Documente Academic

Documente Profesional

Documente Cultură

Simplified VOC Management Plan, Rev

Încărcat de

Sumeet SawantDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Simplified VOC Management Plan, Rev

Încărcat de

Sumeet SawantDrepturi de autor:

Formate disponibile

VOC MANAGEMENT PLAN

SHIP NAME: IMO NUMBER: DOCUMENT REVISION NO.

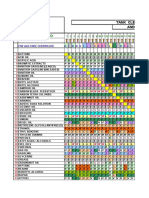

RECORDS OF CHANGES Rev. No. Section Page Date Description Sign.

LIST OF CONTENTS a/a I II III Section Introduction Objectives Additional Considerations pa e

SECTION ! Ca" o tan#$ pa"tic%&a"$ 1.1 Tank arrange ents 1.! Design Particulars SECTION ' Ca" o Tan# (entin $)$te*$ !.1 Description o" t#e vessel$s venting s%ste !.! Set opening pressures o" venting devices SECTION + &.1 &.! &.& Vo&ati&it) o, c"%-e oi&$ . VOC ene"ation *ec/ani$*$ 'ackground T#e volatilit% or vapour pressure o" t#e crude oil (OC generation ec#anis s

SECTION 0 Mean$ ,o" "e-%ction o, VOC e*i$$ion$. ).1 Installations "or reduction o" (OC e issions ).! Operational e issions easures "or t#e reduction o" (OC

SECTION 1 T/e *onito"in an- cont"o& o, VOC "e&ea$e$ SECTION 2 T"ainin p"o "a**e SECTION 3 De$i nate- pe"$on SECTION 4 Li$t o, -"a5in $6 p&an$ an- *an%a&$

Int"o-%ction T#is *anual contains speci"ic in"or ation and procedures "or t#is crude oil tanker to con"or +it# t#e operational re,uire ents and objectives o" t#e I*O -uidelines "or t#e Develop ent o" a (OC *anage ent Plan +#ic# stipulate as "ollo+s. 1.1 Objectives .1 .& The purpose of the VOC management plan is to ensure that the operation of a tanker, to which regulation 15 of MARPO Anne! V" applies, pre#ents or minimi$es VOC emissions to the e!tent possi%le. 'missions of VOC can %e pre#ente( or minimi$e( %)* .1 optimi$ing operational proce(ures to minimi$e the release of VOC emissions+ an(,or .& using (e#ices, e-uipment or (esign changes to pre#ent or minimi$e VOC emissions. .. To compl) with this plan, the loa(ing an( carriage of cargoes which generate VOC emissions shoul( %e e#aluate( an( proce(ures written to ensure that the operations of a ship follow %est management practices for the pre#enting or minimi$ing VOC emissions to the e!tent possi%le. "f (e#ices, e-uipment or (esign changes are implemente( to pre#ent or minimi$e VOC emissions, the) shall also %e incorporate( an( (escri%e( in the VOC management plan as appropriate. 0hile maintaining the safet) of the ship, the VOC management plan shoul( encourage an(, as appropriate, set forth the following %est management practices* .1 the loa(ing proce(ures shoul( take into account potential gas releases (ue to low pressure an(, where possi%le, the routing of oil from cru(e oil manifol(s into the tanks shoul( %e (one so as to a#oi( or minimi$e e!cessi#e throttling an( high flow #elocit) in pipes+ .& 1in case of manual release,%low2(own of ullage pressure is practice(3 the ship shoul( (efine a target operating pressure for the cargo tanks. This pressure shoul( %e as high as safel) possi%le an( the ship shoul( aim to maintain tanks at this le#el (uring loa(ing an( carriage of the rele#ant cargo+ .. when #enting to re(uce tank pressure is re-uire(+ the (ecrease in the pressure in the tanks shoul( %e as small as possi%le to maintain the tank pressure as high as possi%le+

./

./ the amount of inert gas a((e( shoul( %e minimi$e(. "ncreasing tank pressure %) a((ing inert gas (oes not pre#ent VOC release %ut it ma) increase #enting an( therefore increase( VOC emissions+ an( .5 when cru(e oil washing is consi(ere(, its effect on VOC emissions shoul( %e taken into account. VOC emissions can %e re(uce( %) shortening the (uration of the washing or %) using a close( c)cle cru(e oil washing programme. 1.2 Additional considerations .1 A person in charge of carr)ing out the plan .1 A person shall %e (esignate( in the VOC management plan to %e responsi%le for implementing the plan an( that person ma) assign appropriate personnel to carr) out the rele#ant tasks+

.&

Proce(ures for pre#enting or minimi$ing VOC emissions .1 4hip2specific proce(ures shoul( %e written or mo(ifie( to a((ress rele#ant VOC emissions, such as the following operations* .1 .& .. oa(ing+ a(en Vo)age Cru(e oil washing.

.& "f the ship is e-uippe( with VOC re(uction (e#ices or e-uipment, the use of these (e#ices or e-uipment shoul( %e incorporate( into the a%o#e proce(ures as appropriate. .. Training .1 The plan shoul( (escri%e the training programmes to facilitate %est management practices for the ship to pre#ent or minimi$e VOC emissions. Section ! 7 Ca" o tan# pa"tic%&a"$ !.! A&&o5a8&e ca" o tan# %&&a e p"e$$%"e T#e cargo tank structure is designed to +it#stand a range o" design loads and parts o" t#e tank structure +ill also contribute to t#e global longitudinal strengt# o" t#e s#ip. T#e Classi"ication Societies$ speci"ied load conditions and loads are applied in veri"ication o" t#e structural design. /0ceeding t#e a0i u allo+able pressures could lead to structural "ailures. I" suc# a structural "ailure results in opening o" t#e tank structure to at osp#ere1 uncontrolled (OC e issions +ill occur toget#er +it# t#e possibilit% o" oil pollution to t#e seas. 2urt#er1 it could result in loss o" inert gas protection +it# subse,uent #a3ards related to "ire and e0plosion.

T#is s#ip #as 44 cargo tanks and 5 slop tanks. 6 Total volu e o" cargo tanks. 777777 & 6 Total (olu e o" slop tank8s9. 7777777 & 6 Nu ber o" cargo segregations. 7777777 Design particulars. 6 Design vapour pressure. 6 *a0. per itted vacuu . Section ' 7 Ca" o tan# (entin $)$te*$ '.! De$c"iption o, t/e $/ip9$ (entin $)$te*: is included in Section ;. :.44 bar :.:5 bar

T#e s#ip$s cargo tank venting s%ste

!.<.1 Set pressures o" venting devices. 6 Cargo=Slop tank$s P=(6valves. 7777777 barg=777777777bar vacuu 6 *ast riser b%6pass breat#er valve. 7777777 barg=777777777bar vacuu 8i" "itted9 6 *ast riser b%6pass pressure control valve. 7777777 barg=777777777bar vacuu 8i" "itted9 6 >i,uid P=(6breaker. 777777777barg=77777777bar vacuu An) ship that has a P,V2#al#e setting a%o#e the stan(ar( 1/55 mm06, ma) %e consi(ere( to ha#e implemente( a measure for VOC re(uction an( this coul( %e specifie( in the manual. Section + 7 Vo&ati&it) o, c"%-e oi&$ . VOC ene"ation *ec/ani$*$ +.! Bac# "o%n-

?#% li it N*(OC / issions to t#e at osp#ere@ N*(OCs are a pollutant to t#e air and act as a precursor to t#e "or ation o" Troposp#eric O3one A co onl% ter ed S og. Troposp#eric O3one is identi"ied as a -reen#ouse -as +it# a greater contribution per unit volu e or tonnage to Cli ate C#ange t#an t#e base gas1 na el% Carbon Dio0ide. &.! T/e (o&ati&it) o" (apo%" p"e$$%"e o, t/e c"%-e oi&

Crude oil is a i0ture o" #%drocarbon co pounds ranging "ro #eav% li,uids to lig#t li,uids and +it# absorbed #%drocarbon gases not e0isting as li,uids under nor al a bient conditions. T#e easure o" volatilit% is t#e vapour pressure o" t#e crude oil. (apour pressure is given eit#er as. 6 Reid (apour Pressure 8R(P9 or 6 True (apour Pressure 8T(P9 R(P is t#e ost co onl% used easure "or vapour pressure o" oils in t#e oil industr% and is t#e saturated vapour pressure above t#e li,uid easured in a special apparatus at a te perature o" &B.; CC. T#e easuring apparatus is a closed container +#ere a sa ple o" t#e

li,uid +it# a volu e o" !:D o" t#e container volu e is "illed1 i.e. t#e vapour space is ) ti es t#e volu e o" t#e li,uid sa ple. T#e li,uid is #eated to &B.; CC and t#e gauge pressure reading is t#e R(P in absolute pressure. T(P is t#e saturated vapour pressure above a li,uid at a speci"ied te perature. Co pared to R(P t#e T(P represent t#e partial vapour pressure easured in a container +it# a negligible vapour space. 2or a #o ogenous li,uid not containing absorbed gases1 t#e R(P and T(P easured at &B.; CC +ill be appro0i atel% e,ual. 2or a crude oil +#ic# contain absorbed gases1 e.g. et#ane1 et#ane1 propane etc.1 t#e R(P +ill be lo+er t#an T(P at &B.; CC. T#e reason is t#at +#en t#e absorbed gases igrates into a vapour space ) ti es t#e volu e o" t#e li,uid sa ple t#e concentration o" t#ese co ponents in t#e li,uid is reduced. Conse,uentl% t#e easured saturated vapour pressure represent a Ede6gassed$ crude oil and +ill be lo+er t#an t#e true vapour pressure. In a closed and "ull% loaded cargo tank +it# a vapour space about !D o" t#e tank volu e1 t#e actual partial #%drocarbon vapour pressure +ill be t#e true vapour pressure1 T(P. +.+ VOC ene"ation *ec/ani$*$

