Documente Academic

Documente Profesional

Documente Cultură

1 s2.0 S003991400600662X Main

Încărcat de

Amy LoredanaDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

1 s2.0 S003991400600662X Main

Încărcat de

Amy LoredanaDrepturi de autor:

Formate disponibile

Talanta 72 (2007) 6065

Comparison of slurry sampling and microwave-assisted digestion for calcium, magnesium, iron, copper and zinc determination in sh tissue samples by ame atomic absorption spectrometry

Raquel Alonso Bugallo, Susana R o Segade , Esperanza Fern andez G omez

Departamento de Qu mica Anal tica y Alimentaria, Area de Qu mica Anal tica, Universidad de Vigo, Facultad de Ciencias de Ourense, As Lagoas s/n, 32004 Ourense, Spain Received 27 March 2006; received in revised form 24 August 2006; accepted 27 September 2006 Available online 1 November 2006

Abstract The development of a slurry sampling method for the determination of calcium, copper, iron, magnesium and zinc in sh tissue samples by ame atomic absorption spectrometry is described. In comparison with microwave-assisted digestion, the proposed method is simple, requires short time and eliminates total sample dissolution before analysis. Suspension medium was optimized for each analyte to obtain quantitative recoveries from sh tissue samples without matrix interferences. Nevertheless, iron recoveries higher than 46% were not found. Treatment of samples slurried in nitric acid by microwave irradiation for 1530 s at 75285 W permitted to achieve efcient recoveries for calcium, iron, magnesium and zinc. Further improvement in the matrix effects for iron determination was accomplished by the use of an additional step of short microwave-assisted suspension treatment. However, standard addition method was required for calcium and copper determination, being necessary hydrochloric acid as suspension medium for the last one. Although copper could not be determined in the certied reference material using microwave-assisted digestion, the accuracy of the slurry sampling method was veried for all the investigated analytes. Detection limits were 22.8 8.0, 0.884 0.092, 5.07 0.76, 35.5 0.7 and 1.17 0.04 g g1 for calcium, copper, iron, magnesium and zinc, respectively. The standard deviations obtained using slurry sampling method and microwave-assisted digestion were not signicantly different, and the mean relative standard deviation of the over-all method (n = 3) of the slurry sampling method for different concentration levels was below 12%. 2006 Elsevier B.V. All rights reserved.

Keywords: Slurry sampling; Microwave-assisted digestion; Calcium, magnesium, iron, copper and zinc determination; Fish tissue samples; Flame atomic absorption spectrometry

1. Introduction The most time consuming step in solid materials analysis is often sample treatment. Several procedures have been developed for elements determination by atomic spectrometric techniques, in order to short the analysis time and to minimize the problems associated with solid sample treatment (conventional wet acid digestion and dry-ashing), such as sample contamination and analyte loss. So, alkaline [13] and acid [311] digestion methods assisted by microwave [38,10,11] or ultrasound [24,8,9]

Corresponding author. Present address: Estaci on de Viticultura y Enolog a de Galicia, Ponte San Clodio s/n, Leiro, 32427 Ourense, Spain. Tel.: +34 988 488033; fax: +34 988 488191. E-mail address: evegadoc2@cesga.es (S.R. Segade).

energy (involve complete or partial matrix solubilization) permit to short the time required for sample treatment. Furthermore, direct solid sampling offers several advantages, including the minimization of the sample handling and, as a consequence, the reduction of the risks previously mentioned [1215]. The slurry sampling technique has been extensively used for the determination of trace elements in biological and environmental solid samples by electrothermal atomic absorption spectrometry (ETAAS) [4,6,8,1620]. This approach combines the advantages of both liquid and direct solid sampling. However, it is important to emphasize that slurry homogeneity must be preserved during the time required for sample introduction into the atomizer. Furthermore, the particle size affects accuracy and precision. Anyway, literature has been also published in the last years on the analysis of biological [8,21,22] and inorganic [2326] solid samples by slurry sampling ame atomic absorp-

0039-9140/$ see front matter 2006 Elsevier B.V. All rights reserved. doi:10.1016/j.talanta.2006.09.023

