Documente Academic

Documente Profesional

Documente Cultură

Durehete 950

Încărcat de

ellisforheroesDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Durehete 950

Încărcat de

ellisforheroesDrepturi de autor:

Formate disponibile

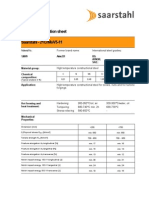

Corus Engineering Steels

Durehete 950

1% CrMoV Steel for bolting applications up to 510OC

Benefits Chemical Composition (wt%)

min C Si Mn P 0.36 0.45 1.00 0.50 0.25 max 0.44 0.40 0.85 0.030 0.030 0.015 1.15 0.65 0.35

Lower design and operating risks Simplified design for bolting configuration compared with martensitic steels or high nickel alloys.

Applications

S Al Cr* Mo V

Power generation turbine fasteners boiler support rods Process plant fasteners

* The Cr range is compatible with the compositional requirements of ASTM A193 B16.

Features

Proven performance in long term service. Extensive database of long term, high temperature test results. High room and elevated temperature strength. Good creep and relaxation resistance to 510 C High notch tolerance. Thermal expansion coefficients compatible with low alloy

O

Related Standards and Specifications

Unless stated otherwise all data are in accordance with BSEN 10269: 1999 , 40CrMoV4-6 , Steel No. 1.7711 BSEN 1515-1: 1999 BS1506 671-850 CEGB GDCD STD1 ISS1 BS4882 ASTM A193 B16

steel turbine casing materials.

Supply Condition & Availability

Readily available from bar stock. Supplied as oil quenched, tempered and cooled in air.

Page 1 of 4 11/2000

The future in metal

Corus Engineering Steels

Durehete 950

Mechanical Properties

Heat treatment (OC)

Diameter (mm) d 100 100<d 200 Min Max Min Max Quench temperature ( OC) 880 950 940 970 oil Coolant oil Temper Temperature (OC) 670 720 600 700

Test Piece Position

Test Piece Position Bar Diameter (mm) d25 25<d100 100<d200 Position centre 12.5mm below surface 25mm below surface* * Position is at greater distance below surface than specified in BS EN 10269: 1999 to coincide with the most highly stressed area of fasteners in service.

Room Temperature Mechanical Properties

Diameter (mm) d 100 100<d 200 Min Max Min Max 0.2% Proof Stress (N/mm ) 700 640 850 1000 850 1000

2

UTS (N/mm2)

Elongation (%) 14 14 -

Reduction of area (%) 45 45 -

Impact Energy (J)* 30 25 -

* Charpy V notch: mean of 3 test pieces.

Mechanical Properties at Elevated Temperatures

Minimum 0.2% Proof Stress (N/mm2) at Temperature (OC) Temperature(OC) d 100mm 100<d 200mm

Page 2 of 4 11/2000

50 687 631

100 670 612

150 647 591

200 631 577

250 608 556

300 593 542

350 577 528

400 554 507

450 523 479

500 470 429

550 400 366

600 293 268

The future in metal

Corus Engineering Steels

Durehete 950

Mechanical, Oxidation & Embrittlement Properties

Mean Stress Rupture Strength (Plain Specimens)

Temperature (OC) Stress to Produce Rupture (N/mm2) 10,000 h 450 500 550 513 321 137 100,000 h 463 210 200,000 h 446 187 -

Oxidation

The oxidation resistance is similar to that obtained with Durehete 900

Mean Stress Rupture Strength (Notched Specimens)

Temperature (OC) Stress to Produce Rupture (N/mm2) 1,000 h 450 500 550 510 295 10,000 h 578 360 143 100,000 h 452 221 -

Mean Stress Relaxation Properties

Strain = 0.15% Temperature (OC) 400 450 500 Residual Stress (N/mm2) 1,000 h 234 188 136 10,000 h 215 157 83 30,000 h 192 141 47

Page 3 of 4 11/2000

The future in metal

Corus Engineering Steels

Durehete 950

Physical Properties

Temperature (OC) 20 Density (kg/m ) Electrical Resistivity (n m) Thermal Expansion (K -1x10-6) Thermal Conductivity (W/mK) Specific Heat (J/kgK) Heat Content (kJ/kg) Modulus of Elasticity (kN/mm2)

