Documente Academic

Documente Profesional

Documente Cultură

Corbel

Încărcat de

Muhammad TausifDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Corbel

Încărcat de

Muhammad TausifDrepturi de autor:

Formate disponibile

http://svaifulsipil96.bloaspot.

com/

syaiful ashari@yahoo.com

CHAPTER ----------------------------------------------THE FLEXURE AM SHEAR DESIGN OF CORBEL BRACKET!

11.1

INTRODUCTION

Corbel or bracket is a reinforced concrete member is a short-haunched cantilever used to support the reinforced concrete beam element. Corbel is structural element to support the pre-cast structural system such as pre-cast beam and pre-stressed beam. The corbel is cast monolithic with the column element or wall element. This chapter is describes the desian procedure of corbel or bracket structure. Since the load from precast structural element is large then it is very important to make a good detailing in corbel.

11.2

BEHAVIOR OF CORBEL

The followings are the major items show the behavior of the reinforced concrete corbel, as follows : & The shear span/depth ratio is less than 1.0, it makes the corbel behave in two-dimensional manner. & Shear deformation is significant is the corbel. & There is large horizontal force transmitted from the supported beam result from long-term shrinkage and creep deformation. & Bearing failure due to large concentrated load. & The cracks are usually vertical or inclined pure shear cracks. & The mode of failure of corbel are : yielding of the tension tie, failure of the end anchorage of the tension tie, failure of concrete by compression or shearinga and bearing failure. The followings figure shows the mode of failure of corbel.

11 - 1

http://svaifulsipil96.bloaspot.com/

syaiful ashari@yahoo.com

FIGURE 11.1 MODES OF FAILURE OF CORBEL

11.3 SHEAR DESIGN OF

11.3.1 GENERAL Since the corbel is cast at interface of the corbel friction reinforcement

CORBEL

different time with the column element then the cracks occurs in the and the column. To avoid the cracks we must provide the shear perpendicular with the cracks direction.

ACI code uses the shear friction theory to design the interface area. 11.3.2 SHEAR FRICTION THEORY

In shear friction theory we use coefficient of friction ^ to transform the horizontal resisting force into vertical resisting force. The basic design equation for shear reinforcement design is : <K > Vu where : Vn Vu ^ = nominal shear strength of shear friction reinforcement = ultimate shear force = strength reduction factor (^ = 0.85)

[11.1]

11 - 2

http://svaifulsipil96.bloaspot.com/

syaiful ashari@yahoo.com

Vu

FIGURE 11.1 SHEAR FRICTION THEORY nominal shear strength of friction reinforcement is :

The shear TABLE 11.1 SHEAR FRICTION REINFORCEMENT STRENGTH

VERTICAL SHEAR FRICTION REINFORCEMENT

INCLINED SHEAR FRICTION REINFORCEMENT

Vn

Vn Avffv^ Af

Avf

Vn

f

Avf

^ Avf

fv^

Vn Avffv (M sin af + cos a f

fv

( sin a< + cos a<) A ( sin a< + cos a<)

A

Af Vn

Af

Vu/ '4* Avf fv M

Vu/

fv

where : Vn Avf Fv M = nominal shear strength of shear friction reinforcement = area of shear friction reinforcement = vield strength of shear friction reinforcement = coefficient of friction

TABLE 11.2 COEFFICIENT OF FRICTION

METHOD

COEFFICIENT OF FRICTION

Concrete Cast Monolithic Concrete Placed Against Roughened Hardened Concrete Concrete Placed Against unroughened Hardened Concrete Concrete Anchored to Structural Steel The value of X is :

1.4X 1.0X 0.6X 0.7X

X = 1.0 normal weight concrete X = 0.85 sand light weight concrete X = 0.75 all light weight concrete

11 - 3

http://svaifulsipil96.bloaspot.com/

syaiful ashari@yahoo.com

The ultimate shear force must follows the following condiitons

<u *<K0.2f'c)bwd <u <^(5.50)bwd

where : <u fc

bw

: : : :

ultimate shear force concrete cylinder strength width of corbel section effective depth of corbel

