Documente Academic

Documente Profesional

Documente Cultură

b22cd205-0269-4f41-931f-2887373cdb75

Încărcat de

cuestajmDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

b22cd205-0269-4f41-931f-2887373cdb75

Încărcat de

cuestajmDrepturi de autor:

Formate disponibile

1

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

Thank you for joining our live webinar today.

We will begin shortly. Please standby.

Thank you.

Need Help?

Call ReadyTalk Support: 800.843.9166

Todays audio will be broadcast through the

internet.

Alternatively, to hear the audio through the

phone, dial 800 750 5849.

International callers, dial 00+1 212 231 2902.

For additional support, please press *0 and you

will be connected to a live operator.

2

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

Todays live webinar will begin shortly.

Please standby.

As a reminder, all lines have been muted. Please type any

questions or comments through the Chat feature on the

left portion of your screen.

Todays audio will be broadcast through the internet.

Alternatively, to hear the audio through the phone, dial

800 750 5849.

International callers, dial 00+1 212 231 2902.

For additional support, please press *0 and you will be

connected to a live operator.

AISC is a Registered Provider with The American Institute of Architects

Continuing Education Systems (AIA/CES). Credit(s) earned on

completion of this program will be reported to AIA/CES for AIA

members. Certificates of Completion for both AIA members and non-

AIA members are available upon request.

This program is registered with AIA/CES for continuing professional

education. As such, it does not include content that may be deemed or

construed to be an approval or endorsement by the AIA of any material

of construction or any method or manner of handling, using,

distributing, or dealing in any material or product.

Questions related to specific materials, methods, and services will be

addressed at the conclusion of this presentation

AISC Night School

3

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

Copyright Materials

This presentation is protected by US and International

Copyright laws. Reproduction, distribution, display and

use of the presentation without written permission of AISC

is prohibited.

The American Institute of Steel Construction 2013

AISC Night School

Session 5: February 25, 2013 Moment Connections Part I

This live webinar covers wind and low seismic moment

connection design. Various moment connections will be

discussed including flange welded-web bolted connections,

flange plate welded-web bolted connections, flange plate

bolted-web bolted connections, and moment end-plate

connections. Column side limit states will be discussed

followed by the presentation of a design example.

Course Description

4

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

At the end of this program, participants will be able to:

Gain familiarity with wind and low seismic moment

connection design.

Gain familiarity with various types of moment connections.

Gain an understanding of column side limit states in moment

connections.

Gain an understanding of designing a moment connection

through the presentation of a design example.

Learning Objectives

8

Presented by

Thomas M. Murray, Ph.D., P.E.

Emeritus Professor

Virginia Tech, Blacksburg, Virginia

thmurray@vt.edu

Fundamentals of Connection Design

Session 5: Moment Connections Part I

February 25, 2013

5

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

January 14, 2013 Fundamental Concepts Part I

January 28, 2013 Fundamental Concepts Part II

February 4, 2013 Shear Connections Part I

February 11, 2013 Shear Connections Part II

February 25, 2013 Moment Connections Part I

March 4, 2013 Moment Connections Part II

March 11, 2013 Moment Connections Part III

March 18, 2013 Bracing Connections

SCHEDULE

9

10

MOMENT

CONNECTIONS

PART I

6

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

11

Moment Connections:

Flange Welded / Web Bolted

Flange Plate Welded / Web Bolted

Flange Plate Bolted / Web Bolted

Column Side Limit States

Design Example

TOPICS

12

MOMENT CONNECTIONS

FR Moment Connections

Rotation,

M

o

m

e

n

t

,

M

M = 0.9M

Typical Beam Line

PR Moment Connection

Simple Shear

Connection

F

M = 0.5M

F

M = 0.2M

F

M

F

S

7

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

13

FLANGE WELDED / WEB

BOLTED

14

Flange Welded / Web Bolted

Limit States

Girder Flange-to-Column Flange Weld

Complete Joint Penetration (CJP)

Partial Joint Penetration (PJP)

Fillet welds (Shop)

Note

Weld Access Holes Reqd

for Field Welds

8

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

15

Flange Welded / Web Bolted

Girder Flange-to-Column Flange Weld

PJP joint welds are not recommended.

Fillet welds should develop the flange in tension.

f

f u

d ' req

b 392 . 1 5 . 1

) t d ( M

D

=

(1) 392 . 1 5 . 1

) 1 ( t F 9 . 0

D

f yf

d ' req

=

or

Recommended

16

Flange Welded / Web Bolted

Web Plate Limit States:

Shear Yielding

Shear Rupture

Bearing and Tear Out

Block Shear

Weld Shear Rupture

V

u

9

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

17

Flange Welded / Web Bolted

Notes:

Web plate connection is developed for direct

shear (no eccentricity).

