Documente Academic

Documente Profesional

Documente Cultură

Lathe Machining Catia

Încărcat de

Intan Kartikaningrum100%(1)100% au considerat acest document util (1 vot)

833 vizualizări37 paginiCATIA LATHE MACHINING

Drepturi de autor

© Attribution Non-Commercial (BY-NC)

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentCATIA LATHE MACHINING

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

100%(1)100% au considerat acest document util (1 vot)

833 vizualizări37 paginiLathe Machining Catia

Încărcat de

Intan KartikaningrumCATIA LATHE MACHINING

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 37

CATIA Training

COPYRIGHT DASSAULT SYSTEMES Version 5 Release 17

September 2006

EDU-CAT-EN-LMG-FS-V5R17

L

L

a

a

t

t

h

h

e

e

M

M

a

a

c

c

h

h

i

i

n

n

i

i

n

n

g

g

D

D

e

e

t

t

a

a

i

i

l

l

e

e

d

d

S

S

t

t

e

e

p

p

s

s

Lathe Machining Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 2

T

T

a

a

b

b

l

l

e

e

o

o

f

f

C

C

o

o

n

n

t

t

e

e

n

n

t

t

s

s

Master Exercise: Crankshaft 3

Step 1A: Open the V5 CATProduct 3

Step 1B: Define parameters of the Part Operation 5

Step 2A: Define a Drilling Operation 7

Step 2B: Define a Rough Turning Operation 10

Step 3: Define a Groove Turning Operation 14

Step 4: Define a Recess Turning Operation 18

Step 5: Define a Profile Finish Turning Operation 21

Step 6: Define a Thread Turning Operation 24

Step 7: Define a Sequential Turning Operation 26

Added Exercises: 30

Step 8: Create a Ramp Rough Turning Operation 30

Step 9: Modify the Design Part 34

Step 10: Generate Outputs 36

Lathe Machining Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 3

Master Exercise: Crankshaft

1. Step 1A: Open the V5 CATProduct

File/Open Open the Set-Up.CATProduct

Access the Lathe Machining Workbench:

Start Lathe Machining workbench

The PPR Tree is displayed in the left of the CATIA Window

Process: The Part Operation & NC Cycles

Lathe Machining Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 4

Product: The Geometry necessary for NC such as Stock, Part, Fixtures, Machine-Tool table,

Safety Planes, Starting points, etc

Resources: The shop floor resources such as Tools, Tool assemblies and Machine-tools

Lathe Machining Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 5

2. Step 1B: Define parameters of the Part Operation

Use the result of previous step or Open Define_PartOperation_Start.CATProcess

2.1 - Define the Stock

Double-click on the Part Operation to edit it (1)

Click on Stock icon (2)

Double-Click on the Stock model (3)

Activate the Automatic Stock Selection for Turning Operations using MB3 on the Stock field

2.2 - Define the Machine-Tool (4)

Select a Horizontal Lathe machine-tool

Select the LATHE.pptable as Post Processor Words table in the Numerical Control tab page

Click OK

2.3 - Define the Machining Axis System

Click on Reference Machining Axis System icon (5)

Select the origin point in the Machining Axis System panel and select the center point of the stock

Select the Z axis in the Machining Axis System panel and key 1, 0, 0 as spindle orientation

Select the X axis in the Machining Axis System panel and key 0, 0, -1 as profile orientation

Lathe Machining Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 6

Click OK to create the Machining Axis system

In Simulation tab page of the Part Operation:

Define a Stock Accuracy of 0.05mm to have a better Video Simulation

Click OK to create the Part Operation

Lathe Machining Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 7

3. Step 2A: Define a Drilling Operation

Use result of previous step or Open Drilling_Operation_Start.CATProcess

Select Manufacturing Program and click on Drilling icon

3.1 - Define the geometry to machine

In Geometry tab page:

Select No Point in the panel

Select the frontal hole on the part (put stock in no show )

3.2 - Define machining parameters

In Strategy tab page:

Enter 3 mm as Approach Clearance value to take into account the stock

3.3 - Define the tool

In tool tab page:

Select external tool database icon

Select Personal_tools_catalog as tools catalog

(check whether Personal_tools_catalog file is copied in intel_a)

Key 3.5 as nominal diameter for the query

Select the candidate tool (tool number 2401)

In tool change assembly panel:

Key a name for the assembly (ex: DrillAssembly)

Set the Power value to Fixed (the part is turning not the tool)

Lathe Machining Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 8

Lathe Machining Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 9

3.4 - Replay the tool path

Simulate the tool path using the video capability

3.5 - Simulate the tool path using the Video capability

The Stock accuracy can be better by modifying the Stock Accuracy default value on the Part

Operation in the Simulation tab page (key 0.02)

Lathe Machining

Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 10

4. Step 2B: Define a Rough Turning Operation

Use result of previous step or Open Rough_Turning_Operation_Start.CATProcess

Click on Rough Turning Operation icon

4.1 - Define the geometry to machine

Select the Part element in the Geometry panel (1)

Select a white point of the blue profile on the Part in order to select the full profile (2)

It is not necessary to select the stock as it has already been selected on the Part Operation

Key 0.5mm as Part offset

4.2 - Define the Tool Assembly

Select the Tool Assembly tab page in Insert tab :

Select the default diamond insert (1)

In Insert-Holder tab page:

Click on more button (2)

Lathe Machining

Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 11

4.3 - Define the strategy to machine

In strategy tab page:

Key 1.5 as new Max depth of cut

Add a part contouring path at the last path only

In Option tab page:

Key 3mm as new Lift-off distance

Tag Min Machining Radius option and key 1mm

Lathe Machining

Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 12

4.4 - Define the macro

Activate Approach macro (1)

Select a predefined macro: Axial-Radial (2)

Define the start point:

Click on start point in the panel (3)

Select the red point on the part (4)

Lathe Machining

Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 13

4.5 - Replay the tool path

4.6 - Simulate the tool path using the video capability

Lathe Machining Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 14

5. Step 3: Define a Groove Turning Operation

Use result of previous step or Open Groove_Turning_Operation_Start.CATProcess

Click on Groove Turning Operation icon

5.1 - Define the geometry to machine

Select the Part element in the panel (1)

Select the edge on the part (2)

Key 0.0 mm as Part offset (3)

5.2 - Define the Strategy

In strategy tab page:

Key 1.5 mm as Max Depth of Cut

Select Center as First plunge Position

Activate Part contouring

Activate Change output point option

Lathe Machining Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 15

In Option tab page:

Key 1.5mm as Lift-off distance

Key 45deg as Lift-off angle

Key 0 deg as Gouging Safety angle

5.3 - Define the Tool Assembly

In Insert tab page:

Select a Groove Insert

Key R1=R2=0.2 mm

Lathe Machining Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 16

In Insert-Holder tab page:

Click on More>>

Key 2.5mm as Insert Width (la)

Select Compensation tab page

Select P9R

Key a value=10 for the corrector Number using MB3 on the P9R field

5.4 - Define the macro

Create the same Axial-radial approach macro as in Rough Turning operation

Lathe Machining Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 17

5.5 - Replay the tool path

5.6 - Simulate the tool path thanks the video capability

Lathe Machining Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 18

6. Step 4: Define a Recess Turning Operation

Use Result of previous operation or Open Recess_Turning_Operation_Start.CATProcess

Put in Show mode the following sketch: Crankshaft/PartBody/Remove.2/Sketch.12

Click on Recess Turning Operation icon

6.1 - Define the geometry to machine

Select the Part element in the panel

Select the 3 edges on the Part belonging to the Sketch.12 (1)

6.2 - Define the strategy

In strategy tab page:

Set the following parameters

6.3 - Define the Tool Assembly

In Tool Assembly tab page:

Click on the button

Select the same tool assembly as for the Rough Turning operation

Lathe Machining Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 19

6.4 - Define the macro

Create the same Axial-radial approach macro as in Rough Turning operation

6.5 - Replay the tool path

Simulate the tool path using the video capability

NB: You have to create another Recess Turning operation to machine the remaining material

of the previous Recess Turning operation

Lathe Machining Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 20

Lathe Machining Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 21

7. Step 5: Define a Profile Finish Turning Operation

Use Result of previous operation or Open

Profile_Finish_Turning_Operation_Start.CATProcess

Click on Profile Finish Turning Operation icon

7.1 - Define the geometry to machine

Select the Part element in the panel

Select the two first elements of the dark blue profile and click on Navigate on Belt of Edges(as

shown)

Click again on this icon to select also the following edges because by default the navigation take

only 10 edges OR click on the Option icon of the Edge Selection tool bar to increase the Max Step