+.+.! :F&a$/in 9 During loading1 lo+ pressure in t#e loading s%ste a% cause absorbed gases to "or gas bubbles and lig#t li,uid "ractions to evaporate. T#is +ill in particular #appen in t#e top o" t#e drop line. T#e pressure at t#is point +ill be belo+ at osp#eric pressure deter ined b% t#e speci"ic +eig#t o" t#e li,uid colu n in t#e drop line inus t#e tank at osp#ere pressure and t#e li,uid #eig#t above t#e drop line outlet in t#e tank. I" t#e pressure "alls belo+ T(P1 vapour bubbles +ill be "or ed in t#e drop line and transported into t#e tank b% t#e li,uid "lo+. Re6 absorption in t#e crude oil +ill be ini al and t#e E"las#$ gases +ill increase t#e pressure in t#e vapour space o" t#e tank. As t#e li,uid level in t#e tank rises1 t#e underpressure in top o" t#e drop line +ill be reduced1 i.e. t#e absolute pressure rises.. ?#en t#e absolute pressure in t#e top o" t#e dropline e0ceeds t#e T(P1 E"las#ing$ +ill cease. +.+.' De. a$$in ; e(apo"ation. T#e sur"ace la%er o" t#e li,uid in t#e tank +ill give o"" vapours until t#e partial pressure o" t#e various vapour co ponents in t#e at osp#ere la%er above t#e li,uid sur"ace reac#es saturation +it# t#e concentration o" absorbed gases in t#e li,uid. Assu ing t#ere is no agitation o" t#e li,uid and o" t#e vapour space a concentration di""erence o" absorbed gases bet+een t#e top la%er o" t#e li,uid and li,uid lo+er in t#e tank. Above t#e li,uid a si ilar concentration gradient +ill occur. Di""usion +ill over ti e even out t#e concentration di""erences but t#is is a slo+ process 8concentration gradient is t#e driving "orce9.

I" agitation o" t#e li,uid and=or tank at osp#ere takes place t#is +ill greatl% speed up t#e reduction o" t#e concentration di""erences and t#ereb% substantiall% increase vapour release "ro t#e li,uid. +.+.+ Te*pe"at%"e inc"ea$e. T#e saturated partial pressures o" vapour increases +it# te perature o" t#e li,uid. An increase in t#e cargo te perature during a vo%age +ill t#ere"ore increase t#e vapour space pressure and cause opening o" P=( valves.. I" t#e te perature increase causes t#e T(P o" t#e crude oil to e0ceed t#e opening pressure o" t#e P=( valves1 vapour release to t#e at osp#ere +ill continue until t#e concentration o" absorbed gases in t#e li,uid reac#es an e,uilibriu +it# t#e partial vapour pressure. Te perature increase o" t#e at osp#ere in t#e vapour space +it#out corresponding te perature increase o" t#e cargo 8sun #eating o" deck plating9 +ill increase t#e vapour space pressure due to t#er al e0pansion o" t#e gas i0ture. T%picall% one +ill see pressure variations during da%6nig#t. Fo+ever1 t#is +ill not cause ore vapour release "ro t#e li,uid. +.+.0 P"e$$%"e -ec"ea$e in (apo%" $pace >eakages1 e.g. t#roug# P=( valves or #atc# gaskets1 +ill decrease t#e vapour space pressure. T#is +ill cause t#e crude oil to give o"" vapours to restore t#e saturated partial vapour pressure1 i.e. T(P i" "ull% loaded tank. T#e sa e takes place i" o" ast riser valve. +.+.1 C"%-e oi& 5a$/in . ?#en a cargo tank is disc#arged inert gas is supplied to "ill t#e increasing vapour space. I" t#e agitation o" t#e li,uid and t#e vapour space is s all or oderate t#e resulting at osp#ere in t#e tank at t#e end o" disc#arge +ill be a la%er o" saturated vapour=inert gas i0ture and a progressivel% leaner i0ture to+ards t#e top o" t#e tank. T#is ean t#at less cargo vapours +ill be displaced at ne0t loading. Fo+ever1 i" t#e tank is crude oil +as#ed during cargo disc#arge t#is causes severe agitation o" t#e tank at osp#ere and release o" cargo vapours "ro t#e +as#ing li,uid as +ell as "ro t#e cargo residues in t#e tank. I" +as#ing is done using E"res#$ crude oil 8bleed6o"" "ro disc#arge line9 t#e resulting tank at osp#ere +ill be saturated +it# vapours +#ic# subse,uentl% +ill be displaced at ne0t loading. I" Eclosed$ crude oil +as#ing is done1 i.e. a crude oil c#arge in slop tanks is re6circulated1 less vapour +ill be released to t#e tank at osp#ere as t#e +as#ing li,uid is de6gassed. +.+.2 Loa-in /i / TVP ca" o T#e SO>AS convention per its loading o" crude oils +it# R(P up to 1 bar 8at osp#eric pressure9. I" suc# a cargo is loaded #aving a te perature o" e.g. )< CC 8 a% +ell #appen during su er season in t#e Arabian -ul"91 t#e cargo +ill release absorbed gases until t#e anual blo+6do+n o" vapour space pressure is done b% e.g. opening

partial vapour pressure1 i.e. T(P1 is belo+ set opening pressure o" t#e P=( valves. T#is release to t#e environ ent ,uite substantial volu es o" vapour. Section 0 7 Mea$%"e$ ,o" "e-%ction o, VOC e*i$$ion$. 0.! 0.!.! In$ta&&ation$ ,o" "e-%ction o, VOC e*i$$ion$