(N) (MPa) (mm) (mm)

11.3.3

STEP - BY - STEP PROCEDURE

The followings are the step - by - step procedure used in the shear design for corbel (bracket), as follows : & Calculate the ultimate shear force Vu. & Check the ultimate shear force for the following condition, if the following condition is not achieved then enlarge the section. <u <<K0.2f'c)bwd <u <<K5.50>wd & Calculate the area of shear friction reinforcement Avf. VERTICAL

SHEAR FRICTION

INCLINED

SHEAR FRICTION

REINFORCEMENT Vn <n = AvffyL

Af Avf

REINFORCEMENT Vn <n - Avffy (Lsin af + cos af)

A

Avf

- < Avf ~ fy L

<n v fy (sin af + cos af)

Af Avf

v _A

-*

fy L

<u/ > /9 v fy (sin af + cos af)

& The design must be follows the basic design equation as follows : * <u

11.4

FLEXURAL DESIGN OF CORBEL

11.4.1

GENERAL

The corbel is design due to ultimate flexure moment result from the supported beam reaction Vu and horizontal force from creep and shrinkage effect Nu.

11 - 4

http://svaifulsipil96.bloaspot.com/

syaiful ashari@yahoo.com

FIGURE 11.2 DESIGN FORCE OF CORBEL

11.4.2

T ENSION REINFORCEMENT

The ultimate horizontal force acts in the corbel Nuc is result from the creep and shrinkage effect of the pre-cast or pre-stressed beam supported bv the corbel. This ultimate horizontal force must be resisted bv the tension reinforcement as follows :

A n

Nuc f

[^

where : An = area of tension reinforcement = vield strength of the tension reinforcement

Nuc = ultimate horizontal force at corbel fv ^ = strength reduction factor = 0.85)

Minimum value of Nuc is 0.2Vuc.

The strength reduction factor is taken 0.85 because the major action in corbel is dominated by shear.

11.4.3

FLEXURAL REINFORCEMENT

FIGURE 11.3 ULTIMATE FLEXURE MOMENT AT CORBEL

11 - 5

http://svaifulsipil96.bloaspot.com/

syaiful ashari@yahoo.com

The ultimate flexure moment Mu result from the support reactions is

Mu Vu (a) + Nuc (h - d) where : Mu Vu a Nuc h d = ultimate flexure moment = ultimate shear force = distance of Vu from face of column = ultimate horizontal force at corbel = height of corbel = effective depth of corbel

[113]

The resultant of tensile force of tension reinforcement is : Tf Affv where : Tf Af fv = tensile force resultant of flexure reinforcement = area of flexure reinforcement = vield strength of the flexure reinforcement

[11.4]

The resultant of compressive force of the concrete is : Cc 0.85f'c ba(cos p) where : Cc fc b a = compressive force resultant of concrete = concrete cvlinder strength = width of corbel = depth of concrete compression zone

[11.5]

The horizontal equilibrium of corbel internal force is : X H 0 ^ Cc Ts 0.85f'c ba(cos p) Affv Affv a ------------ 0.85f'c b(cos p) The flexure reinforcement area is :

[11.7]

[116]

Af _ Mu

11 - 6

http://syaifulsipN96.blogspot.com/

syaiful ashari@yahoo.com

Af

---- ------ Td-

M u

Affy

0.85f'c b(cos p)

Cos p value can be calculated based on the Tan p value as follows

[11.8]

where : a jd

distance of Vu from face of column lever arm Based on the equation above we must trial and error to find the reinforcement

area Af. For practical reason the equation below can be used for preliminary :

Af Mu

[11.9]

f (jd) Mu f (0.85d)

Af

area of flexural reinforcement ultimate flexure moment at corbel : yield strength of the flexural reinforcement : strength reduction factor (* = 0.9)

