Documente Academic

Documente Profesional

Documente Cultură

A Yield Line Component Method For Bolted Flange Connections-1

Încărcat de

sebastian9033Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

A Yield Line Component Method For Bolted Flange Connections-1

Încărcat de

sebastian9033Drepturi de autor:

Formate disponibile

ENGINEERING JOURNAL / SECOND QUARTER / 2011 / 93

A Yield Line Component Method

for Bolted Flange Connections

BO DOWSWELL

ABSTRACT

Bolted connections are often used in steel structures to transfer of tension loads into wide flange members. The strength of these connections

is determined with a prying action design procedure (outlined in the 13th edition AISC Steel Construction Manual) that checks the limit states

of bolt tension rupture and bending of the flange. This procedure is valid only for fittings with limited bolt spacing and limited edge distance.

This paper discusses a method to determine the local flange bending strength of a wide flange member using the yield line method. The

proposed design method includes the effect of prying action on the bolts, and can be applied to many different connection configurations,

including connections with large bolt spacing and edge distances and connections with web stiffeners. Comparisons with test data from 10

independent research projects will be used to verify the accuracy of the proposed method.

Keywords: bolted tension connections, hangers, prying action.

M

any bolted connections in steel structures rely on the

transfer of tension loads into wide flange members

as shown in Figure 1. The strength of these connections is

determined with the prying action design procedure in the

Steel Construction Manual (AISC, 2005a), hereafter re-

ferred to as the Manual, which checks the limit states of bolt

tension rupture and bending of the flange. The procedure in

the Manual is valid only for fittings with limited bolt spac-

ing and edge distance such as clip angles at the end of a

beam.

The Manual does not provide guidance on how to de-

termine the equivalent length of fittings with large edge

distances and bolt spacings. In practice, conservative as-

sumptions are often made. It is commonly assumed that the

tributary length per bolt is twice the distance from the center

of the bolt to the face of the supporting web. This method

is slightly conservative for calculating the elastic stress for

wide cantilever beams loaded at the free end (Young, 1989);

however, it is extremely conservative for calculating the

strength of flanges in bending.

In other cases, unconservative assumptions are some-

times made, where web stiffeners are provided to prevent

flange bending, and the stiffened flange is assumed ade-

quate to carry the applied loads with no further calculations.

However, tests have shown that flange bending is a common

failure mode for connections with web stiffeners (Packer

and Morris, 1977; Garrett, 1977; Ghassemieh et al., 1983;

Moore and Sims, 1986; Zoetemeijer, 1981).

This paper will discuss a method to determine the local

flange bending strength of a wide flange member using the

yield line method. The proposed design method includes the

effect of prying action on the bolts and can be applied to

many different connection configurations, including con-

nections with large spacings and edge distances and connec-

tions with web stiffeners. Comparisons with test data from

10 independent research projects will be used to verify the

accuracy of the proposed method.

Bo Dowswell, P.E., Ph.D., Principal, SDS Resources, Birmingham, AL. E-mail:

bo@sdsresources.com

Fig. 1. Bolted hanger connection.

093-116_ej2q_2011_2010-03r.indd 93 7/21/11 3:42 PM

94 / ENGINEERING JOURNAL / SECOND QUARTER / 2011

BACKGROUND

Prying Action

When bolts are loaded in tension, deformation of the con-

nected parts will cause an increase in bolt tension. This ad-

ditional bolt tension is the prying force, q, shown in Figure 2.

Designing for prying action involves checking the limit

states of bending of the fitting and tension rupture of the

bolts. The two limit states are interdependentfor a given

load, an increase in flange thickness leads to a lower prying

force on the bolt.

The moment diagram of half of the flange is shown in

Figure 2. The moment at the face of the web is always

equal to the plastic capacity of the fitting, but the moment

at the bolt line can be reduced if required to limit the pry-

ing force on the bolt. This behavior is accounted for in the

design method in the Manual. The background for the de-

sign method is provided by Astaneh (1985), Thornton (1985)

and Kulak et al. (1987). To calculate the available tensile

strength when the connection geometry is known, Equation

1 is applicable:

T B

t

t

B

a

c

j

(

,

\

,

(

+

( )

2

1

(1)

where

LRFD ASD

t

Bb

pF

c

u

4 44 .

t

Bb

pF

c

u

6 66 .

+ ( )

j

(

,

\

,

(

,

,

,

]

]

]

]

1

1

2

1 1 00

t

t

c

.

=

1

d

p

b

a

b b

d

b

2

j

(

,

\

,

(

j

(

,

\

,

(

a a

d

b

d

b b

= +

2

1.25 +

2

B = available tensile strength per bolt, kips

a = distance from the bolt centerline to the edge of the

fitting, in.

b = distance from bolt centerline to the face of the web,

in.

d

b

= bolt diameter, in.

d = width of the hole along the length of the fitting, in.

F

u

= specified minimum tensile strength of connecting

element, ksi

p = tributary length of fitting per bolt, in.

t = thickness of the fitting, in.

The Yield Line Method

The yield line method was developed by Hognestad (1953)

and Johansen (1962) to determine the ultimate strength of

concrete slabs. It is an upper-bound solution based on the

principle of virtual work. One form of the upper-bound the-

orem of limit analysis states that a load calculated based on

an assumed mechanism will be greater than or equal to the

true limit load.

The yield line method requires the failure pattern to be

known prior to calculation of the collapse load. Many pat-

terns may be valid for a particular joint configuration. Be-

cause the collapse load is upper bound, the pattern that gives

the lowest load will provide results closest to the true failure

load. Therefore, selection of the proper yield line pattern is

important because an incorrect failure pattern will produce

unsafe results.

The collapse load is calculated assuming that a plastic

mechanism forms along each line of the chosen failure pat-

tern. To maintain equilibrium, the external work done by

the load moving through the virtual displacement, , must

equal the strain energy due to the plastic moment rotating

through virtual rotations,

i

. The virtual rotations are as-

sumed small, so

i

tan(

i

) sin(

i

). The influence of strain

hardening and membrane effects are not accounted for in

yield line analysis; therefore, there is potentially a large re-

serve capacity beyond the calculated collapse load.

Some yield line patterns will produce an equation for the

load in terms of known geometry, but most cases will require

any unknown dimensions to be determined by minimizing

the load with respect to the unknown dimension. To do this,

the load is differentiated with respect to the unknown di-

mension and set equal to zero. From this, an equation for the

unknown dimension can be determined and substituted into

the equation for the load.

The general procedure for deriving an equation based on

yield line analysis is as follows:

Fig. 2. Model for prying action design method.

093-116_ej2q_2011_2010-03r.indd 94 7/21/11 3:42 PM

ENGINEERING JOURNAL / SECOND QUARTER / 2011 / 95

Select a valid yield line pattern.

Determine the equation that describes the external

work done by the load moving through the virtual

displacement.

W

E

= P (2)

where

P = applied load

= virtual displacement

Determine the equation that describes the internal work

done by the rotations along the yield lines,

W M

I pi i

(3)

where

M

pi

= plastic moment capacity of yield line i

= m

p

L

i

i

= virtual rotation of yield line i

m

p

= plastic moment capacity per unit length of the

fitting

= F

y

t

2

/4

L

i

= length of yield line i

Set the external work equal to the internal work and

solve for the load. If required, minimize the load with

respect to unknown dimensions.

Traditionally, the prying action equations have been

derived using equilibrium methods (Kulak et al., 1987), but

the equations can also be derived using energy methods. To

show the similarity between the design method for prying

action and the yield line equations for flange bending, the

Manual equation for the required fitting thickness will be

derived for the case of an infinitely strong bolt. This exercise

will also show the validity of the yield line method for this

simple case.

Considering only one side of the connection in Figure 3,

the external work is

W

E

= T (4)

The internal work is

W

I

= m

p

(L

1

+ L

2

) (5)

where

L

1

= length of yield line 1

= tributary length per bolt, p

L

2

= length of yield line 2

= net tributary length per bolt, pd

Substitute L

1

= p and L

2

= p d into Equation 5 to get

W

I

= m

p

(2p d) (6)

For small angles, = /b'

W

b

m p d

I p

( )

2 (7)

Substitute m

p

= F

y

t

2

/4

W

F t

b

p d

I

y

( )

2

4

2 (8)

Set internal work equal to external work and solve for T

n

T

F t

b

p d

n

y

( )

2

4

2 (9)

The available LRFD strength is

T

F t

b

p d

n

y

( )

2

4

2 (10)

Rearrange Equation 10 and solve for the thickness of the

fitting

t

Tb

F p d

min

y

( )

4

2

(11)

Substitute = 0.90 into Equation 11

t

Tb

F p d

min

y

( )

4 44

2

.