eans

Vapo%" E*i$$ion Cont"o& S)$te*$ 17elete as applica%le3 2or s#ips provided +it# a (/CS s%ste as per I*O or GSC- regulations GSC2 )H C2R Part &I and I*O *SC.Circ.<;<91 t#e control o" N*(OC e issions +ill be t#roug# returning (OC to s#ore ter inal in accordance +it# t#e procedures "ound in t#e onboard (/CS anual. 2or t#is vessel t#e design cargo loading rate o" t#e s#ip is appro0i atel% GGGGG &=# +#en loading t#roug# all cargo ani"olds and loading all cargo oil tanks. T#e design a cargo disc#arge rate is appro0i atel% ((((( &=# +it# t#e use o" all t#ree ain cargo pu ps. Note #o+ever t#at as per t#e (/CS anual t#e "ollo+ing loading rate restrictions appl%. 6 6 6 *a0i u *a0i u *a0i u loading rate o" a single cargo tank. appro0. 4444 &=# loading rate o" slop tanks. appro0. 5555 &=# loading rate o" all cargo tanks. appro0. JJJJJ &=#

T#e above li itations appl% "or a cargo +it# a a0i u vapour gro+t# rate o" 444 and a a0i u densit% o" 555 kg= &. 2or lo+er vapour gro+t# rates and densities1 t#e loading rate a% be increased in accordance +it# t#at stated in t#e (/CS anual.K . 0.!.' Vapo%" P"e$$%"e Re&ea$e Cont"o& Va&(e 17elete as applica%le3 A vapour pressure control valve a% be installed in a b%6pass to t#e ast riser valve to control t#e opening and closing pressure "or vapour pressure release. I" suc# valves #ave t#e capacit% to #andle t#e total gas "lo+ during loading1 it can also be used to aintain a #ig#er pressure t#roug#out t#e loading process. T#e e""ect is to reduce t#e vapour evaporation "ro t#e crude oil. T#e setting o" t#e valve s#ould be just belo+ t#e P=(6valve setting. 0.' 0.'.! Ope"ationa& *ea$%"e$ ,o" t/e "e-%ction o, VOC e*i$$ion$ 8'!ample onl)2 amen(,(elete as applica%le3 Ope"ationa& *ea$%"e$6 ene"a& Carr% out regular inspection o" P=( valves1 #atc#es and pipe connections "or tig#tness. An% leakages detected s#all be entered into t#e aintenance progra "or recti"ication at "irst opportunit%. 0.'.' Ope"ationa& *ea$%"e$ -%"in &oa-in 5it/ no (apo%" "et%"n <VECS= 8'!ample onl)2 amen(,(elete as applica%le3

>oading s#ould be started +it# lo+ to oderate loading rate until loading outlets 8bell out#s9 in tanks are +ell sub erged1 e.g. "illing to 1 . Fig# loading rate per tank eans s#orter "illing ti e and less vapour release "ro t#e crude oil. I" practicable1 considering tri and bending o ent=s#ear "orce1 loading segregation b% segregation at a0 rate is "avourable. Fig# vapour space pressure reduces vapour release "ro t#e cargo during loading. A procedure +#ere t#e initial slo+ loading takes place +it# t#e ast riser valve open "ollo+ed b% closing t#e riser valve and let t#e P=( valves on t#e tanks take care o" t#e release o" e0cess vapour=inert gas during t#e subse,uent loading +ill be bene"icial. 0.'.+ Ope"ationa& *ea$%"e$ -%"in &a-en (o)a e 8'!ample onl)2 amen(,(elete as applica%le3 *anual release=blo+6do+n o" ullage 8vapour space9 pressure s#ould be avoided as "ar as practicable. I" carried out t#e (OCCON procedure s#ould be considered applied. I" lo+ tank pressure occurs aking inert gas top6up necessar% suppl% pressure is kept belo+ opening pressure o" t#e P=( valves. 0.'.0 Ope"ationa& *ea$%"e$ -%"in -i$c/a" in an- CO> 8'!ample onl)2 amen(,(elete as applica%le3 Do not +as# ore tanks t#an +#at is re,uired b% t#e Convention 81=) o" t#e tanks9 unless special circu stances ake it necessar%. A "ull c%cle 8top6botto 6top "or single no33le ac#ines9 +ill nor all% not be necessar%. ?as#ing covering lo+er stringers and tank botto +ill in ost cases be enoug# "or sedi ent control. Closed c%cle CO? a% be considered. I.e. re6circulate crude oil used "or +as#ing to="ro slop tanks. T#is reduces vapour release "ro t#e crude oil co pared to using $"res#$ oil bleed "ro disc#arge lines. I" vessel$s tri =bending o ent per it1 tanks intended to be +as#ed s#ould be disc#arged "irst. (apour released +#en t#ese tanks are +as#ed a% t#en be used to "ill t#e ot#er tanks being disc#arged 0.'.1 Ope"ationa& *ea$%"e$ -%"in 8a&&a$t (o)a e 8'!ample onl)2 amen(,(elete as applica%le3 I" lo+ tank pressure occurs aking inert gas top6up necessar% suppl% pressure is kept belo+ opening pressure o" t#e P=( valves. Section 1.? . T/e Monito"in an- Cont"o& o, NMVOC Re&ea$e$ <.1 S#ips t#at are not provided +it# (OC recover%=reduction installations #ave li ited control over (OC releases during loading or as a result o" auto atic opening o" P=(6 valves. I.e. record keeping is considered relevant onl% i" anual release=blo+6do+n o" t#e ullage pressure is carried out onboard. ake sure t#at t#e ake sure t#at t#e

