Documente Academic

Documente Profesional

Documente Cultură

Renderoc LA 0310

Încărcat de

Tori SmallDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Renderoc LA 0310

Încărcat de

Tori SmallDrepturi de autor:

Formate disponibile

CI/SfB: October 2009

Fosroc Renderoc LA

High performance free flowing low alkali microconcrete conforming to the requirements of BS EN 1504-3 Class R4 Uses

For the reinstatement of reinforced concrete where low permeability characteristics are required and where high compressive strength is a consideration. Renderoc LA has been specificaly developed for the repair of large areas of concrete where access is restricted or where reinforcement is conjested. It is suitable for use where excellent chloride and carbon dioxide resistance is required or for repairs to concrete affected by alkali-silica reaction (ASR). Renderoc LA is alkaline in nature and will protect embedded steel reinforcement. Renderoc LA is suitable for repair methods 3.2, 4.4, 7.1, 7.2 as defined by BS EN 1504-3. Renderoc LA is designed for large volume repairs typically in excess of 50 mm deep. The product can be applied in sections generally up to 150 mm thick although greater thicknesses may be achievable dependent on the configuration of the repair location and the volume of exposed reinforcing steel. Consult the local Fosroc office for further information.

Standards compliance

Renderoc LA complies with the classification R4 according to EN 1504-3, repair methods 3.2, 4.4, 7.1 and 7.2.

Advantages

� Maximum compatibility with concrete of compressive strength 30 - 60 MPa � Dual expansion system compensates for shrinkage in the plastic and hardened states � Low alkali content minimises risk of alkali-silica reaction � Exceptional bond to concrete substrates without independent primer � Suitable for placement by pumping or pouring techniques into restricted locations � Self-compacting nature eliminates honeycombing and displaces air without vibration � High strength and low permeability provide maximum protection against carbon dioxide and chlorides � Pre-bagged to overcome site-batched variations only the site addition of clean water is required � Contains no chloride admixtures

Fosroc Ltd, Drayton Manor Business Park, Coleshill Road, Tamw orth, STAFFS, B78 3TL 09 0370-CPD-0845 EN 1504-3 Concrete repair products for structural repair CC mortar (based on hydraulic cement) Compressive strength Chloride ion content Adhesive bond strength Adhesive bond strength after freeze thaw thermal cycling Carbonation resistance Elastic modulus in compression Reaction to fire Dangerous substances Class R4 ( 45 MPa) 0.05% 2.0 MPa 2.0 MPa dk control concrete 20 GPa Class A1 Complies with 5.4

Description

Renderoc LA is supplied as a ready to use blend of dry powders requiring only the site addition of clean water to produce a free-flowing, shrinkage compensated microconcrete suitable for large volume concrete repairs at nominal thicknesses in excess of 50 mm. The material is based on Portland cement, graded aggregates and additives which impart controlled expansion in both the plastic and hardened states while minimising water demand. Its low alkali content minimises the risk of alkali-silica reaction. The hardened product exhibits excellent thermal compatibility with concrete.

Page 1

CI/SfB: March 2010

Fosroc Renderoc LA

Properties The following results were obtained at a water : powder ratio of 0.13 and a temperature of 20C unless otherwise stated.

Test method Standard EN 1504 R4 Requirement Result @ 1 Day 14 MPa @ 3 Days 30 MPa @ 7 Days 42 MPa @ 28 Days 60 MPa 2.7 MPa 0.02% 2.4 MPa Complies 31 GPa @28 Days Class A1 6.9 MPa @ 28 Days Initial set: 6 1/2 hours Final set: 9 hours Nominally 2300g/m3 < 300 microstrain @ 7 days 1% vol% Initial 5 seconds, 30 min 7 seconds The low permeability of Renderoc LA severely retards chemical attack in aggressive environments. The cured mortar is impermeable to acid gases, waterborne chloirde ions and oxygen. 0.146% after 6 months in 3% NaCL solution at 8-10mmm depth

Compressive Strength

EN 12190:1999

45 MPa

Bond strength by pull off: Chloride ion content: Freez e thaw cycling: Resistance to carbonation dk Elastic Modulus in Compression Fire rating Flexural strength Setting time Fresh w et density Shrinkage 25 x 25 x 285 prisms, 27 OC, 55% RH Alkali reactive particles Flow Properties

EN 1542:1999 EN 1015-17:2000 EN 13687-1:2002 EN 13295:2005 E N 13412 EN 13505-1 BS 6319 Pt 3:1990 BS 4551 Pt 14:1980

2.0 MPa 0.05 % 2.0 MPa ref concrete 20 GPa

Method TI-B 52 UK Highways Agency BD27/86 Clause 4.6(b) EN 13395-2

1000 mm within 10 seconds

Chemical resistance

Chloride ion ingress

E N 13396

Clarification of property values: The typical properties given above are derived from laboratory testing. Results derived from field applied samples may vary.