R.A. Bugallo et al. / Talanta 72 (2007) 6065

61

tion spectrometry (FAAS) in spite of the continuous aspiration of the slurry, which affects atomization efciency. In this context, some investigations have been realized in order to improve the transport of the solid particles to the ame and, therefore, the atomization efciency of the analytes from the slurry. The four principal proposals were the use of special nebulizers [21,27], the addition of wetting agents [28], the acid extraction of analyte into the liquid phase [21] or the use of ow injection systems for the introduction of slurried solid samples into the ame [22,23,25,26]. Most of the methods for determining elements in biological samples by FAAS are based on microwave-assisted acid digestion. In this paper, a method has been developed for the determination of calcium, copper, iron, magnesium and zinc in sh tissue samples by slurry sampling FAAS, using a conventional nebulizer. Very few works have been reported in relation to the analysis of sh tissue samples by the combination of both techniques [8]. The main aims proposed were to short the time required for sample treatment, to avoid the problems related with sample decomposition and to achieve quantication limits suitable for the determination of element concentration present in sh from high sea. The effect of the suspension medium and a novel microwave-assisted slurry treatment was studied, being tested not only the most commonly used acid medium, but also alkaline medium and a complexing agent. Moreover, the inuence of the addition of glycerol as wetting agent and the slurry concentration was also evaluated. The results so obtained for all the tuna samples analyzed were compared with those obtained by means of microwave-assisted acid digestion in order to emphasize the advantages of the proposed method. 2. Experimental

priately diluting the stock standard solutions. Diluted nitric acid, diluted hydrochloric acid, disodium ethylenediaminetetraacetate solution, sodium hydroxide solution and diluted hydrogen peroxide were used for the slurry preparation by adding glycerol as dispersing agent. Concentrated nitric acid was also used in combination with hydrogen peroxide for solid samples digestion. The comestible part of the tuna samples (IIII) was oven dried at 50 C for 48 h to constant weight and ground. The powdered sample with particle size less than 70 m was selected by sieving (nylon sieves) for analysis and stored at room temperature in polyethylene bottles in a desiccator. A certied reference material was used to validate the proposed method. The NCS ZC 80006 (prawn) was obtained from the China National Analysis Center for Iron and Steel. 2.3. Microwave-assisted acid digestion procedure A microwave-assisted wet decomposition of sh tissue samples was performed according to a slightly modied procedure [29]. About 0.1 g of tuna sample were digested with 4 ml of concentrated nitric acid in a Parr reactor by heating in a microwave oven at 510 W for 60 s. After cooling to room temperature in an ice bath, the reactor was opened and the digested sample was after treated with 2 ml of concentrated hydrogen peroxide in the closed reactor by microwave irradiation at 510 W for 120 s. The resulting solution was partially evaporated and quantitatively transferred into a 10 ml calibrated ask, where it was diluted to volume with deionized water. Blanks were prepared with the same reagents undergoing a similar treatment. Finally, all solutions were stored in polyethylene bottles at 4 C. 2.4. Slurry preparation procedure

2.1. Instrumentation The slurry treatment was performed with a Moulinex (Barcelona, Spain) 900 W microwave oven. A Selecta (Barcelona, Spain) Model Agimatic-N magnetic stirrer was used to homogenize the slurry. A Kubota (Tokyo, Japan) Model 5100 centrifuge was employed for the separation of the liquid phase from the slurried samples. The solid materials were also acid digested in a Parr (Moline, IL, USA) Model 4782 mediumpressure reactor heated by the above-mentioned microwave oven. A Perkin-Elmer (Norwalk, CT, USA) Model 2380 atomic absorption spectrometer equipped with an acetylene-air ame was used for element determination. Cathodeon hollow-cathode lamps were used as the radiation source. The instrumental parameters used were those recommended by the manufacturer. 2.2. Reagents, samples and reference material All chemicals used were of analytical reagent grade (Merck, Darmstadt, Germany) and deionized water was used throughout the experiments. The stock standard solutions (1000 mg l1 ) were prepared from pure metal (copper, iron, magnesium and zinc) or from high purity calcium carbonate salt (calcium). Working standard solutions were prepared daily by approA 3300 mg portion of tuna sample was weighed into a 50 ml polyethylene tube and 1050 ml of 0.13 mol dm3 hydrochloric acid, 0.071.5 mol dm3 nitric acid, 0.051 mol dm3 sodium hydroxide, 0.053% (m/v) disodium ethylenediaminetetraacetate or 15% (m/v) hydrogen peroxide containing 0.13% (v/v) glycerol were added. The slurry was homogenized by magnetic stirring for 5 min. When nitric acid was employed as suspension medium, the slurry was microwave irradiated at 75400 W for 560 s and, before aspirating, again homogenized by magnetic stirring. The supernatant liquid was separated from the slurried tuna sample by centrifugation at 2500 rpm for 5 min in order to check extraction efciency of the suspension medium. Blanks were prepared with the same reagents undergoing a similar treatment. 3. Results and discussion 3.1. Optimization of suspension medium The atomization efciency for the elements studied from slurried tuna samples was evaluated by comparison of the absorbance values with those obtained from an aqueous standard. The tuna sample suspended in deionized water and the

