Documente Academic

Documente Profesional

Documente Cultură

Fluent HeatTransfer L02 Conduction

Încărcat de

sourabh78932Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Fluent HeatTransfer L02 Conduction

Încărcat de

sourabh78932Drepturi de autor:

Formate disponibile

2013 ANSYS, Inc. March 28, 2013 1 Release 14.

5

14.5 Release

Lecture 2 - Conduction Heat Transfer

Heat Transfer Modeling using

ANSYS FLUENT

2013 ANSYS, Inc. March 28, 2013 2 Release 14.5

Agenda

Introduction

Energy equation in solids

Equation solved in FLUENT

Shell conduction model

Non-conformal coupled wall

Anisotropic conductivity

Moving solids

Solver parameters

2013 ANSYS, Inc. March 28, 2013 3 Release 14.5

Agenda

Introduction

Energy equation in solids

Equation solved in FLUENT

Shell conduction model

Non-conformal coupled wall

Anisotropic conductivity

Moving solids

Solver parameters

2013 ANSYS, Inc. March 28, 2013 4 Release 14.5

Conduction Definition

Heat transfer is energy in transit due to a temperature difference

Conduction phenomenon:

Energy is transported by basic carriers

Fluids molecules, atoms

Solids free electrons

2013 ANSYS, Inc. March 28, 2013 5 Release 14.5

Fouriers Law

Conduction heat transfer is governed by Fouriers Law.

Fouriers law states that the heat transfer rate is directly proportional

to the gradient of temperature.

Mathematically,

The constant of proportionality is the thermal conductivity (k).

k may be a function of temperature, space, etc.

For isotropic materials, k is a constant value.

In general (for anisotropic materials), k is a matrix.

Table of k values for various materials can be found in the Appendix

Thermal conductivity

T k q V =

conduction

2013 ANSYS, Inc. March 28, 2013 6 Release 14.5

Agenda

Introduction

Energy equation in solids

Equation solved in FLUENT

Shell conduction model

Non-conformal coupled wall

Anisotropic conductivity

Moving solids

Solver parameters

2013 ANSYS, Inc. March 28, 2013 7 Release 14.5

Energy Equation for Solid Materials

Equation solved in FLUENT

The dependent variable h is the enthalpy,

( )

( )

h

S T k

t

h

+ V V =

c

c

Unsteady

Conduction

(Fouriers Law)

Enthalpy

Source

}

=

T

p

T d C h

0

2013 ANSYS, Inc. March 28, 2013 8 Release 14.5

In FLUENT, by default, planar heat transfer is ignored if the wall

thickness is not meshed.

Results from shell (1 layer)

matches with that obtained

using 3 prism layers

Plate Temperature

Along the Flow Direction

Exhaust pipe at 800 K emits

radiation in the direction of the shield

Shield, 2 mm thick

Shell Conduction

3 Prism layers

Shell Conduction ON

Shell Conduction OFF

2013 ANSYS, Inc. March 28, 2013 9 Release 14.5

To activate shell conduction, select it in the wall boundary condition

panel.

Text commands

To activate shell conduction for all walls with nonzero thickness:

grid/modify-zone/create-all-shell

To deactivate all shell conduction zones:

grid/modify-zone/delete-all-shell

Shell Conduction

Dont forget to specify the

material name and wall

thickness!

2013 ANSYS, Inc. March 28, 2013 10 Release 14.5

Shell Conduction

Shell conduction needed regardless of thermal conductivity

k = 0.01 W/mK (1D)

k = 0.01 W/mK (Shell)

k = 200 W/mK (1D)

k = 200 W/mK (Shell)

2013 ANSYS, Inc. March 28, 2013 11 Release 14.5

Shell Conduction Unsteady

The shell conduction model takes into account thermal inertia.

2013 ANSYS, Inc. March 28, 2013 12 Release 14.5

Shell Conduction Postprocessing

Which temperature should we post-process on a boundary wall with

shell conduction?

