Documente Academic

Documente Profesional

Documente Cultură

Air Master Linear Bar Grille With Air Flow Data

Încărcat de

mykel_dpDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Air Master Linear Bar Grille With Air Flow Data

Încărcat de

mykel_dpDrepturi de autor:

Formate disponibile

Linear Bar Grilles

air master

Chapter

INDEX

A

1.

2.

3.

4.

5.

6.

Linear bar grilles:

Supply linear bar grille................: ASLG ..........3.1

Supply linear bar register.............: ASLR ..........3.2

Return linear bar grille................: ARLG..........3.3

Return linear bar register.............: ARLR..........3.4

Supply curved linear bar grille ......: ASLG (C)......3.5

Supply linear bar register (sleek)...: ASLR (S)......3.6

Standard finishes..........................................3.7

Mitered corners............................................3.7

Bar deflection..............................................3.8

Accessories.................................................3.9

End Flanges................................................3.9

Fixing details...............................................3.10

standard sizes..............................................3.11

How to order ...............................................3.11

B

1.

2.

3.

4.

5.

6.

7.

8.

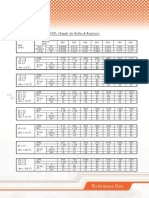

Air flow data (bar spacing 12mm)

Supply air register 15 0-2 way ........: Tab: 3.1.......3.12

Supply air register 15 0-1 way ........: Tab: 3.2.......3.13

Supply air register 0 0 ..................: Tab: 3.3.......3.14

Return air register 15 0-2 way.........: Tab: 3.4.......3.15

Return air register 15 0-1 way.........: Tab: 3.5.......3.16

Return air register 0 0 ..................: Tab: 3.6.......3.17

Supply air register 15 -2 way (6 mm pitch) : Tab: 3.7.......3.18

Return air register 15 -2 way (6 mm pitch) .: Tab: 3.8.......3.19

0

Copyright reserved. Specifications subject to change without notice.

ISO 9002 certified company

Linear Bar Grilles

air master

Supply air linear bar grille

Model: ASLG

Construction:

Frame: High quality extruded aluminium profile

with 30 mm flange width as standard. 12, 16, 24

mm flange widths are optional.

Face bars: High quality aluminium profiles of 00,

150 1 way throw and 150 2 way throw.

Bar spacing: 12 mm as standard. 6 mm as

option.

Grille width: 50 mm to 300 mm with increments

of 50 mm.

Length: 1 meter as standard. Available from 0.2

mt to 5.8 mt in a single piece.

Description:

Frame and face bars are of high quality extruded aluminium profiled construction with the

advantages of corrosion resistance and rigidity.

Total structure is manufactured by mechanical

assembly, assuring rigidity and to maintain

straight-line appearance.

Foam gasket is sealed around the back of the

frame as option to avoid air leakage.

Supplied with C - clamps for concealed fixing.

Horizontal face bars with 00, 150 1 way throw

and 150 2 way throw are fixed rigidly to the

frame with 8-mm pipes.

Vertical aluminium aerofoil blades are fixed at

the rear side of the fame by nylon bushes.

These blades can be adjusted manually and

individually in the vertical plane to obtain optimum air distribution.

For perfect unbroken appearance of continuous

runs, alignment strips are provided with no

additional cost.

Copyright reserved. Specifications subject to change without notice.

ISO 9002 certified company

3.1

Linear Bar Grilles

air master

Supply air linear bar register

Model: ASLR

Construction:

Frame: High quality extruded aluminium profile

with 30 mm flange width as standard. 12, 16, 24

mm flange widths are optional.

Face bars: High quality aluminium profiles of

00, 150 1 way throw and 150 2 way throw.

Bar spacing: 12 mm as standard. 6 mm as

option.

Grille width: 50 mm to 300 mm with increments

of 50 mm.

Length: 1 meter as standard. Available from

0.2 mt to 5.8 mt in a single piece.

Damper frame and blades: High quality

extruded aluminium profiles with natural aluminium finish. Black matt finish as option.

Description:

Frame and face bars are of high quality extruded aluminium profiled construction with the

advantages of corrosion resistance and rigidity.

Grilles are fixed rigidly with an opposed blade

damper by grippers to ensure positive control

over the air stream. Damper blades can be

screw operated from the face opening of the

grille.

Provided with alignment strip for continuous

appearance. Foam gasket is sealed around the

back of the frame to avoid air leakge.

Supplied with C- Clamps for concealed fixing.

Horizontal face bars with 00, 150 1 way throw

and 150 2 way throw are fixed rigidly to the

frame with 8-mm pipes.

Vertical aluminium aerofoil blades are fixed at

the rear side of the fame by nylon bushes.

These blades can be adjusted manually and

individually in the vertical plane to obtain optimum air distribution.

Copyright reserved. Specifications subject to change without notice.

ISO 9002 certified company

3.2

Linear Bar Grilles

air master

Return air linear bar grille

Model: ARLG

Construction:

Frame: High quality extruded aluminium profile

with 30 mm flange width as standard. 12, 16, 24

mm flange widths are optional.

Face bars: High quality aluminium profiles of

00, 150 1 way throw and 150 2 way throw.

Bar spacing: 12 mm as standard. 6 mm as

option.

Grille width: 50 mm to 300 mm with increments

of 50 mm.

Length: 1 meter as standard. Available from

0.2 mt to 5.8 mt in a single piece.

Description:

Frame and face bars are of high quality extruded aluminium profiled construction with the

advantages of corrosion resistance and rigidity.

Foam gasket is sealed around the back of the

frame as option to avoid air leakage.

Supplied with C - clamps for concealed fixing.

Horizontal face bars with 00, 150 1 way throw

and 150 2 way throw are fixed rigidly to the

frame with 8-mm pipes.

For perfect unbroken appearance of continuous

runs, alignment strips are provided with no

additional cost.

Total structure is manufactured by mechanical

assembly, assuring rigidity and to maintain

straight-line appearance.

Copyright reserved. Specifications subject to change without notice.

ISO 9002 certified company

3.3

Linear Bar Grilles

air master

Return air linear bar Register

Model: ARLR

Construction:

Frame: High quality extruded aluminium profile

with 30 mm flange width as standard. 12, 16, 24

mm flange widths are optional.

Face bars: High quality aluminium profiles of

00, 150 1 way throw and 150 2 way throw.

Bar spacing: 12 mm as standard. 6 mm as

option.

Grille width: 50 mm to 300 mm with increments

of 50 mm.

Length: 1 meter as standard. Available from

0.2 mt to 5.8 mt in a single piece.

Damper frame and blades: High quality

extruded aluminium profiles with natural aluminium finish. Black matt finish as option.

For perfect unbroken appearance of continuous

runs, alignment strips are provided with no

additional cost.

Foam gasket is sealed around the back of the

frame as option to avoid air leakage.

Supplied with C clamps for concealed fixing.

Description:

Frame and face bars are of high quality extruded aluminium profiled construction with the

advantages of corrosion resistance and rigidity.

Horizontal face bars with 00, 150 1 way throw

and 150 2 way throw are fixed rigidly to the

frame with 8-mm pipes.

Grilles are fixed rigidly with opposed blade

damper by grippers. This ensures positive control over the air stream. Damper blades can be

screw operated from the face opening.

Copyright reserved. Specifications subject to change without notice.

ISO 9002 certified company

3.4

Linear Bar Grilles

Supply air curved linear bar grille

air master

Model: ASLG (C)

Construction:

Frame: High quality extruded aluminium profile

with 30 mm flange width as standard. 12, 16, 24

mm flange widths are optional.

Face bars: High quality aluminium profiles of

00 1 way throw and 150 2 way throw.

Bar spacing: 12 mm as standard. 6 mm as

option.

Grille width: 50 mm to 300 mm with increments

of 50 mm.

Length: 1 meter as standard.

Description:

Frame and face bars are of high quality extruded aluminium profiled construction with the

advantages of corrosion resistance and rigidity.

Horizontal face bars with 0 1 way throw and

15 2 way throw are fixed rigidly to the frame

with 8-mm pipes.

Supply and return air curved linear bar grilles

are available up to a length of 3 mts with a minimum radius of curvature of 1 meter.

Available without damper. Dampers can be provided to use in plenum boxes as option.