62

R.A. Bugallo et al. / Talanta 72 (2007) 6065

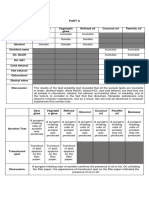

Table 1 Initial and optimum parameters for calcium, copper, iron, magnesium and zinc determination using slurry sampling Parameter Initial Suspension medium Medium concentration (mol dm3 ) Suspension medium volume (cm3 ) Glycerol concentration (%, v/v) Sample amount (mg) Optimum Suspension medium Medium concentration (mol dm3 ) Suspension medium volume (cm3 ) Microwave time (s) Microwave power (W) Glycerol concentration (%, v/v) Sample amount (mg) Ca HNO3 0.15 10 0.3 100 HNO3 0.15 10 15 123 0.3 40 Cu HNO3 0.15 10 0.3 150 HCl 0.10 10 0.3 150 Fe HNO3 0.15 10 0.3 150 HNO3 0.15 10 30 285 0.3 150 Mg HNO3 0.15 50 0.3 50 HNO3 0.15 50 15 75 0.3 3 Zn HNO3 0.15 10 0.3 100 HNO3 0.15 10 15 75 0.3 100

aqueous standard solution were prepared to contain the same analyte concentration. The absorbance signals obtained for all elements from slurried tuna sample were less than those corresponding to the aqueous standard, except for magnesium. The effect of nebulization ow-rate and air/acetylene ow-rates relation on the atomization efciency from the slurry was investigated. Maximum atomization efciency from both the slurry and the aqueous standard was 0.1, 0.02, 0.2, 0.9 and 0.08 for calcium, copper, iron, magnesium and zinc, respectively. The instrumental conditions selected were those corresponding to maximum sensitivity for all elements from aqueous standard solutions. Some investigators have reported that partial extraction of several analytes into the liquid phase improves the precision and accuracy of slurry sampling ETAAS [30]. Moreover, slurry sampling could be replaced by supernatant liquid sampling when the analytes were quantitatively extracted in the suspension medium. Further advantages were the elimination of stirring systems and stabilizing agents since a homogeneous distribution of solid particles was not necessary [31]. In this sense, suspension medium was evaluated in order to establish: (i) the percentage of analyte recovered by the slurry sampling technique in relation to the analyte concentration determined using the microwave-assisted acid digestion procedure; (ii) the extraction efciency of analyte from the slurry into the liquid phase; (iii) the presence of matrix effects. The initial parameters are shown in Table 1. The suspension medium investigated was hydrochloric acid (as acid medium), sodium hydroxide (as alkaline medium) and disodium ethylenediaminetetraacetate (as complexing medium). All determinations were carried out by triplicate using a tuna sample. Fig. 1 shows that quantitative calcium recovery was achieved using either disodium ethylenediaminetetraacetate concentrations equal to or less than 0.5% (m/v) or hydrochloric acid concentrations comprised between 0.5 and 1 mol dm3 . Taking into account that both the greatest slopes of standard addition lines corresponded to the use of disodium ethylenediaminetetraacetate (0.007580.0113 l mg1 ) and absorbance values obtained for reagent blank increased with increasing complexing agent concentration from 0.5% (m/v), the suspension medium selected

Fig. 1. Effect of %disodium ethylenediaminetetraacetate (m/v) ( ), hydrochloric acid (mol dm3 ) ( ) and sodium hydroxide (mol dm3 ) ( ) on recovery of calcium, copper, iron, magnesium and zinc.