The couple is resisted by the flanges.

High seismic design requires special

considerations.

V

u

V

u

18

FLANGE PLATE WELDED /

WEB BOLTED

Top plate is narrower than beam flange.

Bottom plate is wider than beam flange.

10

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

19

Limit States

Flange Plates-to-Column Flange Welds

Complete Joint Penetration (CJP)

Partial Joint Penetration (PJP)

Weld Access Holes Required

Plate-to-Flange Weld

must be made first.

Flange Plate Welded / Web Bolted

20

Tension Flange Plate Yielding

F

fu

= M

u

/ (d + t

p,avg

)

F

fu

< F

y

A

g

= 0.9

Flange Plate Welded / Web Bolted

F

fu

11

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

21

Flange Plate Welded / Web Bolted

Tension Flange Plate Rupture

Longitudinal Welds Only

F

fu

< F

u

A

e

= F

u

U A

g

= 0.75

Using AISCS Table D3.1, Case 4, p. 16.1-28

U = 1.0 for L > 2w

= 0.87 for 1.5w < L < 2w

= 0.75 for w < L < 1.5w

F

fu

L

w

22

Flange Plate Welded / Web Bolted

12

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

23

Tension Flange Plate Weld

F

fu

= M

u

/ d < R

n

= 0.75

R

n

= R

wl

+ R

wt

max 0.85R

wl

+ 1.5R

wt

F

fu

R

wl

R

wt

Flange Plate Welded / Web Bolted

24

Beam Tension Flange Block Shear

Longitudinal welds only.

Flange Plate Welded / Web Bolted

Shear Area

Tension Area

F

fu

13

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

25

Compression Flange Plate Buckling

Local Buckling (Table B4.1a Axial Compression)

Unstiffened

Element

Stiffened

Element

Unstiffened

Element

tp

b

1

y p

2

y p

1

F

E

40 . 1

t

b

7 Case : Stiffened

F

E

0.56

t

b

2 Case : d Unstiffene

<

<

Flange Plate Welded / Web Bolted

b

2

26

Compression

Flange Plate

Local Buckling

Flange Plate Welded / Web Bolted

14

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

27

Compression Plate Buckling

Flexural (Column) Buckling (AISCS J4.4)

For KL/r < 25

P

n

= 0.9F

y

A

g

For KL/r > 25

P

n

= 0.9F

cr

A

g

and provisions of Chapter E apply with k = 0.65

Column

Flange

L

Flange Plate Welded / Web Bolted

28

Compression Flange Plate Weld

F

fu

= M

u

/ d < (weld strengths)

F

fu

1.392 DL

w

Flange Plate Welded / Web Bolted

15

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

29

Flange Plate Bolted / Web Bolted

Web Plate / Web Bolts

Same as for Flange Welded / Web Bolted

Connection (No Eccentricity)

V

u

30

FLANGE PLATE BOLTED /

WEB BOLTED

16

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

31

Flange Plates

Flange Plates usually welded in shop.

Top flange plate is located to above

theoretical beam depth to account for

tolerances.

Figure shims are used if

needed to fill gap when

bolting.

Finger Shim

Flange Plate Bolted / Web Bolted

32

Limit States

Flange Plates-to-Column Flange Welds

Complete Joint Penetration (CJP)

Partial Joint Penetration (PJP)

Fillet Welds

If welded in the field,

welding must be done

before bolting and weld

access holes may be reqd.

Flange Plate Bolted / Web Bolted

17

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

33

Flange Plate Bolted / Web Bolted

Limit States

Tension Flange Plate Limit States

(Same as for a Tension Member.)

F

fu

1

1

2,3

2,3

3,4

3,4

Tension

Yielding

Tension Rupture

Bearing and

Tear Out

Block Shear

34

Flange Plate Bolted / Web Bolted

T

n

= 0.9 F

y

A

g

Tension Yielding

F

fu

1

1

2,3

2,3

3,4

3,4

Tension

Yielding

18

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

35

Flange Plate Bolted / Web Bolted

T

n

= 0.75 F

u

A

e

with A

e

= min (0.85 A

g

, A

n

)