3

100 320 11.1 41 449 33.6 207

200 390 12.1 40 487 86.1 198

300 465 12.9 39 525 147 190

400 560 13.5 36 546 107 183

500 660 13.9 34 567 273 174

600 785 14.1 33 621 349 165

700 955 651 441 -

7810 273 42 420 0 211

Published References

1 H Everson, J. Orr, D. Dulieu: Low Alloy Ferritic Bolting Steels for Steam Turbine Applications The Evolution of the Durehete Steels, ASM/EPRI Conference Advances in Material Technology for Fossil Power Plant, September 1987, Chicago, pp 375-383.

Page 4 of 4 11/2000

The future in metal

www.corusgroup.com

Corus Engineering Steels PO Box 50 Aldwarke Lane Rotherham S60 1DW United Kingdom Telephone +44 (0) 1709 371234 Facsimile +44 (0) 1709 826233

Care has been taken to ensure that the information herein is accurate, but Corus Engineering Steels Limited does not accept responsibility for errors or for information which is found to be misleading.

CES02:6000:UK:03/2000

S-ar putea să vă placă și

- ISO 3755 Cast-Carbon-Steel-General-Engineering-PurposesDocument9 paginiISO 3755 Cast-Carbon-Steel-General-Engineering-PurposesLe Van TamÎncă nu există evaluări

- Materials Data for Cyclic Loading: Low-Alloy SteelsDe la EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsEvaluare: 5 din 5 stele5/5 (2)

- C 45Document10 paginiC 45mohsen_267Încă nu există evaluări

- Materials Data for Cyclic Loading: Aluminium and Titanium AlloysDe la EverandMaterials Data for Cyclic Loading: Aluminium and Titanium AlloysEvaluare: 1 din 5 stele1/5 (1)

- CATALOG Blind and Solid RivetsDocument58 paginiCATALOG Blind and Solid Rivetsjhos douglasÎncă nu există evaluări

- AMS2303 - Steel Cleanliness, Aircraft Quality PDFDocument14 paginiAMS2303 - Steel Cleanliness, Aircraft Quality PDFRATHNAKUMARAÎncă nu există evaluări

- AQA A2 Physics A Chapter 5 Textbook AnswersDocument6 paginiAQA A2 Physics A Chapter 5 Textbook Answerscathylister100% (3)

- Handbook PDFDocument48 paginiHandbook PDFbhaskarjalanÎncă nu există evaluări

- Practical Process Plant Layout and Piping DesignDocument136 paginiPractical Process Plant Layout and Piping Designgonvic7411Încă nu există evaluări

- Interlloy 440C MartensiticDocument4 paginiInterlloy 440C MartensiticGuillaume BoyerÎncă nu există evaluări

- Specialty Materials Hastelloy C-276 ALLOY: Certified To Iso 9001Document3 paginiSpecialty Materials Hastelloy C-276 ALLOY: Certified To Iso 9001Jarbas MoraesÎncă nu există evaluări

- 1 - Din 1683-1e - 0Document4 pagini1 - Din 1683-1e - 0Joaquin AlvarezÎncă nu există evaluări

- PseudoephedrineDocument2 paginiPseudoephedrineSiti Marwasofa100% (3)

- Zintek 200 Spec SheetDocument6 paginiZintek 200 Spec SheetellisforheroesÎncă nu există evaluări

- Atlas Aluminium Datasheet 3003 Rev Oct 2013Document3 paginiAtlas Aluminium Datasheet 3003 Rev Oct 2013PrakashÎncă nu există evaluări

- ASME SA-437-SA-437M Specification For Alloy-Steel Turbine Type Bolting Material Specially Heat Treated For High-Temperature ServiceDocument5 paginiASME SA-437-SA-437M Specification For Alloy-Steel Turbine Type Bolting Material Specially Heat Treated For High-Temperature ServiceWagner Renato AraújoÎncă nu există evaluări

- 40NiCrMo7 PDFDocument2 pagini40NiCrMo7 PDFAmy GriffinÎncă nu există evaluări

- Analyzing Taper Fits For ManufacturingDocument7 paginiAnalyzing Taper Fits For Manufacturingsalgado_24Încă nu există evaluări

