURE

d q s r Fi vqs, vds vqr, vdr Fmd, Fmq Rr Rs Xls Xlr iqs, ids iqr, idr P J Te = Direct axis = Quadrature axis = Stator variable = Rotor variable = Flux linkage (i=q or d & j=s or r) = q and d- axis stator voltage = q and d-axis rotor voltages = q and d-axis magnetizing flux linkages = Rotor resistance = Stator resistance = Stator leakage reactance = Rotor leakage reactance = q and d-axis stator currents = q and d-axis rotor currents = No of pole = Moment of inertia = Electrical output torque

Copyright to IJAREEIE

www.ijareeie.com

3950

ISSN (Print) : 2320 3765 ISSN (Online): 2278 8875

International Journal of Advanced Research in Electrical, Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 2, Issue 8, August 2013

Tl we wb wr = = = = load torque. Stator angular electrical frequency Motor angular electrical base frequency Rotor angular electrical speed

REFERENCES

[1] [2] [3] [4] [5] [6] [7] [8] R. Krishan, Electric motor drives: Modelling, analysis and control, Prentice Hall Company, New Jersey, 2001. K.L. Shi, T.F. Chan, Y. K. Wong and S. L. Ho, Modeling and simulation of the three-phase induction motor using simulink, International Journal of Electrical Engineering Education, vol. 36, pp. 163-172, 1999. M.L. de Aguiar and M.M. Cad, The concept of complex transfer functions applied to the modeling of induction motors, IEEE Power Engineering Society Winter Meeting, vol. 1, pp. 387-391, 2000. P.C. Krause, O. Wasynczuk, S.D. Sudhoff, Analysis of electric machinery and drive systems, IEEE Press, A John Wiley and Sons. Inc. Publication, Second Edition, 2002. P.C. Krause, C.H Thomas, Simulation of symmetrical induction machinery, IEEE Trans. Power Apparatus and Systems, vol. PAS-84, no. 11, pp. 1038-1053, Nov1965. Lee, R.J., Pillay, P., and Harley, R.G., D, Q Reference frame for the simulation of induction motors, Electric Power Systems Research Journal, vol. 8, pp.15-16, October 1984. B.K Bose, Modern power electronics and ac drives, Prentice Hall, 2002. B. Ozpineci, L.M. Tolbert, Simulink implementation of induction machine model- A modular approach, IEEE Int. Conf. Electric Machine and Drives, pp. 728-734, 2003.

BIOGRAPHY

Shakuntla Boora received the B.E degree in Electrical Engineering from MDU Rohtak (Haryana) in 1997 and M.Tech degree in Power Systems from Punjab Engineering College, Chandigarh in 2004. Since 2007, she is the part of YMCA University of Science & Technology as Assistant professor in the Department of Electrical Engineering. She is pursuing Ph.D in the field of Electrical Machines. She has 5 international and national publications in the area of electrical machines and induction generators.

Dr. S.K. Agarwal received the M.Tech Degree from Delhi Technical University, New Delhi and PhD degree in Electronics Engg. From Jamia Millia Islamia, Central University, New Delhi in 1998 and 2008, respectively, since 1990. He has been part of YMCA University of Science & Technology Faridabad (Haryana), as Dean and Chairman in Department of Electronics Engineering.

Dr. Kanwarjit Singh Sandhu was born on December 21, 1957. He received the B.Sc.Eng. (Electrical), M.Sc. (Electrical), and Ph.D. (Electrical Machines) degrees from Regional Engineering College, Kurukshetra University, Kurukshetra, India, in 1981, 1985, and 2001, respectively. He joined the Electrical Engineering Department of Regional Engineering College, Kurukshetra, as a Lecturer in January 1983. Currently, he is Professor in the Electrical Engineering Department, National Institute of Technology, Kurukshetra. He has more than 130 international & national publications in the area of electrical machines & drives/ induction generators/wind energy conversion/ power quality/ artificial intelligence/ power system.