(12)

Fig. 3. Yield line model for prying equation.

093-116_ej2q_2011_2010-03r.indd 95 7/21/11 3:42 PM

96 / ENGINEERING JOURNAL / SECOND QUARTER / 2011

Dranger (1977)

The yield line pattern in Figure 5 was solved by Dranger

(1977), who determined the strength as a function of the un-

known dimension x:

P F t

x

b

c

x

n y

+

j

(

,

\

,

(

2

(15)

Dimension x was then determined by minimizing the load:

x bc (16)

If x from Equation 16 is substituted into Equation 15, the

nominal strength is

P F t

c

b

n y

2

2

(17)

where

c = a + b

Mann and Morris (1979)

Mann and Morris (1979) presented a yield line pattern

with circular corners as shown in Figure 6. The nominal

strength is

P F t

a p d

b

n y

+

+

j

(

,

\

,

(

2

2

(18)

Equation 18 defines the total connection strength, which

is twice the strength of each independent yield line pattern

forming on both sides of the column web. Mann and Morris

also suggested an equation similar to Drangers (1977) for

stiffened connections; however, no guidance was given on

how close the stiffener has to be to the bolt for that equation

to apply.

The LRFD version of the prying equation (on page 9-11 of

the Manual) is

t

Tb

pF

u

min

.

+

( )

4 44

1

(13)

Although the Manual procedure uses the ultimate tensile

strength, F

u

, for prying calculations, which was first sug-

gested by Douty and McGuire (1965) and more recently by

Thornton (1992), yield line analysis has traditionally utilized

the yield strength, F

y

. For comparison with the yield line

derivation, F

y

will be used here. Replacing F

u

with F

y

in

Equation 13, substituting = 1.0 for infinitely strong bolts

and substituting = 1 d/p, Equation 12 is obtained.

EXISTING SOLUTIONS

Yield line theory has been presented as a design method for

bolted connections in several publications, and many dif-

ferent yield line patterns have been proposed. A component

method, similar to the design method proposed in this pa-

per, is currently used in Europe (SCI, 1995; CEN, 2005) to

determine the column flange bending strength and the plate

bending strength in moment end plate connections.

Zoetemeijer (1974)

The equivalent length concept was first discussed by

Zoetemeijer (1974), who used a simplified solution to the

yield line pattern in Figure 4 to get an equivalent tributary

length per bolt of

p b

a p

e

+ + 2

5

8 2

(14)

where

p = spacing between bolts

Fig. 4. Yield line pattern from Zoetemeijer (1974). Fig. 5. Yield line pattern from Dranger (1977).

093-116_ej2q_2011_2010-03r.indd 96 7/21/11 3:42 PM

ENGINEERING JOURNAL / SECOND QUARTER / 2011 / 97

these tests, four connection types were identified, based

on the edge distance and stiffener configuration. These are

presented in Table 1. The specimen details are shown in

Table A1 of Appendix A.

The generalized experimental load-deflection curve is bi-

linear with a nonlinear transition point as shown in Figure 8.

There are four points of interest on the curve:

1. The proportional limit, where the curve transitions

from linear to nonlinear. The load at this deformation

may be of interest as a serviceability limit for connec-

tions that can allow only very small deformations. The

deformation at this point is

p

,

and the load is P

p

.

2. The point where the curve transitions from nonlinear

to linear at the second linear part of the curve. Loads

increased beyond this point are accompanied by large

deformations. The deformation at this point is

s

, and

the load is P

s

.

3. The point of 4-in. deformation. This is proposed here

as the serviceability limit. The deformation at this

point,

4

is 4 in., and the load is P

4

.

Zoetemeijer (1981)

Zoetemeijer (1981) presented a circular yield line pattern as

shown in Figure 7, which he described as a punching fail-

ure. For this pull-through mechanism, the prying force is

theoretically zero. The yield line solution predicts a nominal

strength of

P

n

= F

y

t

2

(19)

Thornton and Kane (1999) and Muir and Thornton

(2006)

Thornton and Kane (1999) and Muir and Thornton (2006)

published the following equation, which provides the aver-

age equivalent length per bolt:

p

p n b a

n

e

( ) + + 1 2

(20)

where

n = number of bolt rows

The equation can be derived by dividing the total equiva-

lent length of the bolt group, based on the yield line pattern

of Mann and Morris (1979), by the total number of bolts in

the joint. The equivalent length is then used with the pry-

ing action procedure in the Manual. This equation accounts

for the prying effect on the bolts; however, the fact that the

outermost bolts take significantly more of the load than the

inner bolts is neglected.

EXPERIMENTAL RESEARCH

Ten independent research projects were located with ex-

perimental results on bolted tension connections. From

Fig. 6. Yield line pattern from Mann and Morris (1979).

Fig. 7. Circular yield line pattern from Zoetemeijer (1981).

Fig. 8. General load versus deformation curve.

093-116_ej2q_2011_2010-03r.indd 97 7/21/11 3:42 PM

98 / ENGINEERING JOURNAL / SECOND QUARTER / 2011

Table 1. Geometry of Experimental Specimens

Specimen Geometry References

Type 1

Garrett (1977)

Grogan and Surtees (1999)

Hendrick and Murray (1983)

Moore and Sims (1986)

Packer and Morris (1977)

Pynnonen and Granstrom (1986)

Tawaga and Gurel (2005)

Zoetemeijer (1974)

Type 2

Packer and Morris (1977)

Garrett (1977)

Moore and Sims (1986)

Zoetemeijer (1981)

Type 3

Garrett (1977)

Type 4

Ghassemieh et al. (1983)

093-116_ej2q_2011_2010-03r.indd 98 7/21/11 3:42 PM

ENGINEERING JOURNAL / SECOND QUARTER / 2011 / 99

4. The ultimate strength. This is a point of interest for

structural integrity and ultimate strength calculations.

The deformation at this point is

u

and the load is P

u

.

Table A2 in Appendix A contains all of the loads described

for each specimen, where they were reported in the refer-

enced document. Many of the listed values are approximate

because they were read from graphs of the test data. The

experimental failure modes are also listed in Table A2. Most

of the specimens with two failure modes listed had the ulti-

mate strength limited by bolt rupture, but only after a large

deformation due to flange bending.

For the specimens with thick flanges, the bolts failed be-

fore the nonlinear part of the load-deformation curve was

reached. For these specimens, the bolt elongation contrib-

uted significantly to the total deformation.

For the specimens with thin flanges, the deformation at

ultimate strength was as much as 2 in. Under large deforma-

tions, the load-transfer mechanism changes from bending to

tension, which results in a tension load with a component

perpendicular to the axis of the bolt. This component is re-

sisted by the bolts in shear. Many of these tests resulted in

bolt fracture due to the applied tension combined with shear,

which was caused by large-deformation membrane action of

the fitting.

DEVELOPMENT OF PROPOSED

DESIGN METHOD

The purpose of this paper is to formulate a simple, accurate

and versatile method to design bolted flange connections. To

do this, the theoretical and experimental information pre-

sented by previous researchers will be analyzed.

The yield line solutions of Zoetemeijer (1974), Dranger

(1977), and Mann and Morris (1979) provide accurate results

for thin fittings where the limit state of bolt rupture is not

applicable. However, where thick flanges dictate that bolt

rupture is the controlling limit state, the yield line solutions

do not provide a method to calculate the prying force on

thebolt.

The method proposed by Thornton and Kane (1999) and

Muir and Thornton (2006) explicitly accounts for the prying

forces on the bolts; however, an equal amount of axial load is

assigned to each bolt. In reality, the outermost bolts will be

more highly stressed than the inner bolts, which could lead

to an unzipping action.

In this paper, a more refined solution has been developed,

where the forces are distributed according to the equivalent

length tributary to each bolt and the strength of each bolt is

evaluated independently. The equivalent tributary length is

calculated using existing yield line solutions.

The Component Method

Many different bolted flange configurations can be analyzed

by the yield line method; however, it would be cumbersome

for engineers to deal with a separate yield line pattern for

each different configuration. To simplify the design process,

the component method can be used, where single-bolt (lo-

cal) yield line patterns are assembled into a larger (global)

pattern for the entire bolt group. To do this, the engineer

simply selects a local pattern that is identical to each part

of the global pattern. The strength of each local pattern is

calculated and summed to get the total strength of the global

pattern.