Facet value of external temperature

In Fluent: External Temperature (Shell)

Facet value of outer wall temperature

In Fluent: Wall Temperature (Outer Surface)

Cell value of Static Temperature

Note : XY plot Wall Temperature (both inner and

outer) allow use of cell values only

Cell value of inner wall temperature

In Fluent: Wall Temperature (Inner Surface)

2013 ANSYS, Inc. March 28, 2013 13 Release 14.5

Shell Conduction Connectivity

Specification of boundary condition at the wall end:

By default, wall shell is adiabatic

If shell conducting wall connects:

Another shell conducting wall The connecting edge has a coupled

boundary condition.

Another non-conducting external wall Edge has the same thermal

boundary condition.

Heat flux on virtual boundaries is not reported in the total heat

flux report.

Boundary condition on

the edge of the shell?

2013 ANSYS, Inc. March 28, 2013 14 Release 14.5

Shell Conduction Limitations

Limitations of the shell conduction model:

Shells cannot be created on non-conformal interfaces.

Shell conduction cannot be used on moving wall zones.

Shell conduction cannot be used with FMG initialization.

Shell conduction is not available for 2D.

Shell conduction is available only when the pressure-based solver is used.

Shell conducting walls cannot be split or merged. If you need to split or

merge a shell conducting wall, you will need to turn off the Shell Conduction

option for the wall (in the Wall dialog box, perform the split or merge

operation, and then enable Shell Conduction for the new wall zones.

The shell conduction model cannot be used on a wall zone that has been

adapted. If you want to perform adaption elsewhere in the computational

domain, be sure to use the mask register described in Section 30.11.1 of the

Fluent User Guide. This will ensure that adaption is not performed on the

shell conducting wall.

2013 ANSYS, Inc. March 28, 2013 15 Release 14.5

Non-Conformal Coupled Wall

Non-conformal coupled

wall:

We can use fine mesh on

fluid zone and coarser mesh

on solid zone

You can also model baffles.

Note:

Use /display/zone-grid ID

to display the shadow walls

2013 ANSYS, Inc. March 28, 2013 16 Release 14.5

Anisotropic Thermal Conductivity

Anisotropic thermal conductivity is only available for solid materials.

By default, the thermal conductivity is considered to be isotropic.

For anisotropic materials, the thermal conductivity is a matrix.

The thermal conductivity matrix can be defined using one of five

different methods:

Orthotropic

Cylindrical orthotropic

General anisotropic

Biaxial (shell conduction only)

j

ij i

x

T

k q

c

c

=

2013 ANSYS, Inc. March 28, 2013 17 Release 14.5

Cylindrical Orthotropic

Orthotropic

Anisotropic

Biaxial

(shell conduction only)

Anisotropic Thermal Conductivity for Solid Zones

Defining parameters may depend on

temperature.

UDF or constant/polynomial definition is also

possible.

2013 ANSYS, Inc. March 28, 2013 18 Release 14.5

Agenda

Introduction

Energy equation in solids

Equation solved in FLUENT

Shell conduction model

Non-conformal coupled wall

Anisotropic conductivity

Moving solids

Solver parameters

2013 ANSYS, Inc. March 28, 2013 19 Release 14.5

Conduction in Moving Solids

Equation solved in FLUENT (for moving solids) :

The convective term comes from an Eulerian description of solid

motion.

If the mesh moves with the solid like for sliding mesh or rigid body

deforming mesh (Lagrangian representation), then the solid motion

term vanishes

( )

( )( ) ( )

h

S T k h

t

h

+ V V = V +

c

c

V

Unsteady

Conduction

(Fouriers Law)

Enthalpy

Source

Solid Motion

2013 ANSYS, Inc. March 28, 2013 20 Release 14.5

Conduction in Moving Solids

The velocity field is taken

from the Solid panel

(rotation and translation)

Note that those velocity

fields satisfy the continuity

equation.

Convection in conducting

solids is justified for:

Solid translation of an

extruded geometry (slab,

plate or sheet)

Solid rotation of a geometry

of revolution

2013 ANSYS, Inc. March 28, 2013 21 Release 14.5

Conduction in Moving Solids

Example of convection in conducting solids

Metal or glass sheet in translation in a furnace.

Brake disc with source data

A solid meshed sheet is moving.

Inlet: Prescribed temperature

Outlet: Adiabatic (temperature

gradient is 0.)

