Documente Academic

Documente Profesional

Documente Cultură

Fulltext1adsorption of CD (II) From Aqueous Solutions by Cellulose Modified With Maleic Anhydride and Thiourea

Încărcat de

kawtherahmedTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Fulltext1adsorption of CD (II) From Aqueous Solutions by Cellulose Modified With Maleic Anhydride and Thiourea

Încărcat de

kawtherahmedDrepturi de autor:

Formate disponibile

583

Adsorption of Cd(II) from Aqueous Solutions by Cellulose Modified with Maleic Anhydride and Thiourea

Yanmei Zhou*, Xiaoyi Hu, Qiang Jin, Xinhai Wang and Tongsen Ma

Institute of Environment and Analytical Science, College of Chemistry and Chemical Engineering, Henan University, Kaifeng, Henan 475004, P.R. China. (Received 8 July 2012; revised form accepted 25 June 2013)

ABSTRACT: In this work, cellulose modified with maleic anhydride and thiourea (CMT) was synthesized as a novel type of adsorbent to remove heavymetal ion. The synthesized adsorbent was characterized by Fourier transform infrared spectroscopy, elemental analysis, scanning electron microscopy, thermogravimetric analysis and X-ray diffraction. Batch experiments were performed to investigate the influence of different factors on the adsorption of Cd(II) from aqueous solution. Based on the adsorption data, the adsorption isotherm model was confirmed and the maximum adsorption capacity of Cd(II) from the Langmuir model was found to be 94.47 mg g1. The adsorption kinetics indicated that the adsorption process followed pseudo-second-order model. Adsorption/desorption experiments for more than six cycles showed the possibility of repeated use of CMT for the adsorption of Cd(II) from aqueous solutions.

1. INTRODUCTION Water pollution is one of the most serious environmental problems facing industrial and economic development, and identifying methods to remove toxic pollutions effectively from the aqueous solution is one of the topics of great interest in the present pollution-control research. Heavy-metal ions constitute a serious environment problem because these substances are non-biodegradable and are also highly toxic to living organisms. Besides the toxic and harmful effects to organisms living in water, heavy-metal ions can also get accumulated through the food chain and eventually cause harm to human beings (Volesky 2001; Martins et al. 2004; Junior et al. 2009). Various methods, such as ion exchange, neutralization, reverse osmosis, precipitation, solvent extraction and adsorption, were used to remove toxic metals from aqueous solution. Compared with other methods, adsorption could be an economical and versatile choice for the removal of different pollutions owing to its easy handling and high efficiency in removing heavy-metal ions, especially at medium or low ion concentrations from wastewater (Reichert and Binner 1996; Trakulsujaritchok et al. 2011). Cadmium is a highly toxic environmental pollutant, which is extensively used in automotive industries, metal finishing, electroplating, battery manufacturing, mining, electric-cable manufacturing, tannery, textile and steel industries. Therefore, there is a high possibility of cadmium ions getting easily accumulated in living tissues, especially in human beings, through the food chain. According to the FAOWHO guidelines, the provisional maximum tolerable daily

*Author to whom all correspondence should be addressed. E-mail: zhouyanmei@henu.edu.cn (Y. Zhou).

584

Y. Zhou et al./Adsorption Science & Technology Vol. 31 No. 7 2013

intake of Cd(II) from all sources is 11.2 g kg1 of body mass. When exceeding this micronutrient level, cadmium ions affect the enzyme activity and cause lung fibrosis, dyspnea, weight loss and even kidney dysfunction in humans (Bhattacharyya and Gupta 2007; Zheng et al. 2010; Wu et al. 2012). Cellulose is the most abundant and renewable polymer resource available worldwide. Cellulose is not only renewable, biodegradable, and inexpensive, but also has many primary active hydroxyls that are easy to trigger many reactions, such as free radical reaction, esterification, halogenation, oxidation and etherification (Stenstad et al. 2008). The modification of cellulose molecules has interested many researchers. In particular, two main approaches have been tried in modification of cellulose to deal with the pollutants in the aqueous solution. One of the methods is a direct modification of the cellulose backbone with the introduction of chelating agents or compounds, which involves pollutant-binding functionalities to produce a range of adsorbents. The other one has focused on grafting of selected monomers to the cellulose backbone by either directly introducing pollutants-binding capability or with subsequent functionalization of the grafted polymer chains with known chelating moieties (OConnell et al. 2008). Several studies on chemical-surface modification of cellulose have been published. For example, Zhou et al. modified cellulose with -cyclodextrin, quaternary ammonium groups and D-glucose to remove Cr(VI) ions from aqueous solutions (Zhou et al. 2011, 2012). Tian et al. modified native cellulose using poly[ N , N(dimethylamino)ethyl methacrylate] to treat solutions containing fluoride and arsenic ions (Tian et al. 2011). Alila and Boufi prepared a modified cellulose adsorbent for the removal of several aromatic organic compounds and three herbicides, namely, alachlor, linuron and atrazine (Alila and Boufi 2009). The aim of this work was to (1) synthesize an appropriate low-cost adsorbent by a cost-effective chemical modification; (2) investigate the removal capacity of Cd(II) ions from the aqueous solution; (3) study the optimum experimental condition, kinetics and adsorption isotherms and (4) test the function of the cellulose modified with maleic anhydride and thiourea (CMT) after regeneration to confirm its stability and reusability.