Foam gasket is sealed around the back of the

frame as option to avoid air leakage.

Supplied with C clamps for concealed fixing.

Model: ARLG-C: Same as ASLG-C, without vertical aerofoil blades.

Vertical aluminium aerofoil blades are fixed at

the rear side of the frame by nylon bushings.

These blades can be adjusted manually and

individually in the vertical plane to obtain optimum air distribution.

For perfect unbroken appearance of continuous

runs, alignment strips are provided with no

additional cost.

Copyright reserved. Specifications subject to change without notice.

ISO 9002 certified company

3.5

Linear Bar Grilles

air master

Supply air linear bar register

with 6 mm pitch

Construction:

Frame: High quality extruded aluminium profile

with 30 mm flange width as standard. 12, 16, 24

mm flange widths are optional.

Face bars: High quality aluminium profiles of

00, 150 1 way throw and 150 2 way throw.

Bar spacing: 6 mm.

Grille width: 50 mm to 300 mm with increments

of 50 mm.

Length: 1 meter as standard. Available from

0.2 mt to 5.8 mt in a single piece.

Damper frame and blades: High quality

extruded aluminium profiles with natural aluminium finish. Black matt finish as option.

Description:

Frame and face bars are of high quality extruded aluminium profiled construction with the

advantages of corrosion resistance and rigidity.

Model: ASLR (S)

Grilles are fixed rigidly with an opposed blade

damper by grippers to ensure positive control

over the air stream. Damper blades can be

screw operated from the face opening of the

grille.

For perfect unbroken appearance of continuous

runs, alignment strips are provided with no

additional cost. Foam gasket is sealed around

the back of the frame as option to avoid air

leakage.

Supplied with C clamps for concealed fixing.

Horizontal face bars with 00, 150 1 way throw

and 150 2 way throw are fixed rigidly to the

frame with 8-mm pipes.

Also available without damper and vertical

blades for return air applications.

Vertical aluminium aerofoil blades are fixed at

the rear side of the frame by nylon bushings.

These blades can be adjusted manually and

individually in the vertical plane to obtain optimum air distribution.

Copyright reserved. Specifications subject to change without notice.

ISO 9002 certified company

3.6

Linear Bar Grilles

air master

Standard finishes:

Natural anodized aluminum finish.

Powder coated colour finish as per RAL colour

codes.

Flexibility of finishing is available as option.

Optional mitered corners

Standard 900 horizontal mitered corner available

for floor, sill and ceiling applications in 00,150 one

way throw and 15 0 two way throw without damper.

Special horizontal mitered corner selection available for floor, sill and ceiling applications includes

an angle greater than 900 and less than 180 0 available in 00, 150 one way throw and 150 two way throw

without damper.

Vertical outside mitered corners are available for

wall application at the junction of two outside walls

with a standard angle of 900. Available in 00, 150

one way throw and 150 two way throw without

damper.

Vertical inside mitered corners are available for

wall application at the junction of two inside walls

with a standard angle of 900. Available in 00, 150one

way throw and 15 0 two way throw without damper.

Copyright reserved. Specifications subject to change without notice.

ISO 9002 certified company

3.7

Linear Bar Grilles

air master

Bar deflections

Standard:

MODEL

00 one way

150 one way

ASLG

ASLR

ARLG

ARLR

Optional

Copyright reserved. Specifications subject to change without notice.

3.8

ISO 9002 certified company

Linear Bar Grilles

air master

Accessories:

A. Linear bar grille with one side access door:

Access door will be provided either right or left side of the grille for special applications

upon request. Size of the door is optional.

B. Linear bar grille with both side access doors:

Access door will be provided to both sides of the grille for special applications upon

request. Size of the door is optional.

End flanges:

Copyright reserved. Specifications subject to change without notice.

3.9

ISO 9002 certified company

Linear Bar Grilles

air master

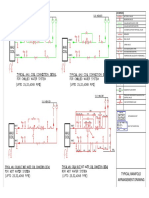

Fixing details

C clamp fixing:

Fixing to the plenum box.

Copyright reserved. Specifications subject to change without notice.

ISO 9002 certified company

3.10

Linear Bar Grilles

air master

Standard Sizes:

Grilles are available with 1 meter length as standard.

Length from 0.2 m to 5.8 mt is available as single piece.

Non standard sizes available as option.

Listed Width in mm

50

100

150

200

250

300

How to order:

Model

ASLG

ASLR

ARLG

ARLR

Face bars

Size

0 = 00

1 = 15 0 one way Specify duct

opening size

Length x height

0

2 = 15 two way in mm x mm

End flange details

Quantity

A. With open ends.

B. One side end flange. Specify in

Right (or) Left.

numbers.

Finish

A. Natural anodized

aluminium finish.

C. Both sides Flanges.

B. RAL 9010

C. Other RAL colours.

Tick the required item.

Ordering example:

1. To select supply air linear bar register with 150 2 way face bars of size 1500 x 150 mm with open

ends of Quantity = 70 numbers, with white powder coated colour finish (RAL 9010).

Order as : ASLR - 2-1500 x 150 - A 70 - B.

2. To select supply air linear bar grille of 6 pitch, 150 1 way face bars of size 1000 x 150 mm with end

flanges of Quantity = 50 numbers, with natural anodized aluminium finish.

Order as : ASLG (S)-1-1000 x 150 - C 50 - A.

Copyright reserved. Specifications subject to change without notice.

ISO 9002 certified company

3.11

Linear Bar Grilles

Supply linear bar register

air master

150 -2 way - 12 mm spacing

Model: ASLR

Table 3.1 Air flow data

Width in

mm

Ak in m2

50

0.039

100

0.059

150

0.078

200

0.097

250

0.116

300

0.136

Face

Velocity

in m/sec.

2.0

2.5

3.0

3.5

4.0

4.5

5.0

Cfm

M3/sec.

Ps in mm H 2O

Throw in m

NC

165

0.078

0.15

2.7-4.0-5.5

<15

207

0.098

0.21

3.4-4.3-6.0

<15

248

0.117

0.21

4.0-4.9-6.7

<15

290

0.137

0.25

4.3-5.2-7.3

16

330

0.156

0.32

4.6-5.5-7.6

22

373

0.176

0.4

4.9-5.8-8.2

25

413

0.195

0.51

4.9-6.0-8.5

30

Cfm

M3/sec.

Ps in mm H 2O

Throw in m

NC

250

0.118

0.15

3.4-4.6-7.0

<15

313

0.148

0.21

4.0-5.2-7.6

<15

375

0.177

0.21

4.6-5.8-8

<15

438

0.207

0.3

5.2-6.0-8.5

17

500

0.236

0.39

5.5-6.7-9.1

22

563

0.266

0.51

5.8-7.3-10

27

625

0.295

0.61

6-7.6-10.7

31

Cfm

M3/sec.

Ps in mm H 2O

Throw in m

NC

330

0.156

0.15

4.0-5.5-8.0

<15

413

0.195

0.21

4.6-6.0-8.8

<15

495

0.234

0.25

5.2-6.7-9.5

<15

578

0.273

0.36

5.8-7.3-10

17

660

0.312

0.46

6.4-8-10.7

23

743

0.351

0.58

6.7-8.5-11.6

28

825

0.39

0.71

7-8.8-12.2

32

Cfm

M3/sec.

Ps in mm H2O

Throw in m

NC

410

0.194

0.2

4.5-6.1-8.8

<15

515

0.243

0.23

5.2-6.7-9.8

<15

616

0.291

0.31

6.0-7.6-10.7

16

718

0.339

0.39

6.7-8.0-11.3

21

821

0.388

0.53

7.3-8.8-11.9

26

925

0.437

0.66

7.6-9.5-12.8

31

1027

0.485

0.91

8.0-9.8-13.7

35

Cfm

M3/sec.

Ps in mm H 2O

Throw in m

NC

491

0.232

0.2

4.9-6.7-9.8

<15

614

0.29

0.25

5.5-7.6-10.7

<15

736

0.348

0.33

6.4-8.2-11.3

20

860

0.406

0.43

7.3-8.8-12.2

25

982

0.464

0.58

8.0-9.5-13.1

31

1105

0.522

0.76

8.2-10-14

34

1228

0.58

0.94

8.5-10.7-15

37

Cfm

M3/sec.

Ps in mm H2O

Throw in m

NC

576

0.272

0.2

5.2-7.3-10.7

<15

720

0.34

0.31

6.1-8.2-11.6

18

864

0.408

0.36

7-9.1-12.2

24

1008

0.476

0.47

7.9-9.8-13.1

28

1152

0.544

0.64

8.5-10.4-14

32

1295

0.612

0.85

8.8-11-15

35

1440

0.68

1.02

9.1-11.6-16.2

40

Data based on one meter unit length of the grille with damper in full open position.

Face velocity is measured in m/sec.

Ps: Static pressure loss is in mm of H2O.

Throw (meters) is measured for a terminal velocities of 0.75, 0.5 & 0.25 m/sec.

NC based on a room attenuation of 10 dB.

Copyright reserved. Specifications subject to change without notice.

3.12

ISO 9002 certified company

Linear Bar Grilles

Supply linear bar register

air master

150 -1 way - 12 mm spacing

Model: ASLR-1

Table 3.2 Air flow data

Width in

mm

Ak in m 2

50

0.040

100

0.065

150

0.088

200

0.111

250

0.134

300

0.162

Face

Velocity

in m/sec.

2.0

2.5

3.0

3.5

4.0

4.5

5.0

Cfm

M3/sec.

Ps in mm H 2O

Throw in m

NC

169

0.08

0.14

2.7-4.1-5.6

<15

212

0.1

0.19

3.5-4.4-6.2

<15

254

0.12

0.21

4.1-5.0-7.0

<15

296

0.14

0.25

4.5-5.4-7.7

17

339

0.16

0.31

4.8-5.8-8.1

22

381

0.18

0.39

5.1-6.1-8.9

25

423

0.2

0.5

5.2-6.4-9.3

31

Cfm

M3/sec.

Ps in mm H 2O

Throw in m

NC

275

0.13

0.14

3.5-4.7-7.1

<15

345

0.163

0.19

4.1-5.3-7.8

<15

413

0.195

0.21

4.7-5.9-8.4

15

483

0.228

0.3

5.4-6.2-9.0

18

550

0.26

0.38

5.8-7.0-9.7

23

620

0.293

0.5

6.1-7.7-10.8

27

688

0.325

0.6

6.4-8.1-11.7

32

Cfm

M3/sec.

Ps in mm H 2O

Throw in m

NC

373

0.176

0.14

4.1-5.6-8.2

<15

466

0.22

0.19

4.7-6.2-9.0

<15

559

0.264

0.25

5.4-6.9-10

16

652

0.308

0.36

6.0-7.6-10.6

18

745

0.352

0.45

6.7-8.4-11.4

24

838

0.396

0.57

7.0-8.9-12.5

29

932

0.44

0.7

7.4-9.3-13.3

34

Cfm

M3/sec.

Ps in mm H 2O

Throw in m

NC

470

0.222

0.18

4.6-6.2-9.0

<15

589

0.278

0.21

5.3-6.9-10.0

16

705

0.333

0.31

6.2-7.8-11.2

17

824

0.389

0.39

6.9-8.3-11.9

21

940

0.444

0.52

7.7-9.2-12.7

26

1058

0.499

0.65

8-9.9-13.8

32

1175

0.555

0.9

8.5-10.4-14.9

36

Cfm

M3/sec.

Ps in mm H 2O

Throw in m

NC

567

0.268

0.2

5.0-6.8-10

<15

709

0.335

0.25

5.6-7.8-11

16

851

0.402

0.33

6.6-8.4-11.9

21

993

0.469

0.42

7.6-9.2-12.9

27

1135

0.536

0.56

8.4-10-14

31

1277

0.603

0.77

8.6-10.5-15.1

35

1419

0.67

0.93

9.0-11.3-16.4

40

Cfm

M3/sec.

Ps in mm H 2O

Throw in m

NC

686

0.324

0.2

5.3-7.5-10.9

<15

857

0.405

0.3

6.2-8.4-11.9

18

1029

0.486

0.36

7.2-9.4-12.8

25

1200

0.567

0.47

8.2-10.2-13.9

30

1372

0.648

0.64

8.9-10.9-15

33

1543

0.729

0.84

9.2-11.6-16.2

37

1715

0.81

1.01

9.6-12.3-17.6

42

Data based on one meter unit length of the grille with damper in full open position.

Face velocity is measured in m/sec.

Ps: Static pressure loss is in mm of H2O.

Throw (meters) is measured for a terminal velocities of 0.75, 0.5 & 0.25 m/sec.

NC based on a room attenuation of 10 dB.

Copyright reserved. Specifications subject to change without notice.

3.13

ISO 9002 certified company

Linear Bar Grilles

Supply linear bar register

air master

00 -12 mm spacing

Model: ASLR-0

Table 3.3 Air flow data

Width in

mm

Ak in m2

50

0.040

100

0.065

150

0.088

200

0.111

250

0.134

300

0.162

Face

Velocity

in m/sec.

2.0

2.5

3.0

3.5

4.0

4.5

5.0

Cfm

M3/sec.

Ps in mm H 2O

Throw in m

NC

169

0.08

0.14

2.7-4.1-5.6

<15

212

0.1

0.19

3.5-4.4-6.2

<15

254

0.12

0.19

4.2-5.1-7.1

<15

296

0.14

0.23

4.6-5.6-7.9

17

339

0.16

0.28

4.9-5.6-8.3

22

381

0.18

0.36

5.4-6.4-9.3

25

423

0.2

0.46

5.5-6.8-9.8

31

Cfm

M3/sec.

Ps in mm H 2O

Throw in m

NC

275

0.13

0.14

3.5-4.7-7.1

<15

345

0.163

0.19

4.1-5.3-7.8

<15

413

0.195

0.19

4.8-6.0-8.6

15

483

0.228

0.28

5.6-6.4-9.3

18

550

0.26

0.35

5.9-7.2-10.0

23

620

0.293

0.46

6.4-8.1-11.3

27

688

0.325

0.56

6.8-8.6-12.4

32

Cfm

M3/sec.

Ps in mm H 2O

Throw in m

NC

373

0.176

0.14

4.1-5.6-8.2

<15

466

0.22

0.19

4.7-6.2-9.0

<15

559

0.264

0.23

5.5-7-10.2

16

652

0.308

0.33

6.2-7.8-10.9

18

745

0.352

0.42

6.9-8.7-11.7

24

838

0.396

0.53

7.4-9.3-13.1

29

932

0.44

0.65

7.8-9.8-14.0

34

Cfm

M3/sec.

Ps in mm H2O

Throw in m

NC

470

0.222

0.16

4.6-6.2-9.0

<15

589

0.278

0.19

5.3-6.9-10.0

16

705

0.333

0.28

6.3-7.9-11.4

17

824

0.389

0.36

7.1-8.5-12.3

21

940

0.444

0.48

7.9-9.5-13.1

26

1058

0.499

0.6

8.4-10.4-14.5

32

1175

0.555

0.84

9.0-11.0-15.8

36

Cfm

M3/sec.

Ps in mm H 2O

Throw in m

NC

567

0.268

0.19

5.0-6.8-10

<15

709

0.335

0.23

5.6-7.8-11

16

851

0.402

0.31

6.7-8.6-12.1

21

993

0.469

0.39

7.8-9.5-13.3

27

1135

0.536

0.52

8.6-10.3-14.4

31

1277

0.603

0.71

9.0-11-15.9

35

1419

0.67

0.86

9.5-11.9-17.4

40

Cfm

M3/sec.

Ps in mm H 2O

Throw in m

NC

686

0.324

0.19

5.3-7.5-10.9

<15

857

0.405

0.28

6.2-8.4-11.9

18

1029

0.486

0.33

7.3-9.6-13.0

25

1200

0.567

0.44

8.4-10.5-14.3

30

1372

0.648

0.59

9.2-11.2-15.4

33

1543

0.729

0.78

9.6-12.2-17.0

37

1715

0.81

0.94

10.2-13-18.6

42

Data based on one meter unit length of the grille with damper in full open position.

Face velocity is measured in m/sec.

Ps: Static pressure loss is in mm of H2O.

Throw (meters) is measured for a terminal velocities of 0.75, 0.5 & 0.25 m/sec.