In many cases, the local pattern will not be symmetrical

about the center of the bolt, and half-patterns can be used.

The strength of a half-pattern is simply half of the strength

of the whole pattern.

Stiffened Connections

If a flange is not adequate to carry the applied load, stiffen-

ers can be used to reinforce the joint as shown in Figure 9.

For stiffeners to be effective, they must be close enough to

the bolt to alter the yield line pattern. Using Drangers (1977)

yield line pattern, the stiffeners are effective if

x

s

< x (21)

where

x

s

= distance from the center of the bolt to the edge of

the stiffener

x = bc

Then, the strength can be determined by substituting x

s

for

x in Equation 15:

P F t

x

b

c

x

n y

s

s

+

j

(

,

\

,

(

2

(22)

Fig. 9. Yield line pattern for a stiffened flange in bending.

093-116_ej2q_2011_2010-03r.indd 99 7/21/11 3:42 PM

100 / ENGINEERING JOURNAL / SECOND QUARTER / 2011

Equivalent Tributary Length Concept

The nominal strength from a given yield line pattern will

be equal to that of a straight yield line of length, p. Using

Equation 9 with d' = 0 and b' = b, the nominal strength for a

straight yield line is

P

F t p

b

n

y

2

2

(23)

To determine the equivalent tributary length of fitting, the

nominal strength of a given yield line solution will be set

equal to Equation 23 and solved for p. For the Dranger

(1977) pattern in Figure 5, the equivalent length is

p bc

d

4

(24)

For single-bolt connections, the equivalent tributary length

for the yield line solution of Mann and Morris (1979), shown

in Figure 6, is

p b a m + 2

(25)

The equivalent tributary length For Zoetemeijers (1981) cir-

cular pattern in Figure 7 is

p b

c

2

(26)

For the stiffened pattern in Figure 9, the equivalent tributary

length is

p x

cb

x

s s

s

+

j

(

,

\

,

(

2

(27)

For single-bolt connections, the yield line solution of

Zoetemeijer (1974), given by Equation 14, reduces to

p b a

z

+ 4 1 25 .

(28)

Selection of Proper Yield Line Solution

Because the yield line method is an upper-bound approach,

the pattern that gives the lowest load will provide results

closest to the true failure load. The normalized equivalent

lengths, p

e

/c, from the yield line solutions of Zoetemeijer

(1974, 1981), Dranger (1977), and Mann and Morris (1979)

are plotted against b/a in Figure 10. It can be seen that the

Mann and Morris (1979) solution results in the minimum

equivalent length for connections with high values of b/a,

and the Zoetemeijer (1981) solution produces the minimum

equival ent length only for connections with very low values

of b/a.

To simplify the design process, it is advantageous to use

only one of the available yield line patterns. Analysis of the

experimental deformations indicate that the yield line pat-

tern developed by Zoetemeijer (1974), shown in Figure 4,

is closest to the actual failure pattern. However, the skewed

yield lines are awkward to deal with if stiffeners are present,

and for most practical b/a ratios, the difference in strength of

the various yield line patterns is small.

The circular yield line pattern presented by Zoetemeijer

(1981) will control the design of fittings with large edge

distances, a. However, if a limit is placed on the b/a ratio,

this yield line pattern will never control the design. The

Zoetemeijer solution is equal to the Dranger (1977) solution

at b/a = 0.68; therefore, if a is limited to 1.47b for design

purposes, Zoetemeijers solution will never control. As a

slightly conservative (about 5%) limit, the prying action de-

sign procedure in the Manual (AISC, 2005a) can be used,

which limits a to a maximum of 1.25b.

When comparing the Dranger (1977) pattern to the Mann

and Morris (1979) pattern for stiffened flanges, the Dranger

pattern more accurately predicts the increase in strength

based on the distance from the bolt to the stiffener. This can

be verified by reviewing the projects that tested specimens

that were identical except for the addition of a stiffener: Pack-

er and Morriss (1977) specimens T6, T7 and T8; Moore and

Simss (1986) specimen T7. For these four specimens, the

Mann and Morris model predicted no increase in strength

due to the stiffeners; however, the average experimental load

increased by 32% compared to identical specimens with no

stiffeners. The Dranger model predicted a 37% increase due

to the stiffeners.

Due to the simplicity and the more accurate prediction of

the strength when stiffeners are present, the Dranger (1977)

yield line pattern is proposed here. A plot of p

min

/p

d

versus

b/a is shown in Figure 11, where p

d

is the tributary length

Fig. 10. Comparison of different yield line patterns.

093-116_ej2q_2011_2010-03r.indd 100 7/21/11 3:42 PM

ENGINEERING JOURNAL / SECOND QUARTER / 2011 / 101

for the Dranger yield line pattern and p

min

is the minimum

tributary length for the yield line patterns of Zoetemeijer

(1974), Dranger (1977), and Mann and Morris (1979). It is

seen that the Dranger solution is unconservative. However,

for most practical b/a ratios, the difference can be neglected

because the beneficial effects of strain hardening and mem-

brane action are not accounted for. Figure 11 also shows the

curve-fit equation, which can be used as a reduction factor

in design if the engineer wants to explicitly account for the

difference among the three different solutions. The curve fit

for the reduction factor is

C

r

= 1.0 0.11(b/a) + 0.019(b/a)

2

(29)

The coefficient of determination, R

2

, is 0.99, indicating a

very good fit. If the equivalent tributary length has been cal-

culated using Drangers solution, the minimum of the three

solutions can be approximated as

p

min

= p

d

C

r

(30)

where

p

min

= approximate minimum equivalent tributary

length per bolt

p

d

= equivalent tributary length per bolt calculated

according to the yield line pattern, developed

by Dranger (1977)

Joints with Bolt Rupture as the Controlling Limit State

In joints where the equivalent tributary length at one bolt is

larger than the remaining bolts in the joint, the bolt forces

will not be distributed equally. When bolt rupture is the con-

trolling limit state, the design procedure must account for

this. The component method accounts for the nonequal dis-

tribution of bolt forces by assigning the loads in proportion

to the tributary length at each bolt.

When bolt rupture controls the design, an additional com-

plication arises because deformation compatibility must be

maintained for all bolts in the joint. Under normal condi-

tions, when one of the bolts within the joint ruptures, it is

unlikely that the full yield line pattern has formed due to the

limited deformation. The local yield line pattern tributary to

the adjacent bolt will also be limited to the deformation at

bolt rupture. Because the internal energy at the yield lines is

proportional to the displacement, deformation compatibility

of the adjacent yield lines can be upheld by reducing the

strength in proportion to the deformation ratio,

r

/.

r a

T

T

1

(31)

where

r

= deformation at bolt rupture

= deformation at full yield line strength assuming

infinitely strong bolts

T

a

= strength of the fitting at bolt rupture (calculated

using Equation 1)

T

=1

= strength of the fitting assuming a full yield line

pattern forms without bolt rupture (calculated

using Equation 1 with = 1)

Using

r

as the deformation limit for the entire joint, the

total strength of the joint as controlled by the critical bolt is

P T

T

T

P

P

n cr

cr

cr

ei

e

+

j

(

,

,

\

,

(

(

j

(

,

,

\

,

(

(

,

,

,

]

]

]

]

1 1

1 ( ) ( )

max

(32)

where

T

cr

= strength of the fitting at the critical bolt (the

bolt with the largest equivalent tributary

length within the joint) (calculated using

Equation 1)

T

cr(=1)

= strength of the fitting at the critical bolt as-

suming a full yield line pattern forms without

bolt rupture (calculated using Equation 1 with

= 1)

P

ei

= summation of the equivalent tributary lengths

for all local yield line patterns within the joint

P

e(max)

= largest equivalent tributary length for all bolts

within the joint

Equation 32 provides a convenient way to deal with the de-

formation compatibility of the joint; however, when com-

pared to the test results of Ghassemieh et al. (1983), the

calculated strengths are very conservative. The conserva-

tism is due to the fact that the equation only accounts for the

flexural deformation of the fitting and neglects other defor-

mations within the joint, such as bolt elongation and shear

deformation of the fitting. As discussed in the section on

experimental research, bolt elongation can be a large portion

of the total joint deformation.