R.A. Bugallo et al. / Talanta 72 (2007) 6065

63

was 0.05% (m/v) disodium ethylenediaminetetraacetate. Furthermore, the inuence of pH value of disodium ethylenediaminetetraacetate on calcium recovery was also investigated. So, an increase in pH value caused calcium amount recovered to decrease, obtaining a calcium recovery of 68% for a pH value of 9. This effect was veried by the use of ammonium chloride/ammonium hydroxide buffer solution or sodium hydroxide concentrations higher than 0.05 mol dm3 as suspension medium, which gave calcium recoveries of 41 and 74%, respectively. The effect of disodium ethylenediaminetetraacetate and sodium hydroxide concentrations on copper recovery was not signicant. Moreover, pH value of disodium ethylenediaminetetraacetate solution had no inuence on copper amount recovered. Fig. 1 shows quantitative copper recoveries only for hydrochloric acid concentrations ranging from 0.1 to 1 mol dm3 . As the maximum slope of standard addition line was attained using 0.1 mol dm3 hydrochloric acid (0.131 l mg1 ), this suspension medium was chosen. The maximum iron recovery (42%) corresponded to hydrochloric acid concentrations comprised between 0.1 and 1 mol dm3 , 0.05 mol dm3 sodium hydroxide or 0.5% (m/v) disodium ethylenediaminetetraacetate, as can be observed in Fig. 1. The alkalinization of the complexing agent or the use of sodium hydroxide concentrations higher than 0.05 mol dm3 caused an important reduction of iron amount recovered. The slopes of external calibration and standard addition lines obtained for iron were not statistically different (t-test; p = 0.05) for the sample slurried in 0.51 mol dm3 hydrochloric acid or 0.053% (m/v) disodium ethylenediaminetetraacetate (0.03830.0400 l mg1 ). Therefore, 0.5 mol dm3 hydrochloric acid could be selected as optimum suspension medium. Fig. 1 shows that magnesium recovery depended on the suspension medium used. Quantitative recoveries were obtained for hydrochloric acid concentrations comprised between 0.1 and 1 mol dm3 , followed by those (67%) corresponding to the use of disodium ethylenediaminetetraacetate concentrations ranging from 0.05 to 2% (m/v). The last ones were maintained practically constant when the solution was alkalinized. However, sodium hydroxide concentrations within the range 0.050.1 mol dm3 or ammonium chloride/ammonium hydroxide buffer solution permitted to obtain magnesium recoveries of 68%. On the other hand, insignicant absorbance signals corresponding to reagent blank and no signicant difference (t-test; p = 0.05) between the slopes of external calibration and standard addition lines (0.647 l mg1 ) were found when low hydrochloric acid concentrations were used as suspension medium. Thus, the suspension medium chosen was 0.1 mol dm3 hydrochloric acid. The inuence of suspension medium on zinc recovery is shown in Fig. 1. So, the use of disodium ethylenediaminetetraacetate concentrations equal to or higher than 0.5% (m/v) or hydrochloric acid concentrations equal to or less than 1 mol dm3 permitted to achieve quantitative recoveries for zinc. The alkalinization of disodium ethylenediaminetetraacetate solution caused the diminution of zinc amount recovered, which was veried by the suspension of the sample in either sodium hydroxide or ammonium chloride/ammonium

hydroxide buffer solution. The slope of standard addition line obtained for both acid and complexing suspension medium was 0.162 l mg1 . Taking into account that low absorbance values were obtained for reagent blank when 0.1 mol dm3 hydrochloric acid was employed, this suspension medium was selected. The concentrations found in the tuna slurry are in accordance with those found in the supernatant liquid for all analytes determined, achieving recoveries higher than 96% in the last one in relation to the concentrations determined in the slurried samples. 3.2. Microwave-assisted suspension treatment The low recoveries obtained for iron and the presence of matrix interferences for calcium, copper and zinc led to the optimization of a microwave-assisted treatment of slurried tuna sample in order to achieve greater matrix decomposition degree. Nitric acid is adequate for microwave-assisted treatments, because of its capability to absorb efciently microwave energy and it is one of the most widely used reagents for biological samples treatment because of its oxidant properties. The effect of nitric acid concentration on calcium, copper, iron, magnesium and zinc recovery was investigated and the results can be seen in Fig. 2. Calcium, copper and magnesium recovery remained practically constant for nitric acid concentrations between 0.07 and 0.7 mol dm3 . Although magnesium recovery was quantitative for a nitric acid concentration of 1.5 mol dm3 , the absorbance values obtained for reagent blank were also high. On the other hand, iron recovery decreased slightly and zinc recovery increased markedly when nitric acid concentration was increased from 0.07 to 0.15 mol dm3 and both recoveries kept constant for higher nitric acid concentrations. Thus, the slopes of standard addition lines obtained using nitric acid as suspension medium were 0.00935, 0.139, 0.0280, 0.668 and 0.195 l mg1 for calcium, copper, iron, magnesium and zinc, respectively. The slopes of external calibration and standard addition lines were signicantly different (t-test; p = 0.05) for calcium, copper and iron. 0.15 mol dm3 (1%, v/v) nitric acid was selected for further experiments. The same concentration was previously used by other authors for metals determination in human scalp hair by slurry sampling FAAS [21].

Fig. 2. Effect of nitric acid concentration on recovery of: calcium (), copper (), iron ( ), magnesium ( ) and zinc ( ).