NC based on a room attenuation of 10 dB.

Copyright reserved. Specifications subject to change without notice.

3.14

ISO 9002 certified company

Linear Bar Grilles

Return linear bar register

air master

150 -2 way - 12 mm spacing

Model: ARLR

Table 3.4 Air flow data

Nominal

Width mm

50

100

150

200

250

300

Cfm

M3/sec.

-Ps in mm H 2O

NC

Cfm

M3/sec.

-Ps in mm H 2O

NC

Cfm

M3/sec.

-Ps in mm H 2O

NC

Cfm

M3/sec.

-Ps in mm H 2O

NC

Cfm

M3/sec.

-Ps in mm H 2O

NC

Cfm

M3/sec.

-Ps in mm H 2O

NC

332

0.157

0.48

<15

417

0.197

0.51

15

500

0.236

0.51

17

585

0.276

0.48

16

667

0.315

0.48

19

750

0.354

0.5

20

417

0.197

0.74

18

500

0.236

0.71

20

585

0.276

0.69

22

667

0.315

0.64

23

750

0.354

0.61

23

833

0.393

0.64

25

500

0.236

1.07

26

585

0.276

0.97

27

667

0.315

0.89

28

750

0.354

0.81

26

833

0.393

0.74

25

1000

0.472

0.77

27

585

0.276

1.47

32

667

0.315

1.27

32

750

0.354

1.14

32

833

0.393

0.99

32

1000

0.472

1.07

31

1167

0.551

1.13

31

667

0.315

1.91

36

750

0.354

1.6

35

833

0.393

1.40

34

1000

0.472

1.42

35

1167

0.551

1.45

35

1333

0.629

1.52

38

750

0.354

2.41

42

833

0.393

1.98

40

1000

0.472

2.01

38

1167

0.551

1.91

40

1332

0.629

1.9

40

1500

0.708

2.0

44

Data based on one meter unit length of the grille.

Ps: Static pressure loss is in mm of H2O.

NC based on a room attenuation of 10 dB.

Copyright reserved. Specifications subject to change without notice.

3.15

ISO 9002 certified company

Linear Bar Grilles

Return linear bar register

air master

150 -1 way - 12 mm spacing

Model: ARLR-1

Table 3.5 Air flow data

Nominal

Width mm

50

100

150

200

250

300

Cfm

M3/sec.

-Ps in mm H 2O

NC

Cfm

M3/sec.

-Ps in mm H 2O

NC

Cfm

M3/sec.

-Ps in mm H 2O

NC

Cfm

M3/sec.

-Ps in mm H 2O

NC

Cfm

M3/sec.

-Ps in mm H 2O

NC

Cfm

M3/sec.

-Ps in mm H 2O

NC

332

0.157

0.46

<15

417

0.197

0.48

<15

500

0.236

0.48

15

585

0.276

0.45

17

667

0.315

0.45

19

750

0.354

0.48

19

417

0.197

0.72

<18

500

0.236

0.69

19

585

0.276

0.67

20

667

0.315

0.64

23

750

0.354

0.59

22

833

0.393

0.6

23

500

0.236

1.03

25

585

0.276

0.93

24

667

0.315

0.86

27

750

0.354

0.78

25

833

0.393

0.71

24

1000

0.472

0.74

25

585

0.276

1.42

31

667

0.315

1.20

31

750

0.354

1.10

31

833

0.393

0.99

30

1000

0.472

1.02

30

1167

0.551

1.05

30

667

0.315

1.88

31

750

0.354

1.55

34

833

0.393

1.34

31

1000

0.472

1.37

34

1167

0.551

1.36

33

1332

0.629

1.45

37

750

0.354

2.32

40

833

0.393

1.88

38

1000

0.472

1.92

37

1167

0.551

1.85

38

1332

0.629

1.79

38

1500

0.708

1.8

42

Data based on one meter unit length of the grille.

Ps: Static pressure loss is in mm of H2O.

NC based on a room attenuation of 10 dB.

Copyright reserved. Specifications subject to change without notice.

3.16

ISO 9002 certified company

Linear Bar Grilles

Return linear bar register

air master

00 -12 mm spacing

Model: ARLR-0

Table 3.6 Air flow data

Nominal

Width mm

50

100

150

200

250

300

Cfm

M3/sec.

-Ps in mm H 2O

NC

Cfm

M3/sec.

-Ps in mm H 2O

NC

Cfm

M3/sec.

-Ps in mm H 2O

NC

Cfm

M3/sec.

-Ps in mm H 2O

NC

Cfm

M3/sec.

-Ps in mm H 2O

NC

Cfm

M3/sec.

-Ps in mm H 2O

NC

332

0.157

0.43

<15

417

0.197

0.45

<15

500

0.236

0.45

15

585

0.276

0.43

17

667

0.315

0.43

19

750

0.354

0.45

19

417

0.197

0.69

17

500

0.236

0.66

18

585

0.276

0.64

17

667

0.315

0.64

22

750

0.354

0.56

21

833

0.393

0.58

22

500

0.236

0.99

24

585

0.276

0.89

23

667

0.315

0.81

26

750

0.354

0.65

24

833

0.393

0.66

23

1000

0.472

0.69

24

585

0.276

1.37

30

667

0.315

1.14

31

750

0.354

1.04

28

833

0.393

0.91

27

1000

0.472

0.94

29

1167

0.551

0.98

28

667

0.315

1.83

33

750

0.354

1.48

33

833

0.393

1.27

30

1000

0.472

1.4

33

1167

0.551

1.27

32

1330

0.629

1.32

36

750

0.354

2.23

38

833

0.393

1.78

36

1000

0.472

1.83

36

1167

0.551

1.8

37

1332

0.629

1.67

36

1500

0.708

1.7

40

Data based on one meter unit length of the grille.

Ps: Static pressure loss is in mm of H2O.

NC based on a room attenuation of 10 dB.

Copyright reserved. Specifications subject to change without notice.

3.17

ISO 9002 certified company

Linear Bar Grilles

Supply linear bar register

air master

150 -2 way - 6 mm spacing

Model: ASLR (S)

Table 3.7 Air flow data

Width in

mm

Ak in m 2

50

0.02

100

0.035

150

0.053

200

0.067

250

0.085

300

0.103

Face

Velocity

in m/sec.

2.0

2.5

3.0

3.5

4.0

4.5

5.0

Cfm

M3/sec.

Ps in mm H 2O

Throw in m

NC

85

0.04

0.16

2.8-4.2-5.8

<15

106

0.05

0.23

3.6-4.5-6.3

<15

127

0.06

0.23

4.3-5.3-7.2

<15

148

0.07

0.28

4.6-5.6-7.9

18

169

0.08

0.36

5.1-6.0-8.4

24

190

0.09

0.45

5.4-6.4-9.0

28

212

0.1

0.59

5.4-6.6-9.4

33

Cfm

M3/sec.

Ps in mm H 2O

Throw in m

NC

148

0.07

0.16

3.6-4.8-7.3

<15

186

0.088

0.23

4.2-5.5-7.9

<15

222

0.105

0.23

4.9-6.3-8.6

17

260

0.123

0.33

5.6-6.5-9.2

20

296

0.14

0.44

6.0-7.4-10.0

25

335

0.158

0.58

6.4-8.11

29

370

0.175

0.7

6.7-8.4-11.9

34

Cfm

M3/sec.

Ps in mm H 2O

Throw in m

NC

224

0.106

0.16

4.2-5.8-8.4

<15

282

0.133

0.23

4.8-6.3-9.2

<15

337

0.159

0.28

5.6-7.2-10.3

17

394

0.186

0.4

6.3-7.9-10.8

20

449

0.212

0.52

7.0-8.8-11.8

27

504

0.238

0.66

7.4-9.4-12.8

30

561

0.261

0.82

7.8-9.8-13.5

35

Cfm

M3/sec.

Ps in mm H 2O

Throw in m

NC

284

0.134

0.22

4.7-6.4-9.2

<15

356

0.168

0.25

5.5-7-10.3

<15

426

0.201

0.34

6.5-8.2-11.6

18

498

0.235

0.43

7.2-8.6-12.2

23

567

0.268

0.6

8-9.7-13.0

29

639

0.302

0.75

8.4-10.4-14

34

709

0.335

1.05

8.9-10.9-15.2

39

Cfm

M3/sec.