Forward

Select End limit mode plane on the tab

Select the limit surface (1)

MB3 on None and select: In (2)

7.2 - Define the strategy

In Machining tab page:

Key -45 as Lift-off angle

Key 0 as Lead-in angle

Key 0 as Leading Safety angle

Lathe Machining Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 22

7.3 - Define local strategy

MB3 on the part element

Select Add local information

Deselect Global feedrate and key 0.4 as local value

Key 0.1mm as local offset

In the same way put the same thickness on the next element of the profile

MB3 on one of a profile element and select Properties. The selected elements are

highlighted

7.4 - Define the Tool Assembly

Select the Turning Tooling Assembly.1 in the list

7.5 - Define the macro

Create the same Axial-Radial approach macro as in previous operation

Lathe Machining Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 23

7.6 - Replay the tool path

7.7 - Simulate the tool path using the video capability

Lathe Machining Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 24

8. Step 6: Define a Thread Turning Operation

Use Result of previous operation or Open Thread_Turning_Operation_Start.CATProcess

Click on Thread Turning Operation icon

8.1 - Define the geometry to machine

Select the Part element in the panel

Double-click on the edge to select it (shown in Red)

Key 15 mm as Length to thread

8.2 - Define the strategy

In thread tab page:

Key 0.5 as Pitch

Select Trapezoidal Profile

In option tab page:

Key 0.5 mm as Clearance on crest diameter.

Key 90 degrees as Lift-off angle

Do not select Change output point option

Do not select Output CYCLE syntax option

Lathe Machining Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 25

8.3 - Define the macro

Create the same Axial-Radial approach macro as in previous turning operation

8.4 - Replay the tool path

8.5 - Simulate the tool path using the video capability

Lathe Machining Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 26

9. Step 7: Define a Sequential Turning Operation

Use Result of previous operation or Open

Sequential_Turning_Operation_Start.CATProcess

Click on Sequential Turning Operation icon

9.1 - Define the Tool Assembly

In the insert tab page:

Select a Groove Insert

Set the following values

In the Insert-Holder tab page:

Select Groove Internal Insert-Holder

Set the following values

Lathe Machining Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 27

In the assembly tab page:

Key 90 deg as Setup angle

9.2 - Define the motions

In the strategy tab page:

a) Create a Go to point motion:

Click on Standard Go or Go-Go icon

Select the first check element on the panel and select the first check element on the part

Select the second check element on the panel and the second check element on the part

Set the first and the second check mode to To using contextual menu

Create the tool motion

b) Create a Go in direction motion:

Select the created tool motion

Click on Go InDirV icon

Select the driving element on the panel and select the Drive element on the part

Select the First check element on the panel and select the Check element on the part

Set the First check mode to To

Create the tool motion

c) Create a Follow motion:

Click on Follow icon

Select the First check element on the panel and select the Check element on the part

Set the First Check mode to Past

Lathe Machining Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 28

Create the tool motion

d) Create a Go in direction motion:

Click on Go InDirV icon

Select the driving element on the panel and select the Drive element on the part

Select the First check element on the panel and select the Check element on the part

Set the First check mode to Past

Create the tool motion

9.3 - Define the macro

Create an approach macro in direct mode starting from the standard start point

Lathe Machining Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 29

9.4 - Replay the tool path

9.5 - Simulate the tool path using the video capability

Close all the CATIA documents

Lathe Machining Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 30

Added Exercises:

1. Step 8: Create a Ramp Rough Turning Operation

1.1 - Create an New CATProcess

Select File / New in the top menu bar

Select Process in the type of new document to create

1.2 - Go to Lathe Machining Workbench

1.3 - Create a Machining Process including a Ramp Rough Turning Operation

Select the Machining Process View icon

Click the Machining Process icon

Select the Ramp Rough Turning operation icon

In Strategy / Rework tab page:

Activate Rework Mode option

In Feeds & Speeds tab page:

Activate Replace RAPID by Air Cutting Feedrate

Lathe Machining Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 31

In Macro tab page:

Create a linking macro with interrupt motion On Time = 500s

Create Linking Axial-Radial Approach & Radial-Axial Retract

1.4 - Define the Tooling query

Double-click on Tooling query in machining process view.