64

R.A. Bugallo et al. / Talanta 72 (2007) 6065 Table 2 Calcium, copper, iron, magnesium and zinc concentration (g g1 ) in the certied reference material using microwave-assisted digestion and slurry sampling methods Element Ca Cu Fe Mg Zn

a b c d

Microwave heating times between 5 and 60 s were optimized at 75 W power. Calcium and iron recoveries increased with increasing microwave time up to 15 and 30 s, respectively. However, the effect of microwave time on copper, magnesium and zinc recoveries was not signicant. Then, in another experiment the inuence of different microwave powers (75400 W) on analyte recovery revealed that maximum recoveries were obtained for calcium (88.1%), copper (55.1%), iron (94.5%), magnesium (85.6%) and zinc (97.9%) when microwave powers ranging 123285, 75, 285400, 75170 and 75170 W, respectively, were employed. The microwave-assisted slurry treatment permitted to avoid matrix interferences for iron because of both slopes of external calibration and standard addition lines were in good agreement (t-test; p = 0.05). Furthermore, the slope of standard addition line for copper increased when microwave energy was applied to the slurry heating. The effect of the addition of hydrogen peroxide to nitric acid suspension medium was also investigated for calcium, copper, iron, magnesium and zinc. However, recoveries and slopes of standard addition lines remained practically constant for all ones when hydrogen peroxide in the range of concentrations from 1 to 5% (m/v) was added. After selecting the optimum conditions for each element (Table 1), glycerol concentration (0.13%, v/v) and sample amount slurried (3300 mg) were evaluated. Thus, the effect of wetting agent concentration on recovery and slope of standard addition line for all elements studied was not signicant. While the sample amount slurried negatively affected to magnesium and zinc recoveries for values higher than 6 and 100 mg, respectively, or to calcium and zinc sensitivity for values higher than 45 and 100 mg, respectively. On the other hand, an analyte extraction percentage into the liquid phase of the slurry close to 100% was reached for all elements. 3.3. Validation of the method The proposed method was validated by the analysis of one biological reference material using the optimum experimental conditions described in Table 1. External calibration with a series of aqueous standards was applied to iron, magnesium and zinc determination. However, standard addition method was applied to calcium and copper determination because of the slope of external calibration line was signicantly different with that corresponding to standard addition line (t-test; p = 0.05). The sample was analyzed 10 times. The results obtained for calcium, copper, iron, magnesium and zinc concentration in the certied reference material by slurry sampling method and the certied values are shown in Table 2. It can be observed that the concentrations found of each ones were in good agreement with the certied values (t-test; p = 0.05). 3.4. Analysis of sh tissue samples Three tuna tissue samples (IIII) were analyzed by triplicate using both microwave-assisted digestion and slurry sampling methodologies. The results obtained for calcium, copper, iron, magnesium and zinc determination are shown in Table 3. Recov-

Certied valuea 3040 4.66 19.8 1600 60.8 60 0.23 0.4 30 1.4

Obtained valuea,b,c 3100 4.58 19.6 1602 60.5 50 0.19 0.3 7 0.6

Obtained valuea,b,d 3008 25 <LOD 19.4 0.2 1586 6 61.2 0.7

Average value standard deviation. n = 10. Results obtained using the slurry sampling. Results obtained using the microwave-assisted digestion.

ery was calculated as quotient between concentrations determined using slurry sampling and microwave-assisted digestion methodologies. Absorbance signals for copper in microwave-assisted digested tuna samples were not detected by the FAAS technique owing to the necessity for the treatment of little sample amounts in pressurized reactors. So, copper concentrations determined using both methodologies could not be compared. The mean relative standard deviation of the over-all method (n = 3) for different concentration levels was 11.1%. The slopes of standard addition lines (0.1250.162 l mg1 ) were signicantly higher than those corresponding to external calibration lines (t-test; p = 0.05), which permitted to determine lower concentrations of copper. There were not signicant differences between calcium, iron, magnesium and zinc concentrations obtained using both slurry sampling and microwave-assisted digestion methodologies

Table 3 Calcium, copper, iron, magnesium and zinc concentration (g g1 ) in three tuna tissue samples using microwave-assisted digestion and slurry sampling methods Element Sample I Ca Cu Fe Mg Zn Sample II Ca Cu Fe Mg Zn Sample III Ca Cu Fe Mg Zn

a b c d

Obtained valuea,b,c 283 12.0 21.0 1708 16.7 233 6.99 48.1 1304 16.2 713 3.73 58.8 1224 37.2 18 1.5 1.8 25 0.9 10 0.63 2.5 20 1.1 37 0.44 2.7 10 0.9

Obtained valuea,b,d 277 11 <LOD 22.0 3.3 1741 5 15.0 1.2 243 8 <LOD 47.6 5.2 1331 7 16.6 0.6 728 15 <LOD 59.4 2.1 1174 13 34.9 1.9

Recovery (%) 102 95.5 98.1 111 95.9 101 98.0 97.6 97.9 99.0 104 107 6 8.2 1.4 6 4.1 5 1.5 6.6 5.1 4.6 1 3

Average value standard deviation. n = 3. Results obtained using the slurry sampling. Results obtained using the microwave-assisted digestion.