Ps in mm H 2O

Throw in m

NC

360

0.17

0.22

5.1-7-10.3

15

451

0.213

0.27

5.7-7.9-11.2

17

540

0.255

0.37

6.9-8.8-12.2

23

631

0.298

0.48

7.9-9.5-13.2

28

720

0.34

0.66

8.8-10.4-14.4

35

811

0.383

0.86

9.0-11-15.4

39

900

0.425

1.08

9.4-11.9-16.6

42

Cfm

M3/sec.

Ps in mm H 2O

Throw in m

NC

436

0.206

0.22

5.4-7.7-11.2

15

546

0.258

0.34

6.4-8.6-12.2

19

654

0.309

0.40

7.6-9.8-13.2

27

764

0.361

0.52

8.5-10.6-14

31

872

0.412

0.72

9.4-11.4-15.4

37

982

0.464

0.96

9.7-12.1-16.5

40

1090

0.515

1.17

10-12.9-18

45

Data based on one meter unit length of the grille with damper in full open position.

Face velocity is measured in m/sec.

Ps: Static pressure loss is in mm of H2O.

Throw (meters) is measured for a terminal velocities of 0.75, 0.5 & 0.25 m/sec.

NC based on a room attenuation of 10 dB.

Copyright reserved. Specifications subject to change without notice.

3.18

ISO 9002 certified company

Linear Bar Grilles

Return linear bar register

air master

150 -2 way - 6 mm spacing

Model: ARLR (S)

Table 3.8 Air flow data

Nominal

Width mm

50

100

150

200

250

300

Cfm

M3/sec.

-Ps in mm H 2O

NC

Cfm

M3/sec.

-Ps in mm H 2O

NC

Cfm

M3/sec.

-Ps in mm H 2O

NC

Cfm

M3/sec.

-Ps in mm H 2O

NC

Cfm

M3/sec.

-Ps in mm H 2O

NC

Cfm

M3/sec.

-Ps in mm H 2O

NC

170

0.08

0.5

17

247

0.117

0.54

17

340

0.161

0.54

19

404

0.191

0.51

18

487

0.23

0.51

21

570

0.269

0.53

22

213

0.101

0.78

20

296

0.139

0.75

22

398

0.188

0.72

24

461

0.218

0.67

25

548

0.259

0.64

25

633

0.299

0.67

27

255

0.12

1.12

29

347

0.164

1.02

30

454

0.214

0.93

31

518

0.245

0.85

29

608

0.287

0.78

28

760

0.359

0.81

30

298

0.141

1.57

35

395

0.187

1.36

35

510

0.241

1.22

35

576

0.272

1.06

35

730

0.345

1.15

34

887

0.419

1.21

34

340

0.161

2.04

39

445

0.21

1.7

38

566

0.267

1.5

37

691

0.326

1.52

38

852

0.402

1.55

39

1013

0.478

1.63

42

382

0.18

2.3

45

494

0.233

2.13

44

680

0.321

2.17

42

806

0.381

2.06

44

972

0.459

2.05

44

1140

0.538

2.16

47

Data based on one meter unit length of the grille.

Ps: Static pressure loss is in mm of H2O.

NC based on a room attenuation of 10 dB.

Copyright reserved. Specifications subject to change without notice.

3.19

ISO 9002 certified company

Security Grilles

Double security bar register

- with steel housing

Model: AMSR-D

Construction:

Frame: Heavy gauge high quality extruded aluminium

profile with 30mm flange width as standard.

Face bars: Heavy gauge extruded aluminium profiles

of 0, 15 - 1 way throw and 15 - 2 way throw. Steel

bars are available as option.

Bar spacing: 12 mm.

Damper frame and blades: High quality extruded

aluminium profiles with natural aluminium finish. Black

matt finish as option.

Description:

Frame and face bars are of high quality extruded aluminium profiled construction with the advantages of

corrosion resistance and rigidity.

Horizontal face bars with 0, 15 - 1 way throw and 15 - 2 way throw are fixed rigidly to the frame with steel rods

welded to the main frame.

Optional vertical aluminium aerofoil blades are fixed at the rear side of the frame by nylon bushings.

Opposed blade damper is fixed to the main frame.

Wall sleeves are made of heavy gauge galvanized steel.

Security grilles are used in areas such as prisons, hospitals and production plants where security is of main concern

Finishes:

Anodised finish.

Powder coated as per RAL color codes.

Model: AMSG-D

Double security bar grille with

steel housing.

Model: AMSR-S

Single security bar grille with volume

control damper and steel housing.

Model: AMSG-S

Single security bar grille with

steel housing.

Fixing:

Rivet fixing to the wall sleeve.

Special tamper proof screw fixing.

Copyright reserved. Specifications subject to change without notice.

2007 Rev. 1

ISO 9001:2000 certified company

3.20

Security Grilles

Maximum Security Perforated Grille

Model: AMPSG

Construction:

Frame: Resistant steel sheet of 4.5mm thick with

welded corners.

Perforated Panel: 4.5mm thick galvanised perforated steel sheet with 8mm holes.

Sleeves: Wall sleeves are made of galvanised

steel.

Optional features:

Damper Frame: Galvanised steel sheet.

Damper Core: High quality extruded aluminium

profile with natural aluminium finish and black matt

finish.

Description:

Frame is constructed from 4.5mm thick resiatant

steel and all sides welded with 4.5mm thick perforated panel having 8mm dia holes. Whole structure is hot dip galvanised with the advantages of

corrosion resistance.

Security grilles are specially designed for maximum security prisons in order to secure the ventilation openings and provide proper air transfer for

the facilities.

The design prevents the inmates from using the

the grille to commit suicide

Available with flanged edges and are supplied

without fixing holes as standard.

Available in square and rectangular sizes.

Standard finishes:

Hot dip galvanised.

Powder coated as per RAL color codes.

Fixing:

40mmx40mmx4mm Angle frame loose supplied,

to be field welded on sleeve.

Rivet fixing to the wall sleeve.

Special tamper proof screw fixing.

Copyright reserved. Specifications subject to change without notice.