2013 ANSYS, Inc. March 28, 2013 22 Release 14.5

Conduction in Moving Solids

Moving reference frame (MRF) is not appropriate for the entire solid

zone in the following situations:

Brake disc with holes

Turbomachinery blade

Adiabatic

500 K

300 K

2013 ANSYS, Inc. March 28, 2013 23 Release 14.5

Conduction in Moving Solids

Can we treat these problems using a

steady approach?

Just like for the fluid problem the

multiple reference frame approach

may be a useful approximation.

Brake disc with holes

Solid region decomposition

Solid zone in the MRF (body of

revolution)

Solid zone in the SRF (part with

holes). This part may actually be

moving. The effect of rotation on

heat transfer will be provided by the

moving material surrounding this

zone.

Solid Region

Decomposition

2013 ANSYS, Inc. March 28, 2013 24 Release 14.5

Conduction in Moving Solids

Can we treat this problem using a steady approach?

Turbomachinery blade

Solid zone: Stationary

Wall / Shadow: Thermally coupled

Wall on solid side: Stationary wall (absolute)

Wall/Shadow on fluid side: Moving wall (relative to adjacent cell zone)

2013 ANSYS, Inc. March 28, 2013 25 Release 14.5

Conduction in Moving Solids

Unsteady state?

Moving reference frame

can also be used in

unsteady problems with

the same limitations as in

steady state.

Sliding mesh or rigid body

deforming mesh is a

rigorous way of treating the

unsteady problem.

Sliding interface should be

located between two fluid

zones

2013 ANSYS, Inc. March 28, 2013 26 Release 14.5

Conduction in Moving Solids

Moving reference frame (MRF) approach is only valid for special

cases.

Rigid-body translation of an extrusion (slab, plate, sheet, )

Rigid-body rotation of a solid of revolution

Multiple reference frame

Moving solid can be treated as stationary if the surrounding fluid or solid is

in the same frame of reference

Sliding mesh is often the most accurate approach

2013 ANSYS, Inc. March 28, 2013 27 Release 14.5

Agenda

Introduction

Energy equation in solids

Equation solved in FLUENT

Shell conduction model

Non-conformal coupled wall

Anisotropic conductivity

Moving solids

Solver parameters

2013 ANSYS, Inc. March 28, 2013 28 Release 14.5

Solver Parameters

Convergence difficulties

Solver parameters affecting solution behavior

Single-precision/double-precision solver

Explicit relaxation of the energy equation

Importance of secondary gradients

MultiGrid methods

2013 ANSYS, Inc. March 28, 2013 29 Release 14.5

Convergence Difficulties

Convergence difficulties can be recognized by the following

symptoms.

Overall imbalance in heat flux at boundaries.

Slow convergence rate (several thousand iterations)

Residuals that diverge

Local (cell) temperatures reaching nonphysical values

Skewed cells and improperly-posed boundary conditions can also

cause convergence problems.

These problems can be either mitigated or avoided completely

through simple modifications to the solution setup.

2013 ANSYS, Inc. March 28, 2013 30 Release 14.5

Double-Precision Solver

The double-precision solver is designed to minimize truncation error

and thus improve the overall heat balance.

fluent 2ddp or fluent 3ddp

As a general rule, the double precision solver should be enabled under

the following conditions:

Cases with large heat fluxes (order of MW)

Large, possibly solution-dependent heat sources in the energy equation.

Widely varying fluid properties (functions of temperature) such as nonlinear

solids or compressible gases/liquids.

Cases where there are large differences in thermal conductivity among

materials.

Energy equation numerics become stiff.

Flux matching conditions become more difficult to maintain at solid interfaces.

2013 ANSYS, Inc. March 28, 2013 31 Release 14.5

MultiGrid Solver Parameters

MultiGrid Methods

The default MultiGrid scheme on

energy equation is Flexible

Using either the W-Cycle or F-Cycle

scheme is preferred when

diffusion is the predominant effect

W-Cycle is recommended for serial

processing

V-Cycle or F-Cycle is recommended

for parallel processing

Modified settings

(14 iterations)

Default settings

(50 iterations)

2013 ANSYS, Inc. March 28, 2013 32 Release 14.5

Explicit Under-Relaxation

Scheme command to activate explicit under-relaxation of temperature

(enter as you would any TUI command).

