Documente Academic

Documente Profesional

Documente Cultură

Sequence of Operation Screen Printing Machine Automation

Încărcat de

Koti Veera BhadramDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Sequence of Operation Screen Printing Machine Automation

Încărcat de

Koti Veera BhadramDrepturi de autor:

Formate disponibile

SEQUENCE OF OPERATION SCREEN PRINTING MACHINE AUTOMATION

HOMING POSITIONS FOR PICK AND PLACE: 1. IN FEED PICK AND PLACE MECHANISM: Home position is on the conveyor (Right Side). 2. OUT FEED PICK AND PLACE MECHANISM: Home position is on the roller conveyor (Left Side). Need a control of pick and place mechanism with the distance from the home position also. HOME POSITION FOR HYDRAULLIC STATIONS: 1. Both the Mechanisms/Lifting Stations are having sensors at Bottom positions, Top Positions and Edge sensing for top sheet with the photo sensor reflector type. 2. For both the stations home positions will be at bottom positions 3. First we need to check the sensor positions of all the sensors on hydraulic stations. ALL THE PNEUMATICS CYLINDERS WILL BE NC CONDITIONS AT STARTING OF THE CYLCLE/HOME POSITION. CONTROLS FOR THE HYDRALLIC LIFTING STATIONS: 1. We have 5 solenoids and 3 valves at the hydraulic power pack. 2. 5/2 valves are for the hydraulic cylinders for the upward and downward movements. 3. 3/2 is for the control for the accumulator. 4. For offset lifting we have to use 3/2 valve always. 5. We have to use 5/2 valves for the normal upward and downward movements. 6. Offset lifting means lifting the hydraulic cylinder by using only accumulator oil, we have to check the lifting height practically to cross check with our digital controls and for interlocks if possible.

PROCESS SEQUENCE: Input process sequence: 1. Process starts from the loading of the stack on to the input station (hydraulic lifting). 2. When the operator placed the stack on to the lifting station/input station we have to take acknowledgement from the operator by push button/HMI Entry. 3. After the acknowledgement stack should lift until the top layer/sheet senses by the photo sensor, this procedure is for the top sheet positioning at fixed position for lifting. 4. Pick and place Mechanism have to move from the home position to the picking position and with forward position of the pneumatic cylinders on the input feeding mechanism gripper it should/will touch the top sheet. 5. At this position we have to switch on the vacuum/suction output in the Vacuum Ejector, vacuum will be generated and gripping will be done, we have to check for the vacuum signal/vacuum feedback here to go further/mechanism movement. 6. If we get the input signal mechanism should place the sheet on to the conveyor (in feeding conveyor), for un-gripping the sheet we have to switch off the vacuum/suction output and ejector signal should be switched on for a movement (1sec) and vacuum feedback signal also we have to check before it goes for the next cycle. 7. Cycle is continuous up to the input stack is empty, empty stack will be acknowledge by the count entry and sensor at stack. 8. Every time we have to check the vacuum acknowledgement, initially we will set the acknowledgement point in the vacuum ejector. 9. When gripper is un-gripping it should be checking for the vacuum acknowledgement 0 position. Sequence on Conveyor/Alignment: 1. By taking the signal from the alignment and placing signal with the gripper we should high the printing machine signal in order to transfer the sheet to printing stage. 2. Before the sheet come on to the printing stage Rotary pneumatic stopper should be in place on the printing machine.

3. We have to ensure the signal of sheet existence by the sensor which is placed on the stopper. 4. Alignment cylinder should be on to align in width direction. 5. We have to high the printing signal once the rotary cylinder in home position, rotary cylinder home position is outside the printing machine, we can check the rotary cylinder position with the sensor which is placed for back position of the rotary cylinder. 6. Once the printing is done machine automatically opens the screens and conveyor starts automatically, meanwhile next sheet should be in place in the Input conveyor with alignment, this cycle is continuous. Output Process Sequence: 1. Once the sheet out of the printing machine sheet will goes in to the dryer machine and comes out from the output conveyor, and it will be pushed on to the idle roller conveyor. 2. One sensor is placed below the conveyor to sense the sheet existence, with the feedback from the sensor and with the time gap we have to actuate the pick and place mechanism, by actuating the cylinder on the gripper to contact the suction cups to the sheet to pick. 3. Placing station is output station i.e hydraulic lower station, we have to ensure that pallet in place before starting the cycle. 4. We have to check the placing edge with the edge reflective sensor. 5. Once the height is maintained initially pick and place mechanism should place the sheet on to the pallet, lower should be done with the counting, no. of sheet will be finalized once the hydraulic offset lifting height is finalized. 6. We have to take count for placing and reset the count once the stack is removed, have to take acknowledge where ever the human interaction is there.

REQUIRED HMI OPTIONS: 1. MANUAL AND AUTO SCREEN. 2. AUTO SCREEN SHOULD DISPLAY THE COUNTER; PARTICULAR WILL BE DECIDED ONCE THE SEQUENCE IS COMPLETED. 3. COUNTER FOR THE EACH SHEET IN A CYCLE. 4. LIMITING THE CYCLE WITH THE COUNTER. (WILL BE USED AT MIN HEIGHT/LOWER HEIGHT STACK /LESS COUNT STACK IS LOADED). 5. PICK AND PLACE MECHANISM SHOULD BE CALIBRATED FOR DISTANCE AND WITH THE DISTANCE PICK AND PLACE MECHANISM SHOULD BE MOVING FORWARD AND BACKWARD DIRECTION, END SENSORS WE KEPT FOR LIMITING AND HOME POSITION AT ONE SIDE.

S-ar putea să vă placă și

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationDe la EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationÎncă nu există evaluări

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe la EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitÎncă nu există evaluări

- Machine Operation For Slit Roll Handling System Before We StartedDocument5 paginiMachine Operation For Slit Roll Handling System Before We StartedOSAMAÎncă nu există evaluări

- Operational Write Up - SCRDocument10 paginiOperational Write Up - SCRZahoor AhmedÎncă nu există evaluări

- Operational Writup of Stacker and ReclaimerDocument10 paginiOperational Writup of Stacker and ReclaimerZahoor AhmedÎncă nu există evaluări

- Rotajet D80Document14 paginiRotajet D80ChrisfergusonnÎncă nu există evaluări

- 2-SFC EnonceDocument11 pagini2-SFC EnonceLuc AusterÎncă nu există evaluări

- Prensa de 15 Ton PGC1500Document16 paginiPrensa de 15 Ton PGC1500abdielÎncă nu există evaluări

- Powerspin: 24 Place CentrifugeDocument11 paginiPowerspin: 24 Place CentrifugeLuz Stella Corzo ChaconÎncă nu există evaluări

- Carbonated Filler MannuelDocument8 paginiCarbonated Filler MannuelDániel CLÎncă nu există evaluări

- 2.160C Operation and Maintenance - DikonversiDocument59 pagini2.160C Operation and Maintenance - DikonversiDedi rahmat100% (1)

- SOP For Cherry Picker 2Document5 paginiSOP For Cherry Picker 2mukeshkatarnavare100% (1)

- Drum Filling UnitDocument24 paginiDrum Filling Unitsathyanand tkÎncă nu există evaluări

- Standard Operating ProceduresDocument8 paginiStandard Operating ProceduresPoer Wandi0% (1)

- SD 660 - Operating Manual - External Steam Supply - RLMDocument23 paginiSD 660 - Operating Manual - External Steam Supply - RLMNormanÎncă nu există evaluări

- Roller Machine GuardingDocument15 paginiRoller Machine GuardingAmeer KhanÎncă nu există evaluări

- CH.4 A.C. System Control DevicesDocument10 paginiCH.4 A.C. System Control Devicescpt.ghostÎncă nu există evaluări

- Control Panel PDFDocument21 paginiControl Panel PDFCesarÎncă nu există evaluări

- Instruction of 3D Tube Bender (DOBLADORA DE TUBOS CHINA)Document19 paginiInstruction of 3D Tube Bender (DOBLADORA DE TUBOS CHINA)MauricioÎncă nu există evaluări

- Sop of Billet Charging BM RHFDocument2 paginiSop of Billet Charging BM RHFwrbmrhfisp100% (1)

- Ucm03 034231Document8 paginiUcm03 034231Cláudio LimaÎncă nu există evaluări

- Manual For Sandblasting MachineDocument9 paginiManual For Sandblasting MachineKamel NaitÎncă nu există evaluări

- Users Manual: Concerto GS Platform LiftDocument12 paginiUsers Manual: Concerto GS Platform LiftRoselle SantiagoÎncă nu există evaluări

- Method Statement For Testing & Commissioning of Vacuum SystemDocument5 paginiMethod Statement For Testing & Commissioning of Vacuum SystemDong VanraÎncă nu există evaluări

- Eliw ewTR 910 TDocument11 paginiEliw ewTR 910 TAnonymous 4aChpF1hZÎncă nu există evaluări

- 590 Super R 695 Super R: Section 82 - LoaderDocument12 pagini590 Super R 695 Super R: Section 82 - LoaderTeknik MakinaÎncă nu există evaluări

- Standard Operation Procedure (SOP) For Centrifuge: SafetyDocument14 paginiStandard Operation Procedure (SOP) For Centrifuge: SafetyYechale TafereÎncă nu există evaluări

- Crane Operators Manual Rev 8-1-14Document14 paginiCrane Operators Manual Rev 8-1-14Dante WilliamsÎncă nu există evaluări

- Feeder CalibrationDocument6 paginiFeeder CalibrationPragneshÎncă nu există evaluări

- Operation Manual - 17210 - 17212 Sopladora JonhuahDocument45 paginiOperation Manual - 17210 - 17212 Sopladora JonhuahWalter DiazÎncă nu există evaluări

- Stair Climber TZ-2040B OkDocument13 paginiStair Climber TZ-2040B Okpaisley510Încă nu există evaluări

- Double Station Pneumatic Heat Press Machine Operation ManualDocument4 paginiDouble Station Pneumatic Heat Press Machine Operation ManualputrastevanofyÎncă nu există evaluări

- 8 Unit Movements: SUPERIX RL180N USER MANUAL - UM - 18005 - 0698 MECALL Sr. 1998 All Rights ReservedDocument15 pagini8 Unit Movements: SUPERIX RL180N USER MANUAL - UM - 18005 - 0698 MECALL Sr. 1998 All Rights ReservedRaklo YukhninÎncă nu există evaluări

- Manual 121029 Imcgx-200 Linear CapperDocument27 paginiManual 121029 Imcgx-200 Linear Capperelkin mezaÎncă nu există evaluări

- 4 Tool Turret Service Manual XYZ Iss1Document13 pagini4 Tool Turret Service Manual XYZ Iss1catur skakÎncă nu există evaluări

- Manual StrandjackDocument17 paginiManual StrandjackSusanto HidayatÎncă nu există evaluări

- ProcduresDocument4 paginiProcduresapi-313081991Încă nu există evaluări

- Deskjet 65X Disassembly ProceduresDocument15 paginiDeskjet 65X Disassembly Procedureserick_ssÎncă nu există evaluări

- ILIFE A4 Smart Robotic Vacuum Cleaner English User ManualDocument13 paginiILIFE A4 Smart Robotic Vacuum Cleaner English User ManualRobertoMartínez100% (1)

- Quanum Manual Multicopter Flying ControllerDocument21 paginiQuanum Manual Multicopter Flying ControllerYimmeeeÎncă nu există evaluări

- Syma X11 ManualDocument12 paginiSyma X11 ManualMauricio MendezÎncă nu există evaluări

- Ection Perating Rocedure: Revision November 2009Document42 paginiEction Perating Rocedure: Revision November 2009ddrb23Încă nu există evaluări

- Citizen E690 Movement GuideDocument40 paginiCitizen E690 Movement GuideAlisanta TjiaÎncă nu există evaluări

- HA480 V4 Tips and Tricks enDocument23 paginiHA480 V4 Tips and Tricks enRay PutraÎncă nu există evaluări

- AKD20503 - 9 Pitch ChannelDocument39 paginiAKD20503 - 9 Pitch ChannelAtiqah Nabilah RazaliÎncă nu există evaluări

- Yaris Verso PDFDocument14 paginiYaris Verso PDFSebas CorvalánÎncă nu există evaluări

- Operation and Control PhilosphyDocument16 paginiOperation and Control Philosphypradeep.selvarajanÎncă nu există evaluări

- Special Vehicle For Rescue From HeightsDocument9 paginiSpecial Vehicle For Rescue From HeightsDenisa-Ermiza FilipoiuÎncă nu există evaluări

- Mary Angelyn R. Martinez August 11, 2017 Ece - 5E Assignment No. 1Document9 paginiMary Angelyn R. Martinez August 11, 2017 Ece - 5E Assignment No. 1angelyn martinezÎncă nu există evaluări

- Endo 3 ManualDocument24 paginiEndo 3 Manualmimosart26Încă nu există evaluări

- Installation and Preoperative TestDocument27 paginiInstallation and Preoperative TestLeonardo BaiaoÎncă nu există evaluări

- Pressurization TextDocument4 paginiPressurization TextHussain NurbhaiÎncă nu există evaluări

- Operator Manual Manuel de L'utilisateur Betriebsanleitung Manual Del OperadorDocument32 paginiOperator Manual Manuel de L'utilisateur Betriebsanleitung Manual Del OperadorCrisz Giovanny Toapanta MedinaÎncă nu există evaluări

- Flight ControlsDocument9 paginiFlight ControlsAziz AimadÎncă nu există evaluări

- Ceutics SopDocument19 paginiCeutics Sopbandameedi.ramu2819Încă nu există evaluări

- ТЕЛЕЖКА механизированная РЭ СТО СD-TVM-01 переводDocument9 paginiТЕЛЕЖКА механизированная РЭ СТО СD-TVM-01 переводSergey Spil'nikÎncă nu există evaluări

- Experiment 7 Silo SimulationDocument7 paginiExperiment 7 Silo SimulationAvinash Umesh SarmaÎncă nu există evaluări

- EN-C160-2A ManualDocument22 paginiEN-C160-2A ManualFelipe ChoqueÎncă nu există evaluări

- CLG 200-3 Page 16-29Document15 paginiCLG 200-3 Page 16-29Preett Rajin MenabungÎncă nu există evaluări

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationDe la EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationÎncă nu există evaluări

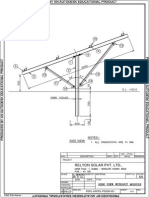

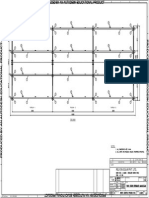

- Rolling Mill Extension Stability Check: Structural Information Input DataDocument3 paginiRolling Mill Extension Stability Check: Structural Information Input DataKoti Veera BhadramÎncă nu există evaluări

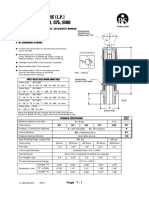

- R - Phase Y - Phase B-Phase: Ed. Original IEC - tpl003 Chakradhar Date Date Appr. Replacement of 4/9/2021 1 Name 1 / 4Document4 paginiR - Phase Y - Phase B-Phase: Ed. Original IEC - tpl003 Chakradhar Date Date Appr. Replacement of 4/9/2021 1 Name 1 / 4Koti Veera BhadramÎncă nu există evaluări

- Job Description: PositionDocument3 paginiJob Description: PositionKoti Veera BhadramÎncă nu există evaluări

- Structural Analysis and Design of Industrial Building in Mcdonald Steel Building Products LTD (MSBPL)Document70 paginiStructural Analysis and Design of Industrial Building in Mcdonald Steel Building Products LTD (MSBPL)Koti Veera BhadramÎncă nu există evaluări

- Kokan Railway PDFDocument1 paginăKokan Railway PDFKoti Veera BhadramÎncă nu există evaluări

- Improvement of Student Performance Using Root Cause AnalysisDocument22 paginiImprovement of Student Performance Using Root Cause AnalysisKoti Veera BhadramÎncă nu există evaluări

- Kokan Railway2Document1 paginăKokan Railway2Koti Veera BhadramÎncă nu există evaluări

- Why 5S - What Is 5S - Who Does 5S - Where To Do 5S - When To Do 5S - How To Do 5SDocument9 paginiWhy 5S - What Is 5S - Who Does 5S - Where To Do 5S - When To Do 5S - How To Do 5SKoti Veera BhadramÎncă nu există evaluări

- Cybage Analysis ReportDocument15 paginiCybage Analysis ReportKoti Veera BhadramÎncă nu există evaluări

- Car Parking Final Output - Steel Design - PDFDocument679 paginiCar Parking Final Output - Steel Design - PDFKoti Veera BhadramÎncă nu există evaluări

- Burkle EasyLam 2135C-SL TechnologyDocument2 paginiBurkle EasyLam 2135C-SL TechnologyKoti Veera BhadramÎncă nu există evaluări

- Calibration Guage DrawingDocument1 paginăCalibration Guage DrawingKoti Veera BhadramÎncă nu există evaluări

- GEI-100547-EX2100 and EX2100e ExcitationControl Factory Testsand Demonstrations Instruction GuideDocument12 paginiGEI-100547-EX2100 and EX2100e ExcitationControl Factory Testsand Demonstrations Instruction GuideLê Trung DũngÎncă nu există evaluări

- 2n3390 91,,92 93 PDFDocument3 pagini2n3390 91,,92 93 PDFAndrei Blas AzañaÎncă nu există evaluări

- Project Guide: Asim Mukherji Lectrurer, ECE, MNNITDocument18 paginiProject Guide: Asim Mukherji Lectrurer, ECE, MNNITashu1ashuÎncă nu există evaluări

- Monitoring Systems For Data Centers - Developed by GamatronicDocument6 paginiMonitoring Systems For Data Centers - Developed by GamatronicGamatronicÎncă nu există evaluări

- Synchronization of MSEB With GeneratorDocument2 paginiSynchronization of MSEB With GeneratorSarah FrazierÎncă nu există evaluări

- Sharjeel Zaidi MicroprocessorDocument23 paginiSharjeel Zaidi MicroprocessorSharjil ZaiDiÎncă nu există evaluări

- Genuine Isuzu - Need Quotation 24.4.2024Document21 paginiGenuine Isuzu - Need Quotation 24.4.2024akomu blissÎncă nu există evaluări

- STS 6 PulleyDocument6 paginiSTS 6 PulleyDebbieÎncă nu există evaluări

- Spider (105-115) PDFDocument184 paginiSpider (105-115) PDFBlagoja PetrovskiÎncă nu există evaluări

- APPLICANT INFORMATION SHEETfinal2Document33 paginiAPPLICANT INFORMATION SHEETfinal2Mario TamayoÎncă nu există evaluări

- Pressure Gauge Dan Diff Gauge Datasheet - Rev.ADocument20 paginiPressure Gauge Dan Diff Gauge Datasheet - Rev.Asugeng wahyudiÎncă nu există evaluări

- IRFP450Document8 paginiIRFP450Erick DavidÎncă nu există evaluări

- Development of CPLD Based Memory Controller For MPC 603E PPC Based Single Board ComputerDocument38 paginiDevelopment of CPLD Based Memory Controller For MPC 603E PPC Based Single Board ComputerkumarbsnspÎncă nu există evaluări

- Dse4510 Mkii Dse4520 Mkii Operator ManualDocument116 paginiDse4510 Mkii Dse4520 Mkii Operator ManualMário GuelreÎncă nu există evaluări

- 1VCP000138 1201Document91 pagini1VCP000138 1201zhang1988Încă nu există evaluări

- 7W Amplifier Circuit TDA2003Document7 pagini7W Amplifier Circuit TDA2003Mar EscÎncă nu există evaluări

- Utdrag Dunstabzug AnleitungDocument52 paginiUtdrag Dunstabzug AnleitungdjokanomcaÎncă nu există evaluări

- HKB Catalog 2012 0829Document2 paginiHKB Catalog 2012 0829mihneazlavoagaÎncă nu există evaluări

- UntitledDocument6 paginiUntitledKiran NarleÎncă nu există evaluări

- AquaCal Tropical Brochure PDFDocument2 paginiAquaCal Tropical Brochure PDFJC ParedesÎncă nu există evaluări

- FC GMDSS en eDocument4 paginiFC GMDSS en eStevien HendryanÎncă nu există evaluări

- Smart Home 9504 PDFDocument28 paginiSmart Home 9504 PDFJefferson ClaytonÎncă nu există evaluări

- BIS Safety Relief ValveDocument1 paginăBIS Safety Relief ValveRahimÎncă nu există evaluări

- Hardware Catalog No Prices (PTHW0208.1C) PDFDocument11 paginiHardware Catalog No Prices (PTHW0208.1C) PDFAhmed TahaÎncă nu există evaluări

- Technical ManualDocument151 paginiTechnical ManualGiannis KavathasÎncă nu există evaluări

- Power InverterDocument10 paginiPower Inverterdakshina656087100% (1)

- Method Statement For Piping Tie-In Sleeper Jetty 5 Area - POWERTECH PKG SMP#5 - Rev.00CrevisiDocument198 paginiMethod Statement For Piping Tie-In Sleeper Jetty 5 Area - POWERTECH PKG SMP#5 - Rev.00CrevisiJohnÎncă nu există evaluări

- 2301D and 2301D-EC Digital Load Sharing and Speed Controls For EnginesDocument148 pagini2301D and 2301D-EC Digital Load Sharing and Speed Controls For EnginesJoe D'AmatoÎncă nu există evaluări

- VECP83665T-4 Customer Information PacketDocument10 paginiVECP83665T-4 Customer Information PackettauasiÎncă nu există evaluări

- PIC Base A9Document28 paginiPIC Base A9Alfonso NiñoÎncă nu există evaluări