Documente Academic

Documente Profesional

Documente Cultură

How to Build a Simple 4x6 Hunting Blind for $125-150

Încărcat de

Julian WeaverTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

How to Build a Simple 4x6 Hunting Blind for $125-150

Încărcat de

Julian WeaverDrepturi de autor:

Formate disponibile

How to Build a

4x6 HUNTING BLIND

Youve built a sturdy platform with the E-Z Bracket system, a 4 x 6 custom blind will fi nish the project nicely. There are many options to make a blind, from a simple box with a roof and windows, to insulated walls, solar-powered LED lighting, carpeting and sliding windows. The safest method of blind construction when dealing with platforms is pre-fabricating the blind on the platform before the legs are installed. Once the basic structure is ready, it is disassembled in sections. The platform is completed and hauled out to the site. Once the platform is in position and anchored, the blind is reassembled on site. These directions will make a simple slanted box blind with a roof, door and windows, utilizing the built-in corner slots on the E-Z Brackets. Additional customizing will be up to you and your budget. This blind was made for about $125-$150.

MATERIALS

(12) 2 x 4 x 8 framing lumber (3) 1 x 2 x 8 furring strips (2) 4 x 8 corrugated roofi ng panels (1) box 1 washer roof nails (1) box 3 framing nails or screws (4) 4 x 8 x plywood sheets (8) 38-16 x 3 carriage bolts with 8 washers (8) 38-16 hex nuts (2) 3 door hinges (1) hook and eye door latch (1) door handle

Since the tallest member of our club is about six-foot tall, the back end of the blind was made to accommodate that height and shortened about six inches toward the front of the blind. This created the slant in the blind to allow rain to ow off the roof. Here are the general directions on creating a 4 x 6 box blind, using the EZBrackets built-in framing pockets: 1. Install the vertical supports of the blind using four framing pockets built in the EZ-Brackets. Bolt the corner framing lumber into EZ-Brackets using carriage bolts, washers and hex nuts. In our blind, we cut 78 rear boards and 72 front boards for 6 of headspace. We also added two vertical supports to create the rear doorframe and front support frame for roof/ window frames. Attach using framing nails or screws. 2. Mark angle of roof line using chalk line from back corners of rear framing boards through back corners of front framing boards. It will be a shallow angle about 7-10 degrees. Cut with angles with circular saw or jigsaw.

1-2

3. Frame horizontal supports of the blind to create shooting rails, window openings, door opening and roof support. Hint: use a chair and measure comfortable shooting heights for shortest hunters to tallest to set rail heights. 4. Cut plywood panels to cover sides, front, back and back door. Attach using framing nails or screws. 5. Add roof support by attaching three 1 x 2 x 8 furring strips to roof frame. Center supports to square roofing panels over blind. Attach using framing nails or screws. 6. Attach roofing with panels overlapping over center support. The channels should be oriented so water will run off the front of the blind. Use washer roof nails to attach to roof framing. 7. Install hinges, door panel, door handle and hook and eye latch to blind. 8. Disassemble blind in sections, i.e. front and panels, left and right panels and roof. 9. Transport to site and reassemble on platform. Once installed, make sure to check on the structure every season and repair/replace any wood or worn hardware. Make sure the platform is anchored solidly. Enjoy your elevated blind and dont forget to introduce someone new to the hunting heritage. P.J. Perea

S-ar putea să vă placă și

- Your Cabinin The WoodsDocument280 paginiYour Cabinin The WoodsJuan Martin Gomez0% (1)

- Deluxe Tree House Plans PDFDocument19 paginiDeluxe Tree House Plans PDFLuis Martinez100% (4)

- Build Your Own Sheds & Outdoor Projects Manual, Fifth Edition: Over 200 Plans InsideDe la EverandBuild Your Own Sheds & Outdoor Projects Manual, Fifth Edition: Over 200 Plans InsideEvaluare: 5 din 5 stele5/5 (1)

- 20 x 30 Cabin Plans Blueprints Construction Drawings 600 sq ft 1 bedroom 1 bath Main With LoftDe la Everand20 x 30 Cabin Plans Blueprints Construction Drawings 600 sq ft 1 bedroom 1 bath Main With LoftÎncă nu există evaluări

