Documente Academic

Documente Profesional

Documente Cultură

JSA-Site Acceptance Test of 33 KV Feeders After Replacing Existing Relay by IEC61850 Facility Relay

Încărcat de

francis_e_tanDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

JSA-Site Acceptance Test of 33 KV Feeders After Replacing Existing Relay by IEC61850 Facility Relay

Încărcat de

francis_e_tanDrepturi de autor:

Formate disponibile

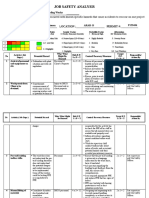

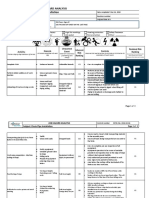

JOB SAFETY ANALYSIS FORM

RISK MATRIX

INCREASING PROBABILITY

QFM-DKN-25-01

Date:

PROJECT/JOB DETAILS

Project Ref./Job Title/Work Order:

GC11106400

A

Potential Severity People Asset/ Production Environment Reputation Never heard of in industry

B

Has occurred in industry

C

Has occurred in QP

D

Occurs several times a year in QP

E

Occurs several times a year at this site Low

Brief Description of Work: Site Acceptance Test of 33 kV Feeders after Replacing Existing Relay BY IEC61850 Facility Relay Job Location:

JSA No. :

GC11106400/

Revision:

No Injury Slight injury or health effects Minor injury or health effects Major injury or health effects Single fatality or permanent total disability Multiple fatalities

No Damage Slight damage, No disruption to operation Minor damage (=QR 250,000)

No Effect

No Impact

No Risk

Low

Low

Low

Sponsoring Department

EDD

Slight effect

Slight impact

Low

Low

Low

Low

Low

Hazard area Classification:

Minor effect Limited impact Low Low Medium Medium Medium

Performing Department

EDD/IMCO

Minor damage (=QR 250,000)

Localized Effect

National impact

Low

Medium

Medium

Medium

High

Permit Requirements: Hot/Cold/Radiography: Participants (Parties involved in JSA) Site Engineer, Site Supervisor and Vendor

All the mitigation measures identified in JSA are in place before starting the activities

Permit Authority

Major damage (=QR 25,000,000) Extensive damage (=QR 25,000,000)

Major effect

Regional Impact

Low

Medium

Medium

High

High

JSA -Approved by:

Massive Effect

International impact

Medium

Medium

High

High

High

PROBABILITY FACTOR

WORKSITE SUPERVISOR

WORK ACTIVITY: _________________________________ Each piece of equipment and crew are associated with known specific hazards that cause accidents to reoccur on one project after another. SITE SUPERVISOR: ________________________ LOCATION; ___________________________________ PERMIT #:_________________

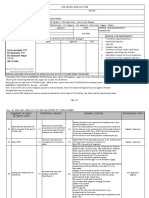

Site Acceptance Test of 33 kV Feeders after Replacing Existing Relay BY IEC61850 Facility Relay

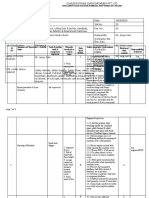

Sl. No. 1

Activity (Job Steps) In case of emergency

Potential Hazards Personnel doesnt know what they will do

Who/What Might Be Harmed IMCO employee

Risk E.P. SxP=T 3xB Medium

Control Recovery Measures All worksite supervisor must aware to the nearest assembly point area Brief all personnel about the emergency evacuation procedure Go to the nearest muster point area. Report directly to RG Plant Supervisor or RG Plant Control Room Upon declaration of an emergency or on hearing the established site alarm or upon receipt of instruction from the Client or local authorities (i.e. Dukhan) every worksite supervisor, crew members, equipment operator and safety officers, shall be ensure the following All work MUST be stopped at once, and All equipment, machines and power tools are shut down. Wind direction is checked through windsocks at the upper level of the work site or adjacent plant. All workers at elevated locations shall come down calmly to the ground level and proceed to the designated safe Assembly Area on foot in an orderly manner to a pre-determined Safe Assembly Area or Muster Point in a crosswind direction. (Running is prohibited except in life

Target E.P. SxP=T 1XA Low

Responsible/ Action By Engineer / Supervisor and Safety Officer

Page 2 of 9

Sl. No.