Fig. 11. Comparison of Dranger (1977) yield line

solution to the minimum of the Zoetemeijer (1974)

and Mann and Morris (1979) solutions.

093-116_ej2q_2011_2010-03r.indd 101 7/21/11 3:42 PM

102 / ENGINEERING JOURNAL / SECOND QUARTER / 2011

group. If the yield line pattern is not symmetrical, two

half-patterns should be selected.

2. Calculate the strength of each bolt and fitting using

the prying action procedure in the Manual (AISC,

2005a), replacing p with p

e

; F

y

should be used in lieu

of F

u

unless large deformations are acceptable.

3. Repeat for all bolts in the bolt group.

4. Sum the individual strengths to get the total strength

of the bolt group.

The equivalent tributary length for the yield line pattern in

Figure 5 is

p bc

e

4

(33)

Where stiffeners are present, the equivalent length for the

pattern in Figure 9 is

p x if

cb

x

e s

s

+

j

(

,

\

,

(

2 x bc

s

< (34a)

p bc

e

4 if x bc

s

(34b)

Straight yield lines will be part of the yield line pattern when

the bolt spacing is less than 4 bc or the edge distance is less

than 2 bc. The equivalent tributary length per bolt is half

the distance between two bolts, p/2, or the distance from the

bolt to the end of the member, l

e

.

In the calculations for the equivalent tributary length, the

limit a 1.25b should be used. For connections subjected to

combined tension and shear, the bolt tension strength should

be reduced to account for the presence of shear.

As shown in the next section, serviceability design of

Due to the conservatism associated with Equation 32, it is

proposed that the strength of each bolt be evaluated indepen-

dently. Then, the total strength of the joint can be calculated

by summing the local capacities for the entire bolt group.

To account for the prying force on the bolt, the equivalent

tributary length, p

e

, is used in the prying action procedure

in the Manual in lieu of the tributary length, p. This proce-

dure provides nominal strengths that compare well with the

experimental loads, as discussed in the Experimental Vali-

dation section.

Large Bolt Spacings

If the distance between bolts, p, is greater than the equiv-

alent tributary length from Equation 24, two independent

yield lines will form for each bolt as shown in Figure 12a.

Figure 12b shows the same bolt pattern with a small bolt

spacing, where half-patterns form at each end and a straight

pattern forms between the bolts. Figure 13 shows a plot of

the equivalent length per bolt versus spacing between bolts.

The transition point between the two yield line patterns is at

a bolt spacing of 4 bc.

A similar problem occurs when a bolt is near the end of a

member. If the edge distance from the bolt to the end of the

member, l

e

, is less than 2 bc, a straight yield line will form

between the bolt and the end of the member.

PROPOSED DESIGN METHOD

The proposed design method consists of the following steps:

1. Select a valid yield line pattern local to each bolt in the

(a) (b)

Fig. 12. Effect of bolt spacing on the yield line

pattern: (a) large bolt spacing; (b) small bolt spacing. Fig. 13. Equivalent length per bolt versus spacing between bolts.

093-116_ej2q_2011_2010-03r.indd 102 7/21/11 3:42 PM

ENGINEERING JOURNAL / SECOND QUARTER / 2011 / 103

connections that can allow only very small deformations

should be based on 60% of the nominal load calculated us-

ing F

y

with the proposed design method. However, for most

standard connections, a reduction for stiffness is not re-

quired because a 4-in. deformation allowance is not uncom-

mon in determining the nominal strength of connections for

various limit states. For example, in the AISC Specification

for Structural Steel Buildings (AISC, 2005b), the nominal

strength for bearing strength at bolt holes is based on a de-

formation limit of 4 in., with an increase in the nominal

strength available if more deformation is allowed.

EXPERIMENTAL VALIDATION

The proposed design method was compared to the results of

59 tests from 10 independent research projects. The experi-

mental results are shown in Table A2 of Appendix A. Table

A3 in Appendix A shows the calculated nominal strengths

and predicted failure modes for all of the specimens. Table

A3 also shows the test-to-calculated ratios for each available

data point on the experimental curves.

The procedure outlined in the proposed design method

was used to calculate the nominal strength of each specimen

using the actual yield strengths and the ultimate strengths

reported in the referenced documents. Several of the refer-

enced documents reported the yield strength of the tested

material, but omitted the ultimate strength; therefore, there

were fewer experimental data points to compare with the

ultimate strength calculations.

For each specimen, the nominal strength at each local

yield line pattern was calculated using Equation 35, with the

nominal value of t

c

calculated without the resistance factor,

as expressed in Equations 36a and 36b for the yield and ulti-

mate strength solutions, respectively.

T r

t

t

r

e t

c

t

j

(

,

\

,

(

+

( )

2

1

(35)

t

r b

p F

c

t

e y

4

(36a)

t

r b

p F

c

t

e u

4

(36b)

where

r

t

= strength of tested bolt in tension

Then, the individual strengths of all local yield line patterns

within the joint were summed to get the total strength of the

joint.

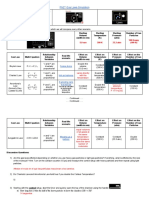

The statistical results are summarized in Table 2, which

provides the number of specimens with adequate data to be

included in the results, the average, the standard deviation

and the low values for the 95% and 99% confidence inter-

vals. Note that P

p

, P

s

, P

4

and P

u

are defined in the section

on Experimental Research, and P

ny

and P

nu

are the nomi-

nal loads calculated with the yield strength and ultimate

strength of the fitting, respectively.

The results show that the load at 4-in. deformation, P

4

,

can be accurately predicted using F

y

with the proposed de-

sign method. From column 4 in Table 2, the average test-to-

predicted ratio for the 23 specimens is 1.12, and the standard

deviation is 0.262. The low values for the 95% and 99% con-

fidence intervals are 1.01 and 0.976, respectively.

The ultimate loads can be accurately predicted using F

u

with the proposed design method. However, the deforma-

tions at ultimate strength can be very largeTable A2 in

Appendix 2 shows experimental deformations greater than

1 in. for several specimens at the maximum test load. From

Table 2. Summary of Calculation Results

[1]

Using F

y

Using F

u

P

P

p

ny

[2]

P

P

s

ny

[3]

P

P

ny

4

[4]

P

P

u

ny

[5]

P

P

p

nu

[6]

P

P

s

nu

[7]

P

P

nu

4

[8]

P

P

u

nu

[9]

Number of specimens 43 30 23 52 14 11 8 12

Average 0.675 0.932 1.12 1.61 0.490 0.685 0.763 1.13

Standard deviation 0.173 0.184 0.262 0.378 0.157 0.148 0.170 0.269

95% confidence interval

(low value)

0.623 0.866 1.01 1.51 0.407 0.597 0.646 0.976

99% confidence interval

(low value)

0.607 0.845 0.976 1.48 0.381 0.570 0.609 0.929

093-116_ej2q_2011_2010-03r.indd 103 7/21/11 3:42 PM

104 / ENGINEERING JOURNAL / SECOND QUARTER / 2011

Example 2

Determine the equivalent tributary length for each bolt in

Figure 15.

For bolt 1: Assume l bc

e

< 2 . The equivalent length is the

distance from bolt 1 to the end of the member plus half of the

distance between bolts 1 and 2.

p l

p

e e

+

2

For bolt 2: The equivalent length is half of the equivalent

length from Equation 33 plus half of the distance between

bolts 1 and 2.

p bc

p

e

+ 2

2

Example 3

Determine the equivalent tributary length for each bolt in

Figure 16.

For bolt 1: Assume l bc

e

< 2 and x

s

< x. The equivalent

length is the distance from bolt 1 to the end of the member

plus half of the equivalent length from Equation 34a.

p l x

bc

x

e e s

s

= + +

1

1

For bolt 2: Assume x

s

< x. The equivalent length is half of

the equivalent length from Equation 34a plus half of the dis-

tance between bolts 2 and 3.

p

p

x

bc

x

e s

s

= + +

23

2

2

2

column 9 in Table 2, the average test-to-predicted ratio for

the 12 specimens is 1.13, and the standard deviation is 0.269.

The low values for the 95% and 99% confidence intervals

are 0.976 and 0.929, respectively.

A comparison of columns 4 and 2 of Table 2 indicates that

the load at the proportional limit is about 60% of the load

at -in. deformation. Based on this, serviceability design

of connections that can allow only very small deformations

may be based on 60% of the nominal load calculated using

F

y

with the proposed design method.