- Weld Repair of Steam Turbine Rotor With 12 CR WeldDocument5 paginiWeld Repair of Steam Turbine Rotor With 12 CR Weldsemarasik_651536604Încă nu există evaluări

- Health and Safety at Work Act 1974Document124 paginiHealth and Safety at Work Act 1974ellisforheroesÎncă nu există evaluări

- Sae Ams 2759-1e-2014Document13 paginiSae Ams 2759-1e-2014Reza NooriÎncă nu există evaluări

- iGCSE Chemistry Revision SheetsDocument26 paginiiGCSE Chemistry Revision SheetsPanagiotis ScordisÎncă nu există evaluări

- wn10 eDocument2 paginiwn10 eRani SaradeÎncă nu există evaluări

- Calculation of Retaining RingsDocument7 paginiCalculation of Retaining RingsDobrica PetrovicÎncă nu există evaluări

- b1 20 1Document31 paginib1 20 1Gustavo FamaÎncă nu există evaluări

- Bisalloy's PlatesDocument16 paginiBisalloy's PlatesMarcoÎncă nu există evaluări

- AISI 440 Martensit PDFDocument4 paginiAISI 440 Martensit PDFJimmyVargasÎncă nu există evaluări

- The Ralin Group LTD: ASTM A565 Grade 616 (UNS S42200)Document1 paginăThe Ralin Group LTD: ASTM A565 Grade 616 (UNS S42200)n1ghtfallÎncă nu există evaluări

- AMS5688Document7 paginiAMS5688Federica FiorentiniÎncă nu există evaluări

- Iso Fdis15614 13 2021Document24 paginiIso Fdis15614 13 2021arabsniperÎncă nu există evaluări

- Lubricants For Cement ProductionDocument21 paginiLubricants For Cement Productiongrameshkreddy2013100% (1)

- Iso 4029Document9 paginiIso 4029ellisforheroesÎncă nu există evaluări

- Old and New DINDocument6 paginiOld and New DINDianaÎncă nu există evaluări

- Iso 2339Document6 paginiIso 2339ellisforheroes100% (1)

- PBL Series K CatalougeDocument117 paginiPBL Series K CatalougeankitkanujiyaÎncă nu există evaluări

- Hollow Bars (ISO2938)Document8 paginiHollow Bars (ISO2938)suku maranÎncă nu există evaluări

- Great Minds of Carbon Equivalent - 1 PDFDocument3 paginiGreat Minds of Carbon Equivalent - 1 PDFSiva SubramaniÎncă nu există evaluări

- Inconel 718 Alloy 718 Uns n07718 Din 2.4668Document3 paginiInconel 718 Alloy 718 Uns n07718 Din 2.4668SamkitÎncă nu există evaluări

- Durehete 1055Document5 paginiDurehete 1055alextentwenty100% (1)

- 21 CR Mo V511Document1 pagină21 CR Mo V511uksrajÎncă nu există evaluări

- GS52Document3 paginiGS52S.Hasan MirasadiÎncă nu există evaluări

- QU AL ITY: Material Data SheetDocument5 paginiQU AL ITY: Material Data SheetAlex007Încă nu există evaluări

- Aerospace Material Specification Ams 2759 PDFDocument11 paginiAerospace Material Specification Ams 2759 PDFKarad KaradiasÎncă nu există evaluări

- Din 7623Document2 paginiDin 7623Racha Amel100% (1)

- En 10140-2006Document14 paginiEn 10140-2006KaanMertÎncă nu există evaluări

- A723A723M-18a 1.05 PDFDocument5 paginiA723A723M-18a 1.05 PDFist93993Încă nu există evaluări

- 722M24 Steel EN40BDocument1 pagină722M24 Steel EN40BRobert StuartÎncă nu există evaluări

- Equivalent Grades of Gray IronDocument2 paginiEquivalent Grades of Gray Ironsujay13780100% (1)

- Parallel Key Calculation According To DIN 6892Document21 paginiParallel Key Calculation According To DIN 6892zahirshah1436923Încă nu există evaluări

- IS1365-1978 BS - 4183 - Din 963 Slotted CSK Head Screw (MatricThd)Document1 paginăIS1365-1978 BS - 4183 - Din 963 Slotted CSK Head Screw (MatricThd)RavinderÎncă nu există evaluări

- RJR PMMTDocument16 paginiRJR PMMTArun PrasadÎncă nu există evaluări

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987De la EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonÎncă nu există evaluări

- Stress-Strain GraphDocument10 paginiStress-Strain GraphEzy WaqaÎncă nu există evaluări

- Tigweldarc Alloys: Certification of TestsDocument1 paginăTigweldarc Alloys: Certification of TestsArunÎncă nu există evaluări

- AlloysDocument4 paginiAlloyslinguy007Încă nu există evaluări

- Piulite Hexagonale-DIN934, IsO4032Document2 paginiPiulite Hexagonale-DIN934, IsO4032butca1Încă nu există evaluări

- About En19Document1 paginăAbout En19ramanamurtytv7176Încă nu există evaluări

- AMS4930LDocument8 paginiAMS4930Lremaja1249Încă nu există evaluări

- Pentair Series H ValveDocument78 paginiPentair Series H Valvea_osorioÎncă nu există evaluări

- KAMAXDocument19 paginiKAMAXNathan PaulÎncă nu există evaluări

- IFI 100 Prevailing Torque LocknutsDocument7 paginiIFI 100 Prevailing Torque LocknutsMarceloGonçalvesÎncă nu există evaluări

- 08chapter6 ShaftfixingsDocument12 pagini08chapter6 Shaftfixingsreinaldosidejunior100% (1)

- Astm E10 2001 PDFDocument9 paginiAstm E10 2001 PDFSofiaJabadanEspulgarÎncă nu există evaluări

- Korloy Grades and Chip BreakersDocument33 paginiKorloy Grades and Chip Breakersznovak77Încă nu există evaluări

- Din 743 E-AssisstDocument24 paginiDin 743 E-AssisstSezgin BayrakÎncă nu există evaluări

- Brass MachiningDocument68 paginiBrass MachiningVaibhav ShuklaÎncă nu există evaluări

- Fatigue Design Procedures: Proceedings of the 4th Symposium of the International Committee on Aeronautical Fatigue held in Munich, 16–18 June 1965De la EverandFatigue Design Procedures: Proceedings of the 4th Symposium of the International Committee on Aeronautical Fatigue held in Munich, 16–18 June 1965E. GassnerÎncă nu există evaluări

- 90 Tonne Aluminium Collapsible 11-4-15Document2 pagini90 Tonne Aluminium Collapsible 11-4-15ellisforheroesÎncă nu există evaluări

- Bs 250 Has ManualDocument28 paginiBs 250 Has ManualellisforheroesÎncă nu există evaluări

- Iso 2339Document3 paginiIso 2339ellisforheroesÎncă nu există evaluări

- DIN 7 - Dowel Pins Specifications: All Measurements in Millimeters (MM)Document1 paginăDIN 7 - Dowel Pins Specifications: All Measurements in Millimeters (MM)ellisforheroesÎncă nu există evaluări

- Anochrome Coating Data Sheet 15-10-14Document3 paginiAnochrome Coating Data Sheet 15-10-14ellisforheroesÎncă nu există evaluări

- Ketronpeek Gf30 e Pds 0907Document1 paginăKetronpeek Gf30 e Pds 0907ellisforheroesÎncă nu există evaluări

- 16114Document6 pagini16114ellisforheroesÎncă nu există evaluări

- Test Certificate in Accordance With Bs en 10204 3.1: Chemical AnalysisDocument1 paginăTest Certificate in Accordance With Bs en 10204 3.1: Chemical AnalysisellisforheroesÎncă nu există evaluări

- Geomet 500bDocument1 paginăGeomet 500bellisforheroesÎncă nu există evaluări

- Technical Product Data Sheet: Rotary Control Valves Side Entry Ansi 1500Document60 paginiTechnical Product Data Sheet: Rotary Control Valves Side Entry Ansi 1500ellisforheroesÎncă nu există evaluări

- Thyssenkrupp Materials International: Material Data SheetDocument4 paginiThyssenkrupp Materials International: Material Data SheetGopal RamalingamÎncă nu există evaluări