Activity (Job Steps)

Potential Hazards

Who/What Might Be Harmed

Risk E.P. SxP=T

Control Recovery Measures threatening situations). All crew supervisors / foremen will wait for their employees in the muster areas. Supervision must ensure all employees working in remote areas and in confined space (if any) have been alerted and have proceeded to the muster area. Crew supervisors / foremen will conduct a head count of their employees. If any employee is found to be missing, the responsible supervisor / foreman shall inform any of Senior IMCO Engineering & Construction Company representatives at the muster area immediately, identifying the employee(s) name and his / their last known location. The senior IMCO Engineering & Construction Company personnel, having received the information must subsequently relay the same information to IMCO Engineering & Construction Company Project Manager, Safety Personnel or Client representative, whoever is immediately available. No attempt shall be made to locate missing employee(s) until a

Target E.P. SxP=T

Responsible/ Action By

Page 3 of 9

Sl. No.

Activity (Job Steps)

Potential Hazards

Who/What Might Be Harmed

Risk E.P. SxP=T

Control Recovery Measures search is authorized by CLIENT or QP Search & Rescue Group when so determined that a search and rescue party can be reasonably protected during such operation. No one is permitted to return to work until INSTRUCTION has been received from CLIENT or local authorities that it is safe to do so. (Note: Return to work instruction could be either verbal instruction at the respective safe assembly areas or via siteestablished All Clear Alarm). No one will resume works unless a new work permit (if applicable) is being applied for and approved. NOTE: All issued work permits, if any, are automatically cancelled during actual emergencies and must be revalidated or replaced with new ones upon resuming work. Authorized PTW holder shall ensure obtaining and maintaining valid work permit. The worksite supervisor responsible for this activity has to check the PPE of his staff to ensure that all required items are available and properly used. Inform all workers regarding permit condition before work starts.

Target E.P. SxP=T

Responsible/ Action By

Work permit from QP to be obtained

Unauthorized commencement of works may result in exposing workers and or potential to harm or danger.

IMCO workers

3xB Medium

1xB Low

Engineer / Supervisor and Safety Officer

Page 4 of 9

Sl. No.

Activity (Job Steps)

Potential Hazards

Who/What Might Be Harmed

Risk E.P. SxP=T

Control Recovery Measures Worksite supervisor shall conduct toolbox talks about nature of works and associated potential hazards and their essential precautionary measure. Ensure that the pre task briefing is given out in a language understood by the work force, have it translated. Ask question regarding the briefing to get feedback from the staff, this ensures full comprehension. Issue required appropriate PPE and replace PPE that has signs of defect. PPE must include both hearing protection as well as dust inhalation protection. Ensure working personnel are strictly following the QP HSE Regulation for Contractors Doc. No. QP-REG-S-001 Rev. 3 Plan the work involving personnel responsible for preparation site acceptance test Use intrinsically safe radio for proper communication between the end user in control room turbine control panel and technician to verify the status of turbine in the field Only competent person shall assign to do the site acceptance test activities which is known to a

Target E.P. SxP=T

Responsible/ Action By

Pre-task briefing toolbox talks and site inspection

The work force does not understand the pre task briefing therefore does not understand the potential dangers and control measures to be implemented. Some of the workers could be lacking PPE or using defective PPE

IMCO workers

3xB Medium

1xB Low

Engineer / Supervisor and Safety Officer

Planning

Non compliance to QP HSE Regulations for Contractors and or to method statement Lack of communication

IMCO workers

3xB Medium

1xB Low

Engineer / Supervisor and Safety Officer Engineer / Supervisor and Safety Officer

IMCO workers

3xB Medium

1xB Low

Unsafe acts cause of inexperience personnel

IMCO workers

3xB Medium

1xB Low

Engineer / Supervisor and Safety Officer

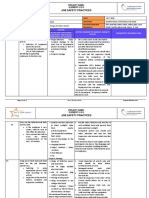

Page 5 of 9

Sl. No.