<.! 2or s#ips t#at do not per"or necessar%. Section 2.? . T"ainin P"o "a**e H.1

anual release=blo+6do+n1 recording is not dee ed

Persons in c#arge o" t#e (OC progra e co prising. 1 ! & ) < H

anage ent onboard #ave co pleted a training

An introduction to t#e purpose o" (OC e ission control. 6 Regulation 1< o" Anne0 (I to *ARPO> B&=B; An introduction to t#e principles o" (OC e ission control. -eneral (OC e ission control options S#ip speci"ic (OC e ission control options *onitoring and recording o" (OC release Fa3ards and Sa"et% related to (OC e ission control

Section 3.? . De$i nate- Pe"$on B.1 T#e person designated to assu e overall c#arge o" t#e (OC s#ip isL 777777777777777777777. Section 4.? . Li$t o, -"a5in $ ;.1 T#e "ollo+ing dra+ings are reco plan. 6 6 6 6 6 6 6 ended included as appendices to t#e anage ent anage ent onboard t#e

-eneral Arrange ent dra+ing Tank plan Sc#e atic dra+ing8s9 o" t#e Cargo tank venting s%ste Sc#e atic dra+ing o" t#e inert gas s%ste Sc#e atic dra+ing o" t#e vapour e ission control s%ste s 8i" applicable9 Sc#e atic dra+ing8s9 (apour Recover% S%ste or ot#er (OC control s%ste s. Details o" pressure vacuu relie" devices including settings and capacities.

Cross Re"erences to s#ip speci"ic anuals or docu ents suc# as. 6 (apour / ission Control S%ste anual 8i" applicable9 6 (apour Recover% S%ste anual 8i" applicable9. 6 Ot#er (OC control s%ste anual 8i" applicable9 6 Inert -as anual 6 CO? anual

S-ar putea să vă placă și

- Guidelines For VOC Management Plan - Final - 2010Document31 paginiGuidelines For VOC Management Plan - Final - 2010Cari RiveraÎncă nu există evaluări

- Consolidated Version of The Survey Guidelines Under HSSC of Survey and CertificateDocument182 paginiConsolidated Version of The Survey Guidelines Under HSSC of Survey and CertificatemecatronicatresÎncă nu există evaluări

- Stowage On Chemical Tankers - MySDocument32 paginiStowage On Chemical Tankers - MySShoaib100% (1)

- LPG Tanker 1Document2 paginiLPG Tanker 1Somayajula SuryaramÎncă nu există evaluări

- Solas Chapter 3 Rule 1 To 13Document38 paginiSolas Chapter 3 Rule 1 To 13Ruby ShajiÎncă nu există evaluări

- Amends To SDs 2011Document214 paginiAmends To SDs 2011duaankushÎncă nu există evaluări

- Air Lubrication TechnologyDocument15 paginiAir Lubrication TechnologyzaladsÎncă nu există evaluări

- 23 - Liquefied Gas CarriersDocument11 pagini23 - Liquefied Gas Carriersrakujin100% (1)

- A Complete Guide of Loading TDI Onboard A Chemical TankerDocument19 paginiA Complete Guide of Loading TDI Onboard A Chemical TankerKunal Singh100% (1)

- LCHS Oil Tanker Cargo Manual2Document50 paginiLCHS Oil Tanker Cargo Manual2Prajyot SinhaÎncă nu există evaluări

- Asian VettingDocument13 paginiAsian Vettingkhaled1160Încă nu există evaluări

- OMHEC Communication Hoisting OperationsDocument20 paginiOMHEC Communication Hoisting OperationsLasse WelleÎncă nu există evaluări

- White Paper On GrabsDocument6 paginiWhite Paper On Grabsbraemarsa100% (1)

- Opex The Ship Management View: V.ShipsDocument19 paginiOpex The Ship Management View: V.Shipsricardo naisÎncă nu există evaluări

- 10 Wartsila K Portin Performance DF Engines in LNG CarriersDocument21 pagini10 Wartsila K Portin Performance DF Engines in LNG Carriersali kharalÎncă nu există evaluări

- Early Designs: Zoroaster, The World's First Tanker, Delivered To The Nobel Brothers in Baku (Azerbaijan)Document7 paginiEarly Designs: Zoroaster, The World's First Tanker, Delivered To The Nobel Brothers in Baku (Azerbaijan)Dincu VladÎncă nu există evaluări

- Inert Gas SysDocument21 paginiInert Gas SysPovenesan Krishnan100% (1)

- Vapour Emission Control System Operation ProcedureDocument2 paginiVapour Emission Control System Operation ProcedureRahulChoudharyÎncă nu există evaluări

- Ocimf 2014年第5版 船靠船作业指南 介绍 20-Tech-feb-2014Document2 paginiOcimf 2014年第5版 船靠船作业指南 介绍 20-Tech-feb-2014xingangÎncă nu există evaluări