- CanoePlansPart1 PDFDocument20 paginiCanoePlansPart1 PDFcockybundoo80% (5)

- FH01JUN CraftsmanShedDocument27 paginiFH01JUN CraftsmanShedjuan100% (3)

- Ultimate Guide: Barns, Sheds & Outbuildings, Updated 4th Edition: Step-by-Step Building and Design Instructions Plus Plans to Build More Than 100 OutbuildingsDe la EverandUltimate Guide: Barns, Sheds & Outbuildings, Updated 4th Edition: Step-by-Step Building and Design Instructions Plus Plans to Build More Than 100 OutbuildingsEvaluare: 3 din 5 stele3/5 (1)

- Ultimate List of 28 DIY Playset PlansDocument45 paginiUltimate List of 28 DIY Playset PlansMikeMeisner67% (3)

- Multipurpose Garden ShedDocument5 paginiMultipurpose Garden ShedEloy Rodriguez100% (1)

- Building the Timber Frame House: The Revival of a Forgotten CraftDe la EverandBuilding the Timber Frame House: The Revival of a Forgotten CraftEvaluare: 3.5 din 5 stele3.5/5 (11)

- DIY Cabin Building Plans PDFDocument6 paginiDIY Cabin Building Plans PDFRoberto Landa100% (5)

- Wichita Cabin Coop2Document81 paginiWichita Cabin Coop2caapromo67% (3)

- Lean ToToolShedDocument18 paginiLean ToToolShedYolohtli Vazquez Castaneda100% (1)

- Shed 10x16 PlansDocument8 paginiShed 10x16 PlansLory Dena Heath100% (1)

- Building A Garden Shed Step By Step Instructions and PlansDe la EverandBuilding A Garden Shed Step By Step Instructions and PlansEvaluare: 2 din 5 stele2/5 (1)

- Easy DIY Garden Shed Plans - 1Document4 paginiEasy DIY Garden Shed Plans - 1Fred Mirtz100% (1)

- Build Low Cost Cabin Just $1,000 Five DaysDocument3 paginiBuild Low Cost Cabin Just $1,000 Five Daysmondomondo75% (4)

- Lean To PlanDocument7 paginiLean To PlandimfoÎncă nu există evaluări

- Sample Plans PDFDocument40 paginiSample Plans PDFMichal SlavíčekÎncă nu există evaluări

- How To Build A 12’ x 16’ Pole Barn Chicken Coop Instructions and PlansDe la EverandHow To Build A 12’ x 16’ Pole Barn Chicken Coop Instructions and PlansEvaluare: 5 din 5 stele5/5 (1)

- Butt and Pass Log Cabin BuildDocument64 paginiButt and Pass Log Cabin BuildJP VersterÎncă nu există evaluări

- Build ADIYLaminatorDocument22 paginiBuild ADIYLaminatoredwin delgado riosÎncă nu există evaluări

- Farm BuildingsDocument198 paginiFarm Buildingsredneckrepairs100% (1)

- Yurt Construction DocumentDocument26 paginiYurt Construction DocumentsepaulsenÎncă nu există evaluări

- GP DeerBlind Installation 09102012Document2 paginiGP DeerBlind Installation 09102012bnorth11100% (4)

- Building-a-16x24-pole-barn-plansDocument38 paginiBuilding-a-16x24-pole-barn-plansPB50% (2)

- Pallet Wood WorkbenchesDocument10 paginiPallet Wood WorkbenchesRicardo Fernandes GalliÎncă nu există evaluări

- How To Pour ConcreteDocument11 paginiHow To Pour ConcreteNabil RamehÎncă nu există evaluări

- Build A Log CabinDocument7 paginiBuild A Log Cabineltorro-t50% (2)

- Slatted Outdoor SofaDocument12 paginiSlatted Outdoor SofaJh CtÎncă nu există evaluări

- Trophy Deer Stand Plans 4x6Document8 paginiTrophy Deer Stand Plans 4x6Will Elsenrath60% (5)

- Lakewoods Cottage & Cabin PlansDocument5 paginiLakewoods Cottage & Cabin PlansFrances Sullivan Mayhall67% (3)

- Pico-Light Teardrop Trailer DesignDocument32 paginiPico-Light Teardrop Trailer Designmanolislem100% (3)

- Secret Treehouse Project Zine - Normal LayoutDocument16 paginiSecret Treehouse Project Zine - Normal Layoutrtfscotland50% (2)

- Fences, Gates, and Bridges: And How to Make ThemDe la EverandFences, Gates, and Bridges: And How to Make ThemÎncă nu există evaluări

- By Zach Dean: LayoverDocument109 paginiBy Zach Dean: LayoverRobertÎncă nu există evaluări

- Elevated Deer StandDocument8 paginiElevated Deer StandWill Elsenrath100% (1)

- Gable Shed Building GuideDocument61 paginiGable Shed Building GuideBach Xuan NguyenÎncă nu există evaluări

- Pergolas and TrellisDocument11 paginiPergolas and TrellisPARVATHY R S 170564Încă nu există evaluări

- Wisdom of Great InvestorsDocument15 paginiWisdom of Great Investorsmunia76Încă nu există evaluări

- Wisdom of Great InvestorsDocument15 paginiWisdom of Great Investorsmunia76Încă nu există evaluări

- Build Your Own YurtDocument17 paginiBuild Your Own YurtvronqÎncă nu există evaluări

- How To Build Modern Barstools Like A ProDocument17 paginiHow To Build Modern Barstools Like A Progerman100% (1)

- The Complete Guide to Building Classic Barns, Fences, Storage Sheds, Animal Pens, Outbuilding, Greenhouses, Farm Equipment, & Tools: A Step-by-Step Guide to Building Everything You Might Need on a Small FarmDe la EverandThe Complete Guide to Building Classic Barns, Fences, Storage Sheds, Animal Pens, Outbuilding, Greenhouses, Farm Equipment, & Tools: A Step-by-Step Guide to Building Everything You Might Need on a Small FarmEvaluare: 4 din 5 stele4/5 (1)

- Rotating Barrel ComposterDocument3 paginiRotating Barrel Compostertraction9261Încă nu există evaluări

- How to Build Your Own Shed or Outdoor Erection - A Guide for Anybody Handy with a Tool Kit and Wishing to Build Their Own ShedDe la EverandHow to Build Your Own Shed or Outdoor Erection - A Guide for Anybody Handy with a Tool Kit and Wishing to Build Their Own ShedÎncă nu există evaluări

- WJ088 Garden BenchDocument13 paginiWJ088 Garden BenchOsvaldo Moraes100% (1)

- Ebook Lithium Battery GuidebookDocument29 paginiEbook Lithium Battery GuidebookMilind MohapatraÎncă nu există evaluări

- Building With LogsDocument67 paginiBuilding With Logslibero95100% (2)

- Uzbek English English Uzbek Dictionary and Phrase Book Romanized Hippocrene Dictionary Amp Phrase BooksDocument91 paginiUzbek English English Uzbek Dictionary and Phrase Book Romanized Hippocrene Dictionary Amp Phrase BooksHakan GunesÎncă nu există evaluări

- Free Deer Stand PlansDocument10 paginiFree Deer Stand PlansloktakwahÎncă nu există evaluări

- Silla MaderaDocument12 paginiSilla Maderagmo2189Încă nu există evaluări

- Passive Cooled Wine CellarDocument11 paginiPassive Cooled Wine Cellarrazzuk100% (1)

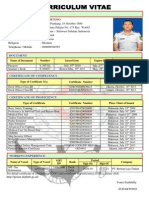

- CV PelautDocument1 paginăCV PelautWesly Rombo Botax100% (5)

- Maximum Allowable Airspeed Indicator Maintenance ManualDocument110 paginiMaximum Allowable Airspeed Indicator Maintenance ManualesedgarÎncă nu există evaluări

- A Complete Guide To Building Your Own Deck PDFDocument16 paginiA Complete Guide To Building Your Own Deck PDFr1greenÎncă nu există evaluări

- Justa Stove PlansDocument18 paginiJusta Stove PlansThomas "Hirudinea" LeechÎncă nu există evaluări

- Is 12592 2002Document17 paginiIs 12592 2002sharmak_anil0% (1)

- Artcl Mortise and Tenon JointsDocument12 paginiArtcl Mortise and Tenon Jointsreader_jim100% (1)

- RadNav Chp16 PBNDocument95 paginiRadNav Chp16 PBNNiyazi Cem GürsoyÎncă nu există evaluări

- A Little Book of Vintage Designs and Instructions for Making Dainty Gifts from Wood. Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box: Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box.De la EverandA Little Book of Vintage Designs and Instructions for Making Dainty Gifts from Wood. Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box: Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box.Încă nu există evaluări

- Second Preboard Exam - MsteDocument8 paginiSecond Preboard Exam - MsteCzatrina QuintasÎncă nu există evaluări

- Transportasi Distribusi MigasDocument25 paginiTransportasi Distribusi MigasDian Permatasari100% (1)

- Chris Flyer PDFDocument1 paginăChris Flyer PDFJulian WeaverÎncă nu există evaluări

- Anton ChigurhDocument1 paginăAnton ChigurhJulian WeaverÎncă nu există evaluări

- KL 2885/11 JUN/FOR-SID: - Not For Real World NavigationDocument31 paginiKL 2885/11 JUN/FOR-SID: - Not For Real World NavigationHenry CalÎncă nu există evaluări

- DabbawalasDocument9 paginiDabbawalasAdil AslamÎncă nu există evaluări

- VHAM - W2 - U2 - ScriptDocument6 paginiVHAM - W2 - U2 - ScriptLinh PhạmÎncă nu există evaluări

- MTO Book 7Document321 paginiMTO Book 7Tony ParkÎncă nu există evaluări

- Highway Eng I, Chapter ThreeDocument87 paginiHighway Eng I, Chapter Threefentawmelaku1993Încă nu există evaluări

- Faa Ad 2021-10-04 R0 Dt. 27 Apr 21Document8 paginiFaa Ad 2021-10-04 R0 Dt. 27 Apr 21Pradeep K sÎncă nu există evaluări

- Sulu PNP Armoured VehicleDocument2 paginiSulu PNP Armoured VehiclePauloHenriqueRibeiroÎncă nu există evaluări

- Sar P01Document46 paginiSar P01Bonsa MitikuÎncă nu există evaluări

- Bollard Pull Calculations - An Introduction (Part I)Document1 paginăBollard Pull Calculations - An Introduction (Part I)Chanaka DilshanÎncă nu există evaluări

- Lleida Alguaire LedaDocument22 paginiLleida Alguaire LedaYaiza BlancoÎncă nu există evaluări

- EGR TuningbotDocument1 paginăEGR TuningbotPablo NuñezÎncă nu există evaluări

- Manual de PartesDocument25 paginiManual de PartesLuis AlegríaÎncă nu există evaluări

- CASE STUDY - JaipurDocument15 paginiCASE STUDY - Jaipurmansi bitoliyaÎncă nu există evaluări

- 3 Green LightsDocument4 pagini3 Green LightsTun HanÎncă nu există evaluări

- Desert Bus Iveco Eurocargo Deniz ModelDocument1 paginăDesert Bus Iveco Eurocargo Deniz ModelkamilÎncă nu există evaluări

- 10.94 TUGAS LATIHAN SOAL Test Formatif M.Muatan ANT 2@49 Ke 26Document7 pagini10.94 TUGAS LATIHAN SOAL Test Formatif M.Muatan ANT 2@49 Ke 26pasisangkatan empatsembilanÎncă nu există evaluări

- Practice Test 4: Explorer's Rainforest Trip and Blind AdventurerDocument6 paginiPractice Test 4: Explorer's Rainforest Trip and Blind AdventurerKhang Nguyen TienÎncă nu există evaluări

- Strahlenfolter - Electronic Harassment - Torture DiaryDocument230 paginiStrahlenfolter - Electronic Harassment - Torture Diary-Targeted-Individuals-Încă nu există evaluări

- Amhara National Regional State Public Procurement and Property Disposal Service (Anrs PPPDS)Document20 paginiAmhara National Regional State Public Procurement and Property Disposal Service (Anrs PPPDS)Eyob LakewÎncă nu există evaluări

- 4X2 Tractor: Build Your Own TruckDocument2 pagini4X2 Tractor: Build Your Own TruckBadrinath RaghavendranÎncă nu există evaluări

- Irc Specifications, Standards, Design CodesDocument14 paginiIrc Specifications, Standards, Design CodesLokeswar SahaÎncă nu există evaluări