R.A. Bugallo et al. / Talanta 72 (2007) 6065

65

(t-test; p = 0.05). Furthermore, the standard deviations obtained for calcium, iron, magnesium and zinc using both methodologies were not signicantly different (F-test; p = 0.05) and mean relative standard deviations of the over-all method (n = 3) for different concentration levels were 5.3, 6.1, 1.3 and 4.9% for calcium, iron, magnesium and zinc, respectively, by slurry sampling. Calcium, iron, magnesium and zinc recoveries were greater than 95%. Finally, 10 tuna tissue samples were analyzed using slurry sampling and standard addition method in order to check the absence of matrix interferences on iron, magnesium and zinc determination by comparing the slopes associated with standard addition lines and with external calibration lines. The differences between both slopes were only signicant (t-test; p = 0.05) for iron determination in some tuna samples (0.02510.0389 l mg1 ). As expected, external calibration with aqueous standards can be used for magnesium and zinc determination. The slopes of standard addition lines for calcium varied between 0.00881 and 0.0186 l mg1 . The detection limits based on the amount necessary to yield a net signal equal to three times the standard deviation of the blank were 22.8 8.0, 0.884 0.092, 5.07 0.76, 35.5 0.7 and 1.17 0.04 g g1 for calcium, copper, iron, magnesium and zinc determination, respectively. It should be noted that the detection limits obtained by the proposed method for copper and zinc are 34 times less than those reported for other slurry sampling FAAS approaches [21]. Therefore, the slurry sampling method proposed in this work permits to spread the application eld to the analysis of sh samples from high sea containing lower copper and zinc concentrations than those found in human scalp hair samples. 4. Conclusions Slurry sampling was compared with microwave-assisted acid digestion for the determination of calcium, copper, iron, magnesium and zinc in sh tissue samples by ame atomic absorption spectrometry. The main advantages of using slurry sampling are the elimination of a tedious and time-consuming step of sample dissolution and quantitative extraction of all analytes studied into the liquid phase of the slurry. Unlike the microwaveassisted digestion method, in which sample amount is limited, long times are required for cooling the digestion vessel after the microwave irradiation and concentrated acids are used, involving high blank values, sampling of the liquid phase present in slurried samples, after microwave irradiation except for copper, does not require stabilizing agents nor nely ground material without nebulizer blockage. The accuracy of both methods was checked using a certied reference material. The results obtained were in good agreement with the certied values for all chosen analytes when slurry sampling method was used. The precision (R.S.D.) was less than 5.3, 11.1, 6.1, 1.3 and

4.9% for calcium, copper, iron, magnesium and zinc at concentration ranging of 233713, 3.7312.0, 21.058.8, 12241708 and 16.237.2 g g1 , respectively. Furthermore, the results obtained using slurry technique were not signicantly different with those corresponding to microwave-assisted digestion for calcium, iron, magnesium and zinc in the sh samples analyzed. References

