Documente Academic

Documente Profesional

Documente Cultură

Chapter 1

Încărcat de

Jeffery YipDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Chapter 1

Încărcat de

Jeffery YipDrepturi de autor:

Formate disponibile

Chapter 1 : AUTOMATION SYSTEM

1) CLASSIFICATION

Now a days a lot of control systems lead to Automation Control System . =Where wherever we go , we are surrounded by such systems in the home , on the street , in the vehicles and in buildings . =In the industrial sector , this Automation Control System very necessary because it can improve the quality and increase the productivity. =Arguably, this automation control system greatly influenced the way future life .

1.1 ) REQUIREMENTS IN INDUSTRIAL AUTOMATION CONTROL SYSTEM

=Automation Control System is a system that is capable of controlling a process with minimal human assistance or without manually. -=And have the ability to start , adjust , act show or measure the variables in the process and stop the process in order to get the desired output . =The main purpose of Automation Control System used in the industry is to increase productivity in terms of : Increase the quantity of the products . Improve the quality of the product . Controlling costs .

1.2) CLASSIFICATION OF AUTOMATION CONTROL SYSTEM

Automation Control System can be classified into two (2) divisions:

a) Automation Equipment (Fixed Automation / Hard-Wire Control)

=The control system is designed to perform a specific task. circuit function control is

fixed and permanent. =Work will be complicated if we want to do other work besides the already existing work on control systems this kind.

b) Flexible Automation / Programmable Control System

=Flexible Automation / Programmable Control System is complex that can perform various tasks. =Function control circuit programmed by the user and can be modified. =When the task to be performed by the machine turns, changes should only done by making changes on the machine control program said.

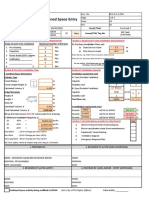

1.3) COMPARISON BETWEEN FIXED WITH AUTOMATION AND AUTOMATION CAN PROGRAMME

AUTOMATION FIXED AUTOMATION CAN PROGRAMME

Use facilities changes / improvements maintenance ability Speed Efficiency in terms of economy

Specific Difficuit

Various Easy

Easy Depending on the design and manufacture Fast Suitable for the small systems

Difficuit So high Slow Suitable for all type of system

example 1.3.1 Permanent control

Programmable Control

example 1.3.2 Permanent control

Programmable Control

1.4) TYPES OF CONTROL SYSTEM

There are THREE (3) types of control systems based on the source of supply. Systems are as follows: i. Pneumatic control system. ii. Hydraulic control system. iii. Electrical control system.

1.5) PNEUMATIC CONTROL SYSTEM

=Pneumatic control system is a system that uses air in compress to produce force / energy to do work. =System pneumatic many found in industrial systems such as the food industry, and petrochemical industries using robotics. =Generally pneumatic system require : i. Compressed air supply ii. control valve iii. connecting tube iv. Transducer Pneumatic control system can be controlled manually and automatically. Systems. This can be represented by a basic block diagram in Figure 1.5A and Figure 1.5B.

human

filter

compressor

valve control

tubes link

signal output

Figure 1.5a: basic block diagram of the pneumatic control system manually

Plc

filter

compressor

valve control

tubes link

signal output Figure 1.5B: basic block diagram of the pneumatic control system automatically using PLC

=Pneumatic control system can be controlled manually and automatically. =Hydraulic control system is a system that uses a fluid to a force / energy to do work. =Many hydraulic systems use in the automobile industry such as power systems, braking systems, cranes, car jack, satellite and so on. =Commonly used fluid is oil. Generally hydraulic system requires:

i. Supply Hydraulic Fluid ii. control valve iii. cylinder =Hydraulic control system can be controlled manually and automatically.

The hydraulic control system can be controlled manually and automatically. These systems can be represented by a basic block diagram in Figure 1.6a and Figure 1.6b.

Figure 1.6a: Block diagram of a hydraulic control system manually

Figure 1.6b: Block diagram of a hydraulic control system automatically using PLC

1.7 )ELECTRICAL CONTROL SYSTEM

Electrical control system is a control system that uses current electricity either direct current (DC) or alternating current (ac) as a source supply. Electrical Control System generally requires: i. Power supply (AT) or (AU) ii. Input elements (switches, sensors, transducers, valve, componentelectronic components, etc.) iii. Output elements (motors, lights, etc.) iv. extension cord

Electrical control system can be controlled manually and automatically. Electrical Control System can be controlled manually and automatically. The systems can be represented by a basic block diagram in Figure 1.7a and Figure 1.7b.

