Documente Academic

Documente Profesional

Documente Cultură

10 Tips Design in Gray Iron

Încărcat de

Pria Akbar SejatiDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

10 Tips Design in Gray Iron

Încărcat de

Pria Akbar SejatiDrepturi de autor:

Formate disponibile

Home > Tips and Facts > Gray Iron Casting Design

Basics of Gray Iron Casting Design: 10 Rules for Engineered Quality

With attention to these key dos and donts of engineering gray iron castings, you can ensure fewer design re!ated defects and optimi"ed cast geometry# In its simp!est form, casting in$o!$es using a pattern to form a mo!d ca$ity into which mo!ten meta! is poured, so!idifies and %ecomes a component# In actua!ity, the process %egins %efore the pattern is made, at the point when an engineer decides on the %est design for the component# &n!y with a working know!edge of what a foundry can and cant do can an engineer design a tru!y efficient part' one that takes ad$antage of %oth materia! and specific casting process ad$antages# Gray iron is one of the most $ersati!e meta!s, %ut a know!edge of its distinct characteristics is integra! to an efficient design# This artic!e detai!s () ru!es of gray iron design# *+uipped with this %asic know!edge, an engineer wi!! ha$e a good %asis for optimi"ing cast components#

Visualize the Casting in the Mold

It can %e difficu!t to fo!!ow a!! section changes and shapes from a %!ueprint# ,y creating a three dimensiona! drawing or constructing a sma!! mode!, an engineer can study how the meta! wi!! enter the mo!d, disco$er how so!idification proceeds and define how parts must %e fed to assure casting soundness# - mode! to sca!e or a fu!! si"e pattern can %e used !ater to he!p the designer see how cores must %e designed, p!aced or omitted# It a!so wi!! he!p the foundry to determine how to mo!d the casting, detect casting weakness .shrinks and cracks/, where to p!ace gates and risers, and answer other +uestions affecting casting soundness, cost and de!i$ery#

Design for

oundness

0ost meta!s and a!!oys shrink when they so!idify# Therefore, design components so that a!! mem%ers of the parts increase in dimension progressi$e!y to one or more suita%!e areas where feeder heads .risers/ can %e p!aced to offset !i+uid shrinkage .Fig# (/# !ig" 1: These i!!ustrations portray how design can %e used to rectify meta! shrinkage defects# To ensure a component is free of shrinkage porosity, design components so that hea$ier sections are c!ose to risers that can feed !i+uid meta! to them#

#$oid har% Corners and #ngles

1o!idification of mo!ten meta! a!ways proceeds from the mo!d face, forming un%a!anced crysta! grains that penetrate into the mass at right ang!es to the p!ane of coo!ing surface# - simp!e section presents uniform coo!ing and greatest freedom from mechanica! weakness# When two or more sections con2oin, mechanica! weakness is induced at the 2unction and free coo!ing is interrupted, creating a 3hot spot,4 the most common defect in casting design# In designing ad2oining sections, rep!ace sharp ang!es with radii and minimi"e heat and stress concentration# 1ome e5amp!es of impro$ed designs are shown in Fig# 6# !ig" &: Designs that incorporate sharp corners wi!! resu!t in structura! weaknesses due to !oca!i"ed hot spots at the 2unctions, howe$er, adding radii that are too !arge a!so may resu!t in shrinkage defects .sections that are !arger wi!! feed thinner wa!!s, !ea$ing a $oid in the thick 2unction/# ,y incorporating sma!! fi!!et radii, hot spots are a$oided, assuring impro$ed strength#

*ngine cy!inder parts such as steam 2acketed cy!inders often are i!! designed with !oca!i"ed casting weaknesses due to sharp corners .Fig# 7/# When engineering a cored part, a$oid designs that do not ha$e a coo!ing surface# !ig" ': These schematics show how a steam 2acketed cy!inder design was impro$ed with rounded 2unctions#

