Documente Academic

Documente Profesional

Documente Cultură

Stationary Concrete Batching Plant

Încărcat de

Na BoDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Stationary Concrete Batching Plant

Încărcat de

Na BoDrepturi de autor:

Formate disponibile

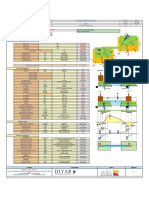

Bona HZS50 Concrete Batching Plant Capacity:50 m3/h Max Aggregate Size:60/80 mm Discharging Height:3800 mm Total Power:80KW Total

Total Weight:40Ton Total Dimensions:182001000019400 mm

Description of Bona stationary concrete batching plant:

Stationary concrete batching plant is the small type product of concrete mixing plant series in Bona

Group, concrete mixers and aggregate lifting use JS1000B type twin-shaft forced type concrete mixer, aggregate batching adopts PLD1600A concrete batching machine, accurate metering and high production efficiency. Suitable for small scale production of construction sites, preformed unit factories and commercial concrete.

Features of Bona HZS50 Concrete Batching Plant: 1 "double composite spiral band" host using iron-chromium alloy wear-resistant materials, its shape and surface are with high shock resistance mechanical strength, good wear-resisting property, its center is with good toughness! Proper working life is 50,000 pots, a substantial increase in product life! 2. The whole plant uses automatic control systems, Siemens PLC, Schneider Electric components, computers and printing integration, simple operation, easy to debug. 3. Pneumatic system is with Taiwan Fusheng well-known air compressor, providing sufficient air supply for the mobile concrete mixing plant . 4. Weighing system adopts international famous brands, weighing accuracy and sensitivity to ensure the quality of concrete. 5. Using section structure, unit modulation, fast installation and debugging and moving is very convenient.

Technical Data of Bona HZS50 Concrete Batching Plant:

Model

HZS50(Bucket type concrete batching plants)

Capacity Mixing system Aggregate feeder Discharging height After-sale service Warranty

25m3/h Twin-shaft concrete mixer Hopper 3900mm Erection & commissioning, operator training 12 months after erection

Concrete mixer Model & Quantity Discharging volume Charging volume Mixing cycle Max. mixing size

JS1000 Concrete Mixer, 1 unit 1000L 1600L 72s 80/60mm

Aggregate batching machine Model & Quantity Storage bins quantity Aggregate scale hopper Aggregate feeding to mixer by

PLD1600, 1 unit 3 or 4 sorts 1600L Hopper

Weighing system Principle & Quantity Water weighing bunker Cement weighing bunker

Force sensor, 1 set 1 unit 1 unit

Control system Type & Quantity

Central control, 1 set

PLC brand Control panel board Electric components Control cabin Size & Quantity High-pressure air system Quantity Air compressor Oil-water separator Solenoid valve

SIEMENS (Optional Part) Buttons, lights, etc Relays, contactors, etc 6m2, 1 unit 1 set 0.6MPa 1 or 2 units 1 or 2 sets

Documentation Spare Parts Operation Guide Maintenance Guide Electrical Diagram Concrete Foundation Projects / Design

1 set 1 set 1 unit 1 unit 1 unit 1 unit

Cement storage and feeding system Cement silo capacity Screw conveyor diameter

Optional parts 50t/60t/80t/ 100t 219mm/273mm

S-ar putea să vă placă și

- RMC Batching PlantDocument20 paginiRMC Batching Plantaditishah20392Încă nu există evaluări

- Checklist Pavement Quality Concrete (PQC) The Work Consists of Providing and Laying 350 MM Thickness Over Prepared SurfaceDocument7 paginiChecklist Pavement Quality Concrete (PQC) The Work Consists of Providing and Laying 350 MM Thickness Over Prepared SurfaceRajneesh BahariÎncă nu există evaluări

- Kia B03 L&T A - BW L1 SPD 1171 2 PDFDocument1 paginăKia B03 L&T A - BW L1 SPD 1171 2 PDFVarunn VelÎncă nu există evaluări

- Construction Equipment 2015Document35 paginiConstruction Equipment 2015miguelÎncă nu există evaluări

- 9078 - 13!02!02 - Pull-Out Testmethod Statement Lot 2 Rev 01Document12 pagini9078 - 13!02!02 - Pull-Out Testmethod Statement Lot 2 Rev 01Avinash LalÎncă nu există evaluări

- Concrete-Boom-Pump-Truck-Plant-Pre-Acceptance ChecklistDocument2 paginiConcrete-Boom-Pump-Truck-Plant-Pre-Acceptance ChecklistTFattahÎncă nu există evaluări

- Reversible Concrete MixerDocument6 paginiReversible Concrete MixerSUPERMIX EquipmentsÎncă nu există evaluări

- 7T04-CS-00-PC-011 R13 Consruction Procedure For Alloy Steel PipingDocument9 pagini7T04-CS-00-PC-011 R13 Consruction Procedure For Alloy Steel PipingMoustafa FaresÎncă nu există evaluări

- 017.JSA - SHE.IV.2013 (Sack Out Water Accumulation of MW)Document3 pagini017.JSA - SHE.IV.2013 (Sack Out Water Accumulation of MW)siswanto sugengÎncă nu există evaluări

- Quotation of Hzs90 Concrete Batching PlantDocument5 paginiQuotation of Hzs90 Concrete Batching PlantZarko LazicÎncă nu există evaluări

- ADOT Asphalt Plant Inspection WorkbookDocument87 paginiADOT Asphalt Plant Inspection Workbookjasimabd100% (1)

- Statement of Construction Method - PACKAGE J - Expansion of Wastewater Treatment Plant (Repaired2)Document23 paginiStatement of Construction Method - PACKAGE J - Expansion of Wastewater Treatment Plant (Repaired2)Lemy ChithuanÎncă nu există evaluări

- Fly Ash Brick Manufacturing PlantDocument5 paginiFly Ash Brick Manufacturing Plantkarthikraja21Încă nu există evaluări

- Rollers BCMDocument15 paginiRollers BCMLokesh SinghÎncă nu există evaluări

- HZS75 Concrete Batching Plant 2Document20 paginiHZS75 Concrete Batching Plant 2zhenheng100% (1)

- Excavator CheckDocument2 paginiExcavator CheckBudi PrayitnoÎncă nu există evaluări

- Vibrotech - Bar Bending & Bar Cutting Machine PDFDocument2 paginiVibrotech - Bar Bending & Bar Cutting Machine PDFMohammed Kashif MasoodÎncă nu există evaluări

- 93840Document20 pagini93840lÎncă nu există evaluări

- Load CellDocument11 paginiLoad CellSiej GoÎncă nu există evaluări

- Cement Feeding SystemDocument2 paginiCement Feeding SystemSUPERMIX EquipmentsÎncă nu există evaluări

- BATCHING PLANT CALIBRATIONDocument10 paginiBATCHING PLANT CALIBRATIONsyed sulemanÎncă nu există evaluări

- Batching PlantDocument12 paginiBatching PlantPratik LikharÎncă nu există evaluări

- 40 Cubic Meter Concrete Batching PlantDocument11 pagini40 Cubic Meter Concrete Batching PlantRanndolf JavierÎncă nu există evaluări

- Civil Store Stock ListDocument32 paginiCivil Store Stock ListfranciscoÎncă nu există evaluări

- Job Procedure For Rock Blasting: Site Grading and Enabling Works For 5 Stream Alumina RefineryDocument9 paginiJob Procedure For Rock Blasting: Site Grading and Enabling Works For 5 Stream Alumina RefineryRishi RajÎncă nu există evaluări

- Batching Plant CalculationDocument3 paginiBatching Plant CalculationSarinÎncă nu există evaluări

- Schedule-J - List of Maintenance Tools and TacklesDocument6 paginiSchedule-J - List of Maintenance Tools and TacklesPrasanna kumar subudhiÎncă nu există evaluări

- Indirect Materials PR-PO Monitoring As of WW19'19Document339 paginiIndirect Materials PR-PO Monitoring As of WW19'19Anonymous jBRLi7Încă nu există evaluări

- GTS 2Document730 paginiGTS 2Aveek SenguptaÎncă nu există evaluări

- Sit E ManagementDocument6 paginiSit E ManagementChathura SrinayakaÎncă nu există evaluări

- Method Statement - Operating Ramdor Barge DC 8 and DC 10Document3 paginiMethod Statement - Operating Ramdor Barge DC 8 and DC 10herlambangÎncă nu există evaluări

- Concrete Batching PlantsDocument6 paginiConcrete Batching PlantsHunaid Elkamushi100% (1)

- Concrete Batching PlantDocument6 paginiConcrete Batching PlantBentara JururundingÎncă nu există evaluări

- Production Method - Process Flow For Rock Crusher PlantDocument5 paginiProduction Method - Process Flow For Rock Crusher Plantmaryannfrancisco16Încă nu există evaluări

- Cavity Wall-Method StatementDocument4 paginiCavity Wall-Method StatementTAHER AMMAR100% (1)

- GRI-GM13 Specification High Density Polyethylene GeomembranesDocument24 paginiGRI-GM13 Specification High Density Polyethylene GeomembranesFauzia Rizky0% (1)

- Godown RequirementsDocument3 paginiGodown RequirementsMaheshwara ReddyÎncă nu există evaluări

- BEACH TECH How To Build A Beach CourtDocument3 paginiBEACH TECH How To Build A Beach Courtinterword222Încă nu există evaluări

- Generator Inspection Checklist: Etwork Evelopment RoupDocument2 paginiGenerator Inspection Checklist: Etwork Evelopment RoupPhel Flores100% (1)

- Commissioning Screw ConveyorDocument3 paginiCommissioning Screw Conveyorrahmankhan823100% (1)

- Waterproofing Treatment and Installation Work Procedure FOR SRA - 03 Raj InfiniaDocument6 paginiWaterproofing Treatment and Installation Work Procedure FOR SRA - 03 Raj InfiniaThink itÎncă nu există evaluări

- Black Bitumen PaintDocument1 paginăBlack Bitumen PaintSUBHOMOYÎncă nu există evaluări

- Commissioning Procedure (Diesel Prime Mover)Document4 paginiCommissioning Procedure (Diesel Prime Mover)Foros IscÎncă nu există evaluări

- Boomlift Operator Checklist: Name: Date: Unit: PmaDocument1 paginăBoomlift Operator Checklist: Name: Date: Unit: PmaIbrahim Bin AhmedÎncă nu există evaluări

- B13058Document21 paginiB13058Syed Ahmedullah HashmiÎncă nu există evaluări

- Kibali 2018 (055 055)Document1 paginăKibali 2018 (055 055)faldoÎncă nu există evaluări

- Erection Instructions For Baghouse FilterDocument13 paginiErection Instructions For Baghouse FilterAnonymous xVCLWJÎncă nu există evaluări

- Shutter MAINDocument22 paginiShutter MAINOvais MunshiÎncă nu există evaluări

- Basic Introduction of Coal Handling SystemDocument7 paginiBasic Introduction of Coal Handling SystemHerman AbdullahÎncă nu există evaluări

- Solid Block Manufacturing ProcessDocument4 paginiSolid Block Manufacturing Processa paul jayakumarÎncă nu există evaluări

- Guidelines From MSRDC PDFDocument15 paginiGuidelines From MSRDC PDFSreekanth SattirajuÎncă nu există evaluări

- Daily Progress ReportDocument24 paginiDaily Progress ReportShaukat Khan0% (1)

- Sequential Control and Automation Project PranuDocument55 paginiSequential Control and Automation Project PranuSai SN KuppaÎncă nu există evaluări

- 1.MS - FoundationDocument11 pagini1.MS - FoundationMalik BilalÎncă nu există evaluări

- MS Erection of PH Activities 63mtr 25.12.21Document8 paginiMS Erection of PH Activities 63mtr 25.12.21AltafÎncă nu există evaluări

- Types: Heavy Equipment Refers To Heavy-DutyDocument11 paginiTypes: Heavy Equipment Refers To Heavy-DutyjackÎncă nu există evaluări

- Bulk Explosive SystemDocument21 paginiBulk Explosive SystemKanhaiya KumarÎncă nu există evaluări

- Fluid Scr24r PremiumDocument2 paginiFluid Scr24r Premiumvenka070% (1)

- Mini Concrete MixerDocument3 paginiMini Concrete MixerNa BoÎncă nu există evaluări

- BonaHZS35 Concrete Mixing PlantDocument3 paginiBonaHZS35 Concrete Mixing PlantBudi SetiadiÎncă nu există evaluări

- Mingchen@Hnlangpu - CN: Address:Room A900,9 Floor, Jinshui District, Zhengzhou City, Henan Province, ChinaDocument3 paginiMingchen@Hnlangpu - CN: Address:Room A900,9 Floor, Jinshui District, Zhengzhou City, Henan Province, ChinaNa BoÎncă nu există evaluări

- 904 TractorDocument5 pagini904 Tractorlangpu2013Încă nu există evaluări

- 950 Wheeled TractorDocument4 pagini950 Wheeled Tractorlangpu2013Încă nu există evaluări

- Soil Brick Making MachineDocument3 paginiSoil Brick Making Machinemixers1Încă nu există evaluări

- Foam Concrete Bricks MachineDocument3 paginiFoam Concrete Bricks MachineNa BoÎncă nu există evaluări

- 504 TractorDocument3 pagini504 Tractorlangpu2013100% (1)

- Cement Brick MachineDocument2 paginiCement Brick MachineNa BoÎncă nu există evaluări

- Fly Ash Brick MachineDocument2 paginiFly Ash Brick MachineNa BoÎncă nu există evaluări

- Fly Ash Brick Making MachineDocument3 paginiFly Ash Brick Making MachineNa Bo100% (1)

- Manual Clay Brick Making MachineDocument4 paginiManual Clay Brick Making Machinemixers1Încă nu există evaluări

- Brick Molding MachineDocument3 paginiBrick Molding MachineNa BoÎncă nu există evaluări

- Bricks Manufacturing MachineDocument3 paginiBricks Manufacturing MachineNa BoÎncă nu există evaluări

- Mini Concrete Mixing PlantDocument4 paginiMini Concrete Mixing PlantNa BoÎncă nu există evaluări

- QMJ4 45Document2 paginiQMJ4 45taike123Încă nu există evaluări

- Automatic Fly Ash Brick Making MachineDocument2 paginiAutomatic Fly Ash Brick Making MachineNa BoÎncă nu există evaluări

- Concrete Batching Mixing PlantDocument4 paginiConcrete Batching Mixing PlantNa BoÎncă nu există evaluări

- Ready Mixed Concrete Mixing PlantDocument4 paginiReady Mixed Concrete Mixing PlantNa BoÎncă nu există evaluări

- Ready Mix Concrete PlantDocument4 paginiReady Mix Concrete PlantNa Bo100% (1)

- Concrete Batching PlantDocument3 paginiConcrete Batching PlantNa BoÎncă nu există evaluări

- Mini Concrete MixerDocument3 paginiMini Concrete MixerNa BoÎncă nu există evaluări

- HZS150 Concrete Batching PlantDocument4 paginiHZS150 Concrete Batching PlantNa BoÎncă nu există evaluări

- Strap Beam Foundations ECPDocument2 paginiStrap Beam Foundations ECPMbark LegdaliÎncă nu există evaluări

- 2023 TVEE AL ResultsDocument80 pagini2023 TVEE AL ResultsArush JamesÎncă nu există evaluări

- M Jayakumar Paper (17142691331)Document12 paginiM Jayakumar Paper (17142691331)N V DhandapaniÎncă nu există evaluări

- Safety Standard For Belt Manlifts: ASME A90.1-2009Document34 paginiSafety Standard For Belt Manlifts: ASME A90.1-2009Marko's Brazon'Încă nu există evaluări

- Time Table (4 Sem Electrical Engineering), Jan-June, 2019Document1 paginăTime Table (4 Sem Electrical Engineering), Jan-June, 2019SubhraJyotiBorahÎncă nu există evaluări

- Plain Mild Steel BarsDocument1 paginăPlain Mild Steel BarsPrabhakar KattulaÎncă nu există evaluări

- ChE 108A Syllabus PDFDocument3 paginiChE 108A Syllabus PDFnadimÎncă nu există evaluări

- ResumeDocument5 paginiResumeRaeyneesha Natguna SingamÎncă nu există evaluări

- CSI Conversion List 1995 vs. 2004 Cross ReferenceDocument16 paginiCSI Conversion List 1995 vs. 2004 Cross ReferenceCarol SantosÎncă nu există evaluări

- Ryan Salvador EstradaDocument5 paginiRyan Salvador EstradaClark InternationalÎncă nu există evaluări

- UNIFLAIR ACCESS FLOOR QUOTEDocument2 paginiUNIFLAIR ACCESS FLOOR QUOTEBaba HansÎncă nu există evaluări

- Managing Ili ProjectsDocument13 paginiManaging Ili ProjectsuncleflowerÎncă nu există evaluări

- Analysis of Appartment BuildingDocument24 paginiAnalysis of Appartment BuildingJay BhavsarÎncă nu există evaluări

- Machinery List Ash ConveyorDocument4 paginiMachinery List Ash ConveyorSyamsu Addi HardinataÎncă nu există evaluări

- Steel Design Calculation For Bridge False WorksDocument10 paginiSteel Design Calculation For Bridge False Worksnelvar2005Încă nu există evaluări

- HVAC Brochure PDFDocument8 paginiHVAC Brochure PDFkollidrÎncă nu există evaluări

- Os C101 PDFDocument46 paginiOs C101 PDFbaratkumrÎncă nu există evaluări

- ACI318-08 Circular Column Design AnalysisDocument6 paginiACI318-08 Circular Column Design Analysisazamislam726537Încă nu există evaluări

- AN18.01 Achieving Best Price Performance Parallel Power SuppliesDocument5 paginiAN18.01 Achieving Best Price Performance Parallel Power SuppliesFarhan ShahÎncă nu există evaluări

- Trelleborg Sealing Solutions - Catalog (2022!07!27 01-05-34 UTC)Document356 paginiTrelleborg Sealing Solutions - Catalog (2022!07!27 01-05-34 UTC)Willian Alexandre SilvaÎncă nu există evaluări

- Hager Pricelist 01.06.2011Document40 paginiHager Pricelist 01.06.2011luthayakÎncă nu există evaluări

- Pendahuluan: Prof. Dr. Syafalni, Dipl.H., M.SCDocument20 paginiPendahuluan: Prof. Dr. Syafalni, Dipl.H., M.SCReza ZulfiÎncă nu există evaluări

- Juan Dela Cruz SampleDocument3 paginiJuan Dela Cruz SampleVictor BiacoloÎncă nu există evaluări

- Dehumidifier - Munters MX2700Document2 paginiDehumidifier - Munters MX2700Bozow SinclairÎncă nu există evaluări

- History of control systems from ancient times to modern computersDocument1 paginăHistory of control systems from ancient times to modern computersAfeef Abu BakarÎncă nu există evaluări

- Operator Driven Reliability BrochureDocument8 paginiOperator Driven Reliability Brochuremcdiazr1961Încă nu există evaluări

- Syllabus PE 101Document6 paginiSyllabus PE 101Jacob SonÎncă nu există evaluări

- Circuitos Electroneumaticos NewDocument29 paginiCircuitos Electroneumaticos NewDaniel PantojaÎncă nu există evaluări

- CAD and RP modeling techniquesDocument24 paginiCAD and RP modeling techniquesGooftilaaAniJiraachuunkooYesusiinÎncă nu există evaluări

- LEED Cover Letter For BID PKGDocument2 paginiLEED Cover Letter For BID PKGIlde Brando Leoncito AdarloÎncă nu există evaluări