:

effective depth of corbel

w h 11.4.4 DISTRIBUTION OF CORBEL REINFORCEMENTS er e : A f M u fy * d CASE 1 CASE 2

FIGURE 11.4 DISTRIBUTION OF CORBEL REINFORCEMENTS

11 - 7

http://svaifulsipil96.bloaspot.com/

syaiful ashari@yahoo.com

From the last calculation we already find the shear friction reinforcement Avf, tension reinforcement An and flexural reinforcement Af. We must calculate the primary tension reinforcement As based on the above

TABLE 11.3 DISTRIBUTION OF CORBEL REINFORCEMENTS

CASE

As

PRIMARY REINFORCEMENT

CLOSED STIRRUP

Ah 1

As

LOCATION

> "3Avf + An > Af + An

As

= 3 Avf + An = Af + An

3" II

As

As

<

Id 3 Id 3

Ah = ?Af reinforcements.

= area of primary tension reinforcement = area of shear friction reinforcement = area of tension

The 2, the

reinforcement = area of flexure reinforcement = horizontal closed stirrup = effective depth of corbel

reinforcements is taken which is larger, case 1 or case distribution of the reinforcements is shown in the figure

above. 11.4.5 LIMITS OF REINFORCEMENTS

The limits of primary steel reinforcement at corbel design is : A where : As Avf An Af Ah d p = -As > 0.04 bd fy f'

[11.10]

where : As b d

area of primary tension reinforcement width of corbel effective depth of corbel The limits of horizontal closed stirrup reinforcement at corbel design is

Ah > 0.5(AS - An) where : As An 11.4.6 = area of primary tension reinforcement = area of tension reinforcement STEP - BY - STEP PROCEDURE

[11.11]

The followings are the step - by - step procedure used in the flexural design for corbel (bracket), as follows :

11 - 8

http://svaifulsipil96.bloaspot.com/

syaiful ashari@yahoo.com

& Calculate ultimate flexure moment Mu.

Mu = Vu (a) + Nuc (h -

d) & Calculate the area of tension reinforcement An.

An = n f & Calculate the area of flexural reinforcement Af.

_ Mu f f (0.85d)

& Calculate the area of primary tension reinforcement As CASE As PRIMARY REINFORCEMENT Ah

CLOSED

STIRRUP LOCATION id 3 id 3

1 2

As As

> "3Avf + An > Af + An

As

_ 3 Avf + An _ Af + An

Ah

_ 3 Avf

1 1

As

Ah _ 3 Af

& Check the reinforcement for minimum reinforcement. A f' p_ -As > 0.04 bd fy Ah > 0.5(As - An)

11.5 APPLICATIONS

11.5.1 APPLICATION 01 - DESIGN OF CORBEL

11 - 9

http://svaifulsipil96.bloaspot.com/

syaiful ashari@yahoo.com

PROBLEM Design the flexural and shear friction reinforcement of corbel structure above.

MATERIAL Concrete strength = K - 300 = Grade 400 Steel gradecvlinder strength = f'c 0.83 x 30 24.9 MPa Concrete

P1 0.85 DIMENSION b h Concrete d cover

= 200 = 400 = 30 = 370 mm mm mm mm

DESIGN FORCE Vu 150000N Nuc 0.2Vu 0.2 x 150000 30000 N Mu Vu (a) + Nuc (h - d) 150000(100) + 30000(400 - 370) 15900000 Nmm

LIMITATION CHECKING <^(0.2f'c)bwd 0.85(0.2x 24.9)200x 370 313242 N <^(5.5)bwd 0.85x5.5x200x 370 345950 N Vu 150000 < ^(0.2f'c)bwd 313242 < ^(5.5)bwd 345950 SHEAR FRICTION REINFORCEMENT M 1.4X 1.4 x 1.0 1.4

Vu 150000/

Avf

-085 315 mm2

TENSION REINFORCEMENT An Nc

30000

f vM

400 x 1.4

88 mm

FLEXURAL REINFORCEMENT Mu 15900000 ... 2 Af r-^r ------------------ 1 -------------- r 140 mm f f (0.85d) 0.9 x 400(0.85 x 370)