Tension Rupture

F

fu

1

1

2,3

2,3

3,4

3,4

Tension Rupture

36

Ffu

Ffu

b

b

a

a

Ffu

c

c

b

b

a, b

a, b

Flange Plate Bolted / Web Bolted

Flange Plate Block Shear

Block Shear Paths

19

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

37

Flange Plate Bolted / Web Bolted

Compression Plate Limit States

Bearing and Tear Out

Local and Flexural Buckling

Stiffened

Element

Unstiffened

Element

b

t

p

Unstiffened

Element

L

Flange

Column

Local Buckling Flexural Buckling

K = 0.65

38

Flange Plate Bolted / Web Bolted

Bolt Rupture

F

u

= M

u

/ d < r

v

Long connection rule (Table J3.2 Footnote [b])

For end loaded connections with a fastener

pattern length greater than 38 in., F

nv

shall be

reduced to 83.3% of the tabulated values.

(Equivalent to =0.75 instead of 0.9. )

20

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

39

Flange Plate Bolted / Web Bolted

Girder Limit States

Reduced Flexural Strength

Block Shear

Bearing Tear-Out

40

V

u

M

u

Reduced Flexural Strength (AISCS F13.1)

Flange Plate Bolted / Web Bolted

21

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

41

Reduced Flexural Strength (AISCS F13.1)

If F

u

A

fn

< Y

t

F

y

A

fg

If F

u

A

fn

> Y

t

F

y

A

fg

no reduction is needed.

where Y

t

= 1.0 for F

y

/F

u

< 0.8 (A992)

= 1.1 otherwise

A

fg

= flange gross area

A

fn

= flange net area

Note: Reduction is based on tensile rupture strength.

x

S

fg

A

fn

A

u

F

=

n

M

Flange Plate Bolted / Web Bolted

42

Flange Plate Bolted / Web Bolted

Beam Flange Block Shear

F

fu

b

F

fu

b

a

a

22

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

43

Flange Plate Bolted / Web Bolted

Web Plate / Web Bolts

Same as for Flange Welded / Web Bolted

Connection (No Eccentricity)

V

u

44

COLUMN SIDE LIMIT

STATES

Flange and Flange Plate Connections

Flange Local Bending (J10.1)

Web Local Yielding (J10.2)

Web Crippling (J10.3)

Web Compression Buckling (J10.5)

Web Panel Zone (J10.6)

23

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

45

Column Side Limit States

Flange Local Bending (AISCS J10.1)

Stress

Concentration

T

u

`

T

u

< R

n

R

n

= 0.9 (6.25 t

fc

2

F

yc

)

If T

u

> R

n

, half depth column

web stiffeners required.

T

u

46

Column Side Limit States

F

y

T

u

or C

u

2.5

1

l

b

= t

fb

or t

p

5

k

d

e

s

i

g

n

+

l

b

Web Local Yielding (AISCSJ10.2)

T

u

or C

u

< R

n

= 1.0 F

yc

(5k

design

+ t

p

) t

wc

If T

u

or C

u

> R

n

, half depth stiffeners required

24

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

47

Column Side Limit States

C

u

C

u

Web Local Crippling (AISCS J10.3)

Same design rules as for beam bearing

with l

b

= t

p

or t

fb

If C

u

> R

n

, half depth stiffeners required

48

Web Local Crippling (AISCS J10.3)

Column Side Limit States

wc

fc yc

5 . 1

fc

wc

c

b 2

wc n

t

t EF

t

t

d

l

3 1 t 0.8 R

(

(

|

|

.

|

\

|

|

|

.

|

\

|

+ =

Web crippling @ >d/2

= 0.75

C

u

25

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

49

Column Side Limit States

Web Compression Buckling (AISCS J10.5)

C

u

< R

n

h = clear distance between fillets

(get from tabulated h/t

w

value)

If max C

u

> R

n

, full depth stiffeners required

h

F E t 24

9 . 0 R

yc

3

wc

n

=

C

u

C

u

50

Column Side Limit States

Transverse Stiffener Design

(AISCS J10.8 Requirements)

T

u

or C

u

t

s

t

wc

b

f

or b

p

bs

b

s

> d/2

t

f

or t

p

26

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

51

Column Side Limit States

Transverse Stiffener Design

y

s

s

p f

s

p f

wc

s

E/F 56 . 0

t

b

2

t or t

t

3

b or b

2

t

b

+

Local Buckling

(Compression only)

52

Column Side Limit States

Load Path Assumptions When Transverse

Stiffeners are Required

Assumptions:

Column resists R

n

Stiffeners resist difference

Stiffener Force = C

u,net

or T

u,net

= (C

u

or T

u

) min R

n

= R

u

min R

n

27

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

53

Required Net Stiffener Area

F .