Figure 1.7a: circuit electrical control systems manually

Figure 1.7b: Block diagram of electrical control system automatically using PLC

1.8) COMPARISON BETWEEN PNEUMATIC CONTROL SYSTEM, SYSTEM

HYDRAULIC CONTROL AND ELECTRICAL CONTROL SYSTEM

Pneumatic control system easy installation system. Design simple systems. Using compressed air as a source of supply to do the job.

Hydraulic control system System installation is complicated. Using a fluid such as oil as a source of supply to do job. If the leak will cause impurities.

Electrical control system The system is easy. Using electricity as a source of supply to do the job. Extensive use. 2.0) TERMINOLOGY -The control system is one of the engineering disciplines . each engineering disciplines have terminology - terminology that own. -Such is the case with the control system . -Thus, in the unit you will be exposed to some of the key terminology used during the learning control system .

2.1) CONTROL SYSTEM -The control system is the components connected to the system or process to be controlled . Basic components of the control system can be divided into five parts: ( i ) the reference signal generator (input / point set ) / signal input / ( ii ) measuring element . ( iii ) Comparator . ( iv ) Controller. ( v) The Actuators . ( vi ) the controlled system ( control system )

2.2 INPUT REFERENCE -Reference input signal is provided at the input of a system such as temperature , pressure , level and so on . Its value is fixed .

2.3 CONTROLLED variable -Controlled variables are controlled signal or variable in products such as the temperature , pressure , level and so on . The value can be changed. 2.4 INTERFERENCE -Harassment is a disturbing element in a control signal control system. Interference can result either from within or outside the system itself. 2.5 ELEMENTS feedback -The feedback element is a function to send an output signal to compared with the input signal by Comparator elements / aggregator in a closed loop system.

2.6 CONTROL SYSTEM OPEN RING -Open loop control system is a type of control system where issue does not affect the action of the control functions of the system. This system can be represented by the block diagram in Figure 2.6 below. Signal reference guard driving

The output signal

The system to be controlled

Figure 2.6: Block diagram of open-loop control system 2.6.1 Examples of Open Loop Control System -The system is controlled by a timer (timer) usually is an open-loop system, eg street lighting. -This lamps will go on at a certain time (at night) and then will be erased the next day (daytime). -Period between time goes on and the time set by the timer (timer). The block diagram for the above example is shown in Figure 2.6.1. Signal reference ( Action set the timer ) guard ( Timer) driving (Relay )

The output signal (Lights ON @ OFF)

The system to be controlled

Figure 2.6.1: Block diagram of traffic lights (open-loop)

2.7 Closed-loop control system -Closed-loop control system is also known as a feedback control system. -The output of this will influence the actions of system control functions said. -Such a system can be represented by the block diagram in Figure 2.7 in bottom.

Checklists

Signal reference The system Elements mEASUREMENT guard driving

TO BE

controlled

The output signal

Figure 2.7: Block diagram of the control system

2.7.1 Sample Loop Control System Close -The system uses sensors (sensor) as the input element is normally closed-loop system. -Take the example of the same of street lighting. - This type of lamp goes on and off on its own when the light sensor detects the brightness, without taking into account the particular period.

If the dark situation happen on during the day, street lights will flash. This is not true open loop control system. Figure 2.7.1 below describe examples described.

Signal reference ( brightness light)

guard

driving (Relay )

The system to be controlled (lamp )

Elements mEASUREMENT ( The light sensor ) The output signal ( brightness light)

Figure 2.7.1: Block diagram of street lighting (closed loop)

2.8 COMPUTER CONTROL SYSTEM -Computerized control system is a control system that uses a computer as the controller. -The system can be represented by the block diagram as shown in Figure 2.8 below.

Computer Signal reference guard driving

The system to be controlle

Elements mEASUREMENT The output signal

Figure 2.8: Block diagram of a computerized control system

2.9 COMPARISON BETWEEN open loop SYSTEMS WITH close loop system Open Loop System The construction is simple. Accuracy depends on the calibration of the elements. Not so experienced instability problems. Not able to reduce the effects of nonlinearity.

Closed Loop System The construction is complicated. The system is very accurate. Having problems of instability. nonlinear effects can be minimized.

