Documente Academic

Documente Profesional

Documente Cultură

Thread Science

Încărcat de

ShanmugarajChandrahasanDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Thread Science

Încărcat de

ShanmugarajChandrahasanDrepturi de autor:

Formate disponibile

American & Efird, Inc.

Thread Science

Thread Science

Introduction: Choosing the Right Thread

Thread is an integral part of many items that we use daily. Certainly the various components of our apparel are joined with thread but what about the string that is attached to our tea bags? What would happen to upholstery, seat belts, and head liner of an automobile if the thread were removed? What about the seams in our tents, back packs, sleeping bags, and other camping equipment? How are the components of baseballs and footballs joined? Each of these products requires a thread with different physical properties to achieve optimum performance. If you consider the many uses of thread, the complexity of designing a thread becomes apparent. Consideration must be given to: Sewability, loop strength, linear strength, elongation, shrinkage, abrasion resistance, colorfastness, and resistance to chemicals, heat, light, etc. Each can affect the desirability of a thread for a particular end-use. A&E threads are designed for many general and specific end-uses. Selecting the proper thread for your product can be simplified if these basic factors are considered: required seam strength; type of seam; stitch type and number of stitches per inch; type of material being sewn; type of sewing machines and related equipment; conditions under which the product must perform; normal life of the product; and cost effectiveness. Analyzing these factors would give an indication of which physical properties are most important in the thread. Selection then becomes a matter of choosing a thread with the most desirable properties. Of course, thorough testing is necessary to confirm that the thread chosen is indeed the correct one. A&E will be glad to provide any necessary technical assistance to help you select the best thread for your use. (See Technical Services.)

10/10/02

Page 1

American & Efird, Inc.

Thread Science: FIBER

Fiber Science

Where Do Fibers Come From?

Fibers used to make industrial sewing threads come from two major sources: Natural Fibers: Come from plants and animals and are spun or twisted into yarns. Cotton is the most common natural fiber used to make thread. Other natural fibers include silk, wool, jute, ramie, hemp, and linen. Natural fibers are generally not as uniform as synthetic fibers and are affected by climatic changes. At A&E, we use cotton as a fiber source for some of our thread. We select our cotton fibers from the best available crops, classifying them depending on the geographic location and climate, seed and type of plant, and the cotton grower's reputation. The two classes of cotton fibers that we use at A&E are SAK (or Supima) cotton that comes from Arizona and CP (or Peeler) that comes from the San Juaquin Valley in California. SAK quality cotton produces stronger spun cotton threads than CP fibers. Synthetic Fibers: Are made from various chemicals or regenerated from cellulose such as wood pulp and cotton waste. We select our synthetic fibers based on their sewability characteristics, seam performance, ease of dying, colorfastness, and pricing. At A&E, the synthetic fibers that we use as a source to make thread are polyester, nylon, Kevlar from Dupont, and Nomex from Dupont.

Fibers Come in What Forms?

When we receive bales of cotton, polyester, nylon, Kevlar, and Nomex, the fiber contained in the bales comes in one of the following forms:

Staple: Refers to natural fibers that vary in length or to synthetic fibers with filaments

that are cut to a definite length during the manufacturing process

Continuous Filament: Refers to synthetic fibers of an indefinite length

10/10/02

Page 2

American & Efird, Inc.

Thread Science: CONSTRUCTION

Thread Construction

We manufacture thread based on the following construction methods:

Is made from cotton or polyester staple fibers that are spun into single yarns and then two or more of these yarns are plied to make a sewing thread. Spun threads have fuzz on their surfacing giving them a soft hand and good lubricity characteristics. Spun threads are used in everything from women's lingerie to heavy leather gloves. (Example products are: Anecot, Anecot Plus, Kevlar from Dupont, Nomex from Dupont, and Perma Spun.) Is made by spinning a wrap of staple cotton or polyester around a continuous filament of polyester fibers. Afterwards, two or more of these single yarns are twisted together to form the thread. Core threads have fuzz on their surface giving them good lubricity characteristics and also a continuous filament core that contributes to high strength and durability. When wrapped with a cotton wrap, core threads have very good needle heat resistance. When wrapped with a polyester wrap, core threads have excellent chemical resistance and colorfastness. Core threads are used in everything from fine blouses to heavy coveralls and overalls. (Example products are: D-Core and Perma Core.) Is made from continuous filaments of polyester or nylon that have been textured by pin, disc, or belt and then heat set to insure proper bulk retention. Textured polyester is usually manufactured with regular or mid tenacity, continuous filaments depending on the application. Textured threads are ideal for overedge, chainstitch, and coverstitch of the finished seam and offers good seam elasticity. Textured threads are usually less expensive when compared to other thread types. (Example products are: Best Stretch, Wildcat, and Wildcat Plus.)