EXAMPLES

Example 1

Determine the equivalent tributary length for each bolt in

Figure 14.

For bolt 1: The equivalent length is half of the equivalent

length from Equation 33 plus half of the distance between

bolts 1 and 2.

p bc

p

e

= + 2

2

12

For bolt 2: The equivalent length is half of the distance be-

tween bolts 1 and 2 plus half of the distance between bolts

2 and 3.

p

p p

e

= +

12 23

2 2

For bolt 3: The equivalent length is half of the equivalent

length from Equation 33 plus half of the distance between

bolts 2 and 3.

p bc

p

e

= + 2

2

23

Fig. 14. Example 1. Fig. 15. Example 2.

093-116_ej2q_2011_2010-03r.indd 104 7/21/11 3:42 PM

ENGINEERING JOURNAL / SECOND QUARTER / 2011 / 105

Fig. 17. Example 4.

Use a = 1.36 in.

=

=

b 2 56

0 75

2

2 18

.

.

.

in.

in.

in.

=

=

a 1 36

0 75

2

1 74

.

.

.

in.

in.

in.

+

=

=

=

b

a

2 18

1 74

1 25

. .

. .

.

in

in

c = b + a = 2.56 in. + 1.36 in. = 3.92 in.

For bolts at row 1,

P

eff

= 3.00 in.

t

Bb

p F

c

eff y

=

=

( )( )( )

( )( )

=

4 44

4 44 29 8 2 18

3 50

1

.

. . . .

.

kips in

in. ksi

339 in.

=

=

=

1

1

0 8125

3

0 729

d

p

eff

.

.

in.

in.

For bolt 3: The equivalent length is half of the equivalent

length from Equation 33 plus half of the distance between

bolts 2 and 3.

p bc

p

e

= + 2

2

23

Example 4

Determine the equivalent tributary length for each bolt in

Figure 17.

For bolts 1 and 2: Assume x

s

< x. The equivalent length is

half of the equivalent length from Equation 33 plus half of

the equivalent length from Equation 34a.

p bc x

bc

x

e s

s

= + + 2

Example 5

Determine the available LRFD strength of the connection in

Figure 18 for the limit states of bolt rupture and beam flange

bending. The beam is a W2155 of A992 material. Bolts are

w-in.-diameter A325 with m-in.-diameter holes. The beam

gage, g, is 52 in.

B = r

n

= 29.8 kips

t

f

= 0.522 in.

t

w

= 0.375 in.

b

f

= 8.22 in.

b =

=

5 5 0 375

2

2 56

. .

.

in. in.

in.

a =

=

8 22 5 5

2

1 36

. .

.

in. in.

in.

For design purposes, a must not be greater than 1.25b.

a < 1.25b

1.36 in. < (1.25)(2.56 in.)

Fig. 16. Example 3. Fig. 18. Example 5hanger connection without stiffeners.

093-116_EJ2Q_2011_2010-03R.indd 105 8/11/11 10:16 AM

106 / ENGINEERING JOURNAL / SECOND QUARTER / 2011

Use = 1.00.

T B

t

t

n

c

j

(

,

\

,

(

+

( )

( )

j

(

,

\

,

(

+

2

2

1

29 8

0 522

1 10

1 0 .

. .

. .

kips

in

in

.. .

.

829 1 00

12 3

( )( ) ,

]

]

kips

For bolts at row 3,

p x

p

eff

+

( )( ) +

2

2

2 3 17

6 5

2

9 59

. .

. .

. .

in

in

in

t

Bb

p F

c

eff y

( )( )( )

( )( )

4 44

4 44 29 8 2 18

9 59 50

.

. . . .

.

kips in

in. ksi

0 776 . in.

1

1

0 8125

9 59

0 915

d

p

eff

.

.

.

in.

in.

+ ( )

j

(

,

\

,

(

,

,

,

]

]

]

]

( ) + ( )

1

1

1

1

0 915 1 1 25

0 776

0 5

2

t

t

c

. .

. .

.

in

222

1

0 588

2

in.

.

j

(

,

\

,

(

,

,

,

]

]

]

]

T B

t

t

n

c

j

(

,

\

,

(

+

( )

( )

j

(

,

\

,

(

+

2

2

1

29 8

0 522

0 776

1 .

. .

. .

kips

in

in

00 915 0 588

20 7

. .

.

( )( ) ,

]

]

kips

The available load for the serviceabili ty limit state is

P

n

= (2)(7.27 kips) + (4)(12.3 kips + 20.7 kips) = 146 kips

If the ultimate strength, F

u

= 65 ksi, is used in the design

procedure, the available load for the strength limit state is

P

n

= (2)(9.43 kips) + (4)(15.9 kips + 23.0 kips) = 174 kips

+ ( )

j

(

,

\

,

(

,

,

,

]

]

]

]

( ) + ( )

1

1

2

1

1

0 729 1 1 25

1 39

0 52

t

t

c

. .

. .

.

in

22

2

1

3 71 1 00

in.

. .

j

(

,

\

,

(

,

,

,

]

]

]

]

>

Use = 1.00.

T B

t

t

n

c

j

(

,

\

,

(

+

( )

( )

j

(

,

\

,

(

+

2

1

29 8

0 522

1 39

2

1 0 .

. .

. .

kips

in

in

.. .

.

729 1 00

7 27

( )( ) ,

]

]

kips

For bolts at row 2,

p

eff

+

3

2

6 5

2

4 75

in. in

in

. .

. .

t

Bb

p F

c

eff y

( )( )( )

( )( )

4 44

4 44 29 8 2 18

4 75 50

.

. . . .

.

kips in

in. ksi

1 10 in. .

1

1

0 8125

4 75

0 829

d

p

eff

.

.

.

in.

in.

+ ( )

j

(

,

\

,

(

,

,

,

]

]

]

]

( ) + ( )

1

1

1

1

0 829 1 1 25

1 10

0 52

2

t

t

c

. .

. .

.

in

22

1

1 84

2

in.

.

j

(

,

\

,

(

,

,

,

]

]

]

]

093-116_ej2q_2011_2010-03r.indd 106 7/21/11 3:42 PM

ENGINEERING JOURNAL / SECOND QUARTER / 2011 / 107

Example 6

If more strength is required for the connection in Example5,

stiffeners can be added as shown in Figure 19. Determine

the strength of the bolts and beam flange.

For bolts at row 1,

P

eff

= 3.00 in.

T

n

7 27 . kips (from Example 5)

For bolts at row 2,

x

s

= 2.50 in.

x bc

( )( )

2 56 3 92

3 17

. . .

.

in. in

in.

Thus, x

s

< x; therefore,

p

p

x

bc

x

eff s

s

+ +

+ +

( )( )

2

3

2

2 50

2 56 3 92

2 50

8

in.

in.

in in

in

.

. . . .

. .

.001 in.

t

Bb

p F

c

eff y

( )( )( )

( )( )

4 44

4 44 29 8 2 18

8 01 50

.

. . . .

.

kips in

in. ksi

0 849 . in.

1

1

0 8125

8 01

0 899

d

p

eff

.

.

.

in

+ ( )

j

(

,

\

,

(

,

,

,

]

]

]

]

( ) + ( )

1

1

1

1

0 899 1 1 25

0 849

0 5

2

t

t

c

. .

. .

.

in

222

1

0 813

2

in.

.

j

(

,

\

,

(

,

,

,

]

]

]

]

Fig. 19. Example 6hanger connection with stiffeners.

T B

t

t

n

c

j

(

,

\

,

(

+

( )

( )

j

(

,

\

,

(

+

2

2

1

29 8

0 522

0 849

1 .

. .

. .

kips

in

in

00 899 0 813

19 5

. .

.

( )( ) ,

]

]

kips

For bolts at row 3,

x

s

= 3.50 in.

x

s

= 3.17 in.

Thus, x

s

> x; therefore,

p x

eff

( )( )

4

4 3 17

12 7

. .

. .

in

in

t

Bb

p F

c

eff y

( )( )( )

( )( )

4 44

4 44 29 8 2 18

12 7 50

.

. . . .

.

kips in

in. ksi

0 674 . in.

093-116_ej2q_2011_2010-03r.indd 107 7/21/11 3:42 PM

108 / ENGINEERING JOURNAL / SECOND QUARTER / 2011

1

1

0 8125

12 7

0 936

d

p

eff

.

.

.

in.

in.

+ ( )

j

(

,

\

,

(

,

,

,

]

]

]

]

( ) + ( )

1

1

1

1

0 936 1 1 25

0 674

0 5

2

t

t

c

. .