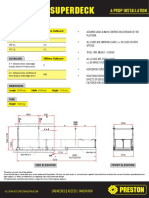

2. EXPERIMENTAL ANALYSIS 2.1. Materials and Reagents The cellulose used in this study was obtained from cotton fibre and supplied by Henan Xiren Cellulose Co., Ltd (China). The maleic anhydride was purchased from Tianjin No. 1 Chemical Reagent Factory (China). The 1, 3-dissopropylcarbodiimide (DIC) was purchased from Shanghai Medpep Co., Ltd (China). Other chemicals such as thiourea, fuchsine, cadmium chloride and anhydrous dimethylformamide (DMF) were of analytical grade and obtained from Sinopharm Chemical Reagent Co., Ltd (China). Distilled water was used throughout the experiments. 2.2. Modification of Cellulose The preparation of CMT adsorbent is depicted in Figure 1. The mercerized cellulose (MC) and the CM were synthesized according to the methodology described in our previous work (Zhou et al. 2012). The CM (3.0 g) was dispersed and stirred in DMF at room temperature for 2 hours, and then CM was treated with DIC at a molar ratio of 1:5 (CM:DIC = 1:5) at room temperature for

Adsorption of Cd(II) from Aqueous Solutions

585

OH O HO OH O O n

O O HO OH O O O O n OH

Maleic anhydride Pyridine

MC

O O NH2 Thiourea DIC O O n

CM

O S

H2N

NH

NH2

O HO OH

CMT Figure 1. Preparation of the CMT adsorbent.

2 hours with constant magnetic stirring (Gurgel et al. 2008). Thiourea (CM:thiourea = 1:10) was then added to this reaction mixture. The media and the materials were allowed to react overnight in order to obtain the adsorbent (CMT). The products were filtered in a sand core funnel, washed with distilled water and ethanol, dried at 80 C overnight and then the adsorbent (CMT) was obtained. 2.3. Degree of Carboxyl Groups The degree of carboxyl groups present in CM was determined by titrating the NaOH solution treated with CM against HCl (Gurgel et al. 2008, 2009). The experiment was carried out three times in parallel in order to obtain exact results. The concentration of carboxylic groups [CCOOH (mmol g1)] was calculated as follows: CCOOH =

(CNaOH VNaOH 4 CHCl VHCl ) 1000

mCM

(1)

where CNaOH is the concentration of NaOH solution (mol L1), CHCl is the concentration of HCl solution (mol L1), VNaOH is the volume of NaOH solution (L), VHCl is the volume of HCl spent in the titration of excessive non-reacted NaOH solution (L) and mCM (g) is the mass of the CM in this experiment. 2.4. Characterization of the New Materials Obtained The IR spectrum of the samples prepared by mixing 1 mg of each material with 100 mg of spectroscopy-grade KBr was recorded from 4000 to 400 cm1 using a Thermo Nicolet Avatar 360 Fourier transform infrared spectroscopy (FTIR) spectrometer.

586

Y. Zhou et al./Adsorption Science & Technology Vol. 31 No. 7 2013

Scanning electron micrographs (SEMs) of samples were recorded using a JEOL JSM5600LV scanning electron microscope. The elemental analysis of intermediate product (CM) and the adsorbent (CMT), which were dried previously, was carried out using a Perkin-Elmer 2400II equipment. Thermogravimetric analysis (TGA) and the differential thermal analysis (DTA) were recorded using a Mettler-Toledo DTA/TGA instrument in the temperature range of 50500 C at a rate of 10 C minute1 under nitrogen flow. Wide-angle X-ray diffraction (XRD) measurement was carried out on an X-ray diffractometer (X-Perpro; Philips, Holland, the Netherlands) in symmetric reflection mode. 2.5. Batch Adsorption Studies Bath adsorption studies were carried out by shaking a certain amount of CMT with 25 mL of simulated wastewater in different conical flasks using a temperature-controlled shaker at 180 rpm for some time. The mixtures were then separated and the supernatant fluid was analyzed for its residual concentration. The concentration of Cd(II) ions were determined by standard ethylenediaminetetraacetic acid titration, with 0.1% xylenol orange chosen as the indicator and 20% hexamethylenetetramine used as the buffer solution (Li et al. 2008; L et al. 2010). The adsorption capacity (q) is expressed as follows: (C0 Ce ) V m

q=

(2)

where q is the adsorption capacity of the adsorbate (mg g1), m is the weight of adsorbent (g), V is the volume of solution (L), and C0 (mg L1) and Ce (mg L1) are initial and equilibrium concentrations of adsorbate in solution, respectively. 2.6. Desorption Study A glass column was used to pack 60 mg of adsorbent. A 25 mL sample solution containing appropriate amount of Cd(II), after adjusting the pH to 4.8, was passed through the column at a flow rate of 0.5 mL minute1. After washing with distilled water, the adsorbed Cd(II) was stripped from the adsorbent using 25 mL NaOH [at a certain pre-specified concentration (0.010.3 mol L1)] at a rate of 0.5 ml minute1.