Activity (Job Steps)

Potential Hazards

Who/What Might Be Harmed

Risk E.P. SxP=T

Control Recovery Measures possible hazard of the insulation test activity Ensure that a worksite supervisor is properly monitored the site activity works. Ensure that the document provided during site acceptance testing is updated of AFC. Take advance approval from end user and focal point before carrying out site acceptance testing Ensure that the competent person only will work on this task Provide AFC drawing for a proper checking of terminal connection Avoid involuntary physical movements during checking the tightness of cable connection. Ensure that the power supply is shutting off before will proceed to disconnect the wire Keep tape isolation for the terminal wiring after removing to the connection Ensure that all test equipment used in loop checking is calibrated Ensure that test equipment is free from defect Only competent person shall assign to do the site acceptance testing activities

Target E.P. SxP=T

Responsible/ Action By

Lack of updated documents and list for site acceptance testing Shutdown of facility system and equipment 5 Checking tightness of control cable Electric shock / electrocution

Property damage IMCO workers

3xB Medium 3xB Medium 3xB Medium

1xB Low 1xB Low 1xB Low

IMCO workers

Engineer / Supervisor and Safety Officer Engineer / Supervisor and Safety Officer Engineer / Supervisor and Safety Officer

Defective tools/appliance

IMCO Workers

3xB Medium

1xB Low

Engineer / Supervisor and Safety Officer Engineer / Supervisor and Safety Officer

Unsafe acts cause of inexperience personnel

IMCO workers

3xB Medium

Low

Page 6 of 9

Sl. No.

Activity (Job Steps)

Potential Hazards

Who/What Might Be Harmed

Risk E.P. SxP=T

Control Recovery Measures Ensure that a worksite supervisor is properly monitored the site activity works. Do not take circuit breaker into service position until completion of SAT. Ensure that circuit breaker rack in is to be carried out by the QP personnel only Do not attempt to access the electrical panel. Ensure that only competent and trained workers do the job Wear appropriate PPE Ensure the identity of the feeder through tag nos. Check the AFC drawing prior to start the test. Identify and confirm the feeder which is going to be tested. Check and confirm that control circuit modification had been done properly with control circuit modification drawing. Extra care must be taken by every personnel involved in the work to make sure that they do not touch the live feeders even by mistake. Do not take circuit breaker into service position until completion of SAT.

Target E.P. SxP=T

Responsible/ Action By

Confirm the status of the protection relay after switching ON the control supply

Unwanted switch on of the circuit breaker

IMCO workers

3xB Medium

Low

Engineer / Supervisor and Safety Officer

Power supply checking

Electrocution

IMCO workers

3xB Medium

Low

Engineer / Supervisor and Safety Officer

Feeder Test

Wrong identity of feeder to be test

Property damage and IMCO worker Property damage

3xB Medium

1xB Low

Engineer / Supervisor and Safety Officer Engineer / Supervisor and Safety Officer

Unmodified control circuit

3xB Medium

1xB Low

Live circuit contact to personnel

Property damage

3xB Medium

1xB Low

Engineer / Supervisor and Safety Officer

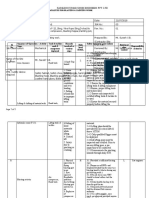

Page 7 of 9

Sl. No.

Activity (Job Steps)

Potential Hazards

Who/What Might Be Harmed

Risk E.P. SxP=T

Control Recovery Measures Ensure that circuit breaker rack in is to be carried out by the QP personnel only Ensure that Warning signs and barricading, with cone and rope, and safety warning tapes shall be installed around working area. Caution signs which read danger shall be installed at strategic locations. Check and Confirm the CT, VT ratio, required protection and its setting with Protection Relay Setting Document and set right if required and fill it in the test report form. Test and note down the status of all LEDs by LED test at Test mode Ensure that all test equipment are calibrated and to date from the inspection prior to use. Testing apparatus shall be operated only by the competent person Live-line tools shall be cleaned and inspected before use and receive a dielectric test whenever their insulating value is suspect. A record of the testing of live-line tools shall be maintained. Circuits and equipment to be worked on shall be disconnected from all electric energy sources.

Target E.P. SxP=T

Responsible/ Action By

Unauthorized personnel

IMCO Workers

3xB Medium

1xB Low

Engineer / Supervisor and Safety Officer

Confirming of protection setting and LED status

Failure of protection setting

Property damage

3xB Medium

1xB Low

Engineer / Supervisor and Safety Officer

10

Measurement test

Failure of test equipment

Property damage and IMCO worker

3xB Medium

1xB Low

Engineer / Supervisor and Safety Officer

Electric shock

IMCO workers

3xB Medium

1xB Low

Engineer / Supervisor and Safety Officer

Page 8 of 9

Sl. No.