- Engine Management - Concept For LNG Carriers PDFDocument20 paginiEngine Management - Concept For LNG Carriers PDFKarim Sowley DelgadoÎncă nu există evaluări

- FAQ On Dangerous Goods by SeaDocument44 paginiFAQ On Dangerous Goods by SeajawaidchemicalsÎncă nu există evaluări

- ABS Low Carbon ShippingDocument80 paginiABS Low Carbon Shippingmsantosu000Încă nu există evaluări

- Nav IV U2 PDFDocument19 paginiNav IV U2 PDFCosmin CaramanÎncă nu există evaluări

- Tanker Operator 11/12 2012Document64 paginiTanker Operator 11/12 2012zisparask78Încă nu există evaluări

- A Complete Guide of Cargo Sampling On Tankers - MySeaTimeDocument17 paginiA Complete Guide of Cargo Sampling On Tankers - MySeaTimevdeviv67% (3)

- Material Safety Data Sheet According To 91/155 ECDocument4 paginiMaterial Safety Data Sheet According To 91/155 ECvinithaÎncă nu există evaluări

- Gard Guidance On Freight Containers: Jeroen de HaasDocument171 paginiGard Guidance On Freight Containers: Jeroen de HaasnaufragatoÎncă nu există evaluări

- Vapour Control SystemsDocument17 paginiVapour Control SystemsDMYTRO STRYZHKOVÎncă nu există evaluări

- BP Open Sampling & Additivisation Procedure 1 - 0Document51 paginiBP Open Sampling & Additivisation Procedure 1 - 0ParaZzzitÎncă nu există evaluări

- 2011-Comparison of Methodologies Estimating Emissions of Aircraft Pollutants, Environmental Impact Assessment Around AirportsDocument13 pagini2011-Comparison of Methodologies Estimating Emissions of Aircraft Pollutants, Environmental Impact Assessment Around Airportsipagoni1Încă nu există evaluări

- Petroleum Calculation SeriesDocument2 paginiPetroleum Calculation SeriesAguara OghenevwedeÎncă nu există evaluări

- Change of Cargo Grades or Preparation For DrydockDocument3 paginiChange of Cargo Grades or Preparation For DrydockAlice Mano JiamaÎncă nu există evaluări

- Guide To Vetting Proceed 2017 - Part74 PDFDocument2 paginiGuide To Vetting Proceed 2017 - Part74 PDFQuang Hòa LưuÎncă nu există evaluări

- XChangeDocument17 paginiXChangeGeileanu Catalin100% (1)

- MM2000 - DatasheetDocument2 paginiMM2000 - DatasheetABDUL GHAFOORÎncă nu există evaluări

- HOEGHDocument597 paginiHOEGHAleksÎncă nu există evaluări

- Tanker Calculation PDFDocument2 paginiTanker Calculation PDFSipuÎncă nu există evaluări

- 19.vapour Return Safety ChecklistDocument2 pagini19.vapour Return Safety Checklistc rkÎncă nu există evaluări

- Ammonia Fueled Vessels: Guide ForDocument62 paginiAmmonia Fueled Vessels: Guide ForFlo MarineÎncă nu există evaluări

- SHIPOWNERS Sampling Procedures For TankersDocument5 paginiSHIPOWNERS Sampling Procedures For TankersErsin SaltÎncă nu există evaluări

- ODMEDocument5 paginiODMEAkhil MathewÎncă nu există evaluări

- Brochure of Dongyang RopesDocument34 paginiBrochure of Dongyang RopesVu Duc Quang100% (1)

- Supervision of Crude Oil Washing (COW) OperationsDocument6 paginiSupervision of Crude Oil Washing (COW) Operationstony100% (1)

- Pub149 LNGPumpTower GNJuly09 PDFDocument64 paginiPub149 LNGPumpTower GNJuly09 PDFZetaÎncă nu există evaluări

- CH 0 Cleaning Cross Refference Table DREW AMEROIDDocument36 paginiCH 0 Cleaning Cross Refference Table DREW AMEROIDPavel ViktorÎncă nu există evaluări

- OCIMF High Risk' Observations ListDocument7 paginiOCIMF High Risk' Observations ListFerdinand ArsolonÎncă nu există evaluări

- SEXTANTDocument5 paginiSEXTANTEmrah GurelÎncă nu există evaluări

- Free Crew Internet Allowance Policy PDFDocument5 paginiFree Crew Internet Allowance Policy PDFLourene Jauod- GuanzonÎncă nu există evaluări

- General Cleaning GuideDocument11 paginiGeneral Cleaning GuidecptmehmetkaptanÎncă nu există evaluări

- 5549-Tank Vessel Cargo Oil Transfer ProceduresDocument3 pagini5549-Tank Vessel Cargo Oil Transfer ProceduresMaaloul FakherÎncă nu există evaluări

- An Estimate of Operating Costs For Bulk, Ro-Ro and Container ShipsDocument50 paginiAn Estimate of Operating Costs For Bulk, Ro-Ro and Container ShipsJoseoÎncă nu există evaluări

- Normam 20 EnglishDocument25 paginiNormam 20 EnglishPaulo FurquimÎncă nu există evaluări

- WWW Sevensurveyor Com Wedge FormulaDocument14 paginiWWW Sevensurveyor Com Wedge FormulaSurya Putra JayaÎncă nu există evaluări