3. RESULTS AND DISCUSSION 3.1. Degree of Carboxyl Groups Based on the results of the titration method the degree of carboxyl groups in CM was determined. Using equation (1), the concentration of carboxyl groups on CM was calculated to be 2.70 mmol g1. 3.2. Characterization of Adsorbent The FTIR spectra of MC, CM and CMT are presented in Figure 2. As depicted in Figure 2(b), the most relevant change observed in the FTIR spectra of CM in relation to MC is

Adsorption of Cd(II) from Aqueous Solutions

587

a

1650

b

1637

1730

1730 1637 1430 1120

3500

3000

2500

2000

1500

1000

500

Wave numbers (cm1) Figure 2. FTIR spectra of (a) MC, (b) CM and (c) CMT.

appearance of bands at 1730 and 1637 cm1. The bands at 1730 cm1 is due to the stretching of the carbonyl group (C = O). The bands at 1162 and 1062 cm1 are attributed to the increase in the number of ether bonds. The band at 1637 cm1 corresponds to deformation vibration of the vinyl groups (C = C) (Chang and Chang 2001; Liu et al. 2007; Stenstad et al. 2008). These spectra suggest that the maleic anhydride has successfully been grafted onto the cellulose surface. As shown in Figure 2(c), the band at 1430 cm1 corresponds to the stretch of CN (Karnitz et al. 2007), and the evident band at 1120 cm1 is attributed to the vibration of C = S, which indicates that the thiourea has also been successfully grafted onto the surface of CM. A wide absorption peak at 3400 cm1 is due to the stretching of the hydroxyl group (OH), whereas the peak at 2900 cm1 is related to the CH vibration of the CH2 groups. Figure 3 shows the SEM images of MC and CMT. These images show the surfaces of cellulose and CMT. As compared with cellulose, the surface of CMT is more irregular and rough, which is due to the swelling effect of cellulose as well as the surface of cellulose being grafted with maleic anhydride and thiourea. Although the specific surface area was not determined, the SEM images suggest that the specific surface area of CMT is larger than MC because of the heterogeneous surface. Obviously, this situation will be helpful to adsorb the pollutants. The constituents of CM and CMT were determined by elemental analysis method. The percentage of carbon and hydrogen present in CM was 41.11% and 6.28%, respectively. Compared with MC, the percentage of carbon and hydrogen in CMT was 45.58% and 5.59%, respectively. In addition, the percentage of nitrogen in CMT was 1.87%, which is due to the thiourea that was grafted onto the surface of CM. The TGA and DTA curves of CM and CMT are presented in Figure 4. The differences in the thermal behaviour of three samples are due to (1) the temperatures of initial weight loss; (2) the rate of weight loss; (3) the magnitude of the enthalpy change and (4) the temperature

588

Y. Zhou et al./Adsorption Science & Technology Vol. 31 No. 7 2013

(a)

20 kV

X1, 000

10 m

22 28 SEI

(b)

20 kV

X1, 000

10 m

21 20 SEI

Figure 3. SEM morphology of (a) MC (magnification 1000) and (b) CMT (magnification 1000).

corresponding to the values of the peak of the DTA curve (Yang and Kokot 1996). When exposed to a nitrogen atmosphere at 120 C, the first weight loss of all the samples is less than 5.0% in the TGA curves and this is attributed to a significant amount of water released from CM and CMT, which corresponds to an endothermic peak in the DTA curves around 60 C (Aggour 2000; Bari and Begum 2009). The second slow weight loss of CM, which commences at about 270 C, is represented by a shoulder and this is the initial stage of thermal degradation (Huang and Li 1998). As for CMT, the second weight loss of CMT, which commences at about 160 C is attributed to thermal degradation of the thiourea groups. The rapid weight loss, from 280 to 370 C, reflects major thermal degradation, which is attributed to the thermal cleavage of the glucosidic units and split of other CO bonds (Espert et al. 2003; Sailaja and Seetharamu 2009), corresponding to an endothermic peak at approximately 360 C (Evans et al. 1996). As shown in Figure 4(a), the weight loss of CMT is more than 90% at 360 C, whereas that of the CM is 80% at 370 C, which is attributed to the thiourea grafted onto the surface of CM. The diffraction patterns with Cu-K radiation ( = 0.15406 nm) at 40 kV and 40 mA were collected in the 2 range from 10 to 40 at a rate of 0.08 second1. The degree of crystallinity