11 - 10

http://syaifulsipN96.blogspot.com/

syaiful ashari@yahoo.com

PRIMARY TENSION REINFORCEMENT CASE As (mm2)

PRIMARY REINFORCEMENT

CLOSED STIRRUP

(mm2) As - 298

Ah (mm2)

LOCATION

(mm) id 3 247

1

As

2

> 3 Avf + An 2 As >|-(315) + 88 > 298

As

1

Ah -

3 Avf 1

Ah - 3 (315)- 105 As - 228 -

> Af + An

As > 140 + 88 > 228

The reinforcement of the corbel are : As - 298 mm Ah -105 mm

2 2

CHECK FOR AS MINIMUM AND AS MAXIMUM f' 24 9 pmin - 0.04-^ - 0.04^^- - 0.00249 Fmin A 298 p-AA^ - bd 200 x 370 fy 400 * OK

0.00402 >pmin - 0.00249

Ah-min - 0.5(As - A n ) - 0.5(298 - 88)- 210 mm Ah - 105 < Ah-min - 210 ^

Ah - 210 mm

The final reinforcement of the corbel are : As - 298 mm Ah - 210 mm CORBEL REINFORCEMENT

2 2

SKETCH OF REINFORCEMENT

11 - 11

http://svaifulsipil96.bloaspot.com/

syaiful ashari@yahoo.com

11 - 12

S-ar putea să vă placă și

- 70-c0807 C c810 C c820 C Rev 5 GB 13 Lug 2005Document47 pagini70-c0807 C c810 C c820 C Rev 5 GB 13 Lug 2005Muhammad Tausif0% (1)

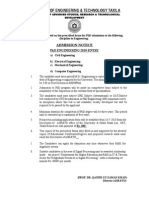

- Mirpur University of Science & Technology (Must), Mirpur Azad Jammu & Kashmir Department of Civil Engineering PH & Fax: +92-5827-961047Document2 paginiMirpur University of Science & Technology (Must), Mirpur Azad Jammu & Kashmir Department of Civil Engineering PH & Fax: +92-5827-961047Muhammad TausifÎncă nu există evaluări

- Zircon Sales Tax 1Document1 paginăZircon Sales Tax 1Muhammad TausifÎncă nu există evaluări

- Scanned by TapscannerDocument15 paginiScanned by TapscannerMuhammad TausifÎncă nu există evaluări

- Payment Sectaxpayer - NTN Taxpayer - Cnic Taxpayer - Name Taxpayer - City Taxpayer - Addr Taxpayer - Sta Taxpayer - Taxable - Amount Tax - AmountDocument7 paginiPayment Sectaxpayer - NTN Taxpayer - Cnic Taxpayer - Name Taxpayer - City Taxpayer - Addr Taxpayer - Sta Taxpayer - Taxable - Amount Tax - AmountMuhammad TausifÎncă nu există evaluări

- DedicationDocument1 paginăDedicationMuhammad TausifÎncă nu există evaluări

- Answer - Darul Ifta Deoband IndiaDocument1 paginăAnswer - Darul Ifta Deoband IndiaMuhammad TausifÎncă nu există evaluări

- University of Engineering & Technology Taxila: Admission NoticeDocument1 paginăUniversity of Engineering & Technology Taxila: Admission NoticeMuhammad TausifÎncă nu există evaluări

- The Chairman, Civil Engineering Department, MUSTDocument1 paginăThe Chairman, Civil Engineering Department, MUSTMuhammad TausifÎncă nu există evaluări

- Advanced Vibration and Overpressure Monito R: Easy To UseDocument3 paginiAdvanced Vibration and Overpressure Monito R: Easy To UseMuhammad TausifÎncă nu există evaluări

- Experimental Work CHP 7Document47 paginiExperimental Work CHP 7Muhammad TausifÎncă nu există evaluări

- Introduction 1Document3 paginiIntroduction 1Muhammad TausifÎncă nu există evaluări

- Ferrocement ReferencesDocument2 paginiFerrocement ReferencesMuhammad TausifÎncă nu există evaluări