2007 Rev. 1

ISO 9001:2000 certified company

3.21

Security Grilles

Maximum Security Perforated Grille

Model: AMPSG

Air flow data

Neck size in mm

Area factor in m2

150x150

0.0748

200x200

0.1454

300x300

0.3724

450x450

0.9538

500x500

1.223

600x600

1.9266

750x750

3.184

Cfm

M3/sec

Face Vel. m/sec

PT in mm H2O

Throw in m

NC

33

0.016

1.5

0.289

1.1-3.7

<15

44

0.021

2.0

0.531

2.3-4.9

<15

55

0.026

2.5

0.820

3.1-6.0

<15

77

0.036

3.5

1.182

3.7-6.6

15

88

0.041

4.0

1.592

4.3-7.2

20

99

0.047

4.5

2.076

4.9-7.8

22

110

0.052

5.0

2.630

5.5-8.1

26

121

0.057

5.5

3.257

6.0-8.6

30

Cfm

M3/sec

Face Vel. m/sec

PT in mm H2O

Throw in m

NC

64

0.030

1.5

0.265

1.4-4.6

<15

86

0.040

2.0

0.483

2.6-6.3

<15

107

0.050

2.5

0.748

4.0-7.8

15

128

0.060

3.0

1.086

4.6-8.9

18

150

0.071

3.5

1.496

5.5-9.5

20

172

0.081

4.0

1.930

6.3-10.4

22

193

0.091

4.5

2.461

6.9-11.0

25

214

0.101

5.0

3.040

7.8-11.5

30

Cfm

M3/sec

Face Vel. m/sec

PT in mm H2O

Throw in m

NC

166

0.078

1.5

0.241

2.0-6.6

<15

221

0.104

2.0

0.434

3.4-8.9

<15

276

0.130

2.5

0.676

5.5-11.2

<15

331

0.156

3.0

0.989

6.6-13.3

16

386

0.182

3.5

1.327

7.8-14.4

19

442

0.209

4.0

1.737

8.9-15.3

24

497

0.234

4.5

2.219

10.1-16.5

26

552

0.260

5.0

2.726

11.2-17.3

30

Cfm

M3/sec

Face Vel. m/sec

PT in mm H2O

Throw in m

NC

284

0.134

1.0

0.217

2.6-9.8

<15

426

0.201

1.5

0.386

4.6-13.0

<15

568

0.268

2.0

0.627

7.2-16.2

16

712

0.336

2.5

0.893

9.8-19.4

19

853

0.403

3.0

1.206

11.0-21.7

23

996

0.470

3.5

1.568

13.0-23.1

27

1137

0.537

4.0

2.0

14.7-24.6

30

1280

0.604

4.5

2.461

16.2-26.0

32

Cfm

M3/sec

Face Vel. m/sec

PT in mm H2O

Throw in m

NC

365

0.172

1.0

0.217

2.9-11.3

<15

545

0.257

1.5

0.374

5.1-14.9

<15

727

0.343

2.0

0.603

8.1-18.7

16

908

0.428

2.5

0.856

11.3-22.3

18

1090

0.514

3.0

1.158

12.9-25.3

24

1270

0.599

3.5

1.520

14.9-27.0

29

1453

0.686

4.0

1.929

16.8-28.7

32

1635

0.772

4.5

2.376

18.7-30.4

35

Cfm

M3/sec

Face Vel. m/sec

PT in mm H2O

Throw in m

NC

554

0.261

1.0

0.217

3.1-12.7

<15

835

0.394

1.5

0.362

5.7-16.7

<15

1113

0.525

2.0

0.579

8.9-21.1

15

1390

0.656

2.5

0.820

12.7-25.1

20

1667

0.787

3.0

1.110

14.7-28.9

25

1944

0.917

3.5

1.472

16.7-30.9

30

2225

1.050

4.0

1.858

18.8-32.7

34

2502

1.180

4.5

2.292

21.1-34.7

38

Cfm

M3/sec

Face Vel. m/sec

PT in mm H2O

Throw in m

NC

939

0.443

1.0

0.217

3.6-14.9

<15

1406

0.663

1.5

0.302

6.7-19.6

<15

1871

0.883

2.0

0.509

10.4-24.8

16

2337

1.103

2.5

0.715

14.9-29.5

22

2810

1.326

3.0

1.090

17.2-34.0

27

3276

1.546

3.5

1.372

19.6-36.3

31

3741

1.766

4.0

1.768

22.1-38.5

35

4208

1.986

4.5

2.182

25.0-40.8

40

Neck size measured in mm.

PT - Total pressure loss is in mm of H2O.

Throw (meters) is measured for a terminal velocities of 0.5 & 0.25 m/sec.

Noice criteria (NC) is based on a room attenuation of 10dB.

Copyright reserved. Specifications subject to change without notice.

2007 Rev. 1

ISO 9001:2000 certified company

3.22

Floor Grilles

Floor Grille - Light Duty

Model: AFG-L

Construction:

Frame: Heavy gauge high quality extruded aluminium profile.

Face bars: 6mm thick high quality aluminium bars

with 12mm pitch.

Description:

Frame is constructed of high quality extruded aluminium profile with the advantages of corrosion

resistance and rigidity.

Structure is robustly constructed with face bars

positioned in the frame.

Face bars assembly is supported by heavy duty

aluminium round rod.

Applicable for installation in gymnasium, sport halls,

hospitals and computer rooms.

Suitable for sill level applications on edges of walkways, passages or raised platforms. Can be supplied in 0o deflection, 15o or 30o one way deflection.

Standard finishes:

Powder coated as per RAL color codes.

Copyright reserved. Specifications subject to change without notice.

2007 Rev. 1

ISO 9001:2000 certified company

3.23

Floor Grilles

Floor Grille - Light Duty

Model: AFG-L

Width in mm

Face Velocity

in m/sec

2.0

2.5

3.0

3.5

4.0

4.5

5.0

Cfm

M/sec

Ps in mm H2O

Throw in m

NC

89

0.042

0.23

0.5-0.7

<20

111

0.053

0.31

0.6-1.1

20

133

0.063

0.52

0.7-1.3

22

156

0.074

0.68

0.9-2.1

25

178

0.084

0.83

1.3-2.5

27

200

0.095

1.18

1.6-3.1

29

222

0.105

1.48

2.2-3.8

30

Cfm

M/sec

Ps in mm H2O

Throw in m

NC

225

0.106

0.23

0.7-1.3

<20

281

0.133

0.31

1.3-2.8

20

337

0.159

0.52

2.3-4.1

25

393

0.186

0.68

2.5-4.8

28

449

0.212

0.83

2.8-5.4

30

505

0.239

1.18

3.5-6.4

32

561

0.265

1.48

4.1-7.3

35

Cfm

M/sec

Ps in mm H2O

Throw in m

NC

347

0.164

0.23

0.8-1.6

<20

434

0.205

0.31

1.5-3.1

20

521

0.246

0.52

2.4-4.5

25

608

0.287

0.68

2.7-5.1

27

695

0.328

0.83

3.3-6.1

30

782

0.369

1.18

4.1-6.9

33

868

0.41

1.48

4.4-7.8

35

Cfm

M/sec

Ps in mm H2O

Throw in m

NC

483

0.228

0.23

0.9-1.8

<20

604

0.285

0.31

1.7-3.7

20

724

0.342

0.52

2.5-4.8

25

845

0.399

0.68

3.1-5.4

28

966

0.456

0.83

3.5-6.7

31

1087

0.513

1.18

4.4-7.3

33

1207

0.57

1.48

4.9-8.2

35

Cfm

M/sec

Ps in mm H2O

Throw in m

NC

602

0.284

0.23

1.1-2.1

<20

752

0.355

0.31

1.8-4.1

20

902

0.426

0.52

2.7-4.9

25

1053

0.497

0.68

3.2-5.7

27

1203

0.568

0.83

3.7-6.9

30

1353

0.639

1.18

4.5-7.2

32

1504

0.71

1.48

5.1-8.3

35

Cfm

M/sec

Ps in mm H2O

Throw in m

NC

724

0.342

0.23

1.2-2.2

<20

905

0.428

0.31

1.8-4.2

20

1087

0.513

0.52

2.6-4.9

25

1268

0.598

0.68

3.0-5.5

28

1449

0.684

0.83

3.6-6.8

31

1630

0.77

1.18

4.5-7.1

33

1811

0.855

1.48

4.9-8.2

35

Af in m

50

0.021

100

0.053

150

0.082

200

0.114

250

0.142

300

0.171

Data based on one meter unit length of the grille with damper in full open position.

Face velocity is measured in m/sec.

Ps - Static pressure loss is in mm of H2O.

Throw (meters) is measured for a terminal velocities of 0.5 & 0.25 m/sec.

Noice criteria (NC) based on a room attenuation of 10dB.

Copyright reserved. Specifications subject to change without notice.

2007 Rev. 1

ISO 9001:2000 certified company

3.24

Floor Grilles

Floor Grille - Heavy Duty

Model: AFG-H

Construction:

Frame: Heavy gauge high quality extruded aluminium profile 4mm thick, flange width 40mm.

Face bars: 60mm high "I" section made up of high

quality extruded aluminium.

Description:

Frame is constructed of high quality extruded aluminium profile with the advantages of corrosion resistance and rigidity.

Structure is robustly constructed with face bars positioned in the frame.

Face bars assembly is reinforced with steel rods to

widthstand heavy loads.

Applicable for installation in gymnasium, sport halls,

hospitals and computer rooms.

A recess of 40mmx4mm has to be provided around

the grille, in the floor to install the grill flush with the

floor (or) carpet level.

Standard finishes:

Powder coated as per RAL color codes.

Grille Size 600x600mm (Overall Size)

Air Flow in CFM

Air Flow in m/sec

192

0.091

383

0.181

424

0.200

574

0.271

766

0.362

957

0.452

1149

0.542

1340

0.632

Neck velocity in m/s

0.96

1.9

2.1

2.9

3.8

4.8

5.7

6.7

Pressure drop in mm of H2O

0.123

0.360

0.480

0.603

0.960

1.55

2.29

3.00

Throw in meters

2.1

2.8

2.9

4.2

5.9

7.5

9.2

10.6

NC

<15

<20

20

25

29

31

33

34

Data based on 600x600mm Grille.

Face velocity is measured in m/sec.

Noise criteria (NC) is based on room attenuation of 10db.

Copyright reserved. Specifications subject to change without notice.

2007 Rev. 1

ISO 9001:2000 certified company

3.25

S-ar putea să vă placă și

- HVAC Equations, Data, and Rules of Thumb, Third EditionDe la EverandHVAC Equations, Data, and Rules of Thumb, Third EditionÎncă nu există evaluări

- Flowtech Grilles & RegisterDocument3 paginiFlowtech Grilles & RegisterLeomark RespondeÎncă nu există evaluări

- Zoning Reference GuideDocument20 paginiZoning Reference GuideqwincyÎncă nu există evaluări

- Saiver AHUDocument12 paginiSaiver AHUNorsyafiqah RoziÎncă nu există evaluări

- Fan Fundamentals PDFDocument57 paginiFan Fundamentals PDFPablo Guzman RetamalÎncă nu există evaluări

- Grilles Registers Diffusers Catalogs 15819Document808 paginiGrilles Registers Diffusers Catalogs 15819Anibal VpÎncă nu există evaluări

- Heat Recovery Units RangeDocument35 paginiHeat Recovery Units RangeGabetsos KaraflidisÎncă nu există evaluări

- 2012 VAV Boxes Energy Efficiency, Air Leakage and ASHRAE 90.1Document29 pagini2012 VAV Boxes Energy Efficiency, Air Leakage and ASHRAE 90.1din_thorpe3248Încă nu există evaluări

- Erv CatalogueDocument12 paginiErv CatalogueSaahil KhaanÎncă nu există evaluări

- Duct CalculationsDocument38 paginiDuct CalculationsDilnesa EjiguÎncă nu există evaluări

- HVAC Systems Duct Design-Duct P DropDocument1 paginăHVAC Systems Duct Design-Duct P DropmhmdjdgmailcomÎncă nu există evaluări

- Hvac-Dbr - R6Document29 paginiHvac-Dbr - R6adkÎncă nu există evaluări

- Plenum Box Sizing For Air Handling Unit (AHU) : Q AxvDocument2 paginiPlenum Box Sizing For Air Handling Unit (AHU) : Q Axvganesh gundÎncă nu există evaluări

- Honeywell Single Duct VAV - VAV Box Schema Eelctrica, Descriere, Mod de FunctionareDocument24 paginiHoneywell Single Duct VAV - VAV Box Schema Eelctrica, Descriere, Mod de FunctionareViorel CatalinÎncă nu există evaluări

- Hospital Operating Theatre PDFDocument56 paginiHospital Operating Theatre PDFfisplÎncă nu există evaluări

- Duct Design For "Super" SupermarketDocument47 paginiDuct Design For "Super" Supermarketkevin_thian_1100% (4)

- High Velocity Duct Design Tips by TraneDocument50 paginiHigh Velocity Duct Design Tips by TraneInventor SolidworksÎncă nu există evaluări

- Ventilation - Electrical Rooms PDFDocument4 paginiVentilation - Electrical Rooms PDFvalentinlupascu33Încă nu există evaluări

- Fresh Air Louver Selection - 11-10-2015Document1 paginăFresh Air Louver Selection - 11-10-2015organicspolybondÎncă nu există evaluări

- ASLI 02 Supply Air Grilles Set - AIR ConditioningDocument21 paginiASLI 02 Supply Air Grilles Set - AIR ConditioningAminul Hassan50% (2)

- Shop Drawing: Welcome Air-Tech (M) SDN BHDDocument1 paginăShop Drawing: Welcome Air-Tech (M) SDN BHDKarthi KeyanÎncă nu există evaluări

- Stair PressurizationDocument11 paginiStair Pressurization185412Încă nu există evaluări

- Supply Air DiffuserDocument6 paginiSupply Air Diffuserntt_121987Încă nu există evaluări

- Air Change RateDocument18 paginiAir Change Ratemumbaimale20009776Încă nu există evaluări

- Ac Duct Sizing TableDocument1 paginăAc Duct Sizing TabledreamagiczÎncă nu există evaluări

- Rainwater DesignDocument64 paginiRainwater DesignarifzakirÎncă nu există evaluări

- Ventilation Lecture 4 PH Alleen LezenDocument25 paginiVentilation Lecture 4 PH Alleen LezenNazimAhmedÎncă nu există evaluări

- AHUDocument5 paginiAHUksahunkÎncă nu există evaluări

- Hvac For AuditoriumDocument15 paginiHvac For AuditoriumkomalÎncă nu există evaluări

- Fcu PipingDocument20 paginiFcu PipingRamadan RashadÎncă nu există evaluări

- Guide 1Document3 paginiGuide 1karimÎncă nu există evaluări

- Dasco 10-18Document9 paginiDasco 10-18Ahmed Azad100% (1)

- FAHU SubmittalDocument62 paginiFAHU SubmittalEngr.MmosaadÎncă nu există evaluări

- SKM Fan Coil Series: Chilled WaterDocument33 paginiSKM Fan Coil Series: Chilled WaterHewa AkreyÎncă nu există evaluări

- Bry-Air Heat Recovery Wheel PDFDocument4 paginiBry-Air Heat Recovery Wheel PDFDak SerikÎncă nu există evaluări

- Duct Sizing & Fan Static Calculation - Week 3Document49 paginiDuct Sizing & Fan Static Calculation - Week 3slow_bbÎncă nu există evaluări

- Fan Fundamentals - Greenheck (May2005)Document24 paginiFan Fundamentals - Greenheck (May2005)jagdishgharoteÎncă nu există evaluări

- Air Diffuser Architecture PDFDocument28 paginiAir Diffuser Architecture PDFBranislavPetrovicÎncă nu există evaluări

- Attenuator Selection ProcedureDocument25 paginiAttenuator Selection ProcedureTuấnÎncă nu există evaluări

- Im j1 Personnel Cooling Load Estimation 2014Document40 paginiIm j1 Personnel Cooling Load Estimation 2014Melvin SanchezÎncă nu există evaluări

- Exhaust Fan SelectionDocument81 paginiExhaust Fan Selectionprabhuselva22100% (1)

- 2020 AHR Expo - FEI - FINALDocument61 pagini2020 AHR Expo - FEI - FINALReinel OrjuelaÎncă nu există evaluări

- Diffuser Sizing GuidelinesDocument1 paginăDiffuser Sizing Guidelinessyed mustafa aliÎncă nu există evaluări

- Comparison of VRF Over ChillersDocument2 paginiComparison of VRF Over ChillersAdil MohdÎncă nu există evaluări

- AHU Replacement DR ESDocument1 paginăAHU Replacement DR ESsajuhereÎncă nu există evaluări

- AHU Vs FCU Comparison PDFDocument5 paginiAHU Vs FCU Comparison PDFamirin_kingÎncă nu există evaluări

- Engineering Guide For Vav TerminalsDocument36 paginiEngineering Guide For Vav TerminalsAmar Singh CÎncă nu există evaluări

- Ceiling DiffusersDocument21 paginiCeiling DiffusersMonal MuthusamyÎncă nu există evaluări

- Fabric Ducting Technical Data Eng North AmericaDocument32 paginiFabric Ducting Technical Data Eng North AmericaVictor MendozaÎncă nu există evaluări

- AHU InstallationDocument2 paginiAHU InstallationYazan AkÎncă nu există evaluări

- BOQ HVAC-Ginger ManesarDocument4 paginiBOQ HVAC-Ginger Manesarmascotengineers100% (1)

- Key Factors To Select FAHU: A Transfer of Knowledge & Expertise ....Document1 paginăKey Factors To Select FAHU: A Transfer of Knowledge & Expertise ....Alihassan100% (1)

- Coil Selection FormatDocument3 paginiCoil Selection FormatFarzanaShaikÎncă nu există evaluări

- Contoh DuctDocument10 paginiContoh DuctBudiman Raharjo'bjo'Încă nu există evaluări

- Ductwork DesignDocument26 paginiDuctwork DesignHafiz Hassan100% (1)

- Run Around Coil Loop Heat RecoveryDocument3 paginiRun Around Coil Loop Heat RecoveryesagcojrÎncă nu există evaluări

- AHU Typical Manifold Arrangement Drawing PDFDocument1 paginăAHU Typical Manifold Arrangement Drawing PDFRajib MondalÎncă nu există evaluări