Adsorption of Cd(II) from Aqueous Solutions

589

(a)

100

80

Weight (%)

60

a CMT CM MC b a b c

40

20

0 0 100 200 300

400

500

Temperature (C) (b)

1.0 0.5

b

Differential temperature (C)

0.0 0.5 1.0 1.5

a

a c

CMT CM MC

2.0 2.5 100 200 300

b c

400

500

Temperature (C) Figure 4. (a) TGA curves of MC, CM and CMT; (b) DTA curves of MC, CM and CMT.

c (%) of the cellulose and modified cellulose was estimated by Rabeks method as follows (Tang et al. 2011): c = Sc 100 Sc + Sa (3)

590

Y. Zhou et al./Adsorption Science & Technology Vol. 31 No. 7 2013

22.7

14.9

16.5

10

15

20

25

30

35

2 () Figure 5. X-ray diffraction patterns of (a) cellulose, (b) CM and (c) CMT.

where Sc and Sa are the area of crystal and amorphous diffraction peaks of samples, respectively. Figure 5 shows the XRD pattern of cellulose, CM and CMT adsorbent. The native cellulose had typical diffraction peaks at 2 = 14.9, 16.5 and 22.7 (Liu and Zhang 2009; Krishnaveni and Thambidurai 2011). As shown in Figure 5, the change in diffraction patterns is not obvious in the chemically modified cellulose (Melo et al. 2009), but there is an increase in the degree of crystallinity of cellulose after the modification. The degree of crystallinity of CM (c = 68.14%) is lower than that of native cellulose (c = 77.22%), indicating that the crystal structure of the native cellulose has been destroyed after the modification with maleic anhydride. Compared with the XRD pattern of CM, the values of CMT (c = 63.09%) are lower than that of CM after thiourea is grafted onto the surface of CM, indicating that the structure of the CMT has been destroyed because of the addition of thiourea on the surface of CM. 3.3. Effect of pH on Adsorption The removal of pollutants from wastewaters by adsorption is highly dependent on the pH of solution. Any variation in solution pH can affect the surface charge of the adsorbent, the degree of ionization and speciation of the adsorbate (Elliott and Huang 1981). To obtain optimal pH, a series of experiments is performed with different pH values. The results are presented in Figure 6. As shown in Figure 6, at low pH values, the concentration of H+ is high, which competes with Cd(II) ions for surface active sites, and the adsorption rate of Cd(II) ions is low (Aydin et al. 2008). The adsorption capacity of Cd(II) ion increases as the pH value increases from 2.0 to 4.8. The optimal pH ranges from 4.0 to 5.0, and the adsorption rate of Cd(II) decreases beyond the optimal pH range (i.e. at larger pH values). The rate of adsorption is reduced because the competitive hydroxyl ions react with the Cd(II) ions when pH > 5.0. Therefore, the optimal initial pH for the removal of Cd(II) ions was determined to be 4.8.

Adsorption of Cd(II) from Aqueous Solutions

591

50 45

Adsorption capacity (mg g1)

40 35 30 25 20 15 2 3 4

pH

Figure 6. Effect of pH on adsorption.

3.4. Effect of Contact Time on Adsorption The adsorption capacities were measured as a function of time to determine the optimal contact time for the adsorption of Cd(II) ions on CMT. The effect of contact time on adsorption is shown in Figure 7. As depicted in Figure 7, the adsorption of Cd(II) ions was fast up to 35 minutes and the equilibrium time is observed to be around 40 minutes, beyond which the adsorption capacity changed inconspicuously. Thus, the optimal contact time for Cd(II) adsorption was determined to be 40 minutes in the subsequent studies.

42

Adsorption capacity (mg g1)

40 38 36 34 32 30 0 20 40 60 80 100 120

Contact time (min) Figure 7. Effect of contact time on adsorption.

592

Y. Zhou et al./Adsorption Science & Technology Vol. 31 No. 7 2013

3.5. Effect of Adsorbent Amount on Adsorption The effect of adsorbent amount on Cd(II) adsorption was studied by changing the amount of adsorbent from 10 to 80 mg, while the concentration of Cd(II) ions was fixed. The results are presented in Figure 8. The adsorption percentage of Cd(II) ions increases with the adsorbent amount up to an optimum dosage, beyond which the adsorption percentage does not significantly change. It could be explained as follows: the increasing adsorbent dosage provides large surface area (or more adsorption sites), which enhanced the adsorption capacity. Moreover, the concentration of initial adsorbate was fixed and the adsorbent is excessive when the adsorbent amount overran the optimum dosage. As shown in Figure 8, the optimal dosage for Cd(II) adsorption was determined to be 60 mg.

7

Adsorption percentage of cadmium (%)

6 5 4 3 2 1 0 10 20 30 40 50 60 70 80 90

Adsorbent amount (mg) Figure 8. Effect of adsorbent amount on adsorption.