- DedicationDocument1 paginăDedicationMuhammad TausifÎncă nu există evaluări

- Chapter No 3Document13 paginiChapter No 3Muhammad TausifÎncă nu există evaluări

- Chapter No 5Document15 paginiChapter No 5Muhammad TausifÎncă nu există evaluări

- Ferrocement guideDocument19 paginiFerrocement guideMuhammad TausifÎncă nu există evaluări

- Board of Intermediate & Secondary Education Rawalpindi: Result of SSC Annual Examination 2014Document2 paginiBoard of Intermediate & Secondary Education Rawalpindi: Result of SSC Annual Examination 2014Muhammad TausifÎncă nu există evaluări

- Unit 5 LipidsDocument71 paginiUnit 5 LipidsMuhammad TausifÎncă nu există evaluări

- Introduction To Molecular Spectroscopy: By: M.Z.IqbalDocument24 paginiIntroduction To Molecular Spectroscopy: By: M.Z.IqbalMuhammad TausifÎncă nu există evaluări

- WaxDocument5 paginiWaxMuhammad TausifÎncă nu există evaluări

- Consumables Are Goods That Require Recurrent Replacement Because They Are Used Up or Transformed in Their UseDocument12 paginiConsumables Are Goods That Require Recurrent Replacement Because They Are Used Up or Transformed in Their UseMuhammad TausifÎncă nu există evaluări

- Detecting Objects in Noisy ImagesDocument5 paginiDetecting Objects in Noisy ImagesMuhammad TausifÎncă nu există evaluări

- Presentation 1Document20 paginiPresentation 1Muhammad TausifÎncă nu există evaluări

- Method For Reducing of Noise by ImprovingDocument6 paginiMethod For Reducing of Noise by ImprovingMuhammad TausifÎncă nu există evaluări

- Board of Intermediate & Secondary Education Rawalpindi: Result of SSC Annual Examination 2014Document2 paginiBoard of Intermediate & Secondary Education Rawalpindi: Result of SSC Annual Examination 2014Muhammad TausifÎncă nu există evaluări

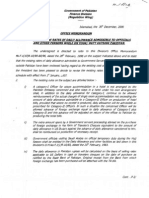

- Daily AllowanceDocument31 paginiDaily Allowanceshafek100% (1)

- Short Questions Ch-3Document3 paginiShort Questions Ch-3Muhammad TausifÎncă nu există evaluări

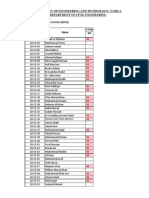

- UET Taxila Civil Engineering Student ListDocument12 paginiUET Taxila Civil Engineering Student ListMuhammad TausifÎncă nu există evaluări

- Mcqs Chapter 7Document1 paginăMcqs Chapter 7Muhammad TausifÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Shrinkage CrackDocument9 paginiShrinkage CrackRiyaz SiddiqueÎncă nu există evaluări

- Manzur 2017Document12 paginiManzur 2017Syed RafiuzzamanÎncă nu există evaluări

- Structural Health Monitoring of Carbon Fibre Reinforced Concrete BeamDocument51 paginiStructural Health Monitoring of Carbon Fibre Reinforced Concrete BeamsavithaÎncă nu există evaluări

- 1985-ACI-ASCE Committee 352-Recommendations For Design of Beam-Column Joints in Monolithic Reinforced Concrete StructuresDocument18 pagini1985-ACI-ASCE Committee 352-Recommendations For Design of Beam-Column Joints in Monolithic Reinforced Concrete StructuresRomanbabu OinamÎncă nu există evaluări

- Topic 3Document25 paginiTopic 35p6zzgj4w9Încă nu există evaluări

- March 2010 Detailing Corner - Wide Beam Stirrup ConfigurationsDocument3 paginiMarch 2010 Detailing Corner - Wide Beam Stirrup Configurationslattmdy100% (1)

- Pile Cap Group Analysis Design ReportDocument8 paginiPile Cap Group Analysis Design ReportchakfarmerÎncă nu există evaluări