constructive solutions

Page 2

CI/SfB: March 2010

Fosroc Renderoc LA

Application instructions

The unrestrained surface area of the repair must be kept to a minimum. The formwork should be rigid and tight to prevent loss of material and have properly sealed faces to ensure that no water is absorbed from the repair material. The formwork should include drainage outlets for pre-soaking and, if beneath a soffit, provision for air-venting. Provision must also be made for suitable access points to pour or pump the mixed micro-concrete into place. Saw cut or cut back the extremities of the repair locations to a depth of at least 10 mm to avoid feather-edging and to provide a square edge. Break out the complete repair area to a minimum depth of 50 mm up to the sawn edge. Clean the surface and remove any dust, unsound or contaminated material, plaster, oil, paint, grease, corrosion deposits or algae. Where breaking out is not required, roughen the surface and remove any laitance by light scabbling or abrasive-blasting. Oil and grease deposits should be removed by steam cleaning, detergent scrubbing or the use of a proprietary degreaser. The effectiveness of decontamination should then be assessed by a pull-off test. Expose fully any corroded steel in the repair area and remove all loose scale and corrosion deposits. Steel should be cleaned to a bright condition paying particular attention to the back of exposed steel bars. Abrasive-blasting is recommended for this process. Where corrosion has occurred due to the presence of chlorides, the steel should be high-pressure washed with clean water immediately after abrasive-blasting to remove corrosion products from pits and imperfections within its surface. Reinforcing steel priming Priming of the steel reinforcement is not normally necessary unless it is to remain exposed in an environment likely to cause corrosion after preparation. When required apply one full coat of Nitoprime Zincrich Plus and allow to dry before continuing. If any doubt exists about having achieved an unbroken coating, a second application should be made and, again, allowed to dry before continuing Substrate priming Several hours prior to placing, the prepared concrete substrates should be saturated by filling the prepared formwork with clean water. Immediately prior to the application of Renderoc LA, any excess water should be removed. In exceptional circumstances, e.g. where a substrate/repair barrier is required, Nitobond EP bonding aid should be used. Contact the local Fosroc office for further information. Mixing Care should be taken to ensure that Renderoc LA is thoroughly mixed. A forced-action mixer is essential. Mixing in a suitably sized drum using an approved Conbextra Spiral Paddle with a slow speed (400/500 rpm) heavy-duty drill is acceptable. Free-fall mixers must not be used. Mixing of part bags should never be attempted. It is essential that machine mixing capacity and labour availability is adequate to enable the placing operation to be carried out continuously. Measure 3.3 litres of drinking quality water and pour three-quarters into the mixer. With the machine in operation, add one full 25 kg bag of Renderoc LA and mix for 1 minute before adding the rest of the water. Mix for a further 2 to 3 minutes until a smooth even consistency is obtained. Note that powder must always be added to water. The quantities mixed may be scaled up as required. When the drill and paddle mixing method is used, the complete 3.3 litres of water should be placed in the mixing drum. With the paddle rotating, add one full 25 kg bag of Renderoc LA and mix for 2 to 3 minutes until a smooth even consistency is obtained. It is recommended that the mixed product be passed through a suitable coarse metal screen prior to placing or pumping to highlight any unmixed material. Mixing warning As with other one pack repair mortars, Renderoc LA may exhibit satisfactory handling characteristics even though inadequately mixed. This will result in a significantly lower level of performance or possible failure. It is therefore essential that mixing instructions are strictly adhered to with particular emphasis on the quantity of water used and the time of the mixing operation. Placing The mixed material should be placed within 30 minutes of mixing in order to gain the full benefit of fluidity and of the expansion process. If placing by pump, standard concrete pumping practice should be followed. Contact the Fosroc Office for further details. Low temperature working In cold conditions down to 5C, the use of warm mixing water (up to 30C) is advisable to accelerate strength development. Normal precautions for winter working with cementitious materials should then be adopted. The material should not be applied when the substrate and/or air temperature is 5C and falling. At 5C static temperature or at 5C and rising, the application may proceed. High temperature working At ambient temperatures above 35C, the material should be stored in the shade and cool water used for mixing.