3.6. Kinetics Study The kinetics and equilibrium of adsorption, which are two important physicalchemical aspects of the process, were studied to evaluate the process of adsorption. Two rate equations were used to analyze the adsorption kinetics data, namely, pseudo-first-order kinetics and pseudo-secondorder reaction kinetics (OConnell et al. 2006; Ai et al. 2011). Lagergrens pseudo-first-order kineticsequation (4)can be represented in a non-linear formequation (5)and a linear formequation (6). Pseudo-second-order kinetics equation (7) can be used to assess the concentration of Cd(II) ions absorbed. The linear form of pseudo-secondorder kinetics is shown in equation (8). dqt dt = k1 (qe qt ) (4)

qt = qe (1 e k1t )

(5)

Adsorption of Cd(II) from Aqueous Solutions

593

ln(qe qt ) = ln qe k1t dqt dt

(6)

= k2 (qe qt )2

(7)

1 1 t = + t 2 qt k2 qe qe

(8)

where qe (mg g1) is the equilibrium amount of adsorbate, and qt (mg g1) is the amount of adsorbate at any time t; k1 (g mg1 minute1) and k2 (dm3 mg1 minute1) are the pseudo-first-order and pseudo-second-order rate constants, respectively. The records of the kinetics study are presented in Table 1. The R2 value of the pseudo-secondorder model is closer to 1. Therefore, the kinetic adsorption for Cd(II) is in accordance with the pseudo-second-order kinetics. The plot showed an exact coefficient (R2), which is coherent with the pseudo-second-order equation proposed Figure 9 shows the pseudo-second-order adsorption kinetics of adsorption on the CMT adsorbent.

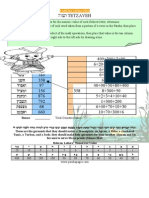

TABLE 1. Pseudo-First-Order and Pseudo-Second-Order Models for Adsorption of Adsorbate Kinetics models Pseudo-first-order Pseudo-second-order qe (mg g1) 9.92 42.08 Parameters k1 (g mg1 minute1) k2 (g mg1 minute1) 4.46 102 1.21 102 R2 0.9575 0.9995

3.0 2.5

t /qt (min g mg1)

2.0 1.5 1.0 0.5 0.0 0 20 40 60 80 100 120

Time (min) Figure 9. Pseudo-second-order adsorption kinetics of adsorption on the CMT adsorbent.

594

Y. Zhou et al./Adsorption Science & Technology Vol. 31 No. 7 2013

3.7. Adsorption Isotherms An adsorption isotherm can be used to characterize the interaction of adsorbate with adsorbents. The isotherm provides a relationship between the concentration of adsorbate in solution and the amount of adsorbate adsorbed on the solid phase when both phases are in equilibrium (Kara et al. 2004). In this study, the temperature was maintained at 30 C, and the adsorption isotherms were analyzed by the three most commonly used models, namely, the Langmuir, Freundlich and Temkin isotherm models. The adsorption isotherm models of Langmuir and Freundlich are shown in equations (9) and (11), respectively, while they can also be represented in the linear form as shown in equations (10) and (12), respectively. The Temkin isotherm model is shown in equation (13). The parameters calculated from the three models are presented in Table 2. In addition, Figure 10 shows the linear plot of Langmuir adsorption isotherm of the adsorbate at 30 C.

TABLE 2. Isotherm Models for Adsorption of Cd(II) Ions Models Langmuir isotherm Parameters Q0 (mg g1) bL (L mg1) R2 KF (L g1) nF R2 AT (L mg1) bT (J mol1) R2 Cd(II) 94.97 2.4041 0.9910 63.37 2.2730 0.9386 19.84 113.41 0.9492

Freundlich isotherm

Temkin isotherm

0.030

0.025

Ce/qe (g l1)

0.020

0.015

0.010

0.005 0.0 0.5 1.0 1.5 2.0 2.5

Ce (mg L1) Figure 10. Linear plots of Langmuir adsorption isotherm at 30 C. Experimental conditions: pH: 4.8; contact time: 40 minutes; dosage amount: 60 mg.

Adsorption of Cd(II) from Aqueous Solutions

595

qe =

Q0 bL Ce 1 + bL Ce

(9)

Ce Ce 1 = 0 + 0 qe Q Q bL

F qe = KF C1/n e

(10)

(11) (12)

ln qe = lnKF +

1 ln Ce nF

qe =

RT RT ln AT + ln Ce bT bT

(13)

where Ce (mg L1) and qe (mg g1) are the concentration and adsorption capacity at equilibrium, respectively. Q0 (mg g1) and bL (L mg1) are adsorption capacity and binding energy of adsorption of Langmuir, respectively. KF and nF are Freundlich constants measuring the adsorption capacity and the adsorption intensity, respectively. AT (L mg1) and bT (J mol1) are the Temkin constants. R is the universal gas constant (8.314 J mol1 K1) and T is the absolute temperature (303 K). As depicted in Table 2, the correlation coefficient (R2) of Langmuir isotherm model is closest to 1, indicating that the adsorption process is better described by the Langmuir isotherm model. The maximum adsorption capacity of the Cd(II) ions was calculated to be 94.47 mg g1. Adsorption capacities of CMT are compared with some materials in Table 3.