R R

A

ys

n u

st

9 0

=

b

s

A

st

/ 2

Clip

3/4" Min.

Clip

3/4" Min.

Column Side Limit States

54

Column Side Limit States

Stiffener-to-Flange Weld

Recommend that weld develop the contact area

Or Complete Joint Penetration Weld (CJP)

(2) (1.392) 1.5

t F ) . (

(2) clip) b ( (1.392) 1.5

t clip) b ( F ) . (

D

s y

s

s s y

9 0 9 0

=

=

28

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

55

Column Side Limit States

Stiffener-to-Web Weld

Tu, net Cu, net

V

u

/ 2

V

u

/ 2

V

u

= C

u,net

+ T

u,net

56

Column Side Limit States

Stiffener Design When Required for Web

Compression Buckling (J10.5)

Design as a Compression

Member with Cruciform

Cross Section.

Provisions are in AISCS J10.8.

25 t

wc

t

wc

t

s

29

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

57

Column Side Limit States

Compression Member Design

A = 25 t

w

2

+ (b

s

t

s

)

k = 0.75

h = d

c

2 t

fc

hL/r F

cr

P

n

P

n

> max C

u

25 t

wc

wc

t

s

b

s

b

s

58

Column Side Limit States

Connections at Top of Columns

Column side strengths

are approximately one-

half of above, see

specification sections

J10.1, J10.2 and J10.3.

C

u

C

u

30

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

59

Column Side Limit States

P

u

Panel Zones

Web Panel Zone Shear

(AISCS J10.6)

60

Column Side Limit States

P

u

Panel

Zones

Web Panel Zone Shear

At Section A-A

0.9 R F

d 95 . 0 t d d

d 95 . 0 t d d

V

d

M

d

M

F

v u

2 2 f 2 2 m

1 1 f 1 1 m

u

2 m

2 u

1 m

1 u

u

= <

=

=

+ =

31

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

61

Column Side Limit States

When effect of panel zone deformation

on frame stability is not considered

(Section AISCS J10.6):

For P

u

< 0.4 P

y

= 0.4 F

y

A

g

R

v

= (0.60 F

y

)(d

c

t

wc

) (shear yielding)

For P

u

> 0.4 P

y

= 0.4 F

y

A

g

R

v

= (0.60 F

y

)(d

c

t

wc

)[1.4 (P

u

/ P

y

)]

Web Panel Zone Shear

62

Column Side Limit States

See J10.6(b) for strength when the effect of

panel zone deformation on frame stability

is considered.

Web Panel Zone Shear

32

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

63

Column Side Limit States

Panel Zone Doubler Plate (AISCS J10.9)

If F

u

> R

v

,

a doubler plate is required.

V

u,dp

= F

u

R

v

Note: Use two plates if required

thickness is greater than 1 in.

P

u

Doubler

Plate

V

u,dp

64

Column Side Limit States

Panel Zone Doubler Plate

Shear Yielding or Buckling

V

u

< V

n

= 1.0

V

n

= 1.0(0.6F

y

)(ht

p

) (Shear Yielding)

Otherwise,

V

n

from AISCS Section G2

h = d - 2t

fc

V

u,dp

t

p

y p

F

E

24 . 2

t

h

If

33

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

65

Panel Zone Doubler Plate

Buckling) (Inelastic

t / h

F / E k 10 . 1

C

F

E k

37 . 1

t

h

F

E k

1.10 For

Yielding) (Shear 1.0 C then

F

E k

10 . 1

t

h

For

C ) ht )( F 6 . 0 ( 0 . 1 V

w

y v

v

y

v

p y

v

v

y

v

p

v p y n

=

< <

=

=

Column Side Limit States

66

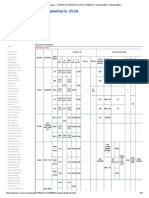

A36 Plate Steel

3/4 in. A325-N Bolts

E70XX

V

u

= 75 k

M

u

W24x103

A992

M

u

= 1050 k-ft

P

u2

= 1335 k

Pu1= 1200 k

W

1

4

x

1

5

9

A

9

9

2

W24x103

A992

Vu Story= 90 k

Vu = 60 k

Example: Design Flange Welded/Web

Bolted Moment Connection

= 1050 k-ft

34

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

67

W24x103 W14x159

M

n

1,050 k-ft

d 24.5 in. 15.00 in.

t

w

0.550 in. 0.745 in.

b

f

9.000 in. 15.6 in.

t

f

0.980 in. 1.19 in.

k 1 .79/2- in.

h/t

w

15.3

A 46.7 in

2

T 10 in.