- IMO Good NotesDocument36 paginiIMO Good NotespawanÎncă nu există evaluări

- IFIA Test Question Book English - August 2010Document84 paginiIFIA Test Question Book English - August 2010Maksim Lemon Rutovic100% (2)

- Cargo Control RoomDocument15 paginiCargo Control RoomStamatis KaragounisÎncă nu există evaluări

- "Absorption": Experiment NoDocument3 pagini"Absorption": Experiment NonithansaÎncă nu există evaluări

- Evaluasi Kinerja Sucker Rod PumpDocument13 paginiEvaluasi Kinerja Sucker Rod PumpRichard Arnold SimbolonÎncă nu există evaluări

- Vapor Pressure in The Transport, Storage, and Bending of Crude OilDocument10 paginiVapor Pressure in The Transport, Storage, and Bending of Crude OilRicardo BecÎncă nu există evaluări

- Hydrogen Sulfide (H2S) - Q & ADocument7 paginiHydrogen Sulfide (H2S) - Q & AJason OrteÎncă nu există evaluări

- Marine Boiler Question AnswersDocument9 paginiMarine Boiler Question AnswersSumeet SawantÎncă nu există evaluări

- Harmonised Survey SystemDocument4 paginiHarmonised Survey SystemSumeet SawantÎncă nu există evaluări

- Function 4b OralsDocument13 paginiFunction 4b OralsSumeet SawantÎncă nu există evaluări

- Charging of Accumulators For Alpha LubricatorDocument4 paginiCharging of Accumulators For Alpha LubricatorSumeet Sawant100% (4)

- Alpha Lubricator System Operation (ALCU) Manual MC EnginesDocument167 paginiAlpha Lubricator System Operation (ALCU) Manual MC Enginesstepewolf91% (22)

- MgpsDocument2 paginiMgpsSumeet SawantÎncă nu există evaluări

- Orals Cl-II-b Nov-2013 (25th Nov To 29th Nov 2013)Document2 paginiOrals Cl-II-b Nov-2013 (25th Nov To 29th Nov 2013)Sumeet SawantÎncă nu există evaluări

- Marine Boiler Question AnswersDocument9 paginiMarine Boiler Question AnswersSumeet SawantÎncă nu există evaluări

- Ibf Mui Agreement 2010 2011Document23 paginiIbf Mui Agreement 2010 2011raghuroxxÎncă nu există evaluări

- Boiler BurnerDocument12 paginiBoiler BurnerSumeet SawantÎncă nu există evaluări

- TRASSIDocument7 paginiTRASSIRohit Mishra50% (2)

- Transportation Law: I. Article 1732 of The Civil CodeDocument2 paginiTransportation Law: I. Article 1732 of The Civil CodeSAMANTHA NICOLE BACARONÎncă nu există evaluări

- Is 1223 2001Document26 paginiIs 1223 2001akÎncă nu există evaluări

- Imanual, and Sohanlal v. Union of India: A.l.R. 1969 S.C. 1306 A.I.R. 1957 S.C. 529Document5 paginiImanual, and Sohanlal v. Union of India: A.l.R. 1969 S.C. 1306 A.I.R. 1957 S.C. 529Ashvani SharmaÎncă nu există evaluări

- Spa - TMK at Venus - GCV (Arb) 4200 - 4000Document25 paginiSpa - TMK at Venus - GCV (Arb) 4200 - 4000Abimanyu SutanegaraÎncă nu există evaluări

- DOLE vs. MaritimeDocument2 paginiDOLE vs. MaritimesoulÎncă nu există evaluări

- White Gold Marine Services Vs Pioneer (GR 154514)Document1 paginăWhite Gold Marine Services Vs Pioneer (GR 154514)Marge OstanÎncă nu există evaluări

- 10 Geagonia V CA G.R. No. 114427 February 6, 1995Document10 pagini10 Geagonia V CA G.R. No. 114427 February 6, 1995ZydalgLadyz NeadÎncă nu există evaluări

- Case Review Soumya Goel Bba LLB PDFDocument4 paginiCase Review Soumya Goel Bba LLB PDFajay thakurÎncă nu există evaluări

- PHYSICS Engineering (BTech/BE) 1st First Year Notes, Books, Ebook - Free PDF DownloadDocument205 paginiPHYSICS Engineering (BTech/BE) 1st First Year Notes, Books, Ebook - Free PDF DownloadVinnie Singh100% (2)

- G.R. No. 160025Document29 paginiG.R. No. 160025Gemrose SantosÎncă nu există evaluări

- Bluntschly v. Schriro Et Al - Document No. 3Document3 paginiBluntschly v. Schriro Et Al - Document No. 3Justia.comÎncă nu există evaluări

- 04-12-17 EditionDocument32 pagini04-12-17 EditionSan Mateo Daily JournalÎncă nu există evaluări

- Covering Letter LapadaDocument3 paginiCovering Letter LapadaTrisha Ace Betita ElisesÎncă nu există evaluări

- Torts - Case CommentaryDocument8 paginiTorts - Case CommentaryAdishree KrishnanÎncă nu există evaluări

- LOKIN V COMELEC - Case DigestDocument3 paginiLOKIN V COMELEC - Case DigestMA RX0% (1)