TABLE 3. Comparison of Adsorption Capacities of Various Adsorbents for Cd(II) Ions Adsorbent CMT Corn stalk NaY zeolite Rice husk Saw dust Walnut sawdust Clinoptilolite Bentonite Bentonite Modified bentonite HA/Ca-Mont pH Reaction time Adsorption capacity Reference 4.8 7.0 6.8 8.0 8.0 5.0 7.0 5.0 40 minutes 6 hours 24 hours 1 hours 10 hours 10 hours 6 hours 94.97 mg g1 22.17 mg g1 108 mg g1 20.24 mg g1 168 mg g1 4.39 mg g1 0.392 mmol g1 0.381 mmol g1 61.35 mg g1 16.00 mg g1 14.15 mg g1 This work Zheng et al. (2010) Britto et al. (2007) Kumar and Bandyopadhyay (2006) Gaey et al. (2000) Bulut and Tez (2007) Faghihian and Nejati-Yazdinejad (2009) Mockovc iakov et al. (2010) Olu-Owolabi et al. (2010) Wu et al. (2011)

3.8. Desorption Regeneration and reuse of the adsorbent are important. In this work, NaOH solution was selected to be a desorption agent in the Cd(II) desorption experiment. The relationship between the desorption percentage and the concentration of NaOH solution was studied and the results are presented in Figure 11. According to the experimental results, the optimum concentration of NaOH solution was determined to be 0.20 mol L1.

596

Y. Zhou et al./Adsorption Science & Technology Vol. 31 No. 7 2013

100

95

Desorption percentage (%)

90

85

80

75 0.00 0.05 0.10 0.15 0.20 0.25 0.30

Concentration of NaOH (mol L1) Figure 11. Effect of concentration of NaOH solution on Cd(II) desorption.

100

90

Adsorption capacity (mg g1)

80

70

60

50 1 2 3 4 5 6

N Figure 12. Effect of recycling adsorbents after Cd(II) adsorption.

The CMT adsorbent was repeatedly used for six times in the adsorption experiment and the results are shown in Figure 12. The adsorption capacity of the adsorbent slowly decreased with increasing cycle number. At the end of the sixth regeneration cycle, the adsorption capacity of Cd(II) was found

Adsorption of Cd(II) from Aqueous Solutions

597

to be 70 mg g1. These results show that the CMT adsorbent has excellent regeneration capability and thus can be reused for Cd(II) uptake for up to six times with 0.20 mol L1 NaOH solution.

4. CONCLUSIONS A novel adsorbent was synthesized, characterized and applied to uptake Cd(II) ions in an aqueous solution. Bath adsorption experiments were performed to evaluate the efficiency of CMT adsorbent towards Cd(II) ions, and the effects of adsorption conditions on adsorptive performance were investigated. The adsorption process fits the assumptions of the Langmuir isotherm and pseudo-second-order kinetics model. In the desorption experiments, the adsorbent shows regeneration and reuse capabilities with 0.20 mol L1 NaOH solution as the desorption agent. The CMT adsorbent has thus been proved as one of the efficient adsorbents for removing Cd(II) ions from aqueous solutions.

ACKNOWLEDGEMENT The authors are grateful for the Key Scientific and Technological Project of Henan province (112102310360, 122300410260), the natural science research project of Henan province Education Department (2011A610005) and the financial support of the Foundation of International Scientific and Technological Cooperation of Henan province (124300510012) in China.