10/10/02

Page 3

American & Efird, Inc.

Thread Science: CONSTRUCTION

Is made from continuous filaments of polyester that are entangled as they pass through a high pressure air jet. This yarn is then twisted, dyed, and wound on cones with lubricant. Air entangled threads are used in everything from seaming flags to heavy denim jeans. (Example product is Magic.)

Is made from continuous filaments of polyester or nylon that are twisted together into a cohesive bundle and then plied to make the thread. They are then dyed, stretched, and heat set to achieve the desired physical characteristics. Twisted Multifilament threads are available either soft or with an additional bond for better ply security and abrasion resistance. They are exceptionally strong for their size and they have excellent resistance and durability. These threads are used for seaming everything from bathing suits to automobile upholstery. (Example products are: Anefil Nylon and Anefil Polyester.)

Is produced from continuous filaments of nylon that have been bonded together. They have very little twist so that they look like a single cord of yarn. Because of the way these threads are made, they appear to be flat and ribbon-like, which provides a high degree of resistance to abrasion. Monocord threads are exceptionally strong for their size so they are used in the manufacturing of furniture, shoes, and other heavy duty applications. (Example product is Anecord.)

Normally produced from a single nylon continuous filament resembling fishing line. Usually monofilament threads are used because the thread is translucent and blends in with many colors. Because it has a tendency to be stiffer than other filament products, it is not recommended for seams that may lay adjacent to the skin. Also, because it is a single filament, it may unravel easily if the thread is not locked in the seam adequately. Monofilament threads have been used in quilting operations on quilts and bedspreads, as well as, in blindstitch operations on drapery and apparel. (Example product is Clearlon.)

10/10/02

Page 4

American & Efird, Inc.

Thread Science: CONSTRUCTION

The above types of thread constructions that involve twisting (such as spun, core, and twisted multifilament) are twisted in the following directions:

"S" direction or right twist for single strand yarn (such as spun) "Z" direction or left twist for ply yarn (such as core and twisted multifilament)

10/10/02

Page 5

American & Efird, Inc.

Thread Science: FINISHING

Thread Finishing

Once the thread is constructed, the thread may be finished in several different ways to enhance its suitability for various end uses. The thread finishes used at A&E and the relationship between construction, fiber type, and finishing are listed below.

Soft:

Refers to thread that receives no further processing to change its general physical characteristics. It is dyed to the proper shade and degree of colorfastness, wound on the proper size package, and lubricated for sewability.

Gassed:

Refers to a finish where cotton thread is passed through a flame at high speed to reduce its fuzz and have a greater sheen. Gassing is done in a wrap form prior to mercerizing and dyeing.

Mercerized:

Refers to a finish where cotton thread is treated in a caustic solution under controlled tension. This process causes the fibers to swell, resulting in greater affinity for dye penetration. Mercerization increases the luster of cotton threads and at the same time increases their strength.

Glaced:

Refers to a finish in which 100% cotton and some cotton wrapped core threads are treated with starches, waxes, and special chemicals under controlled heat and then brushed or polished to a high luster. The result is a glossy, hard finish that protects the thread from abrasion and enhances ply security during the sewing of hard to penetrate fabrics.

Bonded:

Refers to a finish where multifilament polyester or nylon is treated with a special resin that encapsulates the filaments forming a tough, smooth protective coating on the surface of the thread. This bonding process adds significantly to the thread's ability to resist abrasion and greatly enhances ply security during sewing.

Relationship Between Thread Construction, Fiber Type, and Thread Finish

Thread Construction Core Spun Air Entangled Textured Twisted Multifilament Monocord Monofilament Fiber Type Cotton wrapped polyester Polyester wrapped polyester Cotton Polyester Polyester Polyester Nylon Polyester Nylon Nylon Thread Finish Soft Soft Soft, Mercerized, or Glaced Soft Soft Soft Soft Soft or Bonded Bonded Soft

10/10/02

Page 6

American & Efird, Inc.

Thread Science: DYEING

Thread Dyeing

Thread is dyed or colored and then finished depending on the application. At A&E, we use packaging dyeing in which many packages of thread are dyed under pressure in a dye vat. Packages of synthetic threads are dyed by a similar process that uses high temperature to ensure colorfastness, a key thread performance characteristic. A&E also has state-of-the art dye matching and formulation systems in our dyelab. These systems include: A Colorite system from Datacolor, Inc., for emailing color matches, which reduces the time for getting an approved color shade. A Tecnorama Dos and Dye system, which processes up to eight samples at one time, reducing the time it takes to create formulas for custom colors. The Tecnorama system also eliminates the potential for operator error compared to systems where a technician manually weighs the dyes and solutions.