- Chapter 2 27feb2012Document24 paginiChapter 2 27feb2012virtechÎncă nu există evaluări

- Index: Air MasterDocument25 paginiIndex: Air MasterJosephRusselVizmanosÎncă nu există evaluări

- Index: Air MasterDocument6 paginiIndex: Air Masterfysal_845134Încă nu există evaluări

- BS1881-122 1983Document11 paginiBS1881-122 1983surangaÎncă nu există evaluări

- Gate Valves Options: Two-Piece Stem Housing Single Stem ExtensionsDocument2 paginiGate Valves Options: Two-Piece Stem Housing Single Stem Extensionsmykel_dpÎncă nu există evaluări

- BS 3892-1 1997 - Pulverized-Fuel AshDocument22 paginiBS 3892-1 1997 - Pulverized-Fuel Ashmykel_dp100% (1)

- BS 5163-2 Valves For Waterworks Purposes - Stem Caps For Use On Isolating Valves PDFDocument12 paginiBS 5163-2 Valves For Waterworks Purposes - Stem Caps For Use On Isolating Valves PDFLuis Daniel Contreras67% (3)

- BS 1881-119 1983 - Testing Concrete - Determination of Compressive StrengthDocument8 paginiBS 1881-119 1983 - Testing Concrete - Determination of Compressive Strengthmykel_dpÎncă nu există evaluări

- BS 1881-124 1988 - Testing Concrete - Analysis For Hardened ConcreteDocument32 paginiBS 1881-124 1988 - Testing Concrete - Analysis For Hardened Concretemykel_dpÎncă nu există evaluări

- Communication LoopDocument1 paginăCommunication Loopmykel_dpÎncă nu există evaluări

- April 11 Speaking PresentationDocument3 paginiApril 11 Speaking Presentationmykel_dpÎncă nu există evaluări

- BS 1881-113 1983 - Testing Concrete - Making & Curin No-Fines Test CubesDocument10 paginiBS 1881-113 1983 - Testing Concrete - Making & Curin No-Fines Test Cubesmykel_dpÎncă nu există evaluări

- 9 Soft Skills To Prepare For Canada Jobs MarketDocument14 pagini9 Soft Skills To Prepare For Canada Jobs MarketJoeÎncă nu există evaluări

- Communication Skills PresentationDocument2 paginiCommunication Skills Presentationmykel_dpÎncă nu există evaluări

- Fire Protection Engineering For FacilitiesDocument129 paginiFire Protection Engineering For Facilitiesedmondkera1974Încă nu există evaluări

- PNNL 20882 PDFDocument38 paginiPNNL 20882 PDFmykel_dpÎncă nu există evaluări

- Be Appguide Ashrae901 AhuDocument14 paginiBe Appguide Ashrae901 AhuMaria Gabriela BusteloÎncă nu există evaluări

- 3412C 900 kVA Standby LowBsfc EU 50HzDocument6 pagini3412C 900 kVA Standby LowBsfc EU 50HzddzoningcomÎncă nu există evaluări

- 9 Soft Skills To Prepare For Canada Jobs MarketDocument14 pagini9 Soft Skills To Prepare For Canada Jobs MarketJoeÎncă nu există evaluări

- Din 779Document13 paginiDin 779Vicky Gautam100% (1)

- ASHRAE+52 1+vs+52 2+vs+EN+779Document1 paginăASHRAE+52 1+vs+52 2+vs+EN+779Vipul JainÎncă nu există evaluări

- RE Wall ConstructionDocument80 paginiRE Wall ConstructionV Venkata Narayana88% (8)

- 409747576-Table-VII-MULTIPLIER NBCP Rule 7Document1 pagină409747576-Table-VII-MULTIPLIER NBCP Rule 7Paula Marie AgripaÎncă nu există evaluări

- House Construction - Structural Building - Wikibooks, Open Books For An Open WorldDocument8 paginiHouse Construction - Structural Building - Wikibooks, Open Books For An Open WorldJojo JojoÎncă nu există evaluări

- C PJPT P020 S BLKC LMR SP 001 (A) Layout1Document1 paginăC PJPT P020 S BLKC LMR SP 001 (A) Layout1Alexander SÎncă nu există evaluări

- Problem Set 2 V2Document3 paginiProblem Set 2 V2RalphÎncă nu există evaluări

- Toilet: Layout Toilet With Tanggulan Layout Accesible Toilet With TanggulanDocument1 paginăToilet: Layout Toilet With Tanggulan Layout Accesible Toilet With TanggulanhendriÎncă nu există evaluări

- Annex 5 API 650 Storage Tanks Certificate of Compliance SampleDocument3 paginiAnnex 5 API 650 Storage Tanks Certificate of Compliance SampleLi LiuÎncă nu există evaluări

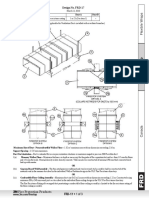

- FRD17Document3 paginiFRD17Raul FloresÎncă nu există evaluări

- Alloy Temperature ChartDocument2 paginiAlloy Temperature ChartDaymer AularÎncă nu există evaluări

- Design Steps of One Way Slab RCCDocument7 paginiDesign Steps of One Way Slab RCCKosygin LeishangthemÎncă nu există evaluări

- Astm B566 93 2002Document2 paginiAstm B566 93 2002rahittÎncă nu există evaluări

- ELECT-TIC-2.1 - (Material Receiving Inspection For MV Power Cables & Accessories)Document2 paginiELECT-TIC-2.1 - (Material Receiving Inspection For MV Power Cables & Accessories)Muhammad IrfanÎncă nu există evaluări

- Wind LoadDocument6 paginiWind LoadRajasekar Meghanadh0% (1)

- Strong Suit of Midas Civil For Malaysian Bridge Engineers: MIDAS Technical Support SystemDocument2 paginiStrong Suit of Midas Civil For Malaysian Bridge Engineers: MIDAS Technical Support SystemjunjiangÎncă nu există evaluări

- Silt TrapDocument5 paginiSilt TrapasyreenhaikalÎncă nu există evaluări

- Asi Steel ConnectionsDocument134 paginiAsi Steel ConnectionsSandro Ledermann-Türme94% (17)

- Module 1 - 863463150Document112 paginiModule 1 - 863463150SACHIDANANDA SÎncă nu există evaluări

- ADM Masonry M1Document26 paginiADM Masonry M1Ronel ConstantinoÎncă nu există evaluări

- Summary of Fluoropolymer Properties - 1Document1 paginăSummary of Fluoropolymer Properties - 1Amir KhanÎncă nu există evaluări

- Rina Membership Application Form - Associate MemberDocument3 paginiRina Membership Application Form - Associate Memberpramodkb_cusatÎncă nu există evaluări

- Mechanical Assembly - Chapter 33Document67 paginiMechanical Assembly - Chapter 33xharpreetxÎncă nu există evaluări

- Architecture Vernacular Terms 2Document2 paginiArchitecture Vernacular Terms 2Christian James TuazonÎncă nu există evaluări

- Hydroflex 30/hydroflex 30S: General DescriptionDocument1 paginăHydroflex 30/hydroflex 30S: General DescriptionNicky LimÎncă nu există evaluări

- Lifting Lug CalculationDocument2 paginiLifting Lug Calculationrustamriyadi100% (2)

- Nfpa 24Document16 paginiNfpa 24Sreenath S KallaaraÎncă nu există evaluări

- 2011 Understanding Stakeholders' Perspective of Cost Estimation in Project ManagementDocument15 pagini2011 Understanding Stakeholders' Perspective of Cost Estimation in Project ManagementHellen HuamanÎncă nu există evaluări

- HVAC Load CalculationDocument5 paginiHVAC Load Calculationthanh_79Încă nu există evaluări

- Asme B18.12-2020Document113 paginiAsme B18.12-2020윤규섭0% (1)

- 547315-En 1.0.0Document160 pagini547315-En 1.0.0Jose MustienesÎncă nu există evaluări

- Garage Door Opener Abridor de Puerta de Cochera: Owner's Manual/Manual Del PropietarioDocument76 paginiGarage Door Opener Abridor de Puerta de Cochera: Owner's Manual/Manual Del PropietarioAbbas ShahidÎncă nu există evaluări