REFERENCES

Aggour, Y.A. (2000) J. Mater. Sci. 35, 1623. Ai, L.H., Li, M. and Li, L. (2011) J. Chem. Eng. Data 56, 3475. Alila, S. and Boufi, S. (2009) Ind. Crop. Prod. 30, 93. Aydin, H., Bulut, Y. and Yerlikaya, *Cdash*. (2008) J. Environ. Manage. 87, 37. Bari, F. and Begum, N. (2009) J. Mater. Sci. 44, 2628. Bhattacharyya, K.G. and Gupta, S.S. (2007) J. Colloid. Interface Sci. 310, 411. Britto, J.S. de Costa, A.C.A., da Luna, A.S. and Henriques, C.A. (2007) Adsorpt. Sci. Technol. 25, 661. Bulut, Y. and Tez, Z. (2007) J. Environ. Sci. 19, 160. Chang, S.T. and Chang, H.T. (2001) Polym. Degrad. Stab. 71, 261. Elliott, H.A. and Huang, C.P. (1981) Water Res. 15, 849. Espert, A., Camacho, W. and Karlson, S. (2003) J. Appl. Polym. Sci. 89, 2353. Evans, R.J., Wang, D., Agblevor, F.A., Chum, H.L. and Baldwin, S.D. (1996) Carbohydr. Res. 281, 219. Faghihian, H. and Nejati-Yazdinejad, M. (2009) Adsorpt. Sci. Technol. 27, 107. Gaey, M., Marchetti, V., Clement, A., Loubinoux, B. and Gerardin, P. (2000) J. Wood Sci. 46, 331. Gurgel, L.V.A., Freitas, R.P. and Gil, L.F. (2008) Carbohydr. Polym. 74, 922. Gurgel, L.V.A., Melo, J.C.P., Lena, J.C. and Gil, L.F. (2009) Bioresour. Technol. 100, 3214. Huang, M.R. and Li, X.G. (1998) J. Appl. Polym. Sci. 68, 293. Junior, O.K., Grugel, L.V.A., Freitas, R.P. and Gil, L.F. (2009) Carbohydr. Polym. 77, 643. Kara, A., Uzun, L., Besirli, N. and Denizli, A. (2004) J. Hazard. Mater. 106, 93. Karnitz, O.J., Grugel, L.V.A., Melo, J.C.P., Botaro, V.R., Melo, T.M.S., Gil, R.P.F. and Gil, L.F. (2007) Bioresour. Technol. 98, 1291. Krishnaveni, R. and Thambidurai, S. (2011) J. Appl. Polym. Sci. 122, 1622. Kumar, U., and Bandyopadhyay, M. (2006) Bioresour. Technol. 97, 104.

598

Y. Zhou et al./Adsorption Science & Technology Vol. 31 No. 7 2013

Li, X.M., Tang, Y.R., Cao, X.J., Lu, D.D., Luo, F. and Shao, W.J. (2008) Colloids Surf., A 317, 512. Liu, C.F., Sun, R.C., Qin, M.H., Zhang, A.P., Ren, J.L., Xu, F., Ye, J. and Wu, S.B. (2007) Ind. Crop. Prod. 26, 212. Liu, S. and Zhang, L. (2009) Cellulose 16, 189. L, L.L., Lu, D.D., Chen, L.H. and Luo, F. (2010) Desalination 259, 120. Martins, R.J.E., Pardo, R. and Boaventura, R.A.R. (2004) Water Res. 38, 693. Melo, J.C.P., Filho, E.C.S., Santana, S.A.A. and Arioldi, C. (2009) Colloids Surf., A 346, 138. kavarla, J. (2010) J. Hazard. Mater. 180, 274. iakov, A., Orolnov, Z. and S Mockovc OConnell, D.W., Birkinshaw, C. and ODwyer, T.F. (2006) J. Appl. Polym. Sci. 99, 2888. OConnell, D.W., Birkinshaw, C. and ODwyer, T.F. (2008) Bioresour. Technol. 99, 6709. Olu-Owolabi, B.I., Popoola, D.B. and Unuabonah, E.I. (2010) Water Air Soil Pollut. 164, 215. Reichert, J. and Binner, J.G.P. (1996) J. Mater. Sci. 31, 1231. Sailaja, R.R.N. and Seetharamu, S. (2009) J. Appl. Polym. Sci. 112, 649. Stenstad, P., Andresen, M., Tanem, B.S. and Stenius, P. (2008) Cellulose 15, 35. Tang, H., Chang, C.Y. and Zhang, L.N. (2011) Chem. Eng. J. 173, 689. Tian, Y., Wu, M., Liu, R.G., Wang, D.Q., Lin, X.B., Liu, W.L., Ma, L., Li, Y.D. and Huang, Y. (2011) J. Hazard. Mater. 185, 93. Trakulsujaritchok, T., Noiphom, N., Tangtreamjitmum, N. and Saeeng, R. (2011) J. Mater. Sci. 46, 5350. Volesky, B. (2001) Hydrometallurgy 59, 203. Wu, P.X., Zhang, Q., Dai, Y.P., Zhu, N.W. Dang, Z., Li, P., Wu, J.H. and Wang, X.D. (2011) Geoderma 164, 215. Wu, X.W., Ma, H.W., Yang, J., Wang, F.J. and Li, Z.H. (2012) Appl. Surf. Sci. 258, 5516. Yang, P.Y. and Kokot, S. (1996) J. Appl. Polym. Sci. 60, 1137. Zheng, L.C., Dang, Z., Zhu, C.F., Yi, X.Y., Zhang, H. and Liu, C.Q. (2010) Bioresour. Technol. 101, 5820. Zhou, Y.M., Jin, Q., Zhu, T.W. and Akama, Y. (2011) J. Hazard. Mater. 187, 303. Zhou, Y.M., Jin, Q., Zhu, T.W., Ma, T.S. and Hu, X.Y. (2012) Sep. Sci. Technol. 47, 157.