For more information on dyeing and colorfastness, contact the American Thread Manufacturers Institute, which is a national trade association that represents thread manufacturers: ATMI Thread Committee 1801 K. Street NW Washington, DC 20006-1301

10/10/02

Page 7

S-ar putea să vă placă și

- Excavation and TrenchingDocument12 paginiExcavation and TrenchingShanmugarajChandrahasanÎncă nu există evaluări

- 360 Excavator - Safe OperationDocument21 pagini360 Excavator - Safe OperationSanket Satpathy0% (2)

- Extinguisher TypeDocument40 paginiExtinguisher TypeShanmugarajChandrahasanÎncă nu există evaluări

- OSHA 3114 - HazardousWaste Operations and Emergency ResponseDocument47 paginiOSHA 3114 - HazardousWaste Operations and Emergency ResponseWahed Mn ElnasÎncă nu există evaluări

- Down To EarthDocument41 paginiDown To EarthARC Electrical Safety ConsultingÎncă nu există evaluări

- Uravugal - Etharkaga by SadhguruDocument77 paginiUravugal - Etharkaga by SadhguruShanmugarajChandrahasanÎncă nu există evaluări

- PDF Siddha MedicineDocument59 paginiPDF Siddha Medicinekr28678100% (1)

- Hindi What Is That, ThisDocument2 paginiHindi What Is That, ThisShanmugarajChandrahasanÎncă nu există evaluări

- Hindi ConsonantsDocument1 paginăHindi ConsonantsShanmugarajChandrahasanÎncă nu există evaluări

- English To Hindi PhrasesDocument2 paginiEnglish To Hindi PhrasesShanmugarajChandrahasanÎncă nu există evaluări

- Family in HindiDocument2 paginiFamily in HindiShanmugarajChandrahasanÎncă nu există evaluări

- Hindi AdjectivesDocument4 paginiHindi AdjectivesShanmugarajChandrahasanÎncă nu există evaluări

- Hindi Survivel TermsDocument2 paginiHindi Survivel TermsShanmugarajChandrahasanÎncă nu există evaluări

- Hindi VowelsDocument1 paginăHindi VowelsShanmugarajChandrahasanÎncă nu există evaluări

- Call UesDocument5 paginiCall UesShanmugarajChandrahasanÎncă nu există evaluări

- Hindi To English Basic WordsDocument12 paginiHindi To English Basic WordsShanmugarajChandrahasanÎncă nu există evaluări

- SI UnitsDocument6 paginiSI UnitsShanmugarajChandrahasanÎncă nu există evaluări

- Data Warehouse ConceptsDocument8 paginiData Warehouse Conceptsmicrosystems1990Încă nu există evaluări

- Shock AttenDocument37 paginiShock AttenShanmugarajChandrahasanÎncă nu există evaluări

- Hindi ConsonantsDocument1 paginăHindi ConsonantsShanmugarajChandrahasanÎncă nu există evaluări

- Class and Individual Characteristic EvidenceDocument10 paginiClass and Individual Characteristic EvidenceShanmugarajChandrahasanÎncă nu există evaluări

- Basic Type of ShoesDocument4 paginiBasic Type of ShoesShanmugarajChandrahasanÎncă nu există evaluări

- Foot Deformities: Morton's NeuromaDocument5 paginiFoot Deformities: Morton's NeuromaShanmugarajChandrahasanÎncă nu există evaluări

- The Formation of The SentenceDocument4 paginiThe Formation of The SentenceIntelligentiaÎncă nu există evaluări

- Running ShoesDocument7 paginiRunning ShoesShanmugarajChandrahasanÎncă nu există evaluări

- CapitalsDocument13 paginiCapitalsUma Devi SankaraÎncă nu există evaluări

- Wike PediaDocument3 paginiWike PediaShanmugarajChandrahasanÎncă nu există evaluări

- Heel Lifts and Shoe LiftsDocument10 paginiHeel Lifts and Shoe LiftsShanmugarajChandrahasanÎncă nu există evaluări

- LacesDocument6 paginiLacesShanmugarajChandrahasanÎncă nu există evaluări

- Clauses: Building Blocks For SentencesDocument11 paginiClauses: Building Blocks For SentencestslnarayanaÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Inorg Chemistry Mar 2018 Module CDocument4 paginiInorg Chemistry Mar 2018 Module CEllah GutierrezÎncă nu există evaluări

- Strength Behavior of Mortar Using Slag As Partial Replacement of CementDocument10 paginiStrength Behavior of Mortar Using Slag As Partial Replacement of Cementteguh widayatÎncă nu există evaluări

- 1.1 Thermoplastic and Thermosetting PolymersDocument5 pagini1.1 Thermoplastic and Thermosetting PolymerssumherilÎncă nu există evaluări