[1] D. Pozebon, V.L. Dressler, A.J. Curtius, J. Anal. Atom. Spectrom. 13 (1998) 1101. [2] R.G.L. Silva, S.N. Willie, R.E. Sturgeon, R.E. Santelli, S.M. Sella, Analyst 124 (1999) 1843. [3] L.M. Costa, S.T. Gouveia, J.A. Nobrega, Anal. Sci. 18 (2002) 313. [4] E.C. Lima, F. Barbosa Jr., F.J. Krug, M.M. Silva, M.G.R. Vale, J. Anal. Atom. Spectrom. 15 (2000) 995. [5] P.R.M. Correia, E. Oliveira, P.V. Oliveira, Anal. Chim. Acta 405 (2000) 205. [6] B. P erez Cid, C. Silva, C. Boia, Anal. Bioanal. Chem. 374 (2002) 477. [7] J. Sastre, A. Sahuquillo, M. Vidal, G. Rauret, Anal. Chim. Acta 462 (2002) 59. [8] P. Bermejo Barrera, A. Moreda Pi neiro, A. Bermejo Barrera, Talanta 57 (2002) 969. [9] M.C. Yebra, A. Moreno Cid, R.M. Cespon, S. Cancela, Atom. Spectrosc. 24 (2003) 31. [10] K. Eilola, P. Per am aki, Analyst 128 (2003) 194. [11] E.C. Lima, J.L. Brasil, A.H.D.P. Santos, Anal. Chim. Acta 484 (2003) 233. [12] E. L ucker, K. Failing, T. Schmidt, Fresen. J. Anal. Chem. 366 (2000) 137. [13] E.M.M. Flores, A.B. da Costa, J.S. Barin, V.L. Dressler, J.N.G. Paniz, A.F. Martins, Spectrochim. Acta 56B (2001) 1875. [14] M.G.R. Vale, M.M. Silva, B. Welz, R. Nowka, J. Anal. Atom. Spectrom. 17 (2002) 38. [15] E.M.M. Flores, J.N.G. Paniz, A.P.F. Saidelles, E.I. M uller, A.B. da Costa, J. Anal. Atom. Spectrom. 18 (2003) 769. [16] E.C. Lima, F.J. Krug, A.T. Ferreira, F. Barbosa Jr., J. Anal. Atom. Spectrom. 14 (1999) 269. [17] M. Gonz alez, M. Gallego, M. Valc arcel, Talanta 48 (1999) 1051. [18] P. Bermejo Barrera, A. Moreda Pi neiro, J. Moreda Pi neiro, T. Kauppila, A. Bermejo Barrera, Atom. Spectrosc. 21 (2000) 5. [19] S.J. Huang, S.J. Jiang, Analyst 125 (2000) 1491. [20] E.C. Lima, F. Barbosa, F.J. Krug, J. Fresenius, Anal. Chem. 369 (2001) 496. [21] P. Bermejo Barrera, A. Moreda Pi neiro, J. Moreda Pi neiro, A. Bermejo Barrera, Fresen. J. Anal. Chem. 360 (1998) 707. [22] P. Jacob, H. Berndt, J. Anal. Atom. Spectrom. 17 (2002) 1615. [23] M.A. Bautista, C. P erez Sirvent, I. L opez Garc a, M. Hern andez C ordoba, Fresen. J. Anal. Chem. 350 (1994) 359. [24] J.H. Brown, J.E. Vaz, Z. Benzo, M. Velosa, Analyst 120 (1995) 1215. [25] M.D. de Almeida, K.C. Leandro, C.V. da Costa, R.E. Santelli, M. de la Guardia, J. Anal. Atom. Spectrom. 12 (1997) 1235. [26] J.A. Sweileh, Anal. Chim. Acta 448 (2001) 151. [27] N. Mohamed, R.C. Fry, Anal. Chem. 53 (1981) 450. [28] J. Stupar, R. Ajlec, Analyst 107 (1982) 144. [29] S. R o Segade, C. Bendicho, Ecotoxicol. Environ. Saf. 42 (1999) 245. [30] N.J. Miller-Ihli, J. Anal. Atom. Spectrom. 9 (1994) 1129. [31] I. Lavilla, J.L. Capelo, C. Bendicho, Fresen. J. Anal. Chem. 363 (1999) 283.

S-ar putea să vă placă și

- Manual de Operare Modernizare Instalatie Cocsare Rev 0Document237 paginiManual de Operare Modernizare Instalatie Cocsare Rev 0Amy Loredana100% (1)

- 1 s2.0 S0009250909005065 Main PDFDocument9 pagini1 s2.0 S0009250909005065 Main PDFAmy LoredanaÎncă nu există evaluări

- Jocurile Foamei Catching Fire PDFDocument382 paginiJocurile Foamei Catching Fire PDFAmy Loredana94% (17)

- 1 s2.0 S002245961200271X Main PDFDocument8 pagini1 s2.0 S002245961200271X Main PDFAmy LoredanaÎncă nu există evaluări

- 1 s2.0 S0926860X13005541 Main PDFDocument11 pagini1 s2.0 S0926860X13005541 Main PDFAmy LoredanaÎncă nu există evaluări

- Vascular Function and Morphology in RheumatoidDocument15 paginiVascular Function and Morphology in RheumatoidMihaela IonescuÎncă nu există evaluări

- 1 s2.0 S0024320505002122 MainDocument9 pagini1 s2.0 S0024320505002122 MainAmy LoredanaÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Double Your Income-Hustle & ConquerDocument54 paginiDouble Your Income-Hustle & ConquerHamza ElmoubarikÎncă nu există evaluări

- Blinding Guideline EssentialsDocument13 paginiBlinding Guideline EssentialsAbdullah Dinsuhaimi100% (1)