constructive solutions

Page 3

CI/SfB: March 2010

Fosroc Renderoc LA

Curing The formwork should be left in place until the compressive strength of the Renderoc LA is 10 MPa or as otherwise specified by the Supervising Officer. Renderoc LA is a cementbased concrete reinstatement material. In common with all cementitious materials, Renderoc LA must be cured immediately after the formwork is stripped in accordance with good concrete practice. Immediately after striking the formwork, all exposed faces of the repair should be thoroughly soaked with clean water and then sprayed with a liquid curing membrane such as Concure WB. In fast drying conditions, supplementary curing with polythene sheeting taped down at the edges must be used. In cold conditions, the finished repair must be protected from freezing. Overcoating with protective decorative finishes Renderoc LA is extremely durable and will provide long term protection to the embedded steel reinforcement within the repaired locations. The surrounding parts of the structure will generally benefit from the application of a barrier/decorative coating to limit the advance of chlorides and carbon dioxide, thus bringing them up to the same protective standard as the repair itself. Fosroc recommend the use of the Dekguard range of protective, anti-carbonation coatings. These products provide a decorative and uniform appearance as well as protecting areas of the structure which might otherwise be at risk from the environment. All traces of form-release oils and curing membranes must be removed prior to the application of Dekguard products. This is best achieved by light grit blasting. Cleaning Renderoc LA and Concure WB should be removed from tools, equipment and mixers with clean water immediately after use. Cured material can only be removed mechanically. Equipment used with Nitoprime Zincrich Plus and Nitobond EP should be cleaned with Fosroc Solvent 102.

Estimating

Supply Renderoc LA: Nitoprime Zincrich Plus: Nitobond EP: Concure WB: Fosroc Solvent 102: Coverage and yield Renderoc LA: Nitoprime Zincrich Plus: Nitobond EP: Concure WB: Approx. 12.0 litres / 25 kg bag 8 m2/litre 10m2 / 4.5kg pack 3.5 to 5 m2/ litre 25 kg bags 1.9 litre and 800 ml cans 4.5 kg packs 20 litre drums 5 and 25 litre tins

Notes: the coverage figures for liquid products are theoretical due to wastage factors and the variety and nature of possible substrates, practical coverage figures will be reduced.

Storage

The product has a shelf life of 12 months from the date of manufacture if kept in dry storage in the original, unopened bags. If stored at high temperatures and/or high humidity the shelf life may be reduced to less than 6 months. Concure WB should be protected from frost.

Precautions

Health and safety For further information refer to the Safety Data Sheet available at www.fosroc.com

Fire

Renderoc LA, Nitobond EP and Concure WB are nonflammable. Nitoprime Zincrich Plus and Fosroc Solvent 102 are flammable. Keep away from sources of ignition. No Smoking. In the event of fire, extinguish with CO2 or foam. Do not use a water jet. Flash points Nitoprime Zincrich Plus: Fosroc Solvent 102: 41C 33C

Limitations

Renderoc LA should not be used when the temperature is below 5C and falling. Do not mix part bags. The product should not be used to reinstate horizontal areas where the surface would remain unrestrained during cure. It should not be exposed to moving water during application. If any doubts arise concerning temperature, application or substrate conditions, consult the local Fosroc office.

Renderoc is the trade mark of Fosroc International Limited

Important note

Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard Conditions for the Supply of Goods and Services, copies of which may be obtained on request. Whilst Fosroc endeavours to ensure that any advice, recommendation, specification of information it may give is accurate and correct, it cannot, because it has no direct or continuous control over where or how its products are applied, accept any liability either directly or indirectly arising from the use of its products, whether or not in accordance with any advice, specification, recommendation of information given by it.

Fosroc Limited

Drayton Manor Business Park Coleshill Road, Tamworth, Staffordshire B78 3TL. UK telephone: +44 (0) 1827 262222 fax: +44 (0) 1827 262444 email: uk@fosroc.com

Certificate number FM 610

www.fosroc.com

Page 4

S-ar putea să vă placă și

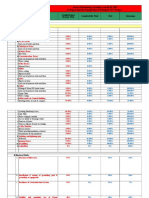

- S.No Item Description Start Date Finish Date Status As On 02.04.2016 1 Walkway Around BuildingsDocument2 paginiS.No Item Description Start Date Finish Date Status As On 02.04.2016 1 Walkway Around BuildingsTori SmallÎncă nu există evaluări

- Item Quantities of Phase-1Document4 paginiItem Quantities of Phase-1Tori SmallÎncă nu există evaluări

- 5-Star Element Hemraj InjuryDocument7 pagini5-Star Element Hemraj InjuryTori SmallÎncă nu există evaluări

- Course Book 6Document19 paginiCourse Book 6Tori SmallÎncă nu există evaluări

- Project: JUAYMAH380/230KV BSP: SL No ADocument4 paginiProject: JUAYMAH380/230KV BSP: SL No ATori SmallÎncă nu există evaluări