Copyright to IJAREEIE

www.ijareeie.com

3951

S-ar putea să vă placă și

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Short Stories For Children PDFDocument44 paginiShort Stories For Children PDFazhagaan100% (16)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- School Earthquake Preparedness Evaluation FormDocument2 paginiSchool Earthquake Preparedness Evaluation FormAdrin Mejia75% (4)

- Post Market Surveillance SOPDocument8 paginiPost Market Surveillance SOPgopinathÎncă nu există evaluări

- G-00-1169 - Grade Designation For Low Carbon Hot Rolled Steel Sheets Used in Automotive Applications - Rev 4Document7 paginiG-00-1169 - Grade Designation For Low Carbon Hot Rolled Steel Sheets Used in Automotive Applications - Rev 4Prince Ali50% (2)

- Archaeology - October 2016 PDFDocument72 paginiArchaeology - October 2016 PDFOmer CetinkayaÎncă nu există evaluări

- 4 Qi Imbalances and 5 Elements: A New System For Diagnosis and TreatmentDocument5 pagini4 Qi Imbalances and 5 Elements: A New System For Diagnosis and Treatmentpixey55100% (1)

- Historic Trial of Ali Brothers and Shankaracharya-1921Document276 paginiHistoric Trial of Ali Brothers and Shankaracharya-1921Sampath Bulusu100% (3)

- Perfil Clinico de Pacientes Con Trastornos de La Conducta AlimentariaDocument44 paginiPerfil Clinico de Pacientes Con Trastornos de La Conducta AlimentariaFrida PandoÎncă nu există evaluări

- Bhaktthi Mangala Gowri VrathamDocument35 paginiBhaktthi Mangala Gowri VrathamTejaswi J DamerlaÎncă nu există evaluări

- CommonPrayer Text and TranslationDocument4 paginiCommonPrayer Text and TranslationAlla Naveen KumarÎncă nu există evaluări

- Basic Ideas of AstrophysicsDocument2 paginiBasic Ideas of AstrophysicsTejaswi J DamerlaÎncă nu există evaluări

- Vadh363rsquos 256dityopasth257na Mantras Telugu T257tparyamDocument2 paginiVadh363rsquos 256dityopasth257na Mantras Telugu T257tparyamTejaswi J DamerlaÎncă nu există evaluări

- Inner Engineering Retreat at Isha Yoga CenterDocument3 paginiInner Engineering Retreat at Isha Yoga CenterTejaswi J DamerlaÎncă nu există evaluări

- Program Schedule IshaDocument3 paginiProgram Schedule IshaTejaswi J DamerlaÎncă nu există evaluări

- Near-Death-Experiences: Between Spiritual Transmigration and Psychopathological HallucinationsDocument50 paginiNear-Death-Experiences: Between Spiritual Transmigration and Psychopathological HallucinationsTejaswi J DamerlaÎncă nu există evaluări

- AedddaDocument3 paginiAedddaTejaswi J DamerlaÎncă nu există evaluări

- The Inner Engineering Retreat Is A Unique Opportunity To Imbibe The Timeless Science of YogaDocument3 paginiThe Inner Engineering Retreat Is A Unique Opportunity To Imbibe The Timeless Science of YogaTejaswi J DamerlaÎncă nu există evaluări

- Health: Green Coffee Extract CapsulesDocument2 paginiHealth: Green Coffee Extract CapsulesTejaswi J DamerlaÎncă nu există evaluări

- Capsule For Indian Railways Recruitent ExamDocument43 paginiCapsule For Indian Railways Recruitent ExamGitanjali RajputÎncă nu există evaluări

- Sha Foundation Is An InternationalDocument4 paginiSha Foundation Is An InternationalTejaswi J DamerlaÎncă nu există evaluări

- State Bank of India Clerks PDFDocument2 paginiState Bank of India Clerks PDFTejaswi J DamerlaÎncă nu există evaluări

- 3rdtime & Work NewDocument36 pagini3rdtime & Work NewAnurag Baraik100% (1)

- LLMDocument1 paginăLLMTejaswi J DamerlaÎncă nu există evaluări

- Imp TopicsDocument11 paginiImp TopicsRavikumarMechÎncă nu există evaluări

- Toddy 1Document2 paginiToddy 1Tejaswi J DamerlaÎncă nu există evaluări

- LBHDocument1 paginăLBHTejaswi J DamerlaÎncă nu există evaluări

- Allm 2Document2 paginiAllm 2Tejaswi J DamerlaÎncă nu există evaluări

- StepsDocument1 paginăStepsTejaswi J DamerlaÎncă nu există evaluări

- Todd 1Document2 paginiTodd 1Tejaswi J DamerlaÎncă nu există evaluări

- AedddaDocument3 paginiAedddaTejaswi J DamerlaÎncă nu există evaluări

- Bigdata Page 3Document1 paginăBigdata Page 3Tejaswi J DamerlaÎncă nu există evaluări