Ex. Flange Welded/Web Bolted M-Connection

68

W24x103 Flange-to-Column Flange Weld

Girder Flange-to-Column Flange

Use Complete Penetration Welds (CJP)

with Backing Bars.

Girder Web-to-Column Flange

Single Plate

No eccentricity considered.

Ex. Flange Welded/Web Bolted M-Connection

35

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

69

4 @ 3"

1

1

4

"

1

1

4

" 1

1

2

"

2"

13/16 in. holes

5/16

Try PL 5/16 x 3 x 1-2 A36 with

W24x103 Web-to-Column Flange Connection

5 - 3/4 in. A325-N Bolts

Ex. Flange Welded/Web Bolted M-Connection

70

V

u

= 75 kips

Limit State Strengths

Shear Yielding: V

n

= 97.9 k OK

Shear Rupture: V

n

= 82.6 k OK

Block Shear: V

n

= 81.5 k OK

Bearing / Tear Out: V

n

= 111.7 k OK

Bolt Shear: V

n

= 89.5 k OK

Weld Rupture: V

n

= 201.8 k OK

Ex. Flange Welded/Web Bolted M-Connection

W24x103 Web-to-Column Flange Connection

36

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

71

W24x103

M

u

= 1,050 ft-kips d

c

= 24.5 in. t

fc

= 0.980 in.

T

u

= C

u

= (1050 x 12) / (24.5 0.980)

= 536 k

Ex. Flange Welded/Web Bolted M-Connection

Column Side Design

72

V = 90 k

u

2

3

23.52 in.

C

u

= 536 k

4

T

u

= 536 k

1

23.52 in.

C

u

= 536 k

T

u

= 536 k

Ex. Flange Welded/Web Bolted M-Connection

Flange Forces

37

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

73

R

n

= 0.9( 6.25 t

fc

2

F

y

)

= 0.9 (6.25 x 1.19

2

x 50)

= 398 k < T

u

= 536 k

For This Loading, Half-Depth Stiffeners

Required at 1 and 3.

Ex. Flange Welded/Web Bolted M-Connection

Column Flange Local Bending (J10.1)

74

R

n

= 1.0 (5 k

design

+ t

fb

) F

y

t

wc

= 1.0 (5 x 1.79 + 0.980) (50) (0.745)

= 370 k < T

u

and C

u

= 535 k

Half-Depth Stiffeners Required at all locations.

Use Full Depth Stiffeners Top and Bottom.

Ex. Flange Welded/Web Bolted M-Connection

Column Web Local Yielding (J10.2)

38

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

75

W24x103 l

b

= t

fb

= 0.980 in.

R

n

= 556 k > C

u

= 536 k OK

Ex. Flange Welded/Web Bolted M-Connection

Column Web Local Crippling J10.3

wc

fc yw

5 . 1

fc

wc

c

b 2

wc n

t

t F E

t

t

d

l

3 1 t (0.80) 0.75 R

(

(

|

|

.

|

\

|

|

|

.

|

\

|

+ =

76

V

u

= 166 + 166

= 332 k

k 166 370 - 536

Yielding Local eb W 370

Bending Local Flange 398

min 536 T

1

= =

=

Ex. Flange Welded/Web Bolted M-Connection

Transverse Stiffener 1-2 Design

1 2

39

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

77

Tension Side:

A

st,reqd

= 166 / (0.9 x 36) = 5.12 in

2

Compression Side:

A

st,reqd

= 166 / (0.9 x 36) = 5.12 in

2

Try PL 5/8 x 6

Clip: k

detailing

t

f

= 2.50-1.19=1.31 Use 1-

A

st

= 2 (6 1.5) (0.625) = 5.63 in

2

> A

st,reqd

OK

Ex. Flange Welded/Web Bolted M-Connection

Transverse Stiffener 1-2 Design

78

OK 9 . 15

36

29000

56 . 0

F

E

64 . 0 6 . 9

625 . 0

6

t

b

y s

s

= = < = =

Ex. Flange Welded/Web Bolted M-Connection

Transverse Stiffener 1-2 Design

Minimum Thickness:

t

s

= 0.625 in. > t

fb

/ 2 = 0.980 / 2 = 0.490 in. OK

Minimum Width:

b

s

= 6 in. > (9.0 / 3) (0.745 / 2) = 2.62 in. OK

Local Buckling:

Use 2 PL 5/8 x 6 Top and Bottom

40

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

79

Stiffener-to-Column Flange Welds:

Minimum Weld Size = 1/4 in.