Activity (Job Steps)

Potential Hazards

Who/What Might Be Harmed

Risk E.P. SxP=T

Control Recovery Measures Ensure to wear an appropriate PPE during electrical activities Ensure that during voltage measurement that does not touch exposed metal objects Prevent any accidental contact to the body during measuring the voltage Make sure that the test voltage does not damage any component to withstand it Ensure that all test equipment are calibrated and to date from the inspection prior to use. Testing apparatus shall be operated only by the competent person Live-line tools shall be cleaned and inspected before use and receive a dielectric test whenever their insulating value is suspect. A record of the testing of live-line tools shall be maintained.

Target E.P. SxP=T

Responsible/ Action By

10

Voltage measurement

Contact during injection of voltage causing electric shock

IMCO workers

3xB Medium

1xB Low

Engineer / Supervisor and Safety Officer

Failure of test equipment

Property damage and IMCO worker

3xB Medium

1xB Low

Engineer / Supervisor and Safety Officer

PREPARED BY (HSE) Name ---------------------------------------Name

REVIEWED BY (QP) ----------------------------------------

Signature --------------------------------------Date ---------------------------------------

Signature --------------------------------------Date ---------------------------------------

Page 9 of 9

S-ar putea să vă placă și

- JHA Maintenance Tech HVACDocument2 paginiJHA Maintenance Tech HVACMdavaÎncă nu există evaluări

- Water Proofing JSADocument9 paginiWater Proofing JSARamÎncă nu există evaluări

- JSA Format Erection of Column 901-C-01Document9 paginiJSA Format Erection of Column 901-C-01sakthi venkatÎncă nu există evaluări

- JSA For Civil Work Activity Including Installation of Shuttering, Rebar, Formwork, Concrete Work, and Backfilling ActivityDocument12 paginiJSA For Civil Work Activity Including Installation of Shuttering, Rebar, Formwork, Concrete Work, and Backfilling Activitybagas prakoso100% (1)

- Composite Works at Manglore For Hpclproject: Project No. W-488 Rev. 01 Page1 0f 2Document2 paginiComposite Works at Manglore For Hpclproject: Project No. W-488 Rev. 01 Page1 0f 2Bhargav BbvsÎncă nu există evaluări

- Jsa For The Installation of I EamDocument5 paginiJsa For The Installation of I EamMohammed MinhajÎncă nu există evaluări

- Job HazardDocument2 paginiJob HazardBre WirabumiÎncă nu există evaluări

- JSA Confined Sapce EntryDocument1 paginăJSA Confined Sapce EntryprasongÎncă nu există evaluări

- Sinopec Northen Construction Camp - Tilenga Job Hazard Analysis (Jha)Document3 paginiSinopec Northen Construction Camp - Tilenga Job Hazard Analysis (Jha)Nora Afzam Abd WahabÎncă nu există evaluări

- Job Safety Practices FirefightingDocument16 paginiJob Safety Practices Firefightingmohammed tofiqÎncă nu există evaluări

- Job Safety Analysis: S.No Activities Hazard Risk Control MeasuresDocument2 paginiJob Safety Analysis: S.No Activities Hazard Risk Control Measureskhaja asifuddinÎncă nu există evaluări

- JSA-019 Manual WeldingDocument5 paginiJSA-019 Manual WeldingMoaatazz Nouisri0% (1)

- Confine Space at Water TankDocument7 paginiConfine Space at Water TanknaraÎncă nu există evaluări

- Working at Height - JHA-1Document13 paginiWorking at Height - JHA-1Burhan KhanÎncă nu există evaluări

- Demolition JhaDocument2 paginiDemolition JhaElvyn Fabellore HerreraÎncă nu există evaluări

- JSA E&I 4.earthing Bonding InstallationDocument3 paginiJSA E&I 4.earthing Bonding InstallationAmyÎncă nu există evaluări

- JSA Scaffolding Erection and Dismentling New 2021Document5 paginiJSA Scaffolding Erection and Dismentling New 2021Captain ChickenÎncă nu există evaluări

- JSA-002-Safety WatchDocument2 paginiJSA-002-Safety WatchNishad MuhammedÎncă nu există evaluări

- Fall From Height Drill: Dammam Crude & Gas Development ProjectDocument17 paginiFall From Height Drill: Dammam Crude & Gas Development ProjectBala MuruganÎncă nu există evaluări

- Aj Infratech: Job Hazard AnalysisDocument5 paginiAj Infratech: Job Hazard AnalysisDwitikrushna RoutÎncă nu există evaluări

- JSA BOOM TRUCK 197iDocument3 paginiJSA BOOM TRUCK 197iImamul HaqueÎncă nu există evaluări

- Job Hazard Analysis PermitDocument1 paginăJob Hazard Analysis PermitKhorchnoi Abaja CalimlimÎncă nu există evaluări

- 23 JSA For Block WorkDocument2 pagini23 JSA For Block WorkWakil AhmadÎncă nu există evaluări

- Pha ExcavationDocument13 paginiPha ExcavationirshadÎncă nu există evaluări

- Jha RebarsDocument7 paginiJha RebarsJaycee QuinÎncă nu există evaluări

- JSA For Coating and Raping Activity in TankDocument7 paginiJSA For Coating and Raping Activity in TankEslam lotfy- Eslam elsadatÎncă nu există evaluări

- Tools / Equipment:: Job Safety Analysis (Jsa)Document5 paginiTools / Equipment:: Job Safety Analysis (Jsa)Sameer AlmahboubÎncă nu există evaluări

- SOP Grinding & CuttingDocument3 paginiSOP Grinding & CuttingIMRANÎncă nu există evaluări

- Cutting & Grinding & WeldingDocument2 paginiCutting & Grinding & Weldingghazi kallelÎncă nu există evaluări

- JSA Formet New Blasting & PaintingDocument5 paginiJSA Formet New Blasting & Paintingsakthi venkatÎncă nu există evaluări

- RAPID-P0027-0005-CON-JHA-3215-0005 - Rev. A JHA of Blasting and PaintingDocument4 paginiRAPID-P0027-0005-CON-JHA-3215-0005 - Rev. A JHA of Blasting and Paintingshaiful annuarÎncă nu există evaluări

- 0 JsaDocument54 pagini0 JsaRavi AmarlapudiÎncă nu există evaluări

- Pre-Job Safety Assessment: Site InformationDocument2 paginiPre-Job Safety Assessment: Site Informationgueettaf faresÎncă nu există evaluări

- Jsa Installing BracketDocument3 paginiJsa Installing BracketHow Chin Engineering Sdn Bhd100% (1)

- Jsa For Lifting Activities With Mechanical EquipmentDocument4 paginiJsa For Lifting Activities With Mechanical EquipmentMuhammad Umar GondalÎncă nu există evaluări

- Akk Jha Installation of Diesel TankDocument3 paginiAkk Jha Installation of Diesel TankDouglas Delly0% (1)

- JHA For Plumbing and Piping TradesDocument84 paginiJHA For Plumbing and Piping TradesKhurram Iqbal100% (2)

- 08n Safety Action PlanDocument103 pagini08n Safety Action PlanMohammed MinhajÎncă nu există evaluări

- Jsa Psa & GisDocument3 paginiJsa Psa & GisMohammed NouzalÎncă nu există evaluări

- JHA Fabrication WorkDocument4 paginiJHA Fabrication WorkRavi thokalÎncă nu există evaluări

- PVCMS-BMV-HSE-JSA-001 InsulationDocument6 paginiPVCMS-BMV-HSE-JSA-001 InsulationBkdn DungÎncă nu există evaluări

- Job Safety Analysis (JSA) : Electronics (Cleaning + Servicing)Document2 paginiJob Safety Analysis (JSA) : Electronics (Cleaning + Servicing)Nishad MuhammedÎncă nu există evaluări

- JSO Cable Drum (02 Sept.'07)Document2 paginiJSO Cable Drum (02 Sept.'07)Francis Enriquez TanÎncă nu există evaluări

- JSA For Scissor Lift, Rev-6Document2 paginiJSA For Scissor Lift, Rev-6Mahamudul HasanÎncă nu există evaluări

- JSA Pipeworks - UEM - RAPID PETRONAS - Common FacilitiesDocument10 paginiJSA Pipeworks - UEM - RAPID PETRONAS - Common FacilitiesNazreen AzriÎncă nu există evaluări

- Job Hazard Analysis PDFDocument8 paginiJob Hazard Analysis PDFashok KumarÎncă nu există evaluări

- Excavation (Company Name) : Phase Hazard AnalysisDocument11 paginiExcavation (Company Name) : Phase Hazard AnalysisDenease CrummieÎncă nu există evaluări

- RA-Suspended Gypsum, Metallic Tiles Celling WorksDocument4 paginiRA-Suspended Gypsum, Metallic Tiles Celling Worksfaizan khanÎncă nu există evaluări

- JSA - For Trays ErectionDocument1 paginăJSA - For Trays ErectionAvinash RaiÎncă nu există evaluări