- Acknowledgment: Electrochemical CellDocument12 paginiAcknowledgment: Electrochemical CellMSD PrajwalÎncă nu există evaluări

- Paper 6 DoubleDocument4 paginiPaper 6 Doublebob bobÎncă nu există evaluări

- Maleic Anhydride: Seeking The Best Route ForDocument4 paginiMaleic Anhydride: Seeking The Best Route ForTCBerkcanErbilgeÎncă nu există evaluări

- Test Report: Signed For and On Behalf of SGS-CSTC Standards Technical Services (Shanghai) Co., LTDDocument20 paginiTest Report: Signed For and On Behalf of SGS-CSTC Standards Technical Services (Shanghai) Co., LTDKagura YorozuuyaÎncă nu există evaluări

- ColaDet KC-40Document1 paginăColaDet KC-40mndmattÎncă nu există evaluări

- Ginko Biloba NIST LC MS TestDocument18 paginiGinko Biloba NIST LC MS TestMd HossainÎncă nu există evaluări

- Searching For Polyurehtanes On STNDocument31 paginiSearching For Polyurehtanes On STNScott L HertzogÎncă nu există evaluări

- LAS-Gen. Chem. Q2 - Week 2Document8 paginiLAS-Gen. Chem. Q2 - Week 2Jennette BelliotÎncă nu există evaluări

- 03 - Mineral and RockDocument191 pagini03 - Mineral and RockBuğra HerdemÎncă nu există evaluări

- Surface & Coatings Technology: SciencedirectDocument9 paginiSurface & Coatings Technology: SciencedirectTugay ArıçÎncă nu există evaluări

- Water TreatmentDocument153 paginiWater Treatmentpoojaabanindran100% (1)

- Fertilizer Technology MCQ PDFDocument13 paginiFertilizer Technology MCQ PDFKapilSahu75% (4)

- Chemistry Page 4 To 20Document17 paginiChemistry Page 4 To 20Boopathi SarvesanÎncă nu există evaluări

- P GC An 2012 06Document12 paginiP GC An 2012 06javiercdeaeÎncă nu există evaluări

- 2016 Specimen Paper 4 Mark SchemeDocument6 pagini2016 Specimen Paper 4 Mark SchemelolismÎncă nu există evaluări

- Case 7.3 PZT Piezoelectric Acoustic SensorDocument3 paginiCase 7.3 PZT Piezoelectric Acoustic SensorSarika AyyathuraiÎncă nu există evaluări

- Data Et Al.. 2007. Preserved Bacterial Strain Activating Culture Medium - Semi-Solid Activating Cultivation Seed Culture Medium RecoveryDocument50 paginiData Et Al.. 2007. Preserved Bacterial Strain Activating Culture Medium - Semi-Solid Activating Cultivation Seed Culture Medium RecoveryAzb 711Încă nu există evaluări

- Supervisors Mrs Shailja Bawa Dr. K Senthil Submitted by Harsh Kumar 14417008Document38 paginiSupervisors Mrs Shailja Bawa Dr. K Senthil Submitted by Harsh Kumar 14417008Sumita ManiÎncă nu există evaluări

- Hku Inorganic Chemistry 2 TestDocument32 paginiHku Inorganic Chemistry 2 TestLittlezerg Z Zzi ZethÎncă nu există evaluări

- Chapter 2: Chemicals, Apparatus, and Unit Operations of Analytical ChemistryDocument28 paginiChapter 2: Chemicals, Apparatus, and Unit Operations of Analytical Chemistryangela100% (2)

- Effects of Air Pollution:: EnvironmentDocument32 paginiEffects of Air Pollution:: EnvironmentPramit GhoshÎncă nu există evaluări

- Welding SymbolsDocument17 paginiWelding SymbolsJustine WilliamsÎncă nu există evaluări

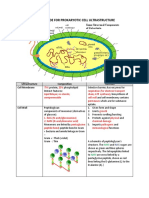

- Study Guide For Prokaryotic Cell UltrastructureDocument2 paginiStudy Guide For Prokaryotic Cell UltrastructureFetalvero EddieÎncă nu există evaluări

- Conbextra GP2: Free Ow, High Strength, Non-Shrink, Cementitious Precision GroutDocument4 paginiConbextra GP2: Free Ow, High Strength, Non-Shrink, Cementitious Precision Grout231340Încă nu există evaluări

- Anachem NeutralizationDocument2 paginiAnachem NeutralizationChristian Ghail MacapagalÎncă nu există evaluări

- Alginat Jurnal PDFDocument7 paginiAlginat Jurnal PDFGeraldo LaurusÎncă nu există evaluări

- Soil Stabilization Using Lime and Fly AshDocument4 paginiSoil Stabilization Using Lime and Fly AshSneha KarmakarÎncă nu există evaluări