Documente Academic

Documente Profesional

Documente Cultură

OHPC Balimela Volume 4

Încărcat de

gmdgfk0 evaluări0% au considerat acest document util (0 voturi)

284 vizualizări309 paginid

Drepturi de autor

© Attribution Non-Commercial (BY-NC)

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentd

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

284 vizualizări309 paginiOHPC Balimela Volume 4

Încărcat de

gmdgfkd

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 309

OD8HA HYDRO POWER CORPORATON LMTED

NTERNATONAL COMPETTVE BDDNG

TENDER 8PECFCATON TENDER 8PECFCATON TENDER 8PECFCATON TENDER 8PECFCATON

FOR FOR FOR FOR

RENOVATON & MODERN8ATON RENOVATON & MODERN8ATON RENOVATON & MODERN8ATON RENOVATON & MODERN8ATON

WTH WTH WTH WTH

NEW TURBNE GENERATOR 8ET NEW TURBNE GENERATOR 8ET NEW TURBNE GENERATOR 8ET NEW TURBNE GENERATOR 8ET

OF OF OF OF

UNT8 1 TO 6 {6 X 60 MW} OF BALMELA POWER UNT8 1 TO 6 {6 X 60 MW} OF BALMELA POWER UNT8 1 TO 6 {6 X 60 MW} OF BALMELA POWER UNT8 1 TO 6 {6 X 60 MW} OF BALMELA POWER

HOU8E HOU8E HOU8E HOU8E

D DD D8TT. MALKANGR,OD8HA,NDA 8TT. MALKANGR,OD8HA,NDA 8TT. MALKANGR,OD8HA,NDA 8TT. MALKANGR,OD8HA,NDA

VOLUM VOLUM VOLUM VOLUME EE E- -- - V VV V

TECHNCAL 8PECFCATON : TECHNCAL 8PECFCATON : TECHNCAL 8PECFCATON : TECHNCAL 8PECFCATON :

ELECTRCAL ELECTRCAL ELECTRCAL ELECTRCAL AND AND AND AND CONTROL & N8TRUMENTATON CONTROL & N8TRUMENTATON CONTROL & N8TRUMENTATON CONTROL & N8TRUMENTATON

PREPARED BY PREPARED BY PREPARED BY PREPARED BY

MECON LMTED, RANCH MECON LMTED, RANCH MECON LMTED, RANCH MECON LMTED, RANCH

DOCUMENT NO. MEC/11/83/10FX/T8/01 DOCUMENT NO. MEC/11/83/10FX/T8/01 DOCUMENT NO. MEC/11/83/10FX/T8/01 DOCUMENT NO. MEC/11/83/10FX/T8/01

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNITS # 1 to 6 (6x60 MW)

R & M WITH NEW TG SET

ELECTRICS AND CONTROL & INSTRUMENTATION

INDEX TO VOLUMES

VOLUME I : NOTICE INVITING TENDER

VOLUME II : GENERAL CONDITIONS OF CONTRACT

VOLUME III: TECHNICAL SPECIFICATION

(MECHANICAL & CIVIL)

VOLUME IV : TECHNICAL SPECIFICATION

(ELECTRICS & C&I)

VOLUME V : TECHNICAL SPECIFICATION

(DRAWINGS)

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNITS # 1 to 6 (6x60 MW)

R & M WITH NEW TG SET

ELECTRICS AND CONTROL & INSTRUMENTATION

TS VOL IV

VOLUME IV

TECHNICAL SPECIFICATION

ELECTRICS

ORISSA HYDRO POWER CORPORATION LIMITED

CHIPLIMA POWER HOUSE, CHIPLIMA

UNIT # 3

R&M WITH NEW TG SET

ELECTRICS AND CONTROL & INSTRUMENTATION

VOL. IV CONTENTS Page 1 of 3

CONTENTS

01. SPECIAL INSTRUCTIONS TO TENDERERS

01.01 Compliance with specification 1 of 5

01.02 Standards and Regulations 1 of 5

01.03 Make and Interchangeability 2 of 5

01.04 Safety 2 of 5

01.05 Coding/Numbering Scheme 4 of 5

01.06 Compliance with rules, regulations and obtaining

statutory approval 4 of 5

01.07 Instruction Manuals 5 of 5

02. BRIEF DESCIPTION OF SCOPE OF WORK AND

ELECTRICAL SYSTEM DESIGN CRITERIA

02.01 Description of Existing plant 1 of 21

02.02 Scope & Brief Description of work 2 of 21

02.03 Electrical System Design 8 of 21

03. PERFORMANCE REQUIREMENT

AND GUARANTEE 1 of 1

04. TECHNICAL SPECIFICATION

04.01 Generator Control Equipment 1 of 160

04.02 Metering and Protection System 10 of 160

04.03 Generator Transformer 27 of 160

04.04 220/11 kV Station Transformer 36 of 160

04.05 Unit Auxiliary Transformer 50 of 160

ORISSA HYDRO POWER CORPORATION LIMITED

CHIPLIMA POWER HOUSE, CHIPLIMA

UNIT # 3

R&M WITH NEW TG SET

ELECTRICS AND CONTROL & INSTRUMENTATION

VOL. IV CONTENTS Page 2 of 3

04.06 11 kV Switchboard 59 of 160

04.07 Unit Auxiliary Board / Station Auxiliary Board 74 of 160

04.08 Electric Motors 87 of 160

04.09 uninterruptible power supply (U.P.S.) 90 of 160

04.10 Battery ,charger and DC distribution board 91 of 160

04.11 Cables 97 of 160

04.12 Miscellaneous 101 of 160

04.13 220kV Switchyard Bay Extension 114 of 160

04.14 Erection specification 143 of 160

04.15 Overhauling of 1000kVA, 11/0.433V 154 of 160

Transformer

05. INSPECTION & TESTING

05.01 Inspection 1 of 17

05.02 Testing 4 of 17

`

06. LIST OF PREFERRED MAKE 1 of 5

07. LIST OF SPECIFICATION DRAWING 1 of 1

08. DRAWING & DOCUMENTS TO BE SUBMITTED

BY THE TENDERER 1 of 6

09. TECHNICAL PARTICULARS TO BE SUBMITTED

BY THE CONTRACTOR

09.01 General 1 of 32

09.02 Design Consideration 2 of 32

09.03 220 kV Equipment 3 of 32

09.04 HT Equipment 14 of 32

ORISSA HYDRO POWER CORPORATION LIMITED

CHIPLIMA POWER HOUSE, CHIPLIMA

UNIT # 3

R&M WITH NEW TG SET

ELECTRICS AND CONTROL & INSTRUMENTATION

VOL. IV CONTENTS Page 3 of 3

09.05 Relays 22 of 32

09.06 Transformer 22 of 32

09.07 Generator Busduct 26 of 32

09.08 LT Equipment 26 of 32

09.09 Motors 29 of 32

09.10 Cables 29 of 32

09.11 UPS System 30 of 32

09.12 DC System 31 of 32

ANNEXURE I SELECTION OF POWER COMPO

NENTS FOR MOTORS 1 of 1

ANNEXURE II LIST OF MANDATORY SPARES 1 of 7

SEC B CONTROL & INSTRUMENTATION

01.00 General 1 of 46

02.00 Scope of work and Supply 2 of 46

03.00 Design Criteria 6 of 46

04.00 General Technical Rules 18 of 46

05.00 List of Measurement 27 of 46

06.00 Drawings and Documents 36 of 46

07.00 List of Spares 40 of 46

08.00 Inspection 43 of 46

09.00 List of Preferred makes 43 of 46

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNITS # 1 to 6 (6x60MW)

R&M WITH NEW TG SET

ELECTRICS AND CONTROL & INSTRUMENTATION

TS VOL IV SEC. A Ch- 01 Page 1 OF 5

01. SPECIAL INSTRUCTIONS TO TENDERERS

01.01 Compliance with Specification

01.01.01 All equipment and accessories covered under this specification shall conform

to `Technical Specifications' given in this document.

01.01.02 All equipment shall be suitable for voltage/freq. variations and other data

given in Electrical System Design.

01.02 Standards and Regulations

01.02.01 The design, manufacture, performance , testing and installation (including

safety, earthing and other essential provisions) of equipment and

accessories covered under this specification shall, in general, comply with

the latest issue of:

Applicable Standards and Codes of Practices published by Bureau of

Indian Standards.

Central Board of Irrigation and Power

Indian Electricity Act.

Central Electricity Authority

Indian Electricity Rules.

01.02.02 Equipment complying with other recognised Standards such as IEC, BS,

VDE, DIN etc. will also be considered if it ensures performance equivalent to

or superior to Indian Standards.

01.02.03 Equipment and accessories for which Indian Standards are not available,

shall be designed, manufactured and tested in accordance with the latest

issues of recognised Standards such as IEC, BS, VDE, DIN etc.

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNITS # 1 to 6 (6x60MW)

R&M WITH NEW TG SET

ELECTRICS AND CONTROL & INSTRUMENTATION

TS VOL IV SEC. A Ch- 01 Page 2 OF 5

01.02.04.1 In case of conflict between applicable Standards referred to in this part and

the Technical Specifications given in Chapter-04, the latter shall govern to

the extent of such difference.

01.03 Make & Interchangeability

01.03.01 The make of major equipment shall be limited to preferred makes indicated

under chapter `List of preferred makes'. Makes of all other equipment and

accessories are subject to prior approval by the purchaser.

01.03.02 Similar equipment and components shall be of same make; equipment of

same type and rating shall be interchangeable.

01.03.03 The purchaser has the option of selecting the manufacturers of electrical

equipment, instruments and controls and any other specialised items in the

interest of standardisation and the successful tenderer shall have to supply

equipment of the particular make, if so required.

01.03.04 The tenderer shall furnish division list of supplies from foreign and Indian

sources indicating the name of the agency or make against the respective

items. It shall be the responsibility of the successful tenderer to arrange the

import licence for the imported items offered and to Co-ordinate the supply of

equipment from foreign and Indian sources and execute the contract within

the agreed time schedule.

01.04 Safety

01.04.01 All equipment shall be complete with approved safety devices wherever a

potential hazard exists and with provision for safe access of personnel to and

around equipment for operational and maintenance functions. The design

shall include not only those usually furnished with elements of machinery

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNITS # 1 to 6 (6x60MW)

R&M WITH NEW TG SET

ELECTRICS AND CONTROL & INSTRUMENTATION

TS VOL IV SEC. A Ch- 01 Page 3 OF 5

but also the additional covers, stairways , ladders, steel structural platforms

for operator's control panels , handrails, partitions etc. which are necessary

for safe operation of the plant.

01.04.02 All danger and caution notice boards' shall be both in English and Odiya

languages.

01.04.03 The Contractor must take sufficient care in moving his construction plants

and equipment from one place to another so that those may not cause any

damage to the property of the Purchaser particularly to the overhead and

underground cables and other service lines.

01.04.04 When the work is carried out at night or in the obscure day light, adequate

arrangements for flood lighting in the working area shall be made by

Contractor at his own cost and got approved by the Purchaser / consultant.

01.04.05 The safety posters/regulation for prevention of accidents shall be displayed

by the Contractor at appropriate places. Notices and warning signs shall be

displayed for all sources of dangers.

01.04.06 All electrical drives and equipment must be equipped with safety devices.

The safety provisions shall conform to the recognized standards, safety

codes and statutory regulations.

01.04.07 All safety measures as required to be adopted as per the statutory

regulations and the safety rules of the plant shall be strictly followed by the

Contractor during the execution of the Contract.

01.04.08 Adequate number of first aid boxes as defined in the State Factory Rules

shall be provided and maintained at all work sites.

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNITS # 1 to 6 (6x60MW)

R&M WITH NEW TG SET

ELECTRICS AND CONTROL & INSTRUMENTATION

TS VOL IV SEC. A Ch- 01 Page 4 OF 5

01.05 Coding/Numbering Scheme

A coding scheme for identifying the drawings, plant and equipment,

structures, spares and shipping documents shall be adopted by the

contractor in a sequential manner. The objective shall be to provide the

following :

- Streamlined archives management

- Effective control with respect to identification of equipment and

drawings to be supplied by different contractors/sub-contractors.

- Identification of the spare parts for easier inventory control.

01.06 Compliance with rules, regulations, and obtaining statutory approval

All equipment/materials shall be installed in accordance with the

requirements of relevant standards, Indian electricity Rules and Acts and

also the Factories Act. It is the responsibility of the tenderer to see that the

electrical installation supplied and erected by him shall be to the entire

satisfaction of Chief Electrical Inspector, Central Electricity Authority or any

other statutory body having jurisdiction in the area and also to the owner/

consultant.

The responsibility for obtaining the Electrical Inspectorates approval for the

installation and modifications to be carried out rests entirely with the

contractor. It shall be the responsibility of the contractor to prepare and

submit all necessary drawings, calculations, test certificates and relevant

details (other than those given by the owner/consultant) to the Electrical

Inspector and obtain prior approval for commencing the work and for the

complete installation work done.

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNITS # 1 to 6 (6x60MW)

R&M WITH NEW TG SET

ELECTRICS AND CONTROL & INSTRUMENTATION

TS VOL IV SEC. A Ch- 01 Page 5 OF 5

01.07 Instruction Manuals

01.07.01 Instruction manual shall give step by step procedure for :

1 Erection, testing and commissioning

2 Operation

3 Maintenance and

4 Repair.

01.07.02 Maintenance instruction shall include:

1 Diagnostic trouble shooting / fault location charts

2 Tests for checking of proper functioning.

3 Periodic Maintenance schedule.

01.07.03 Instruction manual shall also contain:

1 Manufacturer's catalogues with ordering specification for all items.

2 List of consumables with specifications, brand names and annual

consumption figures.

3 Drawings relevant for erection, operation, maintenance and repair of

the equipment.

4 Procedure for ordering spares.

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNITS # 1 TO 6 (6x60 MW)

R&M WITH NEW TG SET

ILICTRICS AN CONTROL & INSTRLMINTATION

TS VOL IV Sec.A Ch-02 Page 1 of 21

02. BRIEF DESCRIPTION OF SCOPE OF WORK AND ELECTRICAL

SYSTEM DESIGN CRITERIA

02.01 DESCRIPTION OF EXISTING PLANT

Balimela Power House at Balimela consists of eight units of which Units 1

to 6 each of 60 MW and units 7 & 8 each are of 75 MW. .

Existing units 1 to 6 (for which renovation and modernization with new TG

work is to be taken up) are connected to 220kV power system through

11/220 kV generator transformers. Generator transformers are located in

transformer yard towards downstream side of power house . The important

parameters of existing generator transformer for each unit are as follows.

Rating - 3x 23400 kVA (Three Single Phase Transformer per Unit

Type of cooling OFWF (Forced oil circulation with forced water

cooling)

Vector group - Delta/star-(DYn 11)

Location - Outdoor

Connection - Bus duct - 11kV side

- Overhead conductor - 220 kV side

Generator output is taken through isolated phase bus ducts and connected

to Generator step up transformer.. Neutral side terminal of generator has

been shorted. Tapping has been taken for LA PT panel. For auxiliary

supply, 11 kV is tapped from generator bus ducts of units 1,3,5 & 7 and

connected to 11kV bus of auxiliary supply system through isolator, reactor,

and MOCB. From the 11kV bus four auxiliary transformers ( named 11T,

12T, 13T and 14T) feed unit and station LT boards. These transformers are

located upstream side of the Power House in the LT transformer yard

Existing LT board is fixed type.

A common control room housing control, protection and annunciation

panels for generators, generator transformer, generator aux. and turbine

control desks is provided. For the indication & relays duplex type panels

are provided. Summation MW, MVAR meters are also located in this

control room. Generator is being synchronized at 220 kV through

synchronization arrangement.

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNITS # 1 TO 6 (6x60 MW)

R&M WITH NEW TG SET

ILICTRICS AN CONTROL & INSTRLMINTATION

TS VOL IV Sec.A Ch-02 Page 2 of 21

The Main Control Room, Battery Room, Battery Charger Room and Unt

Control Room (one per unit) located at EL 174.65 m.The HT and LT

Switchgear room are located at EL 170.12m. Generator is synchronised at

220kV through synchronisation arrangement.

220 kV Switchyard has a switching scheme of double bus with bypass bus

arrangement..

02.02 SCOPE AND BRIEF DESCRIPTION OF WORK

The job shall be done on turnkey basis. The scope of work for the R&M of

Units- 1 to 6 with new TG and extension of 220kV Switchyard includes

dismantling and proper storage of the dismantled equipment/facility.

Design, detailed engineering, construction/manufacture or procurement of

new electrical equipment(refer 02.02.01 below), shop testing, packing,

transportation, loading and unloading, delivery at site, storage at site,

handling, erection, pre-commissioning tests and commissioning of all

equipment/system including preliminary acceptance test, performance

guarantee, post commissioning services.

Scope of contractor shall also include following :

Supply of mandatory spares, commissioning spares

Supply of special tools and tackles for the equipment/systems

supplied

Insurance during transit, storage, erection and commissioning

Minor civil works required for fixing of electrical

equipment/panels/cables, bus duct opening, support and

reinforcement of existing foundation etc.

Procurement of all necessary materials and also carrying out

fabrication work as specified in the respective sections of the

specification.

The Contractor shall be responsible for complete satisfactorily working of

system with guaranteed parameters. All the major equipment shall be

installed, tested and commissioned under supervision of representative of

manufacturer of respective equipment.

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNITS # 1 TO 6 (6x60 MW)

R&M WITH NEW TG SET

ILICTRICS AN CONTROL & INSTRLMINTATION

TS VOL IV Sec.A Ch-02 Page 3 of 21

The Contractor shall also include in their scope of work the fault level

calculation for the complete network taking into account minimum/

maximum generation. The relay settings shall be recommended

accordingly.

Tenderer shall visit the site and make himself aware of existing units, space

for the aux. & Generator transformers, HT/LT Panels, Main Control Room

etc. and shall take care of all aspects while designing/executing the work.

Miscellaneous Activities

Following miscellaneous works shall also be included in the scope of tenderer;

Obtaining certificate from Chief Electrical Inspectorate of the state and CEA for

installation and energizing the complete electrical system and equipment

covered under the package. (Fees paid to statutory authorities shall be

reimbursed to the contractor against production of receipt).

Any modification or additional requirements by Statutory Authorities shall have

to be carried out without time and cost implication to the purchaser.

Arranging any other statutory approval, if required.

02.02.01 Supply, Erection, Testing Commissioning

The scope of tenderer shall include all electrical equipment required for the

power plant units and auxiliaries covered under their scope for R&M of units

1 to 6 with new TG and switchyard extension of Balimela Power House at

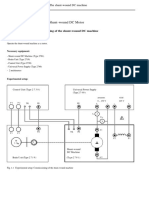

Balimela. The broad scope is envisaged below and shown in Electrical Single

line diagram.

The major equipment covered under scope of supply shall be as follows:

Generator 60 MW, 11kV, 375 rpm 0.9 PF 6 Nos.( Refer Vol III for scope of

work)

Static excitation system & Digital AVR with thyristor controlled dual channel 6

set.. (Refer Vol III for scope of work)

Generator line side terminal cubicles consisting of Surge suppressors, Voltage

transformer, surge capacitor, etc. 6 Nos.

11kV Current Transformers for metering, protection, AVR, synchronisation etc.

Generator neutral side with suitable bus duct links for formation of STAR

POINT. The Generator shall be grounded through neutral grounding

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNITS # 1 TO 6 (6x60 MW)

R&M WITH NEW TG SET

ILICTRICS AN CONTROL & INSTRLMINTATION

TS VOL IV Sec.A Ch-02 Page 4 of 21

transformer.

Generator protection panel with numerical protection relays. Protection scheme

shall also be hard-wired.

Generator metering, synchronizing and annunciation panel.

Microprocessor based control system as elaborated in Sec B of this Volume

Unit control desk

HT Bus duct

11/220 kV, 3x 23.4 MVA Generator Transformer

220 kV Bay Eqipment including extension of Bus, overhead conductor and

associated hardwares

220 / 11kV, 20 MVA Station Transformer

control & protection panel with numerical protection relays for Generator

Transformer, 220/11 kV Station Transformer, Unit Auxiliary Transformer and

Station Auxiliary Transformer

High velocity water spray system for generator transformer and 20 MVA,

220/11kV Station Transformer.

11/ 0.433kV, 3 phase ,750 kVA cast resin dry type unit auxiliary transformer for

each unit

11 KV Switchboard

415 V Unit Auxiliary Board consisting of incomer, bus coupler and out going

feeders (Refer Single Line Diagram MEC/S/10FX/11/S3/E/01)

Refurbishment of 2 nos. 11/0.433 kV, 1000kVA transformers and reuse as

station service transformer.

415 V Station Switchboard consisting of incomers, bus couplers and outgoing

feeders (Refer single line diagram )

Electric Motors and Actuators including LT motors for drives and MOVs etc.

AC distribution board / Power Distribution Board

2 sets of . 220V. battery bank of adequate capacity.

1no. float and float cum boost battery charger for each battery bank

DC switchboard for each battery set

Local Push Button stations for drive motors, Junction boxes etc.

HT & LT Power and control cables, instrumentation and special cables as per

requirement and accessories including their termination at both ends

Cable supporting structures, GI cable trays (ladder type and perforated type),

cable racks, other associated accessories and fire sealing materials for laying,

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNITS # 1 TO 6 (6x60 MW)

R&M WITH NEW TG SET

ILICTRICS AN CONTROL & INSTRLMINTATION

TS VOL IV Sec.A Ch-02 Page 5 of 21

termination and sealing of cables are under contractor's scope of supply. Cable

trestles, if needed within the battery limit for supporting contractors cables,

shall be in the contractors scope. Contractor shall lay separate trays for laying

different type of cables like power, control and screened cables.

All erection materials, required during erection of all types of electrical

equipment under contractors scope.

Complete earthing system for all the equipment/systems - equipment earthing

and electronic earthing as per actual requirement. Earthing connection of all

new equipment to existing network.

Welding sockets (415V), Power receptacles, 240 V sockets, , 240V Industrial

type sockets etc. are included in the scope of the contractor.

UPS system complete in all respect.

Illumination within battery limit including DC emergency lighting.

Lightening Protection for area under extension of 220 kV Switchyard

In addition to above following are also the scope of bidder :

.Supply of hand gloves and shock treatment charts in English and Oriya.

Supply of rubber mats in suitable sections to be provided in front of all switch

boards for their entire lengths.

Supply of danger / caution notice boards in English and Oriya as per IE Rules.

Supply of all foundation bolts, bolts of special design and special embedments

as required for installation of all equipment covered under this specification.

Preparation and submission of lists with specification and itemized prices for

various spares, special tools & tackles for operation, repair and maintenance.

Supply of all consumable materials such as lubricants, transformer oil, etc.

required for first filling, commissioning, start-up and performance test ad

submission of specification including brand names and quantities. The

Tenderer shall also furnish details of yearly requirement for the above

consumables or normal operation.

Preparation and submission of all drawings and documents including progress

reports as called or in this specification.

Determination of electrical soil resistivity at the location of sub-stations by

carrying out actual site test.

Testing of all equipment and accessories covered under this specification at

manufacturers works and / or recognized independent testing centers before

dispatch of same to site as well as all tests at site before handling over the

system, complete in all respects to the Owner.

Arrangement of temporary work yards, material depots and access as required,

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNITS # 1 TO 6 (6x60 MW)

R&M WITH NEW TG SET

ILICTRICS AN CONTROL & INSTRLMINTATION

TS VOL IV Sec.A Ch-02 Page 6 of 21

as well as removal from site of all erection equipment, packing materials etc.

Any item not mentioned in the specification, but considered by the tenderer

necessary for satisfactory operation and maintenance of the plant shall be

included by the tenderer in his scope of supply and installation.

Supply of gravel of uniform size of 50 mm and spreading it to thickness of 100

mm in the expanded portion of the switchyard. Soil shall be treated chemically

to control growth of vegetation and sand shall be spread before spreading

gravels. Supervision of erection, testing and commissioning of TG sets, their

controls including electrics shall be by representatives of respective equipment

manufacturer.Installation & testing of cabling system, including cable,

trays/supports etc. Laying and termination of all interconnecting cabling

required for completeness and commissioning of the Units All control metering

and protection cables required for connection to relays, meters, signaling

alarm, control, monitoring etc. at main station building shall be provided, laid

and terminated at both ends by the tenderer e.g. control cables from HT

transformer's marshalling boxes to MCR, junction boxes of 220 kV isolator,

CB, earth switches, CT/PT of yard to marshalling box and marshalling box to

MCR.

A brief description of control philosophy and layout for complete power plant is

given in the subsequent chapter for understanding of tenderer. Tenderer shall

provide accordingly. Irrespective of the details provided, tenderer shall include

complete electrics for the Units under his scope of work.

The detailed specification and schedule of quantities also covering the minor

equipment shall be worked out by the tenderer for the total implementation of

the job.

The technical requirements of the main equipment involved as per the

scheme are covered in technical specification section and other appropriate

sections forming part of this specification.

The technical requirement of the main equipment involved are covered in

technical specification section and other appropriate sections forming part of

this specification.

All other existing equipment and structures necessary to complete the work

within battery limit.

02.02.02 Dismantling

The scope of the Tenderer shall also include the following;

Dismantling of all equipment within battery limit

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNITS # 1 TO 6 (6x60 MW)

R&M WITH NEW TG SET

ILICTRICS AN CONTROL & INSTRLMINTATION

TS VOL IV Sec.A Ch-02 Page 7 of 21

Tenderer has to remove all the old/existing equipment along with cables. All

the unused existing equipment shall be removed, packed and placed in a

proper place as decided by the purchaser. Following major existing equipment

shall be dismantled

Generator Transformer

11 kV Isolators, Reactors

All electrical panels including 11 kV Switchboards, Unit Aux. Board, Station

Aux. Boards, and control cables pertaining to Units # 1 to 6

All station switchboard

Battery banks, battery chargers and DCDBs

HT, LT and Control cables

Cable trays, supporting structures, cable racks etc

Excitation-AVR-PT Panel

Generator Busducts

Generator control & relay panel, generator metering panel, generator

transformer control, relay & metering panel.

CTs, PTs, LAs etc

All steel structures required under battery limit to complete the job.

In addition to the above equipment dismantling and storage of other equipment /

structures etc as required to complete the job is In the scope of tenderer.

02.02.03 Battery Limits and termination points

a) Generator Transformer Side

Power evacuation up to generator transformer shall be included in tenderers

scope. Connection of EHT conductor from transformer to 220 kV transformer

LA is in the Tenderers scope. Control cable termination at both ends wherever

signals are required to be tapped/transmitted including control cable

termination in yard equipment as per the need.

Auxiliary Side

A new 220 kV Bay for Station Transformer including extension of existing 220

kV Buses to the new bay.

a. )

b) Existing DG set

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNITS # 1 TO 6 (6x60 MW)

R&M WITH NEW TG SET

ILICTRICS AN CONTROL & INSTRLMINTATION

TS VOL IV Sec.A Ch-02 Page 8 of 21

02.02.04 Exclusions

The following equipment have been excluded from the scope :

Units 7 & 8.

02.03 ELECTRICAL SYSTEM DESIGN

02.03.01 General

Standards

The design, manufacture, assembly and testing as well as performance of

the equipment shall conform to the relevant IS specifications (latest

revision). In case the tenderer is not in a position to comply fully with

certain IS specifications, or in respect of certain items for which there are

no IS specifications, the tenderer may base his proposals on

IEC/BS/VDE/DIN recommendations or other reputed national or

international standards subject to the approval of the purchaser/Consultant.

All equipment supplied and all work done including system design and

detailed engineering shall also comply with the statutory requirements of

the Government of India, the Government of Odisha and with the Indian

Electricity Rules.

Climatic Conditions

The climatic conditions generally prevailing at BALIMELA have been

described in volume I.

Electrical Equipment selection and derating shall generally be based on

ambient temperature of 50 deg. C.

02.03.02 Design Criteria

Standard Voltage levels

The standardized voltage levels as given in table no. 02.02 shall be adopted.

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNITS # 1 TO 6 (6x60 MW)

R&M WITH NEW TG SET

ILICTRICS AN CONTROL & INSTRLMINTATION

TS VOL IV Sec.A Ch-02 Page 9 of 21

Table 02.01

Standard Voltage levels

-------------------------------------------------------------------------------------------------------------------------

Sl.No. | Description | Voltage level |

------------------------------------------------------------------------------------------------------------------------

1. Generation 11kV, 3 Phase

2. Evacuation and Transmission 220kV, 3 phase, 3 wire

50 Hz, effectively earthed

3 11kV System 11 kV, 3 Phase, 50 Hz,

Non effectively earthed

2. Station supply 415 V, 3 phase, 4 wire,

50 Hz, effectively earthed.

3. A.C. Drive motors 415 V, 3 phase, 4 wire

effectively earthed

4. Metering 110 V, AC PT. voltage

5. Control & protection 220 V, DC 2 wire unearthed

of EHV, LT switch-

gear, D.C. drives

6. Panel lighting and 230V, 1 phase, 2 wires

space heaters 50 Hz, A.C. with

point earthed.

Permissible variations

The system unit/plant equipment shall be designed suitably for variation in

voltage and frequency as indicated in Table 02.03

Table 02.02

Variation in Voltage and Frequency

-----------------------------------------------------------------------------------------------------------------------

Sl.No| Description Voltage Frequency

-----------------------------------------------------------------------------------------------------------------------

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNITS # 1 TO 6 (6x60 MW)

R&M WITH NEW TG SET

ILICTRICS AN CONTROL & INSTRLMINTATION

TS VOL IV Sec.A Ch-02 Page 10 of 21

1. Permissible variation + 6% to - 6% , + 3% to - 5% For LT

system with rated performance/

rated current and control + 6% to - 9% , + 3% to - 5% For HT

system effectiveness system

maintained +10% to -12.5% + 3% to - 5%For EHT

system

2. Permissible variations +/- 10% , +3% to - 5%

for control and regulation

equipment with rated

performance and control

quality maintained.

3. Permissible voltage dip - 5%

at LT switchgear bus for

starting of LT motors

----------------------------------------------------------------------------------------------------------------------

Basic Insulation Levels

Equipment shall be designed suitably for basic insulation levels as given in

Table 02.03.

Table 02.03

Basic Insulation Levels

----------------------------------------------------------------------------------------------

Sl.No | Nominal voltage kV | BIL kV (peak)

----------------------------------------------------------------------------------------------

1. 220 kV 1050

2. 11 kV 75

3. 415 V 1.1

----------------------------------------------------------------------------------------------

Symmetrical short circuit ratings

The three phase symmetrical short circuit ratings of the switchgear at different

voltage levels will be as indicated in Table 02.04.

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNITS # 1 TO 6 (6x60 MW)

R&M WITH NEW TG SET

ILICTRICS AN CONTROL & INSTRLMINTATION

TS VOL IV Sec.A Ch-02 Page 11 of 21

Table 02.04

Symmetrical Short Circuit Ratings

-------------------------------------------------------------------------------------------------------------------------

Sl. Voltage Symmetrical Making

No. level Breaking capacity

-------------------------------------------------------------------------------------------------------------------------

1. 220 kV 40 kA 100 kA

2. 11 kV 40 kA 100 kA

3. 415 V 30 kA 75 kA

4. 220 V DC 10 kA -

-----------------------------------------------------------------------------------------------------------------------

The rated short circuit withstand duration for switchgear of 220kV is 1.0 sec

and for 11 kV it will be 3 Secs whereas for 415 V including MCCs it will be 1

sec.

Motor Starting and permissible voltage dips :

Voltage dip on starting of the largest motor shall be limited to 15% of the

nominal voltage at the motor terminals.

System Earthing

220 kV systems is effectively earthed.

11 kV System is non-effectively earthed.

415 V system will be effectively earthed in line with IE Rules.

Other Requirements

The electrical distribution scheme to be provided will be subject to approval of

purchaser/purchaser's consultants.

Miscellaneous items such as relays ,type of relays, relay ranges, number of

poles for relays, scale of meters, CT ratios, links, fuses, switches, indication

lamps, terminal blocks, aux. relays, timers associated with main relays, size of

control cables shall be supplied as per the approved scheme/to achieve

scheme requirements.

All HT and LT CTs shall be of 5A secondary and EHT CTs shall be 1 amp.

secondary. Control cable from CT to panel shall of 2.5 sq.mm. copper.

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNITS # 1 TO 6 (6x60 MW)

R&M WITH NEW TG SET

ILICTRICS AN CONTROL & INSTRLMINTATION

TS VOL IV Sec.A Ch-02 Page 12 of 21

All erection/installation accessories, cable termination and jointing kits, cable

fixing, dressing, tag numbers, route markers, supporting materials for all

equipment shall be part of the tenderer's scope.

Motor space heater (if required) power supply shall be fed from respective

shop MCC/Distribution board. Space heaters will be interlocked with motor

main power supply.

Earthing mat is already provided for complete power plant area. Existing

earthing connections/ strips needs to be checked for continuity and to be

refurbished / extended if needed for making suitable to connect all equipment

in the scope of tenderer.

Earthing mat shall be provided for the area of switchyard to be extended and

it shall be joined with existing earthmat.

Selection of components and cable size for MCCs shall be as per chart given

in Annexure-I.

Tenderer to submit a system wise drive list indicating process interlocks,

permissive conditions etc. with places and mode of control for each drive

control system philosophy with provision of various control, indication,

measuring devices at various places. This shall be approved by the

purchaser/consultant. Based on above approved philosophy tenderer shall

have to provide all equipment/materials and prepare a control scheme/logic

diagram.

Above mentioned control philosophy and interlocking logic shall be prepared

as per the technological requirement.

Tenderer shall include in his scope dummy panels for switchgear and control

panels, wherever civil beam blocks cable entry to panel.

For control and protection requirement DC system shall be used.

220V DCDB shall be provided catering all the loads of units and tenderer to

include incoming cable for the same.

220 KV System

The relay and control panels for this transformer bay shall be provided in

existing switchyard control room.

A busbar differential protection scheme (analogue, not numeric

microprocessor based) for working bays of the existing switchyard is

functioning and the panel is installed in the control room of the existing

switchyard. It is proposed to extend this existing busbar differential protection

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNITS # 1 TO 6 (6x60 MW)

R&M WITH NEW TG SET

ILICTRICS AN CONTROL & INSTRLMINTATION

TS VOL IV Sec.A Ch-02 Page 13 of 21

to cover the extension portion of the switchyard. The tenderer shall include in

his scope all the equipment/relays/modifications as per requirement. Tenderer

may use spare core of existing CTs. However, in case of non-availability,

tenderer shall include CTs suitably as per site requirement.

The design of steel structure in the switchyard shall in accordance with the

requirements of IS : 800 for steel. The design of concrete foundation for these

structures will be done as per IS : 456. Wind load shall be as per IS : 875

(Part III).

Outdoor yard shall be designed with consideration of following clearances.

Minimum height of live conductor above ground level (mm) : 7000

Sectional clearances (mm) : 4300

Ground clearances for vehicle movement (mm) : 8000

Phase to phase clearance between conductors (mm) : 4500

The basic system parameters for the 220 kV system are as follows.

Nominal system voltage : 220 kV

Highest system voltage : 245 kV

No. of phases : Three

System frequency : 50 Hz

System earthing : Solidly earthed

Fault level (3 Phase symmetrical) : 40 kA (for 15000 MVA)

Short time current rating (for all : 40 kA for 3 secs

current carrying parts) :

Power frequency withstand voltage : 460 kV RMS (Switch

gear)

Impulse withstand voltage : 1050 kV peak (switch

gear)

220 kV conductor : ACSR Zebra

Current carrying capability of bay bus : 1600 A

The Tenderer shall check the VA rating of metering and protective cores of all

current transformers and potential transformers and satisfy himself thoroughly

regarding their adequacy considering lead burden as well as burden of all

relays, meters ad instruments

offered. The successful Tenderer shall submit for Owners approval details of

relays,meters, instruments and associated circuits as well as calculations for

selecting knee point voltage of all PS class CTs.

Suitable interlocking shall be provided between various switchgear equipment

in the 220kV switchyard to ensure safety of maintenance personnel working

on one section of the equipment with other sections alive and to prevent

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNITS # 1 TO 6 (6x60 MW)

R&M WITH NEW TG SET

ILICTRICS AN CONTROL & INSTRLMINTATION

TS VOL IV Sec.A Ch-02 Page 14 of 21

incorrect switching sequence which could lead to damage to plant and

equipment. The interlocking may be of electrical or mechanical or key type or

any combination thereof, but shall be effective when the equipment is

controlled remotely, locally or under emergency manual operation. However,

in the selection and design of the interlocking scheme, the Tenderer shall give

due consideration to the specific requirements of the Central Electricity

Authority.

The relay and control panel for 220 kV switchgear, and DC distribution board

for the 220 kV switchyard shall be located in the Switchyard control room and

all these are included in the scope of this specification. 415 V ACDB shall be

located at switchyard control room building.

02.03.03 Design of Electrical Auxiliary System.

The electrical auxiliary system shall be designed considering available short

circuit levels, switchgear duties and voltage dips on auxiliary buses for the

various operating conditions. The impedance values of transformer shall be

selected with a view to limit the fault levels and voltage dips.

Manual transfer of auxiliary loads shall be provided during unit starting and

during planned shutdowns, whereas fast automatic transfer shall be provided

between the two incomer. buses of 415V switch boards.

02.03.04 Power Distribution Scheme

The electrical power distribution and control scheme shall be based on the

scheme elaborated below. Tenderer shall follow the system design in general

on these lines and design the equipment based on criteria given in earlier

paragraphs. The generator shall generate power at 11 kV. The generator shall

be directly connected to 220 kV systems through 3 phase 11/220 kV

transformer. The electrical distribution scheme shall be based on unit and

station auxiliaries system feeding separately. The unit loads shall be fed

directly through 750 kVA, 11/0.433kV transformer for each unit. The scheme

is shown in single line diagram and is further elaborated in the following

paragraphs of this chapter.

Power Evacuation

The transformer yard and the switchyard are existing and located adjacent to

power plant building to interconnect the power plant to grid at 220 kV for the

purpose of power evacuation.

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNITS # 1 TO 6 (6x60 MW)

R&M WITH NEW TG SET

ILICTRICS AN CONTROL & INSTRLMINTATION

TS VOL IV Sec.A Ch-02 Page 15 of 21

02.03.05 Elaboration of Electrical Scope of Work

The scope of work and different design requirement have been given in

different chapters, however, for ease of understanding it is briefed in following

paragraphs.

01. Generator CT-PT- LA Cubicle

New Generator CT-PT- LA Cubicle shall be provided. All line side CT for

metering, protection and AVR shall be provided in this cubicle. 11/ 0.110kV

Potential transformer for metering, protection, AVR and for synchronization

shall be provided

02. Neutral Grounding Cubicle

New NGC shall be provided. The generator neutral grounding equipment shall

be housed in a metal enclosed cubicle. The high resistance grounding of a

generator neutral shall be adopted by connecting the primary of a single

phase distribution type earthing transformer between generator neutral and

ground with the transformer secondary being shunted by resistance with a

voltage relay and harmonic filter. Current transformers for metering &

protection shall be provided in this cubicle.

03. Generator Transformer including HVWS System

A new 3 phase, 23400kVA, 11/220/3 transformer for each unit shall be

provided by the tenderer. The new transformers shall be provided with the

microprocessor based numerical transformer management protection

systems.

High Velocity Water Spray System

High velocity water spray system shall be provided for generator transformer.

System shall be designed as per TAC guidelines and shall have auto as well

as manual starting features. For Detail specification refer Vol 3 of TS.

04. Electrical Protection System

The protection required for the various electrical equipment e.g generator,

generator transformer, 220/11 kV, 20 MVA Station transformer, unit aux.

transformers, station auxiliary transformer, , auxiliary motor etc. All the relays

including generator protection relays shall be microprocessor based numeric

type irrespective of their use with communication facilities

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNITS # 1 TO 6 (6x60 MW)

R&M WITH NEW TG SET

ILICTRICS AN CONTROL & INSTRLMINTATION

TS VOL IV Sec.A Ch-02 Page 16 of 21

05 220 kV SYSTEM

A new 220/11 kV, 3 phase, 20 MVA transformer shall be provided

Existing 220kV bus shall be extended to accommodate new station

transformer 220 /11 kV, 20 MVA.

New 220 kV transformer bay consisting of SF

6

breaker, Isolator,

earthing isolator, CT, PT etc as per requirement shall be provided.

Foundation of 220/11 kV , 3 phase, 20 MVA transformer, switchyard

bay equipment etc within battery limit is in the scope of bidder

Earthing mat for extended portion of switchyard and connectivity of it

with existing switchyard is in the scope of bidder.

Lightning protection for extended portion of switchyard is in the scope

of bidder.

Illumination for the extended portion of switchyard is in the scope of

bidder.

New cable trench for extended portion of switchyard and connectivity

with existing cable trench is in the scope of bidder.

Approach road for materials and inspection during normal operation of

new transformer bay is in the scope of bidder. Connectivity of new road

with existing road is in the scope of bidder.

Arrangement of refilling of SF

6

gas, compreesed air and fire fighting is

in the scope of bidder.

C& R panel for transformer bay shall be provided and modification in

cable trench, if required, shall be done by bidder.

06 Generator Busduct

11 kV generator busduct shall be isolated phase with tubular shaped

enclosure. Enclosure shall be continuous type. Tenderer shall include the

Generator busducts consisting of following minimum items;

a) Generator main Busduct from generator terminals to generator

transformers and tap offs to unit auxiliary transformer

b) Generator neutral busduct to the neutral grounding transformer

c) Generator busduct tap off to surge protection & VT cubicle

d) Generator busduct tap off to Excitation Transformer

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNITS # 1 TO 6 (6x60 MW)

R&M WITH NEW TG SET

ILICTRICS AN CONTROL & INSTRLMINTATION

TS VOL IV Sec.A Ch-02 Page 17 of 21

e) All associated equipment/items like flexible/rigid joints, required no. of

bends, silica gel breather, space heater, etc

f) Set of maintenance tools and tackles as required.

g) Earthing of busducts with continuous run of conductors

h) Necessary support structures, erection hardware

07. 11kV Switchboard

New 11kV Switch board shall be provided as per 11kV single line diagram.

The switchgear shall be of metal clad, single bus bar, self standing, dust proof

construction, indoor cubicle type fitted with vacuum/SF6 circuit breakers, in

fully draw out execution.

08 LT AUXILIARY SUPPLY SYSTEM

Dedicated cast resin dry type Unit Auxiliary Transfomers (UAT) shall be

provided for each unit. Each UAT shall be of 11/0.433kV, 750 kVA. Each UAT

shall feed the respective Unit Auxiliary Board(UAB). The UABs will have back

ups incoming supply from existing 11/0.4 kV auxiliary transformers (11T and

12T) and will be called Station Service Transformers(SSTs). The Station

Service Board will meet the station load requirements as well as auxiliary load

of one unit..

7.01 Unit Auxiliary Transformer

New 750kVA, 11/0.433 kV, cast resin dry type transformer shall be

provided for each unit.

7.02 11/0.433 kV Station Transformer

Existing 11/0.433 kV, 1000kVA transformers shall be reused after

refurbishment

7.03 415 V Unit Auxiliary Board

415V Unit Auxiliary Board shall be provided for each unit. It shall have air

circuit breakers & shall be metal clad, indoor type floor mounted (in fully draw

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNITS # 1 TO 6 (6x60 MW)

R&M WITH NEW TG SET

ILICTRICS AN CONTROL & INSTRLMINTATION

TS VOL IV Sec.A Ch-02 Page 18 of 21

out execution).Switchboard shall be in single tier execution for incomers & bus

couplers and two tiers for outgoing feeders.

7.04 Station Auxiliary Switchboard

New station auxiliary switchboard consisting of three incomers (incomers

from station transformers and from DG set), bus couplers and outgoing

feeders as per requirement shall be provided. The incomers will have auto

change over facilities. Switchboard shall be in single tier execution for

incomers & bus couplers and two tiers for outgoing feeders.

7.05 415V Switchgear (MCC, Aux. AC/DC Boards, Local Distribution

Station)

415V draw out type switchgear / MCC shall be provided for feeding different

auxiliaries, as required for the plant.

8 DC System

2x100%,220 V battery bank shall be provided to cater all the requirement of

DC loads of power plant. The battery bank shall also take into account DC

requirement of existing units 7 & 8.

One no. float and float cum boost charger shall be provided for each

battery bank.

.

One set with two sections DC distribution board shall be provided for each

unit.

9 UPS

A dedicated UPS system of adequate capacity and redundancy shall be

provided to cater all requirement of control & instrumentation of unit 1 to 6.

This shall be consisting of battery banks (VRLA, SMF type), battery chargers,

inverter banks, static switches, manual bypass switches, 3 phase to 1 phase

transformer, ACDB and all other associated cabling and accessories.

Sufficient nos. of spare feeders shall be provided in the ACDBs of the UPS for

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNITS # 1 TO 6 (6x60 MW)

R&M WITH NEW TG SET

ILICTRICS AN CONTROL & INSTRLMINTATION

TS VOL IV Sec.A Ch-02 Page 19 of 21

purchasers use. The exact number of feeders shall be decided during

detailed engineering

10 Cabling (Cables, Cable supporting materials, trays etc)

All HT/LT power, control cables and cable accessories supporting

structures, cable installation, cable terminations with necessary junction

boxes and fire sealing are under the scope of tenderer for all areas covered

in the package.

All control and protection cables required for connection to relays, meters,

signalling alarm, control, monitoring etc. at main station building shall be

provided, laid glanded and terminated at both ends by the tenderer.Existing

cables shall be removed and placed in proper condition in a place identified

by the purchaser's store.

All erection/installation accessories, cable termination and jointing kits,

cable fixing, dressing, tag numbers, route markers, supporting materials for

all equipment covered in the package shall be part of the tenderer's scope.

Selection of components and cable size for MCCs shall be as per chart

given in Annexure-I.

Tenderer shall have to submit the layout indicating location of all major

electrical equipment and cable routes including levels of floor, clearances,

entry/exit points, cable structure details during detailed engineering stage.

11. LT Motors

AC squirrel cage industrial motors shall be fed at 415V, 3 phase, 50 Hz,

with DOL start as applicable. For motors above 30 kW rating star delta

starter shall be provided.

415 V AC energy efficient motors shall be provided to all auxiliaries

covered under this package as per system requirement.

12 Illumination

Illumination of Power House Area, Main Control room and extended

switchyard area shall be in scope. Light fittings shall be selected considering

aesthetic look and requirement. Light fittings near all equipment within battery

limit shall be provided.

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNITS # 1 TO 6 (6x60 MW)

R&M WITH NEW TG SET

ILICTRICS AN CONTROL & INSTRLMINTATION

TS VOL IV Sec.A Ch-02 Page 20 of 21

13. Earthing Materials

New GI flexible/flats are to be provided for connecting all equipment within

battery limit to existing earth grid.

14 Ligtning Protection

Lightning protection for extended part of 220kV Switchyard shall be

provided. All required materials shielding wire, down conductor etc are In

the scope of tenderer.

15 Electrics of compressed air system, technical water facility, fire fighting

system, AC & ventilation system and EOT crane is in the scope of bidder

16 Control & Instrumentation

Control system shall be provided as detailed in Sec B of this Volume.

Electronic portion of governor and AVR control shall be compatible to the over

all system requirement.

The automation control shall have normal operation control, Governor control,

process protection control.

The Control System among other things shall have .

- Automatic Control of the unit

- Acquisition of operational data about generating units, transformer,

220 kV CBs. Unit Auxiliaries, Station Auxiliaries.

- On line monitoring of partial discharge, vibration Temp, and trend

indication.

- Indication & recording of faults

- HMI with Technological equipment

- Annunciation

- Operation Documents

The control desk in the main control room shall have one VDU screen with

keyboard, mouse etc. (OWS) for each unit with all the above controls and

one engineering work station (EWS). Each OWS shall have complete

computerized contriol facility. The main control desk of the unit in MCR shall

have the following minimum analogue control, metering and indication.

MANUAL CONTROL

- Normal Start

- Normal Stop

- Emergency Stop

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNITS # 1 TO 6 (6x60 MW)

R&M WITH NEW TG SET

ILICTRICS AN CONTROL & INSTRLMINTATION

TS VOL IV Sec.A Ch-02 Page 21 of 21

- GCB switch ON/OFF

- FCB switch ON/OFF

- Load lower / raise

- Speed Lower / raise

- Voltage Lower / raise

- Reactive power Lower raise

- Synchroscope / Bus Selector Switch.

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNIT # 1 TO 6 (6x60 MW)

R&M WITH NEW TG SET

ELECTRICS AND CONTROL & INSTRUMENTATION

TS VOL IV Sec.A Ch - 03 Page 1 of 1

03. PERFORMANCE REQUIREMENT AND GUARANTEE

03.01 The tenderer shall study the specification and satisfy himself thoroughly

regarding the workability of the plant, equipment and systems offered and also

take full responsibility for the guaranteed operation and performance of the

same as well as for their smooth, safe and reliable working.

03.02 All equipment shall be guaranteed for workmanship, materials design and

satisfactory performance to the parameters in accordance with the specification

document and relevant clauses of the General Conditions of Contract (VOL II of

TS). The guarantee for performance shall cover individual items and systems

for their ratings / outputs.

03.03 The tenderer shall also guarantee the integrated operation of all the systems

and equipment covered in his scope as a whole including interfaces required to

be established with other related systems and equipment.

03.04 The supplier shall conduct performance / acceptance tests on each of the major

items of equipment supplied to demonstrate that the equipment and system

supplied are capable of achieving the performance parameters specified and

contracted for, in accordance with the General Conditions of Contract. The total

system performance shall also be guaranteed and demonstrated.

03.04 Should the tests specified show that the unit has failed to achieve the

guaranteed parameters, the supplier shall carry out necessary modifications or

part replacements to achieve the guaranteed parameters and for successful

demonstration the tests shall be repeated

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNIT # 1 TO 6 (6x60 MW)

R & M WITH NEW TG SET

TECHNICAL SPECIFICATION

ELECTRICS AND CONTROL & INSTRUMENTATION

TS VOL IV Sec .A Ch- 04 Page 1 of 160

04. TECHNICAL SPECIFICATION

04.01 GENERATOR TERMINAL CUBICLE

04.01.01 LINE SIDE TERMINAL CUBICLE

LAVT panel shall consist of Potential Transformer, surge protection

equipment, Protective capacitor and current transformers for AVR and

metering.

Current Transformer for Generator metering and Automatic voltage

Regulator shall be provided in isolated phase busduct

Panel specification shall be as follows :

1. Panel Construction : Sheet steel not less than 2.0 mm thick

2. Gland Plate : 3mm CRCA

3. Type : Indoor, Floor mounted

4. BusBar : Main 100x10x3R AL.(High tensile

fastners to be used for busbar joints.

Earth Bus 50x6 mm Cu. FLAT

5. Cable Entry : Bottom

6. Degree of Protection: IP-54

7. System Fault Level : 40 kA for 3 Sec

8. 11 kV clearance : Phase to Phase : 127 mm (Min)

Phase to earth : 90 mm (Min)

9. Name Plate : Black letters engraved on white

background Adhesive type

10. Wiring : 650 /1100 grade PVC insulated

multistranded Cu cable

11. Painting : Enclosure Interior / Exterior

Generator Voltage Transformer

To provide power supply for metering, synchronisation, AVR and protection

purposes voltage transformer shall be provided in LA-VT panel. These will

be connected after the generator outgoing terminals. VTs shall be of dry type

cast resin design mounted in separate panels. High voltage side of VTs shall

have fuses with MCBs on low voltage side. Low voltage star winding shall

have all three phases and neutral connections brought out to terminals.

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNIT # 1 TO 6 (6x60 MW)

R & M WITH NEW TG SET

TECHNICAL SPECIFICATION

ELECTRICS AND CONTROL & INSTRUMENTATION

TS VOL IV Sec .A Ch- 04 Page 2 of 160

Accuracy class of this shall be 0.2. The technical parameters shall be as

follows :

Rated continuous voltage : 11 kV

Ratio : 11 KV/3 : 0.110 kV/3

Burden : As per requirement Minimum

100 VA

Power frequency withstand voltage : As applicable for generator busduct

Impulse withstand voltage : -- do --

Surge Protection Equipment

The surge protection cubicle shall comprise of surge divertor and protective

capacitor on each phase to protect the generator from the effect of transient

over voltages. Surge protection equipment and VTs as described above

shall be mounted in dust proof isolated phase compartment with provision for

entry of main bus tap off into the compartments.

Protective capacitors shall be single pole units i.e. one per phase, non

inflammable synthetic liquid impregnated type connected between each

phase terminals and ground. Each capacitor shall be provided with a built in

discharge resistor to drain the residual charge after being de-energized.

Surge divertors shall be of station class type with 10 kA discharge current

and shall be of design specifically meant for protection of rotating machines,

other salient particulars of surge divertors should be chosen in accordance

with relevant IS-3070,Part-I, 1974.

Generator Current Transformer

To provide Protection and metering for generator, suitable current

transformers shall be provided in the busduct. Separate cores of CTs shall

be used for differential protection, over current protection and measurement

purposes. CTs shall be bar pirmary type . Generally the measurement CTs

shall have accuracy class as 0.2 whereas protection class shall be 5P30 and

for differential CTs the class shall be PS. The knee point characteristics of

differential CTs shall be matched with the relays. The technical parameters

are elaborated below :

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNIT # 1 TO 6 (6x60 MW)

R & M WITH NEW TG SET

TECHNICAL SPECIFICATION

ELECTRICS AND CONTROL & INSTRUMENTATION

TS VOL IV Sec .A Ch- 04 Page 3 of 160

Type : Epoxy cast resin

Rated continuous current : 5000 amps

Ratio : 5000/5A

No. of cores : As per requirement

Short time rating (3 sec) : 40 kA

Power frequency withstand voltage : As applicable for

generator

busduct

Impulse withstand voltage : -- do --

04.01.02 Generator Neutral Grounding Cubicle

The high resistance grounding of a generator neutral shall be adopted by

connecting the primary of a single phase distribution type earthing

transformer between generator neutral and ground with the transformer

secondary being shunted by resistance with a voltage relay and harmonic

filter. This will reduce transient overvoltage limit at the point of fault and

contribute to a positive selective relaying in the event of generator stator

E/F.

The value of resistance shall be so chosen that the energy loss in the

resistor equals the capacitive kVA of the generator windings, the generator

surge capacitance, the capacitance of the isolated phase busduct and the

associated generator transformer with respect to earth during ground fault

conditions.

The generator neutral grounding cubicle shall consist of Neutral grounding

distribution transformer, Off load manual Isolator, current transformers for

generator protection, resistance.

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNIT # 1 TO 6 (6x60 MW)

R & M WITH NEW TG SET

TECHNICAL SPECIFICATION

ELECTRICS AND CONTROL & INSTRUMENTATION

TS VOL IV Sec .A Ch- 04 Page 4 of 160

Panel specification shall be as follows :

1. Panel Construction : Sheet steel not less than 2.0 mm thick

2. Gland Plate : 3mm CRCA

3. Type : Indoor, Floor mounted

4. BusBar : Main 100x10x3R AL.(High tensile

fastners to

be used for

busbar joints.

Earth Bus 50x6 mm Cu. FLAT

5. Cable Entry : Bottom

6. Degree of Protection: IP-54

7. System Fault Level : 40 kA for 3 Sec

8. 11 kV clearance : Phase to Phase : 127 mm (Min)

Phase to earth : 90 mm (Min)

9. Name Plate : Black letters engraved on white

background

Adhesive type

10. Wiring : 650 /1100 grade PVC insulated

multistranded

Cu cable

11. Painting : Enclosure Interior / Exterior :- RAL

7035

Panel shall also have marshalling box, space heater, thermostat MCBs etc

as per requirement.

The earthing transformers shall be dry type for indoor installation. The

generator neutral grounding equipment shall be housed in a metal enclosed

cubicle. The metal enclosed neutral grounding cubicle shall be connected to

the neutral compartment of the star point of the generator. Technical

parameters of earthing transformer shall be as follows:

Primary voltage : 11.0 kV

Secondary voltage : *

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNIT # 1 TO 6 (6x60 MW)

R & M WITH NEW TG SET

TECHNICAL SPECIFICATION

ELECTRICS AND CONTROL & INSTRUMENTATION

TS VOL IV Sec .A Ch- 04 Page 5 of 160

Continuous capacity based on 30 min. duty cycle : *

* Final values to be decided during detail engg. stage.

04.01.03 GENERATOR BUS DUCT

The 11 kV generator busduct shall be phase isolated type. The busduct

shall be installed inside machine hall.

The generator busduct shall comply with the requirements of the latest

version of relevant IS / IEC standards. The busduct shall be designed to

carry maximum continuous current under normal conditions without

exceeding temperature rise limits

The bus assembly shall be designed to mechanically withstand a rated

continuous current as well as the specified short circuit current without

damage or permanent deformation of any part of the bus structure.

Tenderer shall include the Generator busducts consisting of following

minimum items:

1. Generator main Busduct from generator terminals to generator

transformer with tap off to unit auxiliary transformer and excitation

transformer.

2. Generator neutral busduct to the neutral grounding transformer through

link.

3. Generator busduct tap off to LAVT panel.

4. All associated equipment/items like flexible/rigid joints, required no. of

bends, silica gel breather, space heater, etc

5. Surge protection, VT cubicles and Current Transformers located inside

busducts

6. Set of maintenance tools and tackles as required.

7. Earthing of busducts with continuous run of conductors

8. Necessary support structures, erection hardwares

9. Suitable canopy with proper slope for outdoor portion of the busduct

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNIT # 1 TO 6 (6x60 MW)

R & M WITH NEW TG SET

TECHNICAL SPECIFICATION

ELECTRICS AND CONTROL & INSTRUMENTATION

TS VOL IV Sec .A Ch- 04 Page 6 of 160

GENERAL TECHNICAL REQUIREMENT

1. Applicable Standard IS : 8084

2. Rated system voltage and frequency 11 kV, 50 Hz

3. System earthing Non effectively earthed

4. System short-circuit level, kA (rms)

85 kA (for 3 sec) for main

run

152 kA (for 3 sec) for tap off

5. Type of busduct Phase Isolated

6. Service Indoor / Outdoor Indoor

7. Maximum voltage at which the

busduct can operate continuously

12 kV

8. Busbar material - Conductor Aluminium Alloy

9. Busduct support structure required To be provided

10. Current ratings

11. Rated continuous current 5000A

12. short time Current Rating for 1 sec

40kA

13 Dynamic current withstand rating kA

(peak)

100 kA

14 Type of Cooling AN

15. One min. dry power frequency

withstand voltage

28 kV

16. Impulse withstand voltage 75 kV

17 Supporting insulator

a) Type Porcelain

b) Max. distance between supports To be worked out based on

short circuit calculation

c) Rated Voltage 12 kV

d) One minute power frequency

withstand voltage

35 kV

e) Impulse voltage withstand value with

1.2/50 micro sec. wave shape

75 kV

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNIT # 1 TO 6 (6x60 MW)

R & M WITH NEW TG SET

TECHNICAL SPECIFICATION

ELECTRICS AND CONTROL & INSTRUMENTATION

TS VOL IV Sec .A Ch- 04 Page 7 of 160

f) Minimum Creepage Distance 240 mm

18 Earth Bus

a) Material Al

b) Size As per requirement

19 Enclosure

a) Type Phase Isolated

b) Degree of Protection IP 52

c) Material of Enclosure Al

d) Thickness 3 mm min.

20 Design Ambient Temperature 50

o

C

21 Maximum temperature when carrying

rated current continuously

a) - Conductor

a) 1 Bolted Joints (Plain or tinned) 90

o

C

a) 2 Bolted Joints (Silver Plated) 105

o

C

b) Busduct Enclosure 80

o

C

22 Accessories

a) Seal-off bushings As per requirement

b) Silica gel breather To be provided

Length of the busduct shall be calculated by the tenderer based on approved

layout and location of the generators and generator transformers.

Generator bus duct shall be suitable for air and water tightness test as per IS :

8084

Rating, type and detailed technical particulars of the generator neutral bus duct

shall be as per requirement and as per standards prevailing.

GENERAL ARRANGEMENT

1. 11 kV generator busduct shall be phase isolated with tubular shaped

enclosure. Enclosure shall be continuous type.

2. Comprising of following sections, as applicable, to make the installation

complete and to match with the terminal equipment :

Generator lead-in section with flexible hood and links.

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNIT # 1 TO 6 (6x60 MW)

R & M WITH NEW TG SET

TECHNICAL SPECIFICATION

ELECTRICS AND CONTROL & INSTRUMENTATION

TS VOL IV Sec .A Ch- 04 Page 8 of 160

Straight section in standard length.

Matching section (length as required).

Generator transformer lead-in section with flexible links

Corner sections (horizontal and vertical)

Phase cross-over section (If required to match phase sequence of the

board).

Link section.

3. Silica gel breathers at appropriate locations.

4. Space heaters and power supply arrangement for the space heaters

5. Earthing of busducts with continuous run of conductors

6. Generator neutral bus duct along with all the generator CTs, SAPT, NGT

and loading resistor, all associated accessories, etc

CONSTRUCTION DETAILS

1. Degree of protection for enclosure IP 52 or better inside machine

hall.

2. Enclosure material : Aluminium of minimum thickness 3 mm.

Tenderer shall include enclosure with the thickness required for the

rectangular shape and mechanical/ electrical strength point of view.

3. Maximum temperature of enclosure under rated operating

conditions limited to 80

0

C

4. Bolted covers with gaskets for easy inspection and access to

insulators and bus bar joints.

5. Rubber bellows at transformer end to take care of vibration (Flange

on which rubber bellow shall be seated shall seam welded to avoid

ingress of water into the transformer).

6. Hinged and gasketed inspection access cover at suitable intervels.

7. Seal off bushings and frames complete with bolts

8. Provision for draining moisture.

9. Provision for mounting on brackets.

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNIT # 1 TO 6 (6x60 MW)

R & M WITH NEW TG SET

TECHNICAL SPECIFICATION

ELECTRICS AND CONTROL & INSTRUMENTATION

TS VOL IV Sec .A Ch- 04 Page 9 of 160

10. Supply of GI supporting structures with necessary hardwares.

Supporting structures shall be fabricated from standard steel

sections and shall be hot dipped galvanised after fabrication.

11. For termination at generator end, suitable seal off bushings shall be

provided, if required

12. Necessary supporting foundation including civil works to be

provided

Surface treatment

Two coats of epoxy paint for outdoor and synthetic enamel paint for indoor

application, preceded by de-rusting, cleaning chemically, degreasing,

pickling in acid, cold rinsing, phosphating, passivating and spraying with two

coats of zinc oxide primer.

Shade of paint

Interior : Black/white/light yellow

Exterior : Light grey shade 631 of IS - 5 1978 (unless otherwise specified)

and further stoved.

BUSBARS AND CONNECTIONS

1. Material EC grade aluminium alloy equivalent to E91E WP conforming

to IS 5082-1981.

2. Final operating temperature of both bus bars and joints under

continuous operation in enclosure limited to 90

0

C by thermometer

method.

3. Bus bar arrangement as per IS 5578 (1991).

4. Phase identification by colour at ends and at regular intervals.

5. Busbars shall be of welded construction.

6. Copper flexible busbars surface shall be tinned

7. Contact surfaces shall be silver plated.

8. Flexible connections for termination on equipment.

9. Expansion joints on straight runs with joints staggered in adjacent

phases.

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNIT # 1 TO 6 (6x60 MW)

R & M WITH NEW TG SET

TECHNICAL SPECIFICATION

ELECTRICS AND CONTROL & INSTRUMENTATION

TS VOL IV Sec .A Ch- 04 Page 10 of 160

10. Bimetallic joints for jointing between dissimilar metals.

11. Busbar conductors shall be given coat of black mat.

12. Busbar support insulators of non-hygroscopic material having high

impact and di-electric strength with an anti-tracking contour.

PROTECTIVE EARTHING

1. GI/Aluminium earth bus of size 50 x 10 mm running throughout the

length of the busduct, positively connected to the body of the busduct.

2. Provision at each end of busduct for terminating external earth

conductor.

INSULATORS

1. Bus support insulators shall be interchangeable.

2. The insulator shall be designed and mounted in such a manner so as to

facilitate easy inspection, removal and replacement without disturbing

the conductor.

SPACE HEATER

Adequate number of thermostatically controlled space heater shall be

provided to maintain internal temperature above the dew point to prevent

moisture condensation within the busduct. Supply for space heater shall be

240V, single phase, 50Hz.

BUSDUCT SUPPORT

The busduct shall be supported from floor / roof beams or steel inserts.All

hardware shall be galvanised.

04.02 METERING AND PROTECTION SYSTEM

Control, Relay and Mimic Panel

Complete control, monitoring, interlocking, sequencing, metering,

annunciation and protection of complete TG sets and complete electrics of

the unit shall be performed in DCS. Hardwired back up panels shall also be

provided for turbines and generators.

ODISHA HYDRO POWER CORPORATION LIMITED

BALIMELA POWER HOUSE, BALIMELA

UNIT # 1 TO 6 (6x60 MW)

R & M WITH NEW TG SET

TECHNICAL SPECIFICATION