- Concrete Construction: Estimate The Cost ofDocument12 paginiConcrete Construction: Estimate The Cost ofYay B. GicoÎncă nu există evaluări

- Prestressed Concrete Analysis and Design Antoine NaamanDocument17 paginiPrestressed Concrete Analysis and Design Antoine NaamanMarvin Flores0% (3)

- Design No. J718: BXUV.J718 Fire Resistance Ratings ANSI/UL 263Document3 paginiDesign No. J718: BXUV.J718 Fire Resistance Ratings ANSI/UL 263mmmmmÎncă nu există evaluări

- Report U Ditch RMIDocument25 paginiReport U Ditch RMIDevy ApriyaniÎncă nu există evaluări

- Firewalls To NBCC 2010Document34 paginiFirewalls To NBCC 2010BeammanÎncă nu există evaluări

- Artista Columns ManualDocument24 paginiArtista Columns ManualsotirisÎncă nu există evaluări

- Solutions Long Product Rollling Mills enDocument44 paginiSolutions Long Product Rollling Mills enShubham Kumar SinghÎncă nu există evaluări

- Project Title Discipline Project Stage Client Attendance CirculationDocument4 paginiProject Title Discipline Project Stage Client Attendance CirculationgregÎncă nu există evaluări

- LEARNING ETABS SOFTWARE FOR REINFORCED CONCRETE FRAME ANALYSIS AND DESIGNDocument33 paginiLEARNING ETABS SOFTWARE FOR REINFORCED CONCRETE FRAME ANALYSIS AND DESIGNAnonymous nwByj9LÎncă nu există evaluări

- SPCCCCCDocument10 paginiSPCCCCCbernikaÎncă nu există evaluări

- Concrete SpecificationDocument15 paginiConcrete SpecificationNATHANÎncă nu există evaluări

- Engineeringinterviewquestions Com RCC Structures Design Multiple Choice QuestionDocument87 paginiEngineeringinterviewquestions Com RCC Structures Design Multiple Choice QuestionRajeev BansalÎncă nu există evaluări

- Epoxy Connection TimberDocument6 paginiEpoxy Connection TimberJeffery RoweÎncă nu există evaluări

- Tube Well BOQDocument42 paginiTube Well BOQShah Newaz Kabir100% (1)

- Wuxi Anber Machine Co., LTD.: Pile CageDocument1 paginăWuxi Anber Machine Co., LTD.: Pile CageSyedÎncă nu există evaluări

- Basalt Fibre Reinforced Polymer Rebar Performance in Concrete BeamsDocument12 paginiBasalt Fibre Reinforced Polymer Rebar Performance in Concrete BeamsSARA ISABEL BURBANO MOSQUERAÎncă nu există evaluări

- Material Properties: Reinforcement Details: Design of Concrete BeamDocument1 paginăMaterial Properties: Reinforcement Details: Design of Concrete BeamNick OperarioÎncă nu există evaluări

- PIP STE05121 (Anchor Bolt Design Guide)Document55 paginiPIP STE05121 (Anchor Bolt Design Guide)bowitchhazelÎncă nu există evaluări

- Design of Prestressed Concrete Bridges Made CompositeDocument52 paginiDesign of Prestressed Concrete Bridges Made CompositeBara AlsayedÎncă nu există evaluări

- Detailing of ReinforcementDocument37 paginiDetailing of Reinforcementsoroware100% (9)

- Buj K - Et - Al 2018 Structural - ConcreteDocument7 paginiBuj K - Et - Al 2018 Structural - Concretejuan muneraÎncă nu există evaluări

- Finite Element Strip Design MethodDocument5 paginiFinite Element Strip Design MethodStevenÎncă nu există evaluări

- Evaluation of Minimum Longitudinal Reinforcement Requirements for Reinforced Concrete ColumnsDocument128 paginiEvaluation of Minimum Longitudinal Reinforcement Requirements for Reinforced Concrete ColumnsxfmarcoÎncă nu există evaluări