- HDocument1 paginăHTejaswi J DamerlaÎncă nu există evaluări

- Oshobooks Telugu UDocument2 paginiOshobooks Telugu UTejaswi J DamerlaÎncă nu există evaluări

- Oshobooks TeluguuuDocument3 paginiOshobooks TeluguuuTejaswi J DamerlaÎncă nu există evaluări

- JLMMDocument1 paginăJLMMTejaswi J DamerlaÎncă nu există evaluări

- AllmDocument2 paginiAllmTejaswi J DamerlaÎncă nu există evaluări

- Bigdata PageDocument1 paginăBigdata PageTejaswi J DamerlaÎncă nu există evaluări

- Performace Task 2 Electric Field LinesDocument31 paginiPerformace Task 2 Electric Field LinesStephanie Nichole Ian CasemÎncă nu există evaluări

- Sculpture and ArchitectureDocument9 paginiSculpture and ArchitectureIngrid Dianne Luga BernilÎncă nu există evaluări

- Number SystemsDocument25 paginiNumber SystemsMehwish BilalÎncă nu există evaluări

- Xiaopan OS: DescriptionDocument1 paginăXiaopan OS: DescriptionMan SavliÎncă nu există evaluări

- Theoretical & Conceptual Framework (RESEARCH)Document3 paginiTheoretical & Conceptual Framework (RESEARCH)Rizza Manabat PacheoÎncă nu există evaluări

- Blackrock Methods of Delay AnalysisDocument36 paginiBlackrock Methods of Delay AnalysisAhmed MoubarkÎncă nu există evaluări

- Pengaruh Pemberian Dosis Pupuk Urea Terhadap Pertumbuhan Tanaman Bayam Cabut Putih (AmaranthusDocument10 paginiPengaruh Pemberian Dosis Pupuk Urea Terhadap Pertumbuhan Tanaman Bayam Cabut Putih (AmaranthusMartha YhunickeÎncă nu există evaluări

- 1609 Um009 - en PDocument34 pagini1609 Um009 - en PAnonymous VKBlWeyÎncă nu există evaluări

- Dania - 22 - 12363 - 1-Lecture 2 Coordinate System-Fall 2015Document34 paginiDania - 22 - 12363 - 1-Lecture 2 Coordinate System-Fall 2015erwin100% (1)

- The Effect of Realistic Mathematics Education Approach On Students' Achievement and Attitudes Towards MathematicsDocument9 paginiThe Effect of Realistic Mathematics Education Approach On Students' Achievement and Attitudes Towards MathematicsyusfazilaÎncă nu există evaluări

- Somanabolic+Muscle+Maximizer+PDF+ +eBook+Free+Download+Kyle+LeonDocument34 paginiSomanabolic+Muscle+Maximizer+PDF+ +eBook+Free+Download+Kyle+LeonAaron BarclayÎncă nu există evaluări

- Term Paper - 2022964Document17 paginiTerm Paper - 2022964Md. Ahbab HasanÎncă nu există evaluări

- Jeep TJ Torque SpecsDocument4 paginiJeep TJ Torque SpecsmaulotaurÎncă nu există evaluări

- A Person On A Position of Air Traffic ControllerDocument7 paginiA Person On A Position of Air Traffic ControllerMUHAMMAD RAMZANÎncă nu există evaluări

- IRremote Library, Send & Receive Infrared Remote ControlDocument4 paginiIRremote Library, Send & Receive Infrared Remote ControlJayant SwamiÎncă nu există evaluări

- Pre-Socratic Pluralism AtomismDocument1 paginăPre-Socratic Pluralism AtomismpresjmÎncă nu există evaluări

- Concept MapDocument1 paginăConcept Mapapi-402935758Încă nu există evaluări

- B - ELSB - Cat - 2020 PDFDocument850 paginiB - ELSB - Cat - 2020 PDFanupamÎncă nu există evaluări

- Handout No. 03 - Purchase TransactionsDocument4 paginiHandout No. 03 - Purchase TransactionsApril SasamÎncă nu există evaluări

- What Is E-CollaborationDocument7 paginiWhat Is E-CollaborationToumba LimbreÎncă nu există evaluări

- Ifrs 15Document24 paginiIfrs 15Madhu Sudan DarjeeÎncă nu există evaluări

- Business Communication MCQ PDFDocument54 paginiBusiness Communication MCQ PDFHimanshu ShahÎncă nu există evaluări

- Al Rafay ProfileDocument8 paginiAl Rafay ProfileRana UsmanÎncă nu există evaluări