- Job Safety and Environmental Analysis WorksheetDocument2 paginiJob Safety and Environmental Analysis WorksheetCherry Betonio100% (1)

- JSA Forklift PDFDocument2 paginiJSA Forklift PDFfauziÎncă nu există evaluări

- Job Safety Analysis:: RTR DRAIN LINE REPLACEMENT (Excavation and Backfilling)Document5 paginiJob Safety Analysis:: RTR DRAIN LINE REPLACEMENT (Excavation and Backfilling)Madhan KannanÎncă nu există evaluări

- JSA-049 LVS Equipment & Material InstallationDocument10 paginiJSA-049 LVS Equipment & Material InstallationMoaatazz NouisriÎncă nu există evaluări

- Tower Crane Dismantling JSA HSE ProfessionalsDocument2 paginiTower Crane Dismantling JSA HSE ProfessionalsnabeelÎncă nu există evaluări

- Example JSA Job Safety AnalysisDocument13 paginiExample JSA Job Safety AnalysisSiti MaisarahÎncă nu există evaluări

- Confined Space SOPDocument15 paginiConfined Space SOPrishibarathiÎncă nu există evaluări

- DOD-MST-AKG-2-E-012 (Rev-A) Installation of TransformerDocument4 paginiDOD-MST-AKG-2-E-012 (Rev-A) Installation of TransformerProfessional TrustÎncă nu există evaluări

- Lock-Out / Tag-Out (L.O.T.O.) Permit To Work: Form No: P224-7 Rev0 Page 1 of 2Document2 paginiLock-Out / Tag-Out (L.O.T.O.) Permit To Work: Form No: P224-7 Rev0 Page 1 of 2Ionian TribeÎncă nu există evaluări

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument4 paginiJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagyaÎncă nu există evaluări

- JSA-Water Proofing WorksDocument8 paginiJSA-Water Proofing Worksfrancis_e_tan100% (9)

- JSA-Construction Right of WayDocument3 paginiJSA-Construction Right of Wayfrancis_e_tan100% (6)

- JSA-Manual Lifting of MaterialsDocument3 paginiJSA-Manual Lifting of Materialsfrancis_e_tan75% (4)

- JSA-Site Survey and Downloading of Relay ConfigurationDocument4 paginiJSA-Site Survey and Downloading of Relay Configurationfrancis_e_tan100% (2)

- HSE Non Compliance Report Log SheetDocument1 paginăHSE Non Compliance Report Log Sheetfrancis_e_tan100% (2)

- HSE Non Compliance ReportDocument1 paginăHSE Non Compliance Reportfrancis_e_tan100% (1)

- JSA - Cable Trench ExcavationDocument9 paginiJSA - Cable Trench Excavationfrancis_e_tan75% (4)

- Wind Speed ConvertionDocument1 paginăWind Speed Convertionfrancis_e_tanÎncă nu există evaluări

- Weekly HSE Report GC11110100Document4 paginiWeekly HSE Report GC11110100francis_e_tan100% (2)

- JSA-Cable P 112 QDocument11 paginiJSA-Cable P 112 Qfrancis_e_tanÎncă nu există evaluări

- Principle On Risk Assessment and ControlDocument45 paginiPrinciple On Risk Assessment and Controlfrancis_e_tanÎncă nu există evaluări

- Work Method Statement PHASEDocument1 paginăWork Method Statement PHASEfrancis_e_tanÎncă nu există evaluări

- JSA-Site Survey and Downloading of Relay ConfigurationDocument4 paginiJSA-Site Survey and Downloading of Relay Configurationfrancis_e_tan100% (1)

- JSA Concrete WorksDocument8 paginiJSA Concrete Worksfrancis_e_tan93% (27)

- Rigger Duties & ResponsibilitiesDocument1 paginăRigger Duties & Responsibilitiesfrancis_e_tan100% (9)

- Jsa For KahsDocument3 paginiJsa For Kahsfrancis_e_tan100% (2)

- General Work in Khatiyah North - Main StationDocument6 paginiGeneral Work in Khatiyah North - Main Stationfrancis_e_tanÎncă nu există evaluări

- Reactive Power Compensation 4Document12 paginiReactive Power Compensation 4Younes AkakbaÎncă nu există evaluări

- IEEE Blackout TF Final Report 052307Document233 paginiIEEE Blackout TF Final Report 052307Lam Ch0% (1)