Use 5/16 in. fillet welds B.S.

1/16ths 8 . 4

2 392 . 1 5 . 1

36 625 . 0 9 . 0

D =

=

Ex. Flange Welded/Web Bolted M-Connection

Transverse Stiffener 1-2 Design

80

Stiffener-to-Column Web Welds:

T = 11.25 in. > d

c

-2xt

fc

2xclip = 15.0-2x1.19-1x1.5

= 9.62 Use 9-

D = (166) / (9.5 x 2 x 1.392) = 6.27 1/16s

Minimum weld 5/16 in. Use 7/16 Welds B.S.

Ex. Flange Welded/Web Bolted M-Connection

Transverse Stiffener 1-2 Design

166 / 2 = 83.0 k

166 / 2 = 83.0 k

332 / 2 = 166 k

41

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

81

Strength of Column Web at Welds:

V

n

= 10.75(0.6F

u

)(t

wc

L

w

)

= 0.75(0.6x65)(0.745x9.5)

= 207 k > 166 k OK

Ex. Flange Welded/Web Bolted M-Connection

Transverse Stiffener 1-2 Design

166 / 2 = 83.0 k

166 / 2 = 83.0 k

332 / 2 = 166 k

82

Ex. Flange Welded/Web Bolted M-Connection

M

2 PL 5/8 x 6

u = 1050 k-ft

Typ at

Flanges

W24x103

A992

7/16

P

u2

= 1335 k

M

u

= 1050 k-ft

2 PL 5/8 x 6

W14x159

A992

5/16

V

u Story

= 90 k

P

u1

= 1200 k

Typ at

flanges

W24x103

A992

V

u

= 75 k

Vu = 60 k

Typ at

web

7/16

5/16

Partial Design

42

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

83

Panel Zone Strength

C

u

= 536 k

P

u2

= 1335 k

12.6 in.

Tu = 536 k

V

u Story

= 90 k

23.55 in.

P

u1

= 1200 k

Tu = 536 k

C

u

= 536 k

Ex. Flange Welded/Web Bolted M-Connection

23.55 in.

12.6 in.

P

u2

= 1335 k

P

u1

= 1200 k

84

V

u

= 536+ 536 90.0

= 982 k

P

u

= (1200 + 1335) / 2

= 1268 k

0.4 P

y

= 0.4 F

y

A

g

=0.4 (50 x 46.7)

= 0.4 (2335)

= 934 k < 1268 k

Ex. Flange Welded/Web Bolted M-Connection

23.55 in.

12.6 in.

P

u2

= 1335 k

P

u1

= 1200 k

Panel Zone Strength

43

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

85

Shear Strength of Column Web

Since P

u

> 0.4 P

y

= 934 k

V

n

= 0.9 (0.6 F

y

) (d

c

x t

wc

) (1.4 P

u

/ P

y

)

= 0.9(0.6 x 50)(15.0 x 0.745)

(1.4 1268 / 2335)

= 259 k < V

u

= 980.0 k Doubler Plate(s)

Required

in. 47 . 2

) 0 . 15 )( 36 6 . 0 ( 9 . 0

259 980

d ' req , dp

t =

=

Ex. Flange Welded/Web Bolted M-Connection

Panel Zone Strength

86

Try (2) 1 1/4 in. Web Doubler Plates

h = d 2 t

fc

= 15.0 2 (1.190)

= 12.6 in.

Doubler Plate Slenderness:

Shear yielding controls as assumed.

Use 2 1 A36 Doubler Plates

6 . 63

36

29000

24 . 2 0 . 10

25 . 1

6 . 12

t

h

p

= < = =

Ex. Flange Welded/Web Bolted M-Connection

Panel Zone Strength

44

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

87

Long Side

M = 0

D = 675 / (1.392 x 23.55) = 20.6 1/16s

Use Complete Joint Penetration Weld (CJP)

12.6 in.

23.55 in.

V

u

V

u

(

2

3

.

5

5

/

1

2

.

6

)

k 675

6 . 12

55 . 23

2

259 980

V

uw

=

|

.

|

\

|

|

.

|

\

|

=

Ex. Flange Welded/Web Bolted M-Connection

Panel Zone Welds

88

Short Side

Use minimum weld;

5/16 in. Fillet

or Fill Valley

Doubler Plate

Fill Valley

Stiffener

Ex. Flange Welded/Web Bolted M-Connection

Panel Zone Welds

45

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

89

Ex. Flange Welded/Web Bolted M-Connection

2 PL 5/8 x 6

Mu = 1050 k-ft

Typ at

Flanges

W24x103

A992

7/16

P

u2

= 1335 k

(2) 1 1/4 in Plates

M

u

= 1050 k-ft

2 PL 5/8 x 6

W14x159

A992

5/16

V

u Story

= 90 k

P

u1

= 1200 k

Typ at

flanges

W24x103

A992

V

u

= 75 k

Vu = 60 k

Typ.