- 316 SS Data SheetDocument3 pagini316 SS Data SheetellisforheroesÎncă nu există evaluări

- A194 Chemical PropertiesDocument1 paginăA194 Chemical PropertiesellisforheroesÎncă nu există evaluări

- Es 21001 S100Document11 paginiEs 21001 S100ellisforheroesÎncă nu există evaluări

- Nuclear Fusion PowerDocument11 paginiNuclear Fusion PowerAndré RebelloÎncă nu există evaluări

- Hemanth Karmali & Deepak Pai - FomentoDocument46 paginiHemanth Karmali & Deepak Pai - FomentoNileshÎncă nu există evaluări

- A Thermal Nonlinear Dynamic Model For Water Tube Drum BoilersDocument16 paginiA Thermal Nonlinear Dynamic Model For Water Tube Drum Boilersprabhuene1Încă nu există evaluări

- TLC SprayerDocument4 paginiTLC SprayerShaanNegiÎncă nu există evaluări

- Steel RefiningDocument10 paginiSteel RefiningDiana Bracamonte DyckÎncă nu există evaluări

- Absorbance and Fluorescence Spectroscopies of Green Fluorescent ProteinDocument24 paginiAbsorbance and Fluorescence Spectroscopies of Green Fluorescent ProteinMadel Tutor ChaturvediÎncă nu există evaluări

- SFC 75-125-AC-460V-CAGI-Datasheet - 46-64978Document1 paginăSFC 75-125-AC-460V-CAGI-Datasheet - 46-64978Well Countryson Lumban TobingÎncă nu există evaluări

- Fatigue Testing WorksheetDocument5 paginiFatigue Testing WorksheetMohammed AL-MaaitahÎncă nu există evaluări

- ch03 PDFDocument11 paginich03 PDFFarhan KhanÎncă nu există evaluări

- Fulltext PDFDocument8 paginiFulltext PDFVictor Hugo Azevedo CarneiroÎncă nu există evaluări

- Sri Chaitanya IIT Academy., India.: A Right Choice For The Real AspirantDocument15 paginiSri Chaitanya IIT Academy., India.: A Right Choice For The Real AspirantZaid khanÎncă nu există evaluări

- Topic No. 1 - Introduction To Atomic Structure-1-1Document92 paginiTopic No. 1 - Introduction To Atomic Structure-1-1Chand HiraniÎncă nu există evaluări

- 1 Theory2Document16 pagini1 Theory2Tushar RajÎncă nu există evaluări

- CENG 122 Fall 2014 Syllabus Zhang CurriculumDocument3 paginiCENG 122 Fall 2014 Syllabus Zhang Curriculumtcd_usaÎncă nu există evaluări

- Fast-Charge IC: Features General DescriptionDocument14 paginiFast-Charge IC: Features General DescriptionAlejandro Cortegoso MartinezÎncă nu există evaluări

- Res Guide Electromagnetic WavesDocument8 paginiRes Guide Electromagnetic WavesbrsreddyÎncă nu există evaluări

- Liftex CatalogDocument60 paginiLiftex CatalogomoinleÎncă nu există evaluări

- Ahtk-25 Instructions New RevDocument3 paginiAhtk-25 Instructions New Revpdyba13Încă nu există evaluări

- Chapter-6 Wall SystemDocument102 paginiChapter-6 Wall SystemGebre Haile100% (1)

- Vanadio NMRDocument7 paginiVanadio NMRsergioodin4851Încă nu există evaluări

- Catalase Lab Project PosterDocument1 paginăCatalase Lab Project Posterapi-411085091Încă nu există evaluări

- COD Anaysis and ReductionDocument13 paginiCOD Anaysis and ReductionelaÎncă nu există evaluări

- Unit10 - Phan111 RedoxDocument57 paginiUnit10 - Phan111 RedoxAyille Dorado ArcigalÎncă nu există evaluări

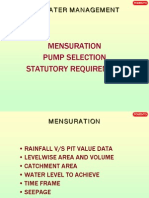

- PPU NotesDocument38 paginiPPU Noteswadhwachirag524Încă nu există evaluări