. .

.

in

222

1

0 317

2

in.

.

j

(

,

\

,

(

,

,

,

]

]

]

]

T B

t

t

n

c

=

j

(

,

\

,

(

+

( )

= ( )

j

(

,

\

,

(

+

2

2

1

29 8

0 522

0 674

1 .

. .

. .

kips

in

in

00 936 0 317

23 2

. .

.

( )( ) ,

]

]

= kips

The available load for the serviceability limit state is

P

n

= (2)(7.27 kips) + (4)(19.5 kips + 23.2 kips) = 185 kips

If the ultimate strength, F

u

= 65 ksi, is used in the design

procedure, the available load for the strength limit state is

P

n

= (2)(9.43 kips) + (4)(21.4 kips + 26.2 kips) = 209 kips

CONCLUSIONS

A method has been proposed to calculate the tension

strength of bolted flange connections, which includes the

effects of prying action. The proposed design procedure,

based on yield line theory, is simple, accurate and versatile.

It can be used to calculate the strength of many different

connection configurations, including stiffened connections,

connections with large bolt spacing and connections close to

the end of the member.

The bolt forces within a group are distributed according to

the equivalent length tributary to each bolt, and the strength

of each bolt is evaluated independently. The total strength of

the joint is then calculated by summing the nominal strength

at each bolt for the entire bolt group.

The calculated strengths were compared to the results of

59 tests from 10 independent research projects, and the pro-

posed design method, which uses the yield strength of the

fitting, was shown to be accurate for a deformation limit of

approximately 4 in. The ultimate strength of the fitting can

be determined by using the proposed design procedure with

the ultimate strength, F

u

, of the fitting. However, the defor-

mations at the ultimate strength can be large.

SYMBOLS

B Availa ble tension per bolt

C

r

Curve fit for the reduction factor is

F

y

Specified minimum yield strength of the fitting

F

u

Specified minimum tensile strength of the fitting

L

i

Length of yield line i

M

pi

Plastic moment capacity of yield line i

P Applied load

P

ny

Nominal load calculated with the yield strength of

the fitting

P

nu

Nominal load calculated with the ultimate strength

of the fitting

P

p

Experimental load at the proportional limit

P

s

Experimental load at the nonlinear transition

point on the load-deformation curve

P

u

Experimental load at ultimate failure

P

Experimental load at -in. deformation

T

a

Available tensile strength of fitting

T

cr

Strength of the fitting at the critical bolt (the bolt

with the largest equivalent tributary length within

the joint) (calculated using Equation1)

T

cr (=1)

Strength of the fitting at the critical bolt

assuming a full yield line pattern forms without

bolt rupture (calculated using Equation 1 with

=1)

T

=1

Strength of the fitting assuming a full yield line

pattern forms without bolt rupture (calculated

using Equation 1 with =1)

a Distance from the bolt centerline to the edge of

the fitting, but 1.25b for calculations using the

proposed design method

b Distance from bolt centerline to the face of the

web

d

b

Bolt diameter

d Width of the hole along the length of the fitting

l

e

Edge distance from the bolt to the end of the

member

m

p

Plastic moment capacity per unit length of the

fitting

n Number of bolt rows

p Spacing between bolts

093-116_ej2q_2011_2010-03r.indd 108 7/21/11 3:42 PM

ENGINEERING JOURNAL / SECOND QUARTER / 2011 / 109

p

z

Equivalent tributary length per bolt calculated

according to the yield line pattern developed by

Zoetemeijer (1974)

r

t

Strength of tested bolt in tension

r

n

Nominal strength of bolt in tension

t Thickness of the fitting, in.

x bc

x

s

Distance from the center of the bolt to the edge of

the stiffener

Virtual displacement

i

Virtual rotation of yield line i

p

Experimental deformation at the proportional

limit

s

Experimental deformation at the nonlinear

transition point on the load-deformation curve

u

Experimental deformation at ultimate failure

p

c

Equivalent tributary length per bolt calculated

according to the circular yield line pattern

developed by Zoetemeijer (1981)

p

d

Equivalent tributary length per bolt calculated

according to the yield line pattern developed by

Dranger (1977)

p

e

Equivalent length of fitting tributary to the bolt

in question for connection type 4, the equivalent

length of fitting tributary to the bolt farthest from

the end

p

el

For connection type 4, the equivalent length of

fitting tributary to the bolt closest to the end

p

m

Equivalent tributary length per bolt calculated

according to the yield line pattern developed by

Mann and Morris (1979)

p

min

Minimum equivalent tributary length per bolt;

minimum of p

d,

p

z

and p

m

p

min

Approximate minimum equivalent tributary

length per bolt calculated with Equation 30

p

s

Equivalent tributary length per bolt calculated

according to the stiffened yield line pattern in

Figure 9

093-116_ej2q_2011_2010-03r.indd 109 7/21/11 3:42 PM

110 / ENGINEERING JOURNAL / SECOND QUARTER / 2011

APPENDIX A

Table A1. Specimen Properties

Specimen

F

y

(ksi)

F

u

(ksi)

t

(in.)

b

(in.)

a

(in.)

p

e

(in.)

p

el

(in.)

d

b

(in.)

d

(in.)

r

t

(kips)

Notes

Garrett (1977)

1 41.2 66.5 0.465 1.62 1.51 7.00 0.875 0.938 54.1

2 41.2 66.5 0.465 1.62 1.51 9.00 0.875 0.938 54.1

3 41.2 66.5 0.465 1.62 1.51 9.00 0.875 0.938 54.1

Ghassemieh et al. (1983)

TH-1 43.5 65.9 0.5 1.5 2.92 5.62 2.08 0.625 0.688 27.1

TH-2 38.7 70.1 0.5 2.5 2.92 8.23 2.08 0.625 0.688 27.1

TH-3 45.4 66.5 1 1.5 2.92 5.00 2.08 0.625 0.688 27.1

TH-4 43.1 73.9 1 2.5 2.92 10.3 2.08 0.625 0.688 27.1

TH-5 44.9 72.5 0.75 1.5 2.92 5.62 2.08 0.625 0.688 27.1

TH-6 37.7 65.2 0.75 2.5 2.92 8.23 2.08 0.625 0.688 27.1

Grogan and Surtees (1999)

E1 42.8 0.559 2.59 2.24 10.0 1.18 1.30 64.4

E15 42.2 0.559 2.59 2.24 14.4 1.18 1.30 64.4

Hendrick and Murray (1983)

1 38.3 0.778 2.52 3.26 9.95 1.38 1.44 133

2 34.6 0.813 2.50 4.54 10.7 1.38 1.44 133

3 39.7 0.718 2.54 3.25 9.57 1.13 1.19 89.5

4 39.7 0.718 2.54 3.25 10.14 1.50 1.56 159

Moore and Sims (1986)

T1 44.8 0.268 1.57 1.30 6.22 0.630 0.709 25.2

T8 44.8 0.268 1.57 1.30 8.54 0.630 0.709 25.2

Packer and Morris (1977)

T1 42.9 0.268 1.58 1.12 6.04 0.630 0.811 36.7

T2 43.0 0.268 1.58 1.12 6.04 0.630 0.811 36.7

T3 42.5 0.354 1.56 1.12 6.01 0.630 0.811 36.7

T4 44.7 0.268 1.73 0.96 7.26 0.630 0.811 36.7

T5 43.6 0.528 1.49 1.12 5.86 0.630 0.811 36.7

T6 43.2 0.268 1.58 1.12 8.30 0.630 0.811 36.7

T7 43.9 0.268 1.58 1.12 8.30 0.630 0.811 36.7

T8 44.8 0.268 1.58 1.12 8.30 0.630 0.811 36.7

Pynnonen and Granstrom (1986)

1 46.1 68.4 0.366 1.38 1.65 6.07 0.630 0.709 31.1

5 46.1 68.4 0.366 1.74 1.30 6.57 0.630 0.709 31.1

11 46.1 68.4 0.366 1.74 1.30 6.57 0.945 1.02 71.6

15 44.8 64.4 0.551 2.19 3.54 9.07 0.945 1.02 71.6

21 44.8 64.4 0.551 3.42 2.32 10.8 0.945 1.02 71.6

093-116_ej2q_2011_2010-03r.indd 110 7/21/11 3:42 PM

ENGINEERING JOURNAL / SECOND QUARTER / 2011 / 111

Table A1. Specimen Properties (continued)