(rpsetvar temperature/explicit-relax? #t)

Advantages

Improved convergence for poor quality meshes

Improved convergence when material properties are strongly dependent on

temperature

Motivation

Energy under-relaxation factor of 1 often recommended

Temperature under-relaxation may be preferred

Settings:

Once the Scheme command is activated, the energy under-relaxation is

regarded as a temperature under-relaxation

Temperature URF typically 0.20.5 and energy URF = 1

2013 ANSYS, Inc. March 28, 2013 33 Release 14.5

Secondary Gradients

What is a secondary gradient?

Secondary gradients are used primarily as a corrective measure (the flux

vector may not be parallel to the face normal vector)

c

T

w

T

h A

( ) T f

h

T T

k

T k q

c w

A +

A

=

V = n

2013 ANSYS, Inc. March 28, 2013 34 Release 14.5

Secondary Gradients

Influence of secondary gradients

The secondary gradient effect increases with mesh skewness. With poor

mesh (skewness greater than 0.9), disabling secondary gradient treatment

will aid in convergence.

Perfect Hexahedral Mesh

Secondary Gradient = 0

Skewed Tetrahedral Mesh

Secondary Gradient

depends on skewness

c

T

w

T

h A

r

c

T

w

T

h A

r

2013 ANSYS, Inc. March 28, 2013 35 Release 14.5

Secondary Gradients

Secondary gradient influence

With poor mesh (skewness greater than 0.9), disabling secondary gradient

treatment will aid in convergence.

3 possibilities :

Disable secondary gradients in all zones

(rpsetvar 'temperature/secondary-gradient? #f)

Disable secondary gradients only on wall zones

solve/set/expert/

use-alternate-formulation-for-wall-temperature? yes

Disable secondary gradients only on shell conduction zones

(rpsetvar 'temperature/shell-secondary-gradient? #f)

2013 ANSYS, Inc. March 28, 2013 36 Release 14.5

Secondary Gradients

Is accuracy compromised by neglecting secondary gradients?

Default Without Secondary Gradients

2013 ANSYS, Inc. March 28, 2013 37 Release 14.5

14.5 Release

Appendix

2013 ANSYS, Inc. March 28, 2013 38 Release 14.5

Material

Thermal

Conductivity

at 20 C

(W/m K)

Silver 430

Copper 387

Aluminum 202

Steel 16

Glass 1

Water 0.6

Wood 0.17

Glass wool 0.04

Polystyrene 0.03

Air 0.024

Thermal Conductivity of Selected

Materials

2013 ANSYS, Inc. March 28, 2013 39 Release 14.5

Conductive Flux Calculation

Diffusive flux on an interior face

= Temperature for conduction

k = Thermal conductivity

Primary flux Secondary

gradient

The flux at a boundary face has a similar expression,

|

1

is replaced by |

f

and ds replaced by dr

|

|

.

|

\

|

| V | V +

| |

~

| V =

s

s f

s

f

f f

k

ds

k

k D

e A

A A

e A

e A

A A

A

0 1

s

s

e

d

d

s

=

Cell or face centroid

Node

Face f

s d

r d

A

Cell C0

Cell C1

S-ar putea să vă placă și

- Homework Helpers - Chemistry PDFDocument311 paginiHomework Helpers - Chemistry PDFTamby100% (1)

- Ansys Contact TutorialDocument40 paginiAnsys Contact Tutorialviluk100% (2)

- Methods of DehumidificationDocument4 paginiMethods of Dehumidificationprashant_mahitkar4532100% (3)

- Assignment 11 Rotational MotionDocument1 paginăAssignment 11 Rotational MotionMrinal TripathiÎncă nu există evaluări

- Aswc2014 Underhood Thermal Modeling PDFDocument41 paginiAswc2014 Underhood Thermal Modeling PDFTia SetiawanÎncă nu există evaluări

- NMIMS Business Law PPT Chapter 1 To 10 6xrfvqbymnDocument273 paginiNMIMS Business Law PPT Chapter 1 To 10 6xrfvqbymnsourabh78932Încă nu există evaluări

- Ansys Workbench Shah Ruck TutorialsDocument25 paginiAnsys Workbench Shah Ruck TutorialsNagamani Arumugam0% (1)