In the Holder query tab page:

Select External Insert-Holder

Select the catalog to look in: LatheInsertsAndHoldersSample.catalog

Define the 2 following constraints:

Insert Length <2*Ramp Rough Turning. Max depth of cut

Insert Length >1.4*Ramp Rough Turning. Max depth of cut

Lathe Machining Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 32

In the Insert query tab page:

Select the catalog to look in: LatheInsetrsAndHoldersSample.catalog

Define the 2 following constraints:

Nose Radius >1.5*Ramp Rough Turning.Max depth of cut

Nose Radius <2*Ramp Rough Turning. Max depth of cut

1.5 - Save the current CATProcess

File / Save As and named it MyLMGMachiningProcess.CATProcess

1.6 - Store the Machining Process in a Catalog

Use MB3 on the Machining Process to save it in a new catalog (named it

MyLMGCatalog.catalog)

1.7 - Close the current CATProcess

1.8 - Open the RampRough_Turning_Operation_Start.CATProcess

Access to recently saved MyLMGCatalog.catalog through the Open Catalog icon in LMG.

Select the new Machining Process previously created.

Instantiate (click OK) the Ramp Rough Turning operation without selecting any geometry.

Lathe Machining Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 33

1.9 - Define Geometry elements

Edit the Ramp Rough Turning operation

Select the blue profile along the part as Part Element profile

Select Round Insert in Tool tab

Define the Start & End points for the linking Approach and Retract macro

1.10 - Replay the tool path

Simulate the tool path using the video capability

Close all the CATIA documents

Lathe Machining Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 34

2. Step 9: Modify the Design Part

Open the DesignChange_Start.CATProcess

MB3 on the Manufacturing Program then Compute Stock and Tool Path

2.1 - Change parameters to modify the Part

Double-click on the CATPart: Crankshaft to go to Product Structure Workbench

Open the Relation node

(if Relations node is not active, go to Tools-Options-Part Infrastructure-Display and make

Relations node active.)

Double click on Design Table to go to Knowledge Advisor Workbench

Expand it

Select Configuration 2 in the Design Table

Update manually the Crankshaft.CATPart if necessary

Click OK to update the impacted operations by the modification

Double-click on the Part operation to go back to LMG Workbench

Select the Manufacturing Program

2.2 - Replay the Operations on new geometry

Select the Last Machining Operation

Click on Tool Path Replay icon

Simulate the complete new program

Click on Video icon

Click Forward Replay to replay all the manufacturing Program

Lathe Machining Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 35

Lathe Machining Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 36

3. Step 10: Generate Outputs

Open GenerateNCOutput_Start.CATProcess

3.1 - Processing a NC documentation

Click on the Generate Documentation icon

Define the path for the output Generated files

Click on OK to generate the NC Documentation

Click on Yes in the VBScript panel to open the HTML document

Lathe Machining Detailed Steps

COPYRIGHT DASSAULT SYSTEMES 37

3.2 - Processing an APT Source

MB3 on Manufacturing Program.1

Select Generate NC code interactively

In the NC Data Type, Select APT

Make sure that Associate output NC file to the program tab is active

Click on Execute

A Pop-up window appears at the end of the APT computation

Browse the result, using MB3 on the Manufacturing Program and Display NC File

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- N164.UCPE12B LANmark - OF - UC - 12x - Singlemode - 9 - 125 - OS2 - PE - BlackDocument2 paginiN164.UCPE12B LANmark - OF - UC - 12x - Singlemode - 9 - 125 - OS2 - PE - BlackRaniaTortueÎncă nu există evaluări

- 2015 Grade 4 English HL Test MemoDocument5 pagini2015 Grade 4 English HL Test MemorosinaÎncă nu există evaluări

- Curriculum Policy in IndonesiaDocument23 paginiCurriculum Policy in IndonesiaEma MardiahÎncă nu există evaluări

- Green ProtectDocument182 paginiGreen ProtectLuka KosticÎncă nu există evaluări

- Week 1-2 Module 1 Chapter 1 Action RseearchDocument18 paginiWeek 1-2 Module 1 Chapter 1 Action RseearchJustine Kyle BasilanÎncă nu există evaluări

- Comparison of Multi-Coil and Diaphragm Spring ClutchesDocument3 paginiComparison of Multi-Coil and Diaphragm Spring Clutchesmasb_994077Încă nu există evaluări