1tream!ining an e5terior may resu!t in a hea$y section at 2unctions# Thin, e!ongated cores forming the ca$ities within the component resu!t in a heat concentration accentuating the hea$y sections# The resu!ting shrinkage defect causes !eakage# - rounded 2unction wi!! offer uniform strength properties# (e)t8 9u!e :# 0inimi"e the ;um%er of 1ections >>

Mini*ize the (u*+er of ections

- we!! designed casting %rings the minimum num%er of sections together at one point# - simp!e wa!! section wi!! coo! free!y from a!! surfaces, %ut %y adding a section .forming a T/, a hot spot is created at the 2unction, and it wi!! coo! !ike a wa!! that is <)= !arger# 1taggering sections minimi"es hot spot effects, thus e!iminating weakness and reducing distortion# If staggering is not possi%!e, a cored ho!e through the center of the 2unction wi!! he!p to speed so!idification and a$oid hot spots .Fig# :/# !ig" ,a - ,+: To pre$ent une$en coo!ing, %ring the minimum num%er of sections together or stagger them so that no more than two sections con2oin# When this is not possi%!e, a circu!ar we% with ad2oining sections is the preferred way to design structures that must intersect .:%/#

E*%loy .nifor*

ections

Thicker wa!!s wi!! so!idify more s!ow!y, so they wi!! feed thinner wa!!s, resu!ting in shrinkage $oids# The goa! is to design uniform sections that so!idify e$en!y# If this is not possi%!e, a!! hea$y sections shou!d %e accessi%!e to feeding from risers# !ig" /: This hydrau!ic coup!ing was origina!!y designed with a core that caused !oca!i"ed porosity# ,y redesigning the component with uniform wa!!s, the weight of the casting was reduced, !owering the manufacturing cost and remedying the shrinkage pro%!em#

Correctly 0ro%ortion Inner 1alls

Inner sections of castings .resu!ting from comp!e5 cores/ coo! much s!ower than outer sections and cause $ariations in strength properties# - good ru!e is to reduce inner sections to )#> of the thickness of the outer wa!!# -$oid rapid section changes %ecause they wi!! resu!t in porosity pro%!ems simi!ar to what is seen with sharp ang!es# Whene$er comp!e5 cores must %e used, design for uniformity of section to a$oid !oca! hea$y masses of meta!# The inside diameter of cy!inders and %ushings shou!d e5ceed the wa!! thickness of castings# When the inside diameter of a cy!inder is !ess than the wa!! thickness, it is %etter to cast the section so!id, as ho!es can %e produced %y cheaper .and safer/ methods than with e5treme!y thin cores# !ig" 2: To remedy the shrinkage defects in the origina! design of a hydrau!ic coup!ing, e5cessi$e meta! was remo$ed, resu!ting in a !ighter weight casting with !ess strain in the !ight radia! $eins#

!illet #ll

har% #ngles

Fi!!ets .round ed corners/ ha$e three functiona! purposes8 to reduce the stress concentration in a casting in service; to eliminate cracks, tears and draws at reentry angles; to make corners more moldable by eliminating hot spots. The num%er of fi!!et radii in one pattern shou!d %e the minimum possi%!e, prefera%!y on!y one# To fu!fi!! engineering stress re+uirements and reduce stress concentration, re!ati$e!y !arge fi!!ets may %e used with radii e+ua!ing or e5ceeding casting section# Fi!!ets that are too !arge are undesira%!e'the radius of the fi!!et shou!d not e5ceed ha!f the thickness of the section 2oined#

To a$oid a section si"e that is too !arge at an ?@? 2unction, round an outside corner to match the fi!!et on the inside wa!!# Where this is not possi%!e, consideration must %e gi$en to which is more $ita!8 the engineered design or the possi%!e casting defect# In the case of a ?A? or ?B? sections and other angu!ar forms, a!ways design them so that a generout radius e!iminates !oca!i"ation of heat# !ig" 3a - 3d: In Ca, wa!!s meet at acute ang!es, creating hot spots# The %est design is Cd in which honeycom%ing produces uniform coo!ing conditions, assuring impro$ed strength with minima! risk of distortion and structura! weakness#