- Presentatiom of Evidence CasesDocument42 paginiPresentatiom of Evidence CasesCrizedhen VardeleonÎncă nu există evaluări

- Madarang v. CA, 14 July 2005Document6 paginiMadarang v. CA, 14 July 2005dondzÎncă nu există evaluări

- Poindexter v. GreenhowDocument17 paginiPoindexter v. GreenhowAlvin SamonteÎncă nu există evaluări

- DIFC-DP-GL-08 Rev.02 GUIDE TO DATA PROTECTION LAWDocument44 paginiDIFC-DP-GL-08 Rev.02 GUIDE TO DATA PROTECTION LAWMustafa ÇıkrıkcıÎncă nu există evaluări

- New England v. OSHRC, 1st Cir. (1994)Document5 paginiNew England v. OSHRC, 1st Cir. (1994)Scribd Government DocsÎncă nu există evaluări

- Moot Court ProblemDocument13 paginiMoot Court ProblemSonal ChouhanÎncă nu există evaluări

- Yaptinchay v. Torres, G.R. No. L-26462, June 9, 1969Document1 paginăYaptinchay v. Torres, G.R. No. L-26462, June 9, 1969MonicaCelineCaroÎncă nu există evaluări

- Lea 1 2023 Post TestDocument6 paginiLea 1 2023 Post TestHan WinÎncă nu există evaluări

- Jva (Historical Bond)Document5 paginiJva (Historical Bond)notapernota101100% (1)

- Invention Essay AssignmentDocument1 paginăInvention Essay AssignmentdevorehumanitiesÎncă nu există evaluări

- Mayer Steel Pipe Vs CADocument3 paginiMayer Steel Pipe Vs CAChanel GarciaÎncă nu există evaluări

- Practice Court 1 PJADocument145 paginiPractice Court 1 PJAchester paul gawaran100% (5)

- Ownership of A Work Created in The Course of Employment' by A Person Under A Contract of Service': Critical AnalysisDocument30 paginiOwnership of A Work Created in The Course of Employment' by A Person Under A Contract of Service': Critical AnalysisMr KkÎncă nu există evaluări

- Antistain LP 30 Msds SdsDocument8 paginiAntistain LP 30 Msds SdsS.A. MohsinÎncă nu există evaluări

- Industrial Licensing Act 1951Document28 paginiIndustrial Licensing Act 1951MOHD.ARISHÎncă nu există evaluări

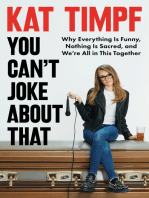

- You Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherDe la EverandYou Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherÎncă nu există evaluări

- The House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedDe la EverandThe House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedEvaluare: 4.5 din 5 stele4.5/5 (5)

- The Importance of Being Earnest: Classic Tales EditionDe la EverandThe Importance of Being Earnest: Classic Tales EditionEvaluare: 4.5 din 5 stele4.5/5 (44)

- The Inimitable Jeeves [Classic Tales Edition]De la EverandThe Inimitable Jeeves [Classic Tales Edition]Evaluare: 5 din 5 stele5/5 (3)

- Welcome to the United States of Anxiety: Observations from a Reforming NeuroticDe la EverandWelcome to the United States of Anxiety: Observations from a Reforming NeuroticEvaluare: 3.5 din 5 stele3.5/5 (10)

- The Asshole Survival Guide: How to Deal with People Who Treat You Like DirtDe la EverandThe Asshole Survival Guide: How to Deal with People Who Treat You Like DirtEvaluare: 4 din 5 stele4/5 (60)

- The Book of Bad:: Stuff You Should Know Unless You’re a PussyDe la EverandThe Book of Bad:: Stuff You Should Know Unless You’re a PussyEvaluare: 3.5 din 5 stele3.5/5 (3)

- Sex, Drugs, and Cocoa Puffs: A Low Culture ManifestoDe la EverandSex, Drugs, and Cocoa Puffs: A Low Culture ManifestoEvaluare: 3.5 din 5 stele3.5/5 (1428)

- The Smartest Book in the World: A Lexicon of Literacy, A Rancorous Reportage, A Concise Curriculum of CoolDe la EverandThe Smartest Book in the World: A Lexicon of Literacy, A Rancorous Reportage, A Concise Curriculum of CoolEvaluare: 4 din 5 stele4/5 (14)

- The Comedians in Cars Getting Coffee BookDe la EverandThe Comedians in Cars Getting Coffee BookEvaluare: 4.5 din 5 stele4.5/5 (8)

- The Little Book of Big F*#k Ups: 220 of History's Most-Regrettable MomentsDe la EverandThe Little Book of Big F*#k Ups: 220 of History's Most-Regrettable MomentsÎncă nu există evaluări

- Take My Advice: Letters to the Next Generation from People Who Know a Thing or TwoDe la EverandTake My Advice: Letters to the Next Generation from People Who Know a Thing or TwoJames L. HarmonEvaluare: 4 din 5 stele4/5 (5)

![The Inimitable Jeeves [Classic Tales Edition]](https://imgv2-2-f.scribdassets.com/img/audiobook_square_badge/711420909/198x198/ba98be6b93/1712018618?v=1)