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- MF 5460Document586 paginiMF 5460Maximiliano Hitschfeld100% (2)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- IQ, OQ, PQ: A Quick Guide To Process ValidationDocument9 paginiIQ, OQ, PQ: A Quick Guide To Process ValidationGonzalo MazaÎncă nu există evaluări

- Ice-Cream ProductionDocument65 paginiIce-Cream ProductionMujtaba HaseebÎncă nu există evaluări

- Numerical Simulations of Piano StringsDocument7 paginiNumerical Simulations of Piano StringsMihai DincaÎncă nu există evaluări

- Branding & Advertising (T NG H P) PDFDocument44 paginiBranding & Advertising (T NG H P) PDFNguyễn Ngọc Quỳnh Anh100% (1)

- Line Follower Robot ProjectDocument45 paginiLine Follower Robot ProjectJeffery YipÎncă nu există evaluări

- Ventilation Plan For Confined Space EntryDocument9 paginiVentilation Plan For Confined Space EntryMohamad Nazmi Mohamad Rafian100% (1)

- Piccolo: Operating and Maintenance Instructions For The Deck OvenDocument44 paginiPiccolo: Operating and Maintenance Instructions For The Deck OvenAdam B100% (1)

- Chapter 4 - HalalluddinDocument46 paginiChapter 4 - HalalluddinJeffery YipÎncă nu există evaluări

- Electropneumatic COURSEDocument17 paginiElectropneumatic COURSEJeffery YipÎncă nu există evaluări

- English-Chinese Chinese-English DictionaryDocument126 paginiEnglish-Chinese Chinese-English DictionaryCarlosAmadorFonsecaÎncă nu există evaluări

- Cooling TowerDocument56 paginiCooling TowerJeffery YipÎncă nu există evaluări

- 2000-01 Report PDFDocument174 pagini2000-01 Report PDFImran KaiÎncă nu există evaluări

- 1 Nodal AnalysisDocument11 pagini1 Nodal AnalysisJeffery YipÎncă nu există evaluări

- Objectives: Mesh Current MethodDocument3 paginiObjectives: Mesh Current MethodJeffery YipÎncă nu există evaluări

- End of Chapter PDFDocument4 paginiEnd of Chapter PDFJeffery YipÎncă nu există evaluări

- TitleDocument3 paginiTitleJeffery YipÎncă nu există evaluări

- Pb201 Case StudyDocument2 paginiPb201 Case StudyJeffery YipÎncă nu există evaluări

- The Laplace Transform: DT e T F S F T F LDocument11 paginiThe Laplace Transform: DT e T F S F T F LJeffery YipÎncă nu există evaluări

- Chapter 3Document9 paginiChapter 3Jeffery YipÎncă nu există evaluări

- Objectives: Mesh Current MethodDocument3 paginiObjectives: Mesh Current MethodJeffery YipÎncă nu există evaluări

- 1 Nodal AnalysisDocument11 pagini1 Nodal AnalysisJeffery YipÎncă nu există evaluări

- 2010 IASSym CompDocument95 pagini2010 IASSym CompChabi MongarÎncă nu există evaluări

- Project8 Design ReviewDocument19 paginiProject8 Design ReviewJeffery YipÎncă nu există evaluări

- JM302 Material Technology Buoyancy Case StudyDocument5 paginiJM302 Material Technology Buoyancy Case StudyJeffery YipÎncă nu există evaluări

- Distribution Box: Green Is EarthDocument1 paginăDistribution Box: Green Is EarthJeffery YipÎncă nu există evaluări

- Aluminium Properties and ApplicationsDocument8 paginiAluminium Properties and ApplicationsJeffery YipÎncă nu există evaluări

- Aluminium Properties and ApplicationsDocument8 paginiAluminium Properties and ApplicationsJeffery YipÎncă nu există evaluări

- What Is Shear ForceDocument16 paginiWhat Is Shear ForceJeffery YipÎncă nu există evaluări

- IntroductionDocument12 paginiIntroductionJeffery YipÎncă nu există evaluări

- Aluminium Properties and ApplicationsDocument8 paginiAluminium Properties and ApplicationsJeffery YipÎncă nu există evaluări

- End of Chapter 3Document10 paginiEnd of Chapter 3Jeffery YipÎncă nu există evaluări