#$oid #+ru%t

ection Changes

The difference in re!ati$e thickness of ad2oining sections shou!d not e5ceed a ratio of 68(# If a greater difference is una$oida%!e, consider a design with detacha%!e parts, !ike machine too! %eds that can %e %o!ted# When a change in thickness is !ess than 68(, it may take the form of a fi!!et# When the difference is greater, the recommended shift is in the form of a wedge# Howe$er, wedgeshaped changes in wa!! thickness shou!d not taper more than ( in :# Where a com%ination of !ight and hea$y sections is una$oida%!e, use fi!!ets and tapered sections to temper the shifts#

Ma)i*ize Design of Ri+s and Brac4ets

9i%s ha$e two functions8 to increase stiffness and to reduce weight# If they are too sha!!ow or too wide!y spaced, they can %e ineffecti$e# The thickness of ri%s shou!d appro5imate D)= of the ad2oining thickness and shou!d %e rounded at the edge# In other words, thin ri%s shou!d %e a$oided when 2oined to a hea$y section or they may !ead to high stresses and cracking# The design preference is for the ri%s to %e deeper than they are thickE the ri%s shou!d so!idify %efore the casting section they ad2oin# In addition, the space %etween ri%s shou!d pre$ent any !oca!i"ed accumu!ation of meta!# In genera!, ri%s in compression offer a greater safety factor than ri%s in tension# Howe$er, castings ha$ing thin ri%s or we%s in compression may re+uire design changes to pro$ide necessary stiffening and a$oid %uck!ing# -$oid cross ri%s or ri%%ing on %oth sides of a casting# Cross ri%%ing creates hot spots and makes feeding difficu!t# Instead, design cross coup!ed ri%s in a staggered dou%!e ?T? form# -$oid comp!e5 ri%%ing, which comp!icates mo!ding, hinders uniform so!idification and creates hot spots# Conse+uent!y, ri%s are on!y prefera%!e when the casting wa!! cannot %e made strong or stiff enough on its own# 9i%s meeting at acute ang!es a!so may cause mo!ding difficu!ties, increase costs and aggra$ate the risk of casting defects# ?Honeycom%ing? often wi!! pro$ide increased strength and stiffness without creating hot spots .Fig# C/# ,rackets carrying offset !oads introduce %ending moments'!oca!i"ed and in the %ody of the casting# -s a remedy, taper ?@? shaped %rackets and make the !ength of contact with the main casting as amp!e as possi%!e# -s another option, %rackets may fre+uent!y %e cast separate!y and then attached, simp!ifying mo!ding# - ri%%ed %racket wi!! offer a stiffness ad$antage, %ut a$oid heat concentration %y pro$iding cored openings in we%s and ri%s# 1uch openings shou!d %e as !arge as possi%!e, and consistent with strength and stiffness# -$oid rectangu!ar shaped cored ho!es in ri%s or we%sE use o$a! shaped ho!es with the !ongest dimension in the direction of the stresses#