Typ at

web

7/16

5/16

Final Design

End of Session 5

Thank You for

Attending

Next Up

90

46

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

February 25, 2013 Moment Connections Part I

March 4, 2013 Moment Connections Part II

March 11, 2013 Moment Connections Part III

March 18, 2013 Bracing Connections

Topics

Tee Stub Moment Connections

End-Plate Moment Connections

Next Session

91

Individual Webinar Registrants

Within 2 business days

You will receive an email on how to report attendance from:

ceu@aisc.org.

Be on the lookout: Check your spam filter! Check your junk folder!

Completely fill out online form. Dont forget to check the boxes next to

each attendees name!

OR

CEU/PDH Certificates

47

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

Individual Webinar Registrants

Within 2 business days

Go to: http://www.wynjade.com/aiscspring13/webinarCEU.

Username: Your Web ID(found on your registration receipt)

+ session number

Password: Your Last Name

Example Joe Steel; Web ID 123456; session 5

Login: 1234564

Password: Steel

Questions? Please email us at nightschool@aisc.org.

CEU/PDH Certificates

Access to the quiz: Information for accessing the quiz will be emailed

to you by Wednesday, February 27. It will contain a link to access the quiz.

EMAIL COMES FROM NIGHTSCHOOL@AISC.ORG.

Reasons for quiz:

EEU must take all quizzes and final to receive EEU

CEUs/PDHS If you watch a recorded session you must take

quiz for CEUs/PDHs.

REINFORCEMENT Reinforce what you learned tonight. Get

more out of the course.

NOTE: If you attend the live presentation, you do not have to

take the quizzes to receive CEUs/PDHs.

8-Session Registrants

48

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

Quiz Results: www.aisc.org/nightschool

-Choose Current Course Details

8-Session Registrants

Quiz Results: www.aisc.org/nightschool

-Choose Current Course Details, scroll down

-Session 4 quiz re-takes due by March 1.

8-Session Registrants

49

AISC NIGHT SCHOOL: Lecturer: Tom Murray, P.E., PhD

FUNDAMENTALS OF CONNECTION DESIGN Emeritus Professor, Virginia Tech

Session 5 Moment Connections Part I Copyright 2013

February 25, 2013 American Institute of Steel Construction

Access to the recording: Information for accessing the recording

will be emailed to you by Wednesday, February 13. The recording will be

available until February 24. For 8-session registrants only. EMAIL

COMES FROM NIGHTSCHOOL@AISC.ORG.

CEUs/PDHS If you watch a recorded session you must take

AND PASS the quiz for CEUs/PDHs.

8-Session Registrants

S-ar putea să vă placă și

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- STORAGE TANK SPECDocument10 paginiSTORAGE TANK SPECpapathsheilaÎncă nu există evaluări

- FS 2004D Rev.08Document26 paginiFS 2004D Rev.08Shakeel AhmedÎncă nu există evaluări

- Pipe Stress Analysis Training Complete CourseDocument24 paginiPipe Stress Analysis Training Complete CourseFábio GamaÎncă nu există evaluări

- Collar Bolts: in Shell and Tube Heat ExchangersDocument2 paginiCollar Bolts: in Shell and Tube Heat ExchangersMahdi HocineÎncă nu există evaluări

- Cameron Through Conduit Gate Valve Catalogue PDFDocument20 paginiCameron Through Conduit Gate Valve Catalogue PDFSmith780512Încă nu există evaluări

- Wartsila Vasa - 12v32 - Spare PartsDocument326 paginiWartsila Vasa - 12v32 - Spare PartsNezih Yanıkman100% (2)

- RWPL TG Capital Overhauling Scope of JobDocument8 paginiRWPL TG Capital Overhauling Scope of JobSreekanthMylavarapuÎncă nu există evaluări

- Diagram of Filling Drain Pipes ForDocument9 paginiDiagram of Filling Drain Pipes ForCornel CrlÎncă nu există evaluări

- Gauge MeasureDocument13 paginiGauge MeasuremonikitismonikitisÎncă nu există evaluări

- Cafco Blaze Shield Ii HP PDFDocument3 paginiCafco Blaze Shield Ii HP PDFcuestajmÎncă nu există evaluări

- DITinstallation Orig PDFDocument2 paginiDITinstallation Orig PDFcuestajmÎncă nu există evaluări

- Welder FaqDocument3 paginiWelder FaqcuestajmÎncă nu există evaluări

- 3D at Canopy PDFDocument1 pagină3D at Canopy PDFcuestajmÎncă nu există evaluări

- Compressed Air Drain Trap Condensate Drain TrapDocument2 paginiCompressed Air Drain Trap Condensate Drain TrapJozsef MagyariÎncă nu există evaluări

- KOSO Kent Introl GlobeAngle Cage Guided Control Valves 3Document18 paginiKOSO Kent Introl GlobeAngle Cage Guided Control Valves 3DEFRIZALÎncă nu există evaluări

- Fabricated Carbon Steel Piping SpecificationDocument12 paginiFabricated Carbon Steel Piping SpecificationFortunato SegubanÎncă nu există evaluări

- Kjlced09 Sec01 Pages129-145 Bellowstubing&WeldfittingsDocument17 paginiKjlced09 Sec01 Pages129-145 Bellowstubing&Weldfittingsabhishek198327Încă nu există evaluări

- MSS SP-70 Gray Iron Gate Valves Flanged and Threaded EndsDocument15 paginiMSS SP-70 Gray Iron Gate Valves Flanged and Threaded Endstitos eliteÎncă nu există evaluări

- HFY-PIP-SP-00012 X Specification For Expansion Joint - A-CommentedDocument9 paginiHFY-PIP-SP-00012 X Specification For Expansion Joint - A-CommentedVignesh PanchabakesanÎncă nu există evaluări

- PERSTA Lieferprogramm eDocument12 paginiPERSTA Lieferprogramm eJohnes MichealÎncă nu există evaluări

- ACT Flow Irons CatalogueDocument56 paginiACT Flow Irons CataloguePHILIPUAEÎncă nu există evaluări

- Wastewater Pump Station GuidelinesDocument86 paginiWastewater Pump Station Guidelinese cubeÎncă nu există evaluări

- ANSI/ISA-75.19.01-2013: Hydrostatic Testing of Control ValvesDocument9 paginiANSI/ISA-75.19.01-2013: Hydrostatic Testing of Control ValvesSherin K MonÎncă nu există evaluări

- Guia Cat Camisas 2 PDFDocument4 paginiGuia Cat Camisas 2 PDFcabarajasrÎncă nu există evaluări

- Materials: Pressure Parts and Applicable Service TemperaturesDocument14 paginiMaterials: Pressure Parts and Applicable Service Temperaturesmohan babuÎncă nu există evaluări

- Fivalco PDFDocument16 paginiFivalco PDFjhoger2012Încă nu există evaluări

- BAT - 2 Ton LPG Tank at ThikaDocument3 paginiBAT - 2 Ton LPG Tank at ThikamusewejamesoumaÎncă nu există evaluări

- Rociador Ty LDocument8 paginiRociador Ty LOscar Fernandez SanchezÎncă nu există evaluări

- Pump Care ManualDocument52 paginiPump Care ManualGreenbuild ZM-JVÎncă nu există evaluări

- 0976排气室疏水管道布置qme 00 g 141b 000 Ei 164 en a 0976 Msdm, Exh Plenum Drain Piping Arr(124t1635)0976Document6 pagini0976排气室疏水管道布置qme 00 g 141b 000 Ei 164 en a 0976 Msdm, Exh Plenum Drain Piping Arr(124t1635)0976ALAMGIR HOSSAINÎncă nu există evaluări

- Saipem - Serept - Piping ClassDocument67 paginiSaipem - Serept - Piping ClassAHMED AMIRAÎncă nu există evaluări

- User'S Manul: 3Gp Series Steam Boiler Feed PumpDocument25 paginiUser'S Manul: 3Gp Series Steam Boiler Feed PumpEdinsonUribeTorresÎncă nu există evaluări

- KJLC Ed09 Sec02 Web200910Document44 paginiKJLC Ed09 Sec02 Web200910NickMoloÎncă nu există evaluări

- Equivalent Standards - A - SA516-70, A - SA515-70, ST52-3, S355J2+N, SAILMA 350HI, SAILMA 450HIDocument10 paginiEquivalent Standards - A - SA516-70, A - SA515-70, ST52-3, S355J2+N, SAILMA 350HI, SAILMA 450HIPuneet BahriÎncă nu există evaluări