Specimen

F

y

(ksi)

F

u

(ksi)

t

(in.)

b

(in.)

a

(in.)

p

e

(in.)

p

el

(in.)

d

b

(in.)

d

(in.)

r

t

(kips)

Notes

Tawaga and Gurel (2005)

T-N 41.8 61.9 0.394 1.44 1.38 6.03 0.787 0.866 50.9

Zoetemeijer (1981)

1 36.4 0.457 2.21 2.36 13.9 0.787 0.866 50.9

2 36.4 0.457 3.18 1.38 18.2 0.787 0.866 50.9

4 36.4 0.457 2.21 2.36 12.8 0.787 0.866 50.9

5 36.4 0.457 3.18 1.38 9.54 0.787 0.866 50.9

6 36.4 0.457 3.18 1.38 15.3 0.630 0.709 32.9

7 36.4 0.457 3.18 1.38 15.8 0.787 0.866 50.9

8 40.6 0.492 4.39 1.36 20.7 0.945 1.02 67.5

9 40.6 0.492 2.19 3.56 13.7 0.945 1.02 67.5

10 40.6 0.492 4.39 1.36 20.7 0.945 1.02 67.5

11 40.6 0.492 2.19 3.56 14.2 0.945 1.02 67.5 1

12 40.6 0.492 4.39 1.36 27.6 0.945 1.02 67.5

13 40.6 0.492 2.19 3.56 13.7 0.945 1.02 67.5

14 40.6 0.492 2.19 3.56 17.5 0.945 1.02 67.5 1

15 40.6 0.492 4.39 1.36 27.6 0.945 1.02 67.5

Zoetemeijer (1974)

5 37.7 0.315 1.68 0.965 5.78 0.787 0.866 39.4

6 37.7 0.315 1.28 1.13 5.09 0.787 0.866 39.4

7 38.8 0.335 1.77 1.26 6.21 0.787 0.866 39.4

8 41.8 0.492 1.77 1.22 6.17 0.787 0.866 41.1

9 41.8 0.492 1.38 1.13 5.29 0.787 0.866 41.1

10 39.2 0.906 1.61 1.26 5.88 0.787 0.866 38.9

11 43.5 0.591 1.87 1.12 6.29 0.787 0.866 41.1

12 43.5 0.669 1.69 1.26 6.03 0.787 0.866 38.3

13 37.7 0.315 1.68 0.97 5.78 0.787 0.866 39.4

14 37.7 0.315 1.68 0.97 5.78 0.787 0.866 39.4

20 30.5 0.571 2.48 1.12 7.54 0.787 0.866 40.7

21 30.5 0.571 2.48 1.12 7.54 0.787 0.866 40.7

22 30.5 0.571 2.48 1.12 7.54 0.787 0.866 37.2

23 30.5 0.571 2.48 1.12 7.54 0.787 0.866 37.2

1. Four bolts per bolt row.

093-116_ej2q_2011_2010-03r.indd 111 7/21/11 3:42 PM

112 / ENGINEERING JOURNAL / SECOND QUARTER / 2011

Table A2. Experimental Results

Specimen

P

p

(kips)

P

s

(kips)

P

4

(kips)

P

u

(kips)

p

(in.)

n

(in.)

u

(in.)

Failure

Mode

Notes

Garrett (1977)

1 56 82 92 164 0.08 0.18 1.39 F

2 72 102 106 174 0.12 0.23 0.74 F

3 85 97 117 239 0.13 0.17 1.29 F

Ghassemieh et al. (1983)

TH-1 80 105 0.002 0.006 B

TH-2 40 110 140 0.001 0.016 > 0.1 F B

TH-3 165 200 0.006 N 1

TH-4 150 175 195 0.007 0.014 0.03 B

TH-5 130 150 170 0.006 0.012 > 0.02 F B

TH-6 70 140 0.001 0.011 N 2

Grogan and Surtees (1999)

E1 90 124 248 F

E15 112 169 292 F

Hendrick and Murray (1983)

1 110 160 200 0.003 0.021 0.065 N 1

2 120 160 200 0.012 0.033 0.088 N 1

3 60 200 0.023 0.22 N 1

4 110 170 200 0.012 0.056 0.14 N 1

Moore and Sims (1986)

T1 22 27 31 60 0.10 0.18 > 0.7 O

T8 34 40 43 74 0.16 0.22 > 0.6 O

Packer and Morris (1977)

T1 22.5 63.0 F B

T2 22.1 62.8 F B

T3 36.0 69.3 F B

T4 27.0 45.5 F O

T5 63.0 103 O B

T6 31.5 73.6 F O

T7 31.5 73.6 F O

T8 29.3 67.7 F O

Pynnonen and Granstrom (1986)

1 51 68 83 97.7 0.03 0.08 > 0.6 F B

5 22 50 61 90.0 0.05 0.08 > 0.6 F B

11 30 57 94 151 < 0.01 0.05 > 0.9 F

15 72 110 130 212 < 0.01 0.03 > 0.9 F B

21 191 F B

093-116_ej2q_2011_2010-03r.indd 112 7/21/11 3:42 PM

ENGINEERING JOURNAL / SECOND QUARTER / 2011 / 113

Table A2. Experimental Results (continued)

Specimen

P

p

(kips)

P

s

(kips)

P

4

(kips)

P

u

(kips)

p

(in.)

n

(in.)

u

(in.)

Failure

Mode

Notes

Tawaga and Gurel (2005)

T-N 61 74 94 97 0.024 0.063 0.32 N 3

Zoetemeijer (1981)

1 167 F

2 56 76 79 144 0.08 0.24 1.2 F

4 161 F

5 135 F

6 117 B

7 133 F

8 50 80 79 183 0.09 0.18 2.4 B

9 90 150 140 244 0.04 0.35 2.0 B

10 40 65 68 183 0.08 0.20 2.2 O

11 97 150 140 266 0.06 0.35 1.4 B

12 150 O

13 130 190 221 0.08 B

14 250 290 280 300 0.12 0.43 0.59 O

15 159 O

Zoetemeijer (1974)

5 22 32 45 49.5 0.004 0.02 > 0.2 F 4

6 32 45 63 67.4 0.01 0.03 > 0.2 F 4

7 26 40 48 67.4 0.01 0.03 > 0.2 F 4

8 135 F B

9 135 F B

10 148 F B

11 126 F B

12 153 F B

13 22 29 36 49.5 0.02 0.04 > 0.2 F 4

14 25 30 36 40.5 0.04 0.05 > 0.2 F 4

20 120 F B

21 43 63 84 103 0.02 0.04 > 0.2 F B 4

22 111 F B

23 128 F B

Notes

1. Maximum test load was 200 kips, which was the machine capacity.

2. Test result for ultimate load was not available; 140-kip load was taken

from finite element model.

3. Test was stopped at a load of 97 kips.

4. Loads at 4-in. deformation were conservatively read from the highest

graphed deformations, which were between 0.12 and 0.16 in.

Failure modes

N: No failure

F: Flange bending

B: Bolt rupture

O: Other

093-116_ej2q_2011_2010-03r.indd 113 7/21/11 3:42 PM

114 / ENGINEERING JOURNAL / SECOND QUARTER / 2011

Table A3. Calculation Results

Specimen

Nominal

Strength (kips)

Predicted

Failure Mode

P

P

p

ny

P

P

s

ny

P

P

ny

4

P

P

u

ny

P

P

p

nu

P

P

s

nu

P

P

nu

4

P

P

u

nu

Notes

Using

F

y

Using

F

u

Using

F

y

Using

F

u

Garrett (1977)

1 98.6 159 F F 0.57 0.83 0.93 1.66 0.35 0.52 0.58 1.03

2 129 176 F F B 0.56 0.79 0.82 1.35 0.41 0.58 0.60 0.99 2

3 129 176 F F B 0.66 0.75 0.91 1.85 0.48 0.55 0.66 1.36 2

Ghassemieh et al. (1983)

TH-1 116 144 F B F B 0.69 0.91 0.56 0.73 1

TH-2 81.8 111 F B F B 0.49 1.34 1.71 0.36 0.99 1.26 1

TH-3 204 217 B B 0.81 0.76 1

TH-4 177 195 B B 0.85 0.99 1.10 0.77 0.90 1.00 1

TH-5 182 201 B B 0.71 0.82 0.93 0.65 0.75 0.85 1

TH-6 125 167 F B B 0.56 0.42 1

Grogan and Surtees (1999)

E1 126 F 0.71 0.98 1.97

E15 181 F 0.62 0.93 1.61

Hendrick and Murray (1983)

1 233 F 0.47 0.69

2 252 F 0.48 0.63

3 186 F 0.32

4 215 F 0.51 0.79

Moore and Sims (1986)

T1 30.0 F 0.73 0.90 1.03 2.00

T8 41.8 F 0.81 0.96 1.03 1.77 1

Packer and Morris (1977)

T1 27.4 F 0.82 2.30

T2 27.5 F 0.80 2.28

T3 47.9 F 0.75 1.45

T4 31.1 F 0.87 1.46

T5 108 F B 0.58 0.95

T6 38.7 F 0.81 1.90 1

T7 39.3 F 0.80 1.87 1

T8 40.1 F 0.73 1.69 1

Pynnonen and Granstrom (1986)

1 66.1 98.1 F F 0.77 1.03 1.26 1.48 0.52 0.69 0.85 1.00

5 54.0 80.1 F F 0.41 0.93 1.13 1.67 0.27 0.62 0.76 1.12

11 59.1 87.8 F F 0.51 0.96 1.59 2.55 0.34 0.65 1.07 1.72

15 135 194 F F 0.53 0.81 0.96 1.57 0.37 0.57 0.67 1.09

21 95.4 137 F F 2.00 1.39

093-116_ej2q_2011_2010-03r.indd 114 7/21/11 3:42 PM

ENGINEERING JOURNAL / SECOND QUARTER / 2011 / 115

Table A3. Calculation Results (continued)

Specimen

Nominal

Strength (kips)

Predicted

Failure Mode

P

P

p

ny

P

P

s

ny

P

P

ny

4

P

P

u

ny

P

P

p

nu

P

P

s

nu

P

P

nu

4

P

P

u

nu

Notes

Using

F

y

Using

F

u

Using

F

y

Using

F

u

Tawaga and Gurel (2005)

T-N 69.5 103 F F 0.88 1.06 1.35 0.59 0.72 0.91

Zoetemeijer (1981)

1 112 F 1.49 1, 3

2 96.8 F 0.58 0.79 0.82 1.49 1

4 103 F 1.56 1

5 49.5 F 2.73 1

6 74.2 B 1.58

7 83.5 F 1.59

8 101 F 0.50 0.79 0.78 1.81 1

9 152 F 0.59 0.99 0.92 1.61 3

10 101 F 0.40 0.64 0.67 1.81 1

11 157 F 0.62 0.96 0.89 1.69

12 133 B 1.13 1, 3

13 152 F 0.86 1.25 1.45 1, 3

14 195 F 1.28 1.49 1.44 1.54 1

15 133 B 1.20 1, 3

Zoetemeijer (1974)

5 31.2 F 0.71 1.03 1.44 1.59

6 39.2 F 0.82 1.15 1.61 1.72

7 36.5 F 0.71 1.10 1.32 1.85

8 84.3 F 1.60

9 99.8 F 1.35

10 155 B 0.95

11 115 F B 1.10

12 126 F B 1.21

13 31.2 F 0.71 0.93 1.15 1.59

14 31.2 F 0.80 0.96 1.15 1.30

20 67.9 F 1.77

21 67.9 F 0.63 0.93 1.24 1.52

22 67.9 F 1.63

23 67.9 F 1.89

Notes

1. x

s

< x

2. x

s

> x

3. Theory indicates circular yield line controls the design. This was accounted for in the listed values.

093-116_ej2q_2011_2010-03r.indd 115 7/21/11 3:42 PM

116 / ENGINEERING JOURNAL / SECOND QUARTER / 2011

Moore, D.B. and Sims, P.A.C. (1986), Preliminary Inves-

tigations into the Behavior of Extended End-Plate Steel

Connections with Backing Plates, Journal of Construc-

tional Steel Research, pp. 95122.

Muir, L.S. and Thornton, W.A. (2006), Connections,

Ch.3, Structural Steel Designers Handbook, R.L. Brock-

enbrough and F.S. Merritt, Eds., McGraw-Hill, New York.

Packer, J.A. and Morris, L.J. (1977), A Limit State Method

for the Tension Region of Bolted Beam-Column Connec-

tions, The Structural Engineer, Vol. 5, No. 10.

Pynnonen, J. and Granstrom, A. (1986), Beam-to-Column

Connections with Backing Plates, Swedish Institute of

Steel Construction Report 86:6, April.

SCI (1995), Joints in Steel Construction-Moment Connec-

tions, The Steel Construction Institute, Ascot, Berkshire,

UK.

Tawaga, H. and Gurel, S. (2005), Strength Evaluation of

Bolted Moment Connections Stiffened with Channels,

Handout for poster session at the North American Steel

Construction Conference.

Thornton, W.A. (1985), Prying ActionA General Treat-

ment, Engineering Journal, AISC, Vol. 22, No. 2, pp.

6775.

Thornton, W.A. (1992), Strength and Serviceability of

Hanger Connections, Engineering Journal, Vol. 29, No.

4, pp. 145149.

Thornton, W.A. and Kane, T. (1999), Design of Connec-

tions for Axial, Moment and Shear Forces, Ch. 2, Hand-

book of Structural Steel Connection Design and Details,

A.R. Tamboli, Ed., McGraw-Hill, New York.

Young, W.C. (1989), Roarks Formulas for Stress and Strain,

6th ed., McGraw-Hill, p. 207.

Zoetemeijer, P. (1974), A Design Method for the Tension

Side of Statically Loaded, Bolted Beam-to-Column Con-

nections, Heron, Vol. 20, No. 1.

Zoetemeijer, P. (1981), Semi-Rigid Bolted Beam-to-Beam

Column Connections with Stiffened Column Flanges and

Flush End Plates, Joints in Structural Steelwork, Proc.

International Conference, Teesside Polytechnic, April

69, John Wiley and Sons.

REFERENCES

AISC (2005a), Steel Construction Manual, 13th ed., Ameri-

can Institute of Steel Construction, Chicago, IL.

AISC (2005b), Specification for Structural Steel Buildings,

American Institute of Steel Construction, Chicago, IL.

Astaneh, A. (1985), Procedure for Design and Analysis of

Hanger-Type Connections, Engineering Journal, AISC,

Vol. 22, No. 2, pp. 6366.

CEN (2005), Eurocode 3: Design of Steel Structures-

Part 18: Design of Joints, European Committee for

Standardization.

Douty, R.T. and McGuire W. (1965), High Strength Bolted

Moment Connections, Journal of the Structural Divi-

sion, ASCE, Vol. 91, No. ST2, pp. 101128.

Dranger, T.S. (1977), Yield Line Analysis of Bolted Hang-

ing Connections, Engineering Journal. AISC, Vol. 14,

No. 3.

Garrett, J.L. (1977), An Investigation of High Strength

Bolted Tension Connections, Masters Thesis, Iowa State

University.

Ghassemieh, M., Kukreti, A. and Murray, T.M. (1983), In-

elastic Finite Element Analysis of Stiffened End Plate

Moment Connections, Report FSEL/AISC 83-02, School

of Civil Engineering and Environmental Science, Univer-

sity of Oklahoma, June.

Grogan, W. and Surtees, J.O. (1999), Experimental Be-

havior of End Plate Connections Reinforced with Bolted

Backing Angles, Journal of Constructional Steel Re-

search, Vol. 50, pp. 7196.

Hendrick, A. and Murray, T.M. (1983), Column Web and

Flange Strength at End-Plate Connections, Report FSEL/

AISC 83-01, School of Civil Engineering and Environ-

mental Science, University of Oklahoma, February.

Hognestad, E. (1953), Yield Line Theory for the Ultimate

Flexural Strength of Reinforced Concrete Slabs, Journal

of the American Concrete Institute, Vol. 24, No. 7.

Johansen, K.W. (1962), Yield Line Theory, Cement and Con-

crete Association, London, England.

Kulak, G.L., Fisher, J.W. and Struik, J.H.A. (1987), Guide to

Design Criteria for Bolted and Rivited Joints, John Wiley

and Sons, New York.

Mann, A.P. and Morris, L.J. (1979), Limit Design of Ex-

tended End-Plate Connections, Journal of the Structural

Division, ASCE, March, pp. 511526.

093-116_ej2q_2011_2010-03r.indd 116 7/21/11 3:42 PM

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)