- CFX-Intro 16 L09 HeatTransferDocument23 paginiCFX-Intro 16 L09 HeatTransferMoh SenÎncă nu există evaluări

- Introduction to Finite Element Method (FEMDocument20 paginiIntroduction to Finite Element Method (FEMkpvraj100% (1)

- Robot DynamicsDocument52 paginiRobot Dynamicssilviocus88Încă nu există evaluări

- Fluent-Intro 17.0 Module08 HeatTransferDocument45 paginiFluent-Intro 17.0 Module08 HeatTransferNui Computercenter Swu Onk100% (2)

- Fluent-Intro 16.0 L06 SolverSettings PDFDocument49 paginiFluent-Intro 16.0 L06 SolverSettings PDFAnonymous 8209ZTÎncă nu există evaluări

- Ansys Multiphysics Systems CouplingDocument33 paginiAnsys Multiphysics Systems CouplingmanjunathbagaliÎncă nu există evaluări

- 6 SolarLoadDocument22 pagini6 SolarLoadali100% (1)

- ANSYS Fluent Tutorial Part 2 OverviewDocument10 paginiANSYS Fluent Tutorial Part 2 OverviewSWAPNIL PATILÎncă nu există evaluări

- Fluent Multiphase 19.0 L03 DPMDocument36 paginiFluent Multiphase 19.0 L03 DPMAmjad Ali PashaÎncă nu există evaluări

- ANSYS FLUENT Population Balance Module ManualDocument80 paginiANSYS FLUENT Population Balance Module ManualGokul PrabuÎncă nu există evaluări

- Fluent HeatTransfer L01 Introduction PDFDocument50 paginiFluent HeatTransfer L01 Introduction PDFHoÎncă nu există evaluări

- Mesh-Intro 14.5 L07 Assembly MeshingDocument32 paginiMesh-Intro 14.5 L07 Assembly Meshinganmol6237Încă nu există evaluări

- Module 03: Setting Up Physics: Introduction To ANSYS FluentDocument53 paginiModule 03: Setting Up Physics: Introduction To ANSYS FluentLuis Alejandro Amante SantanaÎncă nu există evaluări

- Fluent-Intro 16.0 L05 PostProcessing PDFDocument68 paginiFluent-Intro 16.0 L05 PostProcessing PDFAnonymous 8209ZTÎncă nu există evaluări

- Ansys Fluent Advanced Rotating Machinery: Lecture 6 Sliding Mesh Model (SMM)Document53 paginiAnsys Fluent Advanced Rotating Machinery: Lecture 6 Sliding Mesh Model (SMM)cpersonneÎncă nu există evaluări

- Fluent-Intro 16.0 L07 TurbulenceDocument50 paginiFluent-Intro 16.0 L07 TurbulenceDaniel CastroÎncă nu există evaluări

- Elasto-Hydrodynamic Lubrication: International Series on Materials Science and TechnologyDe la EverandElasto-Hydrodynamic Lubrication: International Series on Materials Science and TechnologyÎncă nu există evaluări

- Fluent-Intro 14.5 WS04 Airfoil PDFDocument38 paginiFluent-Intro 14.5 WS04 Airfoil PDFVigneshkumarÎncă nu există evaluări

- Fluent HeatTransfer L07 HeatExchangersDocument40 paginiFluent HeatTransfer L07 HeatExchangerssingourÎncă nu există evaluări

- Introduction To Using ANSYS FLUENTDocument27 paginiIntroduction To Using ANSYS FLUENTSatrio Tri JayantoÎncă nu există evaluări

- Astm D1250 Table 56Document7 paginiAstm D1250 Table 56Frankie Nguyen100% (4)

- Fluent-Adv Turbulence 15.0 L02 Rans ModelsDocument46 paginiFluent-Adv Turbulence 15.0 L02 Rans Modelsbecool_bcn75Încă nu există evaluări

- Eulerian and Mixture Multiphase Models in ANSYS Fluent: Surya Deb Ansys Inc. November 21, 2019Document43 paginiEulerian and Mixture Multiphase Models in ANSYS Fluent: Surya Deb Ansys Inc. November 21, 2019umair35Încă nu există evaluări

- Fluent-Intro 17.0 Module01 IntroCFDDocument14 paginiFluent-Intro 17.0 Module01 IntroCFDLuis Alejandro Amante SantanaÎncă nu există evaluări

- Fluent-Adv Turbulence 15.0 L04 Les and UtmmDocument55 paginiFluent-Adv Turbulence 15.0 L04 Les and Utmmbecool_bcn75Încă nu există evaluări

- Combustion Modeling Strategies FLUENTDocument7 paginiCombustion Modeling Strategies FLUENTKrozeÎncă nu există evaluări

- Combustion Modeling Strategies FLUENTDocument7 paginiCombustion Modeling Strategies FLUENTKrozeÎncă nu există evaluări

- 8 PorousMedia PDFDocument24 pagini8 PorousMedia PDFaliÎncă nu există evaluări

- Fluent-Adv Turbulence 15.0 L03 Wall ModelingDocument38 paginiFluent-Adv Turbulence 15.0 L03 Wall Modelingbecool_bcn75Încă nu există evaluări

- Curious About Making User Defined Functions in ANSYS Fluent?Document23 paginiCurious About Making User Defined Functions in ANSYS Fluent?bajank agus739Încă nu există evaluări

- Lecture 10: Heat Transfer: ANSYS Fluent Getting StartedDocument17 paginiLecture 10: Heat Transfer: ANSYS Fluent Getting StartedSahil JawaÎncă nu există evaluări

- Fluent-Intro 14.5 WS06 Sliding MeshDocument35 paginiFluent-Intro 14.5 WS06 Sliding MeshalfredozegarraÎncă nu există evaluări

- Fluent-Intro 16.0 L08 HeatTransfer PDFDocument45 paginiFluent-Intro 16.0 L08 HeatTransfer PDFAnonymous 8209ZTÎncă nu există evaluări

- 10 Pbed Reactor PDFDocument16 pagini10 Pbed Reactor PDFAdrian García MoyanoÎncă nu există evaluări

- Fluent-Adv Turbulence 15.0 L05 Case StudiesDocument51 paginiFluent-Adv Turbulence 15.0 L05 Case StudiesEnrique FloresÎncă nu există evaluări

- FLUENT Modeling Unsteady FlowsDocument101 paginiFLUENT Modeling Unsteady Flows조기현100% (1)

- Tips and Tricks ANSYSDocument62 paginiTips and Tricks ANSYSnuvanÎncă nu există evaluări

- Houston Ugm Phase Change ModelingDocument45 paginiHouston Ugm Phase Change Modelingsunilpatil.043827Încă nu există evaluări

- Fluent HeatTransfer L02 ConductionDocument40 paginiFluent HeatTransfer L02 ConductionsingourÎncă nu există evaluări

- Fluent HeatTransfer L04 NaturalConvectionDocument51 paginiFluent HeatTransfer L04 NaturalConvectionsingourÎncă nu există evaluări

- Transition ModelsDocument36 paginiTransition ModelsSadullah TaşkınÎncă nu există evaluări

- Udf Training 05Document76 paginiUdf Training 05Datz SorianoÎncă nu există evaluări

- 2020R1 FluentDocument65 pagini2020R1 Fluentagrbovic100% (1)

- Fluent-Adv-rm 14.5 L05 MRFDocument37 paginiFluent-Adv-rm 14.5 L05 MRFMohamed SelwenÎncă nu există evaluări

- Fluent-Adv-rm 14.5 L06 MPMDocument50 paginiFluent-Adv-rm 14.5 L06 MPMMohamed SelwenÎncă nu există evaluări

- ANSYS FSI For Thermal Management and Aeroelasticity 11th May 2011 PDFDocument52 paginiANSYS FSI For Thermal Management and Aeroelasticity 11th May 2011 PDFdharmeswarÎncă nu există evaluări

- Tutorial 5 FluentDocument56 paginiTutorial 5 FluentCrisner ToicenÎncă nu există evaluări

- Ask-The-experts ANSYS Advanced MeshingDocument47 paginiAsk-The-experts ANSYS Advanced MeshingShaheen S. RatnaniÎncă nu există evaluări