S-ar putea să vă placă și

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- 38 Synthesis and Spectroscopic Studies of Copper (II) and Cobalt (II) Complexes With Tetradentate Ligand Derived From Thiophene-2-CarbaldehydeDocument10 pagini38 Synthesis and Spectroscopic Studies of Copper (II) and Cobalt (II) Complexes With Tetradentate Ligand Derived From Thiophene-2-CarbaldehydekawtherahmedÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Technetium Radiopharmaceutical ChemistryDocument77 paginiTechnetium Radiopharmaceutical ChemistrykawtherahmedÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- 31p NMRDocument17 pagini31p NMRperulageaÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Ic401607underscoring The Influence of Inorganic Chemistry On Nuclear Imaging With RadiometalszDocument20 paginiIc401607underscoring The Influence of Inorganic Chemistry On Nuclear Imaging With RadiometalszkawtherahmedÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Accepted Manuscript: PolyhedronDocument41 paginiAccepted Manuscript: PolyhedronkawtherahmedÎncă nu există evaluări

- Fluorescent and Colorimetric Sensors For Detection of Lead, Cadmium, and Mercury IonsDocument36 paginiFluorescent and Colorimetric Sensors For Detection of Lead, Cadmium, and Mercury IonskawtherahmedÎncă nu există evaluări

- CSTR in SeriesDocument3 paginiCSTR in SeriesDhananjay KadamÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Arthashastra: Citation NeededDocument4 paginiArthashastra: Citation NeededtusharÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- UntitledDocument33 paginiUntitledapi-235198167Încă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Astm C97/C97M-09Document3 paginiAstm C97/C97M-09Azuriak150% (2)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Angle DesignDocument245 paginiAngle DesignGian CarloÎncă nu există evaluări

- Maintenance Component Main Function Level Activity Frequency Line DepartmentDocument7 paginiMaintenance Component Main Function Level Activity Frequency Line DepartmentBarathÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Module 2 Notes - PSOCDocument24 paginiModule 2 Notes - PSOCpriyaÎncă nu există evaluări

- Name: Class Number: - Date: - Section: - ScheduleDocument11 paginiName: Class Number: - Date: - Section: - ScheduleErica AguirreÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Topic: Partnership: Do Not Distribute - Highly Confidential 1Document7 paginiTopic: Partnership: Do Not Distribute - Highly Confidential 1Tharun NaniÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Shaw, Milton C. Metal Cutting PrinciplesDocument759 paginiShaw, Milton C. Metal Cutting PrinciplesJuan Sebastian Quinche Velandia75% (4)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Woodward LeoPC Engineering ManualDocument40 paginiWoodward LeoPC Engineering ManualZafar AwanÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Din 2095Document42 paginiDin 2095Eduardo ValenciaÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Applications of Heat PipeDocument17 paginiApplications of Heat PipeManikantaNaupadaÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- SuperDeck All ModelsDocument12 paginiSuperDeck All Modelsarthur chungÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Data Sheet Cummins BT5,9-G6Document4 paginiData Sheet Cummins BT5,9-G6acere18100% (1)

- Research Proposal TransformerDocument3 paginiResearch Proposal Transformersohalder1026Încă nu există evaluări

- Walking Bass Line Theory BasicsDocument11 paginiWalking Bass Line Theory BasicsKikemol Lv O100% (10)

- TP 3017D Taman Angkasa Nuri - V01Document25 paginiTP 3017D Taman Angkasa Nuri - V01Najwa AzmanÎncă nu există evaluări

- Cisco Ccna Icnd PPT 2.0 OspfDocument15 paginiCisco Ccna Icnd PPT 2.0 OspfAMIT RAJ KAUSHIKÎncă nu există evaluări

- BQ 76 PL 102Document23 paginiBQ 76 PL 102AlexÎncă nu există evaluări

- Tetzaveh Parsha GematriaDocument1 paginăTetzaveh Parsha GematriaRabbi Benyomin HoffmanÎncă nu există evaluări

- Manual AvicadDocument676 paginiManual AvicadOlivia BlanaruÎncă nu există evaluări

- C1 Questions Part 4Document34 paginiC1 Questions Part 4Mohammad KhanÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Planning SchedulingDocument20 paginiPlanning Schedulingvague100% (1)

- Hydrogen Production From Water Electrolysis: Role of CatalystsDocument23 paginiHydrogen Production From Water Electrolysis: Role of CatalystsFreddy Negron HuamaniÎncă nu există evaluări

- Slide 1: No-Churn TelecomDocument11 paginiSlide 1: No-Churn Telecomleongladxton100% (1)

- Is 4031 Part 4 - ConsistencyDocument4 paginiIs 4031 Part 4 - ConsistencyCrypto AbhishekÎncă nu există evaluări

- SRU Presentation For NewDocument47 paginiSRU Presentation For Newviettanct100% (3)

- Prediction of Graduate Admission IEEE - 2020Document6 paginiPrediction of Graduate Admission IEEE - 2020Anu RamanujamÎncă nu există evaluări

- Service Manual: LC-32SV1EA/RUA LC-32SA1EA/RUADocument48 paginiService Manual: LC-32SV1EA/RUA LC-32SA1EA/RUATri YuliantoÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)