- Management of StutteringDocument182 paginiManagement of Stutteringpappu713100% (2)

- Standalone Financial Results, Limited Review Report For December 31, 2016 (Result)Document4 paginiStandalone Financial Results, Limited Review Report For December 31, 2016 (Result)Shyam SunderÎncă nu există evaluări

- D&D 3.5 Edition - Fiendish Codex I - Hordes of The Abyss PDFDocument191 paginiD&D 3.5 Edition - Fiendish Codex I - Hordes of The Abyss PDFIgnacio Peralta93% (15)

- Using MonteCarlo Simulation To Mitigate The Risk of Project Cost OverrunsDocument8 paginiUsing MonteCarlo Simulation To Mitigate The Risk of Project Cost OverrunsJancarlo Mendoza MartínezÎncă nu există evaluări

- Yuzu InstallerDocument3 paginiYuzu InstallerJohnnel PrietosÎncă nu există evaluări

- Digital Signatures: Homework 6Document10 paginiDigital Signatures: Homework 6leishÎncă nu există evaluări

- Thesis Statement On Corporate Social ResponsibilityDocument5 paginiThesis Statement On Corporate Social Responsibilitypjrozhiig100% (2)

- Enzymatic Hydrolysis, Analysis of Mucic Acid Crystals and Osazones, and Thin - Layer Chromatography of Carbohydrates From CassavaDocument8 paginiEnzymatic Hydrolysis, Analysis of Mucic Acid Crystals and Osazones, and Thin - Layer Chromatography of Carbohydrates From CassavaKimberly Mae MesinaÎncă nu există evaluări

- Advantages of The CapmDocument3 paginiAdvantages of The Capmdeeparaghu6Încă nu există evaluări

- Promoting The Conservation and Use of Under Utilized and Neglected Crops. 12 - TefDocument52 paginiPromoting The Conservation and Use of Under Utilized and Neglected Crops. 12 - TefEduardo Antonio Molinari NovoaÎncă nu există evaluări

- Manual de Utilizare HUMAX DIGI TV RDSDocument116 paginiManual de Utilizare HUMAX DIGI TV RDSenamicul50Încă nu există evaluări

- SSC 211 ED Activity 4.1Document4 paginiSSC 211 ED Activity 4.1bernard bulloÎncă nu există evaluări

- Annotated Bibliography 2Document3 paginiAnnotated Bibliography 2api-458997989Încă nu există evaluări

- Dr. Babasaheb Ambedkar Technological UniversityDocument3 paginiDr. Babasaheb Ambedkar Technological UniversityalfajÎncă nu există evaluări

- State Common Entrance Test Cell: 3001 Jamnalal Bajaj Institute of Management Studies, MumbaiDocument9 paginiState Common Entrance Test Cell: 3001 Jamnalal Bajaj Institute of Management Studies, MumbaiSalman AnwarÎncă nu există evaluări

- Sip Poblacion 2019 2021 Revised Latest UpdatedDocument17 paginiSip Poblacion 2019 2021 Revised Latest UpdatedANNALLENE MARIELLE FARISCALÎncă nu există evaluări

- Brochure - Actiwhite PWLS 9860.02012013Document12 paginiBrochure - Actiwhite PWLS 9860.02012013J C Torres FormalabÎncă nu există evaluări

- Deictics and Stylistic Function in J.P. Clark-Bekederemo's PoetryDocument11 paginiDeictics and Stylistic Function in J.P. Clark-Bekederemo's Poetryym_hÎncă nu există evaluări

- Project Report On HeritageDocument39 paginiProject Report On HeritageBALA YOGESH YANDAMURIÎncă nu există evaluări

- CMS156Document64 paginiCMS156Andres RaymondÎncă nu există evaluări

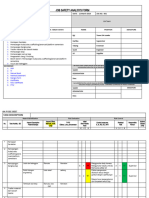

- JSA FormDocument4 paginiJSA Formfinjho839Încă nu există evaluări

- Lenovo S340-15iwl Compal LA-H101P SchematicDocument53 paginiLenovo S340-15iwl Compal LA-H101P SchematicYetawa Guaviare100% (4)

- Robert Egby - DecreesDocument9 paginiRobert Egby - DecreesmuzickaueÎncă nu există evaluări

- Computer Science HandbookDocument50 paginiComputer Science HandbookdivineamunegaÎncă nu există evaluări