- Mech HeatTransfer 15.0 L07 TransientThermalDocument30 paginiMech HeatTransfer 15.0 L07 TransientThermalpercys99Încă nu există evaluări

- Fluent-Intro 15.0 L03 BoundaryConditionsDocument48 paginiFluent-Intro 15.0 L03 BoundaryConditionsravi456comp100% (1)

- Dynamic MeshDocument30 paginiDynamic Meshical_0nly0neÎncă nu există evaluări

- Fluent12 Lecture07 Heat TransferDocument36 paginiFluent12 Lecture07 Heat TransferEnes ŞavlıÎncă nu există evaluări

- Heat ExchangersDocument41 paginiHeat ExchangersARABOÎncă nu există evaluări

- CFD Lab Manual PK Final PDFDocument55 paginiCFD Lab Manual PK Final PDFYBSV PRASADÎncă nu există evaluări

- CFX-Intro 14.5 L09 HeatTransferDocument26 paginiCFX-Intro 14.5 L09 HeatTransferShaheen S. RatnaniÎncă nu există evaluări

- Heat Transfer CFDDocument20 paginiHeat Transfer CFDARABOÎncă nu există evaluări

- Dokumen - Tips Heat Transfer Modeling Using Ansys Transfer Modeling Using Ansys FluentDocument57 paginiDokumen - Tips Heat Transfer Modeling Using Ansys Transfer Modeling Using Ansys Fluentроман гаврилівÎncă nu există evaluări

- Prezentare Grosan Marius Bogdan An 2 ADSCSDocument25 paginiPrezentare Grosan Marius Bogdan An 2 ADSCSGanea Marius BogdanÎncă nu există evaluări

- Thermography Imaging Based On Equivalent Wave Field Transform For ClientDocument28 paginiThermography Imaging Based On Equivalent Wave Field Transform For Clientcarlito79Încă nu există evaluări

- El513 Casestudy5 CFD 09-2012Document111 paginiEl513 Casestudy5 CFD 09-2012antonio lopez100% (1)

- Assignment MarketingDocument5 paginiAssignment Marketingsourabh78932Încă nu există evaluări

- Affidavit for Not Owning Any Apartment Plot-3rd PrefrenceDocument2 paginiAffidavit for Not Owning Any Apartment Plot-3rd Prefrencesourabh78932Încă nu există evaluări

- NMIMS DS - Course Presentation-Chapter 1 To 10 F10zQvgjC3Document297 paginiNMIMS DS - Course Presentation-Chapter 1 To 10 F10zQvgjC3sourabh78932Încă nu există evaluări

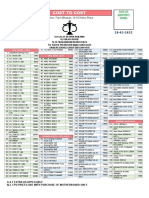

- Cost To Cost: Whatsapp: 9811616164 7303906164 Aoc 4K (U2879Vf) 16990Document7 paginiCost To Cost: Whatsapp: 9811616164 7303906164 Aoc 4K (U2879Vf) 16990sourabh78932Încă nu există evaluări

- Front Disc Y1kDocument1 paginăFront Disc Y1ksourabh78932Încă nu există evaluări

- Monthly Invoice: Page 1 of 2Document2 paginiMonthly Invoice: Page 1 of 2sourabh78932Încă nu există evaluări

- Introduction To Accounting: Earning BjectivesDocument22 paginiIntroduction To Accounting: Earning Bjectiveslalu morwalÎncă nu există evaluări

- GHGDCBDocument34 paginiGHGDCBAnish Veeru AnandÎncă nu există evaluări

- Muse 222Document1 paginăMuse 222sourabh78932Încă nu există evaluări

- V2i6 Ijertv2is60390Document6 paginiV2i6 Ijertv2is60390praveenÎncă nu există evaluări

- 53 Tutorial Mouse enDocument15 pagini53 Tutorial Mouse enh_eijy2743Încă nu există evaluări

- Today He Was Feeling NormalDocument2 paginiToday He Was Feeling Normalsourabh78932Încă nu există evaluări

- AjhjDocument1 paginăAjhjsourabh78932Încă nu există evaluări

- Total Deformation: Subject: Author: Prepared For: Date CommentsDocument1 paginăTotal Deformation: Subject: Author: Prepared For: Date Commentssourabh78932Încă nu există evaluări

- Ansys Fluent Custom Input ParametersDocument15 paginiAnsys Fluent Custom Input Parameterskristeen78100% (1)

- Chapter 01Document37 paginiChapter 01Thyago de LellysÎncă nu există evaluări

- DreamlessDocument1 paginăDreamlesssourabh78932Încă nu există evaluări

- Moisture and Total Solids AnalysisDocument44 paginiMoisture and Total Solids AnalysisNicholas BoampongÎncă nu există evaluări

- Section A: Multiple Choice Questions (20 Marks)Document4 paginiSection A: Multiple Choice Questions (20 Marks)saed cabdiÎncă nu există evaluări

- Quantum Physics Practice QuestionsDocument2 paginiQuantum Physics Practice QuestionsKrizzi Dizon GarciaÎncă nu există evaluări

- Design, Analysis and Fabrication of Split Braking SystemDocument6 paginiDesign, Analysis and Fabrication of Split Braking Systemhabib nawazÎncă nu există evaluări

- Nur Aqilah Binti Mohamad AminDocument35 paginiNur Aqilah Binti Mohamad Aminrasim_m1146Încă nu există evaluări

- 2015 BFnature15750 MOESM58 ESMDocument9 pagini2015 BFnature15750 MOESM58 ESMmacheng yangÎncă nu există evaluări

- Valence MOTheoryDocument50 paginiValence MOTheoryRodolfo Angulo OlaisÎncă nu există evaluări

- National Level E-Conference On Innovative Trends in MechanicalDocument16 paginiNational Level E-Conference On Innovative Trends in MechanicalA BBÎncă nu există evaluări

- Errata FE WasimDocument4 paginiErrata FE WasimchafobostonÎncă nu există evaluări

- Biconvex WinsDocument4 paginiBiconvex WinsSoorya PrashanthÎncă nu există evaluări

- Physics Form 4. Chapter 2. 2.5 ForceDocument49 paginiPhysics Form 4. Chapter 2. 2.5 ForceNuridahBintiZaimi100% (1)

- Structural Control System for Water TankDocument4 paginiStructural Control System for Water TankJOSMRIVERCÎncă nu există evaluări

- JEE Advanced 2020 Analysis JEE Advanced 2021 Analysis: WWW - Motion.ac - inDocument16 paginiJEE Advanced 2020 Analysis JEE Advanced 2021 Analysis: WWW - Motion.ac - inSarthak OmarÎncă nu există evaluări

- Solved Problems On TheveninDocument16 paginiSolved Problems On TheveninsathyaeceÎncă nu există evaluări

- Engineering Mechanic Sem 1 Session 0809Document10 paginiEngineering Mechanic Sem 1 Session 0809Amirul AizatÎncă nu există evaluări

- Foundation Class X PCMBDocument1.571 paginiFoundation Class X PCMBJack CrookÎncă nu există evaluări

- Noise Level Calculations: Example #1Document2 paginiNoise Level Calculations: Example #1Susheel WankhedeÎncă nu există evaluări

- Test Planner-Repeater Course - 2023-2024 - (Phase-03)Document2 paginiTest Planner-Repeater Course - 2023-2024 - (Phase-03)SbjÎncă nu există evaluări

- 2018 Experimental and CFD Analysis of Solar Air Heater With Rectangular ShapedDocument5 pagini2018 Experimental and CFD Analysis of Solar Air Heater With Rectangular ShapedaliÎncă nu există evaluări

- Resonance - Wikipedia, The Free EncyclopediaDocument10 paginiResonance - Wikipedia, The Free Encyclopedialoke06235Încă nu există evaluări

- Applications Using The Partial Differential Equation ToolboxDocument11 paginiApplications Using The Partial Differential Equation ToolboxIgor WosniakÎncă nu există evaluări

- FEA 2 McqsDocument26 paginiFEA 2 Mcqsrak RoyÎncă nu există evaluări

- Biazar Aminikhah Burgers EquationDocument7 paginiBiazar Aminikhah Burgers EquationSaeb AmirAhmadi ChomacharÎncă nu există evaluări

- Grounding - Industry Experiences - 2013Document292 paginiGrounding - Industry Experiences - 2013Minhthien NguyenÎncă nu există evaluări