- 978 0 387 95864 4Document2 pagini978 0 387 95864 4toneiamÎncă nu există evaluări

- Articol Indicatori de PerformantaDocument12 paginiArticol Indicatori de PerformantaAdrianaMihaiÎncă nu există evaluări

- Results and Discussion of Lipid Solubility, Identification, and AnalysisDocument5 paginiResults and Discussion of Lipid Solubility, Identification, and AnalysisStarrrÎncă nu există evaluări

- Chapter 1Document19 paginiChapter 1Shehzana MujawarÎncă nu există evaluări

- Total Chrom TutorialDocument94 paginiTotal Chrom TutorialRachelHechanovaÎncă nu există evaluări

- WWWWWW WWWWWW WWWWWW WWWWWW WWWW WWWW WWWWWW: Data Transformation With DplyrDocument2 paginiWWWWWW WWWWWW WWWWWW WWWWWW WWWW WWWW WWWWWW: Data Transformation With DplyrManuel HerreraÎncă nu există evaluări

- Anti-Photo and Video Voyeurism Act SummaryDocument3 paginiAnti-Photo and Video Voyeurism Act SummaryHan SamÎncă nu există evaluări

- Socio-Economic and Government Impact On Business: Lesson 4.4Document18 paginiSocio-Economic and Government Impact On Business: Lesson 4.4racelÎncă nu există evaluări

- CLMD4A CaregivingG7 8Document25 paginiCLMD4A CaregivingG7 8Antonio CaballeroÎncă nu există evaluări

- Thermal Engineering Lesson Plan for Mechanical Engineering StudentsDocument3 paginiThermal Engineering Lesson Plan for Mechanical Engineering StudentsblessyÎncă nu există evaluări

- CAE Reading and Use of English 4Document4 paginiCAE Reading and Use of English 4Marina MeirelesÎncă nu există evaluări

- Consultancy Project Assessment SheetDocument1 paginăConsultancy Project Assessment SheetSadeeqÎncă nu există evaluări

- DuPont Shift Schedule ExplainedDocument3 paginiDuPont Shift Schedule ExplainedHanzÎncă nu există evaluări

- Hubungan Kelimpahan Dan Keanekaragaman Fitoplankton Dengan Kelimpahan Dan Keanekaragaman Zooplankton Di Perairan Pulau Serangan, BaliDocument12 paginiHubungan Kelimpahan Dan Keanekaragaman Fitoplankton Dengan Kelimpahan Dan Keanekaragaman Zooplankton Di Perairan Pulau Serangan, BaliRirisÎncă nu există evaluări

- Annex 2.1: Contingency Plan Template For SchoolDocument21 paginiAnnex 2.1: Contingency Plan Template For SchoolJapeth PurisimaÎncă nu există evaluări

- M S Ramaiah Institute of Technology Department of CIVIL ENGINEERINGDocument10 paginiM S Ramaiah Institute of Technology Department of CIVIL ENGINEERINGPrashant SunagarÎncă nu există evaluări

- ICICI Securities ReportDocument4 paginiICICI Securities ReportSaketh DahagamÎncă nu există evaluări

- Graduates Constituency Voters Enrollment Form 18Document4 paginiGraduates Constituency Voters Enrollment Form 18DEEPAKÎncă nu există evaluări

- TemperatureDocument5 paginiTemperatureEltierry SoaresÎncă nu există evaluări

- Design of Cities PDFDocument3 paginiDesign of Cities PDFGaming ID100% (2)

- McKinsey & Company Managing Knowledge & LearningDocument3 paginiMcKinsey & Company Managing Knowledge & LearningWidya Wardani100% (2)

- Bba Summer InternshipDocument3 paginiBba Summer InternshipVedanth ChoudharyÎncă nu există evaluări

- Chapter Seven: Activity Analysis, Cost Behavior, and Cost EstimationDocument72 paginiChapter Seven: Activity Analysis, Cost Behavior, and Cost EstimationEka PubyÎncă nu există evaluări

- Introduction To Well ServiceDocument16 paginiIntroduction To Well ServiceDini Nur IslamiÎncă nu există evaluări

- Hashing Concepts in DBMS PDFDocument7 paginiHashing Concepts in DBMS PDFkaramthota bhaskar naikÎncă nu există evaluări

- Week 33 17Document56 paginiWeek 33 17Adam RudnickÎncă nu există evaluări

- Opa An AssDocument8 paginiOpa An Assgvkreddyg100% (1)

- MCQ | Cryptography Hash FunctionsDocument3 paginiMCQ | Cryptography Hash Functionsvikes singhÎncă nu există evaluări