- JYM Project - Schedule (Rev-3, 11.09.2015)Document15 paginiJYM Project - Schedule (Rev-3, 11.09.2015)Tori SmallÎncă nu există evaluări

- 7-2-c Form - Gen Consultant PQ Summary Rev-0Document4 pagini7-2-c Form - Gen Consultant PQ Summary Rev-0Tori SmallÎncă nu există evaluări

- SVC Safaniyah (BSP) Punch List (4) XLSX 1Document52 paginiSVC Safaniyah (BSP) Punch List (4) XLSX 1Tori SmallÎncă nu există evaluări

- 5-Star Element Hemraj InjuryDocument7 pagini5-Star Element Hemraj InjuryTori SmallÎncă nu există evaluări

- Assets List Against File # 23352: Alfanar ConstructionDocument1 paginăAssets List Against File # 23352: Alfanar ConstructionTori SmallÎncă nu există evaluări

- Assets List Against File # 23352: Alfanar ConstructionDocument1 paginăAssets List Against File # 23352: Alfanar ConstructionTori SmallÎncă nu există evaluări

- Acomplishment Chart 380kVDocument8 paginiAcomplishment Chart 380kVTori Small100% (1)

- I Site Progress Civil Works: A 380 KV GIS BuildingDocument3 paginiI Site Progress Civil Works: A 380 KV GIS BuildingTori SmallÎncă nu există evaluări

- Assets List Against File # 17920: Alfanar ConstructionDocument1 paginăAssets List Against File # 17920: Alfanar ConstructionTori SmallÎncă nu există evaluări

- Current & Previous Reading For Brake Pad Change (June 2015)Document2 paginiCurrent & Previous Reading For Brake Pad Change (June 2015)Tori SmallÎncă nu există evaluări

- Request# Status: Visitor Management SystemDocument1 paginăRequest# Status: Visitor Management SystemTori SmallÎncă nu există evaluări

- 230kv Ohtl Sub - 10 Cut Over Plan Updated 29.2.16Document10 pagini230kv Ohtl Sub - 10 Cut Over Plan Updated 29.2.16Tori SmallÎncă nu există evaluări

- SI No 02 For Erection of Steel Structure For MarjanDocument3 paginiSI No 02 For Erection of Steel Structure For MarjanTori SmallÎncă nu există evaluări

- DPR - 22!12!2015 Safaniyah BSP, SVC and Sub-10Document12 paginiDPR - 22!12!2015 Safaniyah BSP, SVC and Sub-10Tori SmallÎncă nu există evaluări

- Prism Online QuestionnaireDocument2 paginiPrism Online QuestionnaireTori SmallÎncă nu există evaluări

- Concrete ChaklistDocument1 paginăConcrete ChaklistTori SmallÎncă nu există evaluări

- Car Wash Dec 14 (New)Document2 paginiCar Wash Dec 14 (New)Tori SmallÎncă nu există evaluări

- BSP AccessDocument14 paginiBSP AccessTori SmallÎncă nu există evaluări

- Drawing2 - GIBDocument1 paginăDrawing2 - GIBTori SmallÎncă nu există evaluări

- Details of Company Car Expenses (01.12.15)Document266 paginiDetails of Company Car Expenses (01.12.15)Tori SmallÎncă nu există evaluări

- Main Lab: FT-A-21226 29Y Female SelfDocument1 paginăMain Lab: FT-A-21226 29Y Female SelfTori SmallÎncă nu există evaluări

- Expense Sheet: Yasir Nisar Syed Project Engineer (Civil) Khalid AkhterDocument4 paginiExpense Sheet: Yasir Nisar Syed Project Engineer (Civil) Khalid AkhterTori SmallÎncă nu există evaluări

- Shahrour FreedomDocument14 paginiShahrour FreedomTori SmallÎncă nu există evaluări

- Imam Hussain Sermon at MinaDocument15 paginiImam Hussain Sermon at MinaTori SmallÎncă nu există evaluări

- Tuhaf Al UqulDocument840 paginiTuhaf Al Uqulapi-3738883Încă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- CW December 2012Document68 paginiCW December 2012Clint FosterÎncă nu există evaluări

- The Ozone Layer: Formation and Depletion: By-Ramen Gogoi Imsc 9 Sem Roll No 16Document43 paginiThe Ozone Layer: Formation and Depletion: By-Ramen Gogoi Imsc 9 Sem Roll No 16Ramen KukoiÎncă nu există evaluări

- Color Reactions R&DDocument2 paginiColor Reactions R&DJennifer HerediaÎncă nu există evaluări

- Material Safety Data Sheet For Magnesium Based Hot Metal Desulphurisation ProductDocument4 paginiMaterial Safety Data Sheet For Magnesium Based Hot Metal Desulphurisation Productrmallik1972Încă nu există evaluări

- D7997-15 Standard Practice For Polyurethane Raw Materials Gel Tests For Polyurethane Non-Foam FormulationsDocument7 paginiD7997-15 Standard Practice For Polyurethane Raw Materials Gel Tests For Polyurethane Non-Foam FormulationsMohamedÎncă nu există evaluări

- Cross-Specialization Training For Grades 7-10 Science TeachersDocument13 paginiCross-Specialization Training For Grades 7-10 Science TeachersJen DescargarÎncă nu există evaluări

- Combined PPT PSA Oxygen PlantDocument39 paginiCombined PPT PSA Oxygen Plantshivani50% (2)

- NEW Laboratory ReportDocument10 paginiNEW Laboratory ReportShōyōHinataÎncă nu există evaluări

- CLASS IX, Selina, Atmospheric PollutionDocument12 paginiCLASS IX, Selina, Atmospheric PollutionHirakjyoti SarkarÎncă nu există evaluări

- An Investigation On The Weldability of Grey Cast Iron Using Nickel Filler MetalDocument5 paginiAn Investigation On The Weldability of Grey Cast Iron Using Nickel Filler MetalKhin Aung ShweÎncă nu există evaluări

- Preparation of P-NitroanilineDocument11 paginiPreparation of P-NitroanilineRebecca Badour50% (2)

- Copper Injection Molding Using A Thermoplastic Binder Based On Paraffin WaxDocument6 paginiCopper Injection Molding Using A Thermoplastic Binder Based On Paraffin Waxromeoromeo1234Încă nu există evaluări

- Bailey's Industrial Oil and Fat ProductsDocument15 paginiBailey's Industrial Oil and Fat ProductsSinem Gökçe Dursun25% (4)

- 2 FuelsDocument18 pagini2 FuelsCllyan ReyesÎncă nu există evaluări

- Benzyl Alcohol IP STP BPDocument5 paginiBenzyl Alcohol IP STP BPshakt londaÎncă nu există evaluări

- Pi 0508 Hiblack 20bt WebDocument2 paginiPi 0508 Hiblack 20bt Web王偉仲Încă nu există evaluări

- Draw LewisDocument3 paginiDraw LewisclrgeekÎncă nu există evaluări

- Fiflows Thai Version PDFDocument3 paginiFiflows Thai Version PDFSaowalak PhonseeÎncă nu există evaluări

- Factors Affecting Relative Rates of Nucleophilic Substitution ReactionsDocument5 paginiFactors Affecting Relative Rates of Nucleophilic Substitution ReactionsXyrell Claude MontaÎncă nu există evaluări

- CHEM1PH Lec Midterms QUESTIONNAIREDocument4 paginiCHEM1PH Lec Midterms QUESTIONNAIREIvy Rose OrozcoÎncă nu există evaluări

- Existing EN AW 5251 H14 Al-Mg2Mn0,3 CompositionDocument8 paginiExisting EN AW 5251 H14 Al-Mg2Mn0,3 Compositionamh.fpdÎncă nu există evaluări

- Insecticides: S.No Technical Name Formulation Trade NamesDocument13 paginiInsecticides: S.No Technical Name Formulation Trade NamesRamkannan Parasumanna Chandrasekaran75% (16)

- Classi of PoisonDocument12 paginiClassi of PoisonShaik Abdul MuneerÎncă nu există evaluări

- A1 Poster - Adjustable WrenchDocument1 paginăA1 Poster - Adjustable WrenchKah KiatÎncă nu există evaluări

- Marking MAR 4461 20090428Document41 paginiMarking MAR 4461 20090428sensor_versionÎncă nu există evaluări

- HybridisationDocument14 paginiHybridisationAnand MurugananthamÎncă nu există evaluări

- Appendix A Perhitungan Neraca MassaDocument27 paginiAppendix A Perhitungan Neraca MassariyantimalinaÎncă nu există evaluări

- Soalan 11 & 12 D1Document5 paginiSoalan 11 & 12 D1veronica francisÎncă nu există evaluări

- Sem IDocument38 paginiSem Iomenlopes6Încă nu există evaluări

- Project Ethyl Benzene .. 2019-20 .. Jay RSDocument100 paginiProject Ethyl Benzene .. 2019-20 .. Jay RSBhatu DevareÎncă nu există evaluări