- End of Chapter 4Document12 paginiEnd of Chapter 4Jeffery YipÎncă nu există evaluări

- IeDocument94 paginiIeJeffery YipÎncă nu există evaluări

- End of Chapter 1Document10 paginiEnd of Chapter 1Jeffery YipÎncă nu există evaluări

- IeDocument94 paginiIeJeffery YipÎncă nu există evaluări

- Idea of CultureDocument28 paginiIdea of CultureGustavo Dias VallejoÎncă nu există evaluări

- The Reference Frame - Nice Try But I Am Now 99% Confident That Atiyah's Proof of RH Is Wrong, HopelessDocument5 paginiThe Reference Frame - Nice Try But I Am Now 99% Confident That Atiyah's Proof of RH Is Wrong, Hopelesssurjit4123Încă nu există evaluări

- Borrero Nuevo Delaunay Mendez - 2019 - Ethnographical and Historical Accounts For Understanding The Exploration of New Lands The Case PDFDocument16 paginiBorrero Nuevo Delaunay Mendez - 2019 - Ethnographical and Historical Accounts For Understanding The Exploration of New Lands The Case PDFBárbara Olguín MuñozÎncă nu există evaluări

- Gradient of A Scalar Field and Its Geometrical InterpretationDocument3 paginiGradient of A Scalar Field and Its Geometrical InterpretationMichael100% (1)

- ProjectDocument5 paginiProjectMahi MalikÎncă nu există evaluări

- P - Issn: 2503-4413 E - Issn: 2654-5837, Hal 35 - 42: Jurnal Ekonomi Dan Bisnis, Vol. 11 No. 1 Juli 2022Document8 paginiP - Issn: 2503-4413 E - Issn: 2654-5837, Hal 35 - 42: Jurnal Ekonomi Dan Bisnis, Vol. 11 No. 1 Juli 2022Nova KartikaÎncă nu există evaluări

- A Study On Consumer Preference Towards Skincare With Special Reference To Himalaya Herbal Products in Nilambur at Malappuram District of KeralaDocument4 paginiA Study On Consumer Preference Towards Skincare With Special Reference To Himalaya Herbal Products in Nilambur at Malappuram District of Keralaarcherselevators50% (2)

- Safety and Arming Device Timer 6-7-1976Document5 paginiSafety and Arming Device Timer 6-7-1976nguyenhÎncă nu există evaluări

- Ropes and Wires: Malaysian Maritime Academy/Seamanship/May2003 1 of 6Document6 paginiRopes and Wires: Malaysian Maritime Academy/Seamanship/May2003 1 of 6Rohit SinghÎncă nu există evaluări

- WHLP in Reading and Writing Week 8Document4 paginiWHLP in Reading and Writing Week 8Manuel Despabiladeras0% (2)

- Load of Pedstrain On FobDocument26 paginiLoad of Pedstrain On FobPOOJA VÎncă nu există evaluări

- Bruxaria e Historia Cultural PDFDocument25 paginiBruxaria e Historia Cultural PDFGeorge Henri FernandoÎncă nu există evaluări

- Anthony Robbins With Harvard Business SchoolDocument3 paginiAnthony Robbins With Harvard Business SchoolluffylovemangaÎncă nu există evaluări

- Hwids - 2012 05 22 - 19 04 00Document9 paginiHwids - 2012 05 22 - 19 04 00RONAL DAMIANO PAREJAÎncă nu există evaluări

- How To Review A Book in Up To 5,000 Words: First StepsDocument3 paginiHow To Review A Book in Up To 5,000 Words: First StepsAnnaÎncă nu există evaluări

- EGGAR - Final ReportDocument8 paginiEGGAR - Final ReportAndrew LeeÎncă nu există evaluări

- Water Is EnergyDocument96 paginiWater Is EnergyRadu BabauÎncă nu există evaluări

- Six Sigma MotorolaDocument3 paginiSix Sigma MotorolarafaÎncă nu există evaluări

- Logisitim CircuitDocument7 paginiLogisitim CircuitDragos ManoleaÎncă nu există evaluări

- Ty 9900Document4 paginiTy 9900Samir DarweshÎncă nu există evaluări

- MMA Electrode ClassificationDocument3 paginiMMA Electrode ClassificationRathnakrajaÎncă nu există evaluări

- Design Prof BlankoDocument11 paginiDesign Prof BlankoAousten AAtenÎncă nu există evaluări