- 11 Russia KogayDocument15 pagini11 Russia KogaySyamil DzulfidaÎncă nu există evaluări

- Tiristor 3ct12a 500 V 12 A To220 0Document5 paginiTiristor 3ct12a 500 V 12 A To220 0morucha_chicleÎncă nu există evaluări

- 4 Integrated Refinery-Cracker The New Paradigm - FluorDocument24 pagini4 Integrated Refinery-Cracker The New Paradigm - FluorxinghustÎncă nu există evaluări

- CIL&SCCL Ncwa-XDocument92 paginiCIL&SCCL Ncwa-XSandeep PatelÎncă nu există evaluări

- Sanken Regulator-ICs-Catalog PDFDocument119 paginiSanken Regulator-ICs-Catalog PDFJoseni FigueiredoÎncă nu există evaluări

- Frequently Asked Questions (FAQ) : State Aid: Just Transition Fund (JTF)Document15 paginiFrequently Asked Questions (FAQ) : State Aid: Just Transition Fund (JTF)amicoadrianoÎncă nu există evaluări

- Euro Ref SitesDocument21 paginiEuro Ref Sitesjaykrit20009389Încă nu există evaluări

- Annexure V Bidder Response SheetDocument2 paginiAnnexure V Bidder Response SheetAshishÎncă nu există evaluări

- PETROM Asset IntegrityDocument18 paginiPETROM Asset Integrityghostforever0Încă nu există evaluări

- Bonding & Grounding Controlling Static ElectricityDocument3 paginiBonding & Grounding Controlling Static Electricityعزت عبد المنعم100% (1)

- Ir3030 Ir3045 Ir4570 2870 2230 3530 Series-PcDocument152 paginiIr3030 Ir3045 Ir4570 2870 2230 3530 Series-PcTerry BogardÎncă nu există evaluări

- SIEMENS 33 KV GIS ManualDocument68 paginiSIEMENS 33 KV GIS ManualAnonymous kielG2Încă nu există evaluări

- Cost Data 2024 Dated 08022024 - 240209 - 144302Document78 paginiCost Data 2024 Dated 08022024 - 240209 - 144302sreejitvpÎncă nu există evaluări

- Stirlings Fittings CatalogueDocument108 paginiStirlings Fittings CatalogueJúlio HenriquesÎncă nu există evaluări

- Electrical TestDocument3 paginiElectrical TestAce SpionÎncă nu există evaluări

- GTMA ARM BriefingDocument60 paginiGTMA ARM BriefingGTMAAdminÎncă nu există evaluări

- AdvEn Solutions - Battery ResearchDocument19 paginiAdvEn Solutions - Battery ResearchGreenEnergyFuturesÎncă nu există evaluări

- Plumbing Arithmetic RefresherDocument80 paginiPlumbing Arithmetic RefresherGigi AguasÎncă nu există evaluări

- Eaton Cutler-Hammer Motor Control Center Info Cat.71.01t.e. - 2 PDFDocument42 paginiEaton Cutler-Hammer Motor Control Center Info Cat.71.01t.e. - 2 PDFDaniel Ajailla AveÎncă nu există evaluări

- AC ManualDocument24 paginiAC ManualSathiaselan PasskerenÎncă nu există evaluări

- Energy Saving Method of Manufacturing PDFDocument2 paginiEnergy Saving Method of Manufacturing PDFamirq4Încă nu există evaluări

- 2014 - Burguer King CatalogDocument48 pagini2014 - Burguer King CatalogJuan Gabriel Martinez RuizÎncă nu există evaluări

- Catálogo SEPCO PDFDocument17 paginiCatálogo SEPCO PDFAnonymous v4akjrQxKÎncă nu există evaluări

- Wellington Middle East UnrestDocument5 paginiWellington Middle East UnrestmariovassarÎncă nu există evaluări

- Gilian Operating ManualDocument37 paginiGilian Operating ManualMatthew KingÎncă nu există evaluări

- 1 VHPC Presentation Comprehensive - Oct 2008Document37 pagini1 VHPC Presentation Comprehensive - Oct 2008Carlo MonsalveÎncă nu există evaluări

- The Assay The Assay Battery Materials PDFDocument60 paginiThe Assay The Assay Battery Materials PDFValdy OktafianzaÎncă nu există evaluări

- Construction of 3phase AC Induction MotorsDocument3 paginiConstruction of 3phase AC Induction Motorsat35Încă nu există evaluări