10 Rules for Good Casting

The !ast few years ha$e witnessed an unprecedented increase in our understanding of the casting process# Thus, as understanding has increased, the !ist of re+uirements has %een steadi!y amended as they ha$e %ecome known# 1tarting from an initia! !ist of four ru!es, () ru!es ha$e now %een identified that incorporate the !atest techno!ogy for producing re!ia%!e castings# These are 2ust the start# -dditiona! ru!es may e5ist, %ut they remain to %e further researched and c!arified# The () ru!es that fo!!ow are proposed as necessary, %ut not, of course, sufficient# They shou!d %e used in addition to e5isting con$entiona! technica! specifications such as a!!oy type, strength and tracea%i!ity $ia I1& >))), etc#, and other con$entiona! foundry contro!s such as casting temperature, etc# -!though not yet tested on a!! cast materia!s, there are fundamenta! reasons for %e!ie$ing that the ru!es ha$e genera! $a!idity, and are app!ica%!e for a!! types of meta!s and a!!oys, inc!uding those %ased on a!uminum, "inc, magnesium, cast irons, stee!s, air and $acuum cast nicke!, co%a!t and titanium# ;e$erthe!ess, a!though a!! materia!s wi!! pro%a%!y %enefit from the app!ication of the ru!es, some wi!! %enefit a!most out of recognition, whereas others wi!! %e !ess affected# @isted in summary form, the ru!es are intended to assist the casting industry# -dhering to them wi!! speed up the process of producing the casting right the first time, and shou!d contri%ute great!y to reducing scrap when the casting goes into production# In this way, the casting industry wi!! %e a%!e to raise standards without any significant increase in costs# 1uperior +ua!ity can %e offered with confidence# &n!y in this way wi!! castings %e accepted %y the engineering profession as re!ia%!e, engineered products, and assure the future prosperity of the casting industry and its customers# Con$erse!y, the ru!es constitute a draft process specification, which %uyers of castings cou!d demand if they wished to %e assured that they were %uying the %est possi%!e casting +ua!ity# If %uyers specified that their casting sources fo!!owed such ru!es, the +ua!ity and re!ia%i!ity of the castings wou!d %e higher than cou!d %e achie$ed %y any amount of e5pensi$e +ua!ity contro! on the finished product#

Rule 1" 0ro$ide a Good Quality Melt

Immediate!y prior to casting, the me!t sha!! %e prepared and treated if necessary using the %est current practice# The aim is to pro$ide a me!t at the correct temperature, correct chemistry and with !ow residua! !e$e!s of disso!$ed gas and inc!usions# Inc!usions, particu!ar!y o5ide fi!ms, are reintroduced into the !i+uid meta! %y poor hand!ing, such as

pouring from furnaces and !ad!es prior to casting# Frocedures to a$oid such reintroduction of damage need to %e introduced# The figure %e!ow shows the hydrogen so!u%i!ity in a!uminum and two of its a!!oys, i!!ustrating the a%rupt fa!! in so!u%i!ity on so!idification#

The chart %e!ow shows mechanica! property regimes for an -! :#< Cu (#< 0g a!!oy in fi!tered and unfi!tered conditions GHed2a"i et a!# .(>C</H#

Home > Tips and Facts > () 9u!es for Good Casting > 9u!e 6

Rule &" #$oid 5i6uid !ront Da*age

This is the re+uirement that the !i+uid meta! front .the meniscus/ shou!d not go too fast# 0a5imum meniscus $e!ocity is a%out )#< mIs# .This ma5imum $e!ocity may %e raised to ( mIs in sections on!y a few mm thick#/ Howe$er, surface tur%u!ence damage can %e a$oided e$en at higher speeds if the casting fi!!ing system is sufficient!y narrow to constrain the meniscus, not a!!owing room for sp!ashing or drop!et formation# The scematics %e!ow show the effect of increasing height on a fa!!ing stream of !i+uid, i!!ustrating8 .a/ the o5ide fi!m remaining intactE .%/ the o5ide fi!m %eing detached and accumu!ating to form a dross ringE .c/ the o5ide fi!m and air %eing entrained in the %u!k me!t#

The schematic $iew of a sp!ash of mo!ten a!uminum shows the formation of a fo!ded .dou%!e/ fi!m that might consist of thick o!d fi!m, or new thin fi!m, or %oth, a!! !ike!y to occ!ude air in the fo!ds#

Rule '" #$oid #rrest of the 5i6uid !ront

This is the re+uirement that the !i+uid meta! front shou!d not go too s!ow!yJ -nd, more precise!y, shou!d not stop at any point on the front#

The ad$ancing !i+uid meta! meniscus must %e kept ?a!i$e? and free from thick o5ide fi!m that can %e incorporated into the casting# This is achie$ed %y ensuring that the !i+uid front on!y ad$ance uphi!! .in the case of gra$ity poured casting processes, from the %ase of the sprue onwards/# This imp!ies that8 on!y %ottom gating is permissi%!e, and no fa!!ing or s!iding downhi!! of !i+uid meta! is a!!owed# The meniscus must e5perience continuous uninterrupted upward ad$ance# That is, no stopping due to arrest of pouring, and no e5tensi$e hori"onta! sections or waterfa!! effects .a$oided %y casting design or mo!d orientation/, which wi!! cause a genera! temporary arrest of the !i+uid front in the casting, and thus !ead to o5ide !aps, or if pro!onged, e$en co!d !aps#

This drawing shows the unsta%!e ad$ance of a fi!m forming a!!oy, showing the formation of !aps as the interface intermittent!y stops and restarts %y %ursting through and f!ooding o$er the surface fi!m#

Rule ," #$oid Bu++le Da*age

;o air %u%%!es shou!d %e entrained %y the running system# If they are entrained, then they shou!d not %e a!!owed to pass through the !i+uid meta! in the mo!d ca$ity# If this happens, then a mi5ture of o5ide %u%%!e trai!s, together with residua! misshapen %u%%!es in the casting, wi!! resu!t# This is %y far the most common defect in castings, and is common!y mistaken for shrinkage porosity# This se$ere defect may %e a$oided %y8

Fast %ackfi!! of fi!!ing system %y $irtue of proper!y designed sprue and pouring %asin, and use of a stopper in sma!! castings, ceramic foam fi!ters p!aced c!ose to sprueIrunner 2unction, and %u%%!e traps# -ny so!utions must %e demonstrated as effecti$e using some suita%!e techni+ue such as rea! time K ray radiography# ;o interruptions to pouring#

This drawing i!!ustrates the most common defect in castings %u%%!e damage as a mi5ture of o5ide cracks and residua! entrapped %u%%!es#

Rule /" #$oid Core Blo7s

Gases from cores or e$en occasiona!!y from parts of the mo!d shou!d not %e a!!owed to penetrate the !i+uid meta!# Core or mo!d %!ows cause a rather different type of defect than the entrained air %u%%!es#

Cores shou!d %e demonstrated to %e of sufficient!y !ow gas content andIor ade+uate!y $ented to pre$ent %u%%!es from core %!ows# .This demonstration might %e carried out %y a $ideo recording of the fi!!ing of the mo!d without a cope, for instance#/ No clay-based core or mold repair paste should be used unless demonstrated to be resistant to the creation of blow defects.

,e!ow is a ?core %!ow? a trapped %u%%!e containing core gases# 1hown at the %ottom of the i!!ustration is a %u%%!e trai!, ending in an e5fo!iated dross defect as the resu!t of a passage of copious $o!umes of core gas# G-fter Fraw!ey et a!# .(>C:/H#

I!!ustrated %e!ow is the detachment of a %u%%!e from the top of a core, %e+ueathing a %u%%!e trai! as a permanent !egacy of its 2ourney# This %u%%!e may %e ear!y enough to escape at the free surface of the rising meta!#

Home > Tips and Facts > () 9u!es for Good Casting > 9u!e L

Rule 2" #$oid Da*age

hrin4age

;o feeding uphi!! %ecause of unre!ia%!e pressure gradient .a!so see 9u!e C on con$ection/# Demonstrate good feeding design fo!!owing a!! se$en feeding ru!es, %y an appro$ed computer so!idification mode!, and test castings# Contro! the !e$e! of f!ash at mo!d and core 2ointsE mo!d coats and mo!d temperatures# 9andom f!ashImo!d coatsImo!d temperatures can gi$e random feeding effecti$eness %y unpredicted changes to the temperature distri%ution in the casting#

This figure shows castings with %!ind risers# F6 is correct!y $ented, %ut has mi5ed resu!ts on sections 17 and 1:# 9iser F7 is not $ented and therefore doesnMt feed at a!!# The unfa$ora%!e pressure gradient draws !i+uid from a fortuitous skin puncture in section 1D# The %ottom drawing i!!ustrates the p!astic coffee cup ana!ogue8 the water is he!d up in the upturned cup and cannot %e re!eased unti! air is admitted $ia a puncture# The !i+uid it contains is then immediate!y re!eased#

Rule 3" #$oid Con$ection Da*age

Thin or thick section castings automatica!!y a$oid con$ection pro%!ems# Thin section castings free"e +uick!y %efore con$ection %ui!ds up# In

thick section castings, con$ection he!ps redistri%ute hot meta! into the risers on the top of the casting, since there is p!enty of time %efore free"ing starts# Howe$er, intermediate sections, which represent the great ma2ority of castings, ha$e a free"ing time commensurate with the time taken for con$ection to operate .in a few minutes/ and can cause damage# Nnsuita%!e temperature gradients in the casting can undermine the effecti$eness of risers, and !ead to segregation and apparent shrinkage damage in castings# This is a !itt!e known and !itt!e researched area that most current computer simu!ations cannot tack!e# For such intermediate sections, either8 Reduce the problem by avoiding convection loops in the geometry of the casting and rigging. Eliminate convection by 1 !-degree roll-over after mold filling. These i!!ustrations show the encouragement of therma! con$ection %y .a/ side and .%/ %ottom feeding, and its e!imination %y .c/ top feeding#

Rule 8" 0lan egregation Distri+ution

Change of section wi!! norma!!y in$o!$e change in distri%ution of a!!oying e!ements in the casting# This can mean parts of the casting are out of chemica! specification# 1uch pro%!ems may need to %e addressed if properties are threatened .such as a !oca! %ritt!eness, especia!!y in a stressed region/ and may re+uire prior negotiation with the customer#

Rule 9" Control Residual

tress

-$oid unknown or random residua! stress %y for%idding +uenching of !ow ducti!ity, !ight a!!oy castings into water fo!!owing high temperature so!ution treatment# ,oi!ing water is a!so not permitted since it represents a neg!igi%!e impro$ement o$er co!d water# Howe$er, po!ymer +uenchant or forced air +uench may %e accepta%!e if casting stress is shown to %e neg!igi%!e# F!anned residua! stress may %e %eneficia! if designed correct!y into the +uenching process# This chart shows the rates of coo!ing of a 6) mm diameter a!uminum %ar when +uenched %y $arious means from >76OF .<))OC/#

*!ongation to Fai!ure 9esu!ts from Different Puenching 0edia *!ongation .=/ 0ean Q6#< +.(, - ..(. /.+( - 1./( $. 1 - !.1/

Puenching 0edia "ot-water #uench 1$ %& '(!%)* )old-water #uench 0ater-glycol #uench

0inimum ..!1 +. ! +. $

Rule 10" 0ro$ide 5ocation 0oints

-!! castings wi!! %e pro$ided with agreed !ocation points for dimensiona! reference and for pickup for machining# The com%ination of c!amping points to %e used during machining is a!so usua!!y he!pfu! and easi!y incorporated, as i!!ustrated in Fig# () %e!ow# These drawings show ways in which the si5 point !ocation method can %e used on a casting#

S-ar putea să vă placă și

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Red Heart Yarns 2010-2011 CollectionDocument28 paginiRed Heart Yarns 2010-2011 CollectionRed Heart Yarns33% (3)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Mission Style Open Shelf Bathroom Vanity: AdvancedDocument22 paginiMission Style Open Shelf Bathroom Vanity: AdvancedMaricruz Valdivieso de PalaciosÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- DLL - Tle 6 - Q4 - W2Document6 paginiDLL - Tle 6 - Q4 - W2RhoseÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- 21st CENTURY LITERATURE - Q2 SUMMATIVE 3Document2 pagini21st CENTURY LITERATURE - Q2 SUMMATIVE 3Dave SulamÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Lead Sheet Brenton Brown - Lion and The LambDocument4 paginiLead Sheet Brenton Brown - Lion and The LambAndrea VargaÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Romance & Sex - ProstitutionDocument146 paginiRomance & Sex - ProstitutionThe 18th Century Material Culture Resource Center95% (22)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- PDFDocument204 paginiPDFNihat KalkandelenÎncă nu există evaluări

- CG Book 1Document64 paginiCG Book 1cg40701Încă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Schlumberger CollectionDocument265 paginiThe Schlumberger Collectionhbraga_sruival100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- 10 Dollar Store Crafts For Christmas PDFDocument25 pagini10 Dollar Store Crafts For Christmas PDFBelleBealsGarcia100% (4)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Apartment 1 Front Apartment Apartment 4 Front Apartment: Bathroom BathroomDocument1 paginăApartment 1 Front Apartment Apartment 4 Front Apartment: Bathroom BathroomOluwaseyi AdegokeÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- 21st Century 4Document2 pagini21st Century 4Sean CaloyloyÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- BrochureDocument3 paginiBrochureShamari Tamayao Cauilan II100% (1)

- Romeo and Juliet L14 - Anticipation PowerPointDocument12 paginiRomeo and Juliet L14 - Anticipation PowerPointmarex.fr1234Încă nu există evaluări

- Dla Q2Document8 paginiDla Q2LEonard CasoneteÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

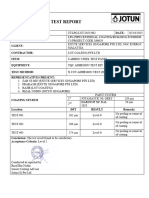

- Painitng Cross Cut Test ReportDocument2 paginiPainitng Cross Cut Test ReporttinzarmoeÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Estimation of Thread Consumption of GarmentDocument2 paginiEstimation of Thread Consumption of GarmentK.s. Ramesh100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- APPENDIX and References For Paper-MakingDocument7 paginiAPPENDIX and References For Paper-MakingMariejade PontingÎncă nu există evaluări

- Jerry Bergonzi: BiographyDocument2 paginiJerry Bergonzi: BiographymrnogoodÎncă nu există evaluări

- Assignment 48-Species Counterpoint 1: Homework ExercisesDocument2 paginiAssignment 48-Species Counterpoint 1: Homework ExercisesMilica Kulacin0% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Literary Elements Study GuideDocument4 paginiLiterary Elements Study Guideapi-236365630Încă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1091)

- Pollini - Ashkenazy (Chopin)Document2 paginiPollini - Ashkenazy (Chopin)FabrizioÎncă nu există evaluări

- American Art Songs VocalDocument450 paginiAmerican Art Songs VocalLambroula Maria Pappas75% (4)

- Lived Space in Architecture and CinemaDocument8 paginiLived Space in Architecture and CinemaVera Beltrão100% (1)

- How To Present A Memorable Flash Talk in 12 Easy Steps - EMBL EventsDocument4 paginiHow To Present A Memorable Flash Talk in 12 Easy Steps - EMBL EventsNicolas RomeroÎncă nu există evaluări

- E-Book Vista Ipanema Residencial SC ENGLISHDocument50 paginiE-Book Vista Ipanema Residencial SC ENGLISHJottaÎncă nu există evaluări

- Musical Instruments: 1. What's The Word?Document2 paginiMusical Instruments: 1. What's The Word?n.feliciaÎncă nu există evaluări

- Music6 q1 Mod4 Creating-Rhythmic-Patterns Version3 PDFDocument32 paginiMusic6 q1 Mod4 Creating-Rhythmic-Patterns Version3 PDFShin BarachinaÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Daftar Bintang Tamu Running ManDocument4 paginiDaftar Bintang Tamu Running Manmahasiswa0% (1)

- 500 Miles (LH Chords) - LTR - NotDocument2 pagini500 Miles (LH Chords) - LTR - NotJo DiÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)