Documente Academic

Documente Profesional

Documente Cultură

Preventive Maintenance of Machines

Încărcat de

zaheermechDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Preventive Maintenance of Machines

Încărcat de

zaheermechDrepturi de autor:

Formate disponibile

ADC Standard Testing Systems Preventive Maintenance Guidelines

Page 1 of 6

BEFORE ATTEMPTING MAINTENANCE ON ANY ADC SYSTEM, REMOVE ALL ELECTRICAL POWER AND COMPRESSED AIR FROM THE SYSTEM.

In order to assure many years of trouble-free service from any ADC system, the following guidelines should be followed. Each of the suggestions below has been classified as to its recommended frequency. If any damage is discovered, or if any questions should arise, contact ADC or the representative for additional information.

A. Daily Inspection

1. Inspect the test chamber. Remove any debris or broken balls from the system. 2. Inspect the ball rails inside and outside of the chamber. Remove any debris, dirt or dust from the rails. 3. Check for any loosened bolts and screws, especially in the area of moving parts. 4. Inspect all airlines and wires to detect any pinching or chafing. Repair or relocate as necessary. 5. Add air power to the system and inspect all airlines and fitting for leaks. If any are detected, remove the air power from the system and make the necessary repair.

B. Weekly Inspection

1. Inspect and clean all sensors, especially any photo-eyes and particularly the ADC iBeam sensors. Any dust or dirt on the sensing surfaces could affect the operation and sensing capability of the visual sensors. 2. Refer to Figure 1. Check the water level in the moisture-collection filter and empty it if the level is above the safe operating point. 3. Again, refer to Figure 1. Inspect the dust-collection filter to assure that the filter is clean and not clogged with debris.

Dust Filter

Moisture-collection Filter

Figure 1

ADC Standard Testing Systems Preventive Maintenance Guidelines

C. Monthly Inspection

Page 2 of 6

1. ADC Ball Cannon, Style II (Available on all ADC Systems) Refer to Figure 2 Carefully inspect the cannon, outer & inner surfaces. Remove any debris and dirt from all cannon surfaces. Verify that all screws and bolts are tight. Verify that the Cannon Ball Retaining Rod is tight and in the proper position. Using a rag and a suitable rod, clean the firing tube inner surface. Apply a light oil lubricant to the tube inner surface. Apply a white silicon grease lubricant to the cannon breech slide.

Firing Tube Ball Retaining Pin

Breech Slide (Lube here)

ADC Cannon II

ADC Standard Testing Systems Preventive Maintenance Guidelines

Page 3 of 6

2. Club Clamping Mechanism (ADC ClubTesters ONLY) Refer to Figure 3 &4. Inspect the Club Clamping for any wear or misalignment of the clamping blocks. Clean the surfaces of the slide shafts of both the horizontal and vertical slides. Apply a white silicon lubricant and remove any excess lubricant from the mechanism.

Clamp Blocks

Slide Shafts

Figure 3

Figure 4

3. Ball Accumulation-Style Elevator (ADC ClubTesters ONLY) Refer to Figure 5 Carefully inspect the elevator assembly. Remove any debris or dirt from the assembly. Verify that all screws, bolts are tight. Check all air lines. Verify that the photo-eye is clean and tight. Apply white silicon lubricant to the air cylinder rods as shown below.

Photo Eye

Lubrication Points

Figure 5

ADC Standard Testing Systems Preventive Maintenance Guidelines

Page 4 of 6

4. Single-Ball Elevator (ADC Ball COR/Durability Systems). Carefully inspect the elevator assembly. Remove any debris, dust or dirt from the area. Verify that all screws and bolts are tight. Check all air lines. Verify that the BALL PRESENT photo-eye is clean and tight. Verify that the end-of-stroke proximity sensors are clean and in good working order. Clean the Rodless Elevator Pneumatic Cylinder and apply a white silicon lubricant to the outer surface of the cylinder tube as shown below.

Apply White Silicon Lube To Cylinder Body

Top Position Sensor

Bottom Position Sensor

Single Ball Elevator

Ball Present Photoeye

ADC Standard Testing Systems Preventive Maintenance Guidelines

Page 5 of 6

5. Inspect the Ball Size-Checker (Available on ALL ADC Systems). Clean all surfaces and remove any debris that may affect function. Carefully remove the yellow guard and apply white silicon lubrication to the bronze slides and the cylinder rod. Verify that the photo-eye is clean and unobstructed.

Photo-eye

Guard

Figure 7, Ball COR/Durability

Bronze Slides

Figure 8, Club Tester

ADC Standard Testing Systems Preventive Maintenance Guidelines

D. Semi-Annual Inspection

Page 6 of 6

1. (ADC ClubTesters ONLY) Refer to Figure 6. Inspect the club Stabilizer mechanism for wear. Assure that the device is properly adjusted for the best performance. 2. (Available on ALL ADC Systems) Inspect the Ball Catch Tarp and the Cannon Ball seal for wear. If these items are worn, contact ADC or their authorized representative for replacement parts.

Figure 2

S-ar putea să vă placă și

- Small Block Chevrolet: Stock and High-Performance RebuildsDe la EverandSmall Block Chevrolet: Stock and High-Performance RebuildsEvaluare: 4 din 5 stele4/5 (6)

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsDe la EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsEvaluare: 5 din 5 stele5/5 (5)

- SOP - Bob CatDocument37 paginiSOP - Bob CatvozefjadavÎncă nu există evaluări

- 4 Post Lift MaintenanceDocument4 pagini4 Post Lift MaintenanceBorislav VulicÎncă nu există evaluări

- PASS M0 - Maintenance Manual - 2GJA600065 (E)Document8 paginiPASS M0 - Maintenance Manual - 2GJA600065 (E)dwas1314Încă nu există evaluări

- Carburador Keihin CDKDocument2 paginiCarburador Keihin CDKRosana Espinola100% (1)

- Machine Maintenance.: General Workshop ProceduresDocument23 paginiMachine Maintenance.: General Workshop Proceduresvld7rpmÎncă nu există evaluări

- Maintenance Schedule For BOP - 5131086 - 01Document4 paginiMaintenance Schedule For BOP - 5131086 - 01franko guddiÎncă nu există evaluări

- API Inspection GuideDocument14 paginiAPI Inspection Guidesouilah100% (1)

- Optima 2003 2.4L Service-manual-DesbloqueadoDocument997 paginiOptima 2003 2.4L Service-manual-DesbloqueadoLuis Enrique PeñaÎncă nu există evaluări

- M250-B17 O+mmDocument14 paginiM250-B17 O+mmturboshaftÎncă nu există evaluări

- 2.5l 4 Cyl Vin HDocument17 pagini2.5l 4 Cyl Vin HFrank MartínezÎncă nu există evaluări

- Maintenance Working Hours Flow For Gas TurbineDocument7 paginiMaintenance Working Hours Flow For Gas TurbineHilmi HanoinÎncă nu există evaluări

- Seaquest Regulator ServiceDocument38 paginiSeaquest Regulator Serviceuranotek100% (1)

- Nissan GTR R32 Service ManualDocument804 paginiNissan GTR R32 Service ManualGorkandMork67% (6)

- Quality Audit - Check Sheet - Carriage WorkshopDocument24 paginiQuality Audit - Check Sheet - Carriage WorkshopEnd End100% (1)

- Wabco Air Suspension Compressor Piston Ring Seal RDocument3 paginiWabco Air Suspension Compressor Piston Ring Seal RgarcolÎncă nu există evaluări

- Chapter 2 Machine Maintenance.: General Workshop ProceduresDocument22 paginiChapter 2 Machine Maintenance.: General Workshop ProcedureswillifenlonÎncă nu există evaluări

- KiaOptima Seccion 001Document19 paginiKiaOptima Seccion 001Luis Enrique PeñaÎncă nu există evaluări

- Inspection Checklist For LYCODocument22 paginiInspection Checklist For LYCODavid DoughtyÎncă nu există evaluări

- Air Dryer - Maint - Manual - Rev - 1 PDFDocument34 paginiAir Dryer - Maint - Manual - Rev - 1 PDFCristiTancuÎncă nu există evaluări

- MJR For 30M Maintenance Check of Check ValvesDocument9 paginiMJR For 30M Maintenance Check of Check Valvesxtremewhiz100% (1)

- Inspection ChecklistDocument6 paginiInspection Checklistmechman5Încă nu există evaluări

- Screenshot 2023-05-23 at 12.45.15 AMDocument25 paginiScreenshot 2023-05-23 at 12.45.15 AMp.elpop56Încă nu există evaluări

- Click Wrench RepairDocument31 paginiClick Wrench RepairTu PhamÎncă nu există evaluări

- 250 - C28 Series Operation and Maintenance: Rolls - RoyceDocument6 pagini250 - C28 Series Operation and Maintenance: Rolls - RoyceturboshaftÎncă nu există evaluări

- Motorcycle Service Bulletin 2023 04 BS VI E Carb Cleaning SOPDocument7 paginiMotorcycle Service Bulletin 2023 04 BS VI E Carb Cleaning SOPAkshay KumkarÎncă nu există evaluări

- Subaru LegacyDocument118 paginiSubaru LegacyrajlackanÎncă nu există evaluări

- SB PDFDocument14 paginiSB PDFTony JenÎncă nu există evaluări

- Caterpillar DozersDocument20 paginiCaterpillar Dozerslulu3232100% (1)

- M3036 Block 5861Document21 paginiM3036 Block 5861Gregory StewartÎncă nu există evaluări

- 4fJ - L, - C: HalliburtonDocument4 pagini4fJ - L, - C: HalliburtonKhalfan Al HabsiÎncă nu există evaluări

- Beechcraft 1900 - CMM FuelDocument331 paginiBeechcraft 1900 - CMM FuelPear LibraryÎncă nu există evaluări

- How To Inspect Gear BoxDocument11 paginiHow To Inspect Gear BoxSubbarayan SaravanakumarÎncă nu există evaluări

- Chicksan Inspection ProcedureDocument9 paginiChicksan Inspection ProcedureBanu Stefan Adrian100% (7)

- Catalogue ACDelco Steering PDFDocument32 paginiCatalogue ACDelco Steering PDFSelvin GalindoÎncă nu există evaluări

- General Information: To IndexDocument9 paginiGeneral Information: To IndexRaymond FrostÎncă nu există evaluări

- P.M. Shale Shaker Six Months Instructions PDFDocument4 paginiP.M. Shale Shaker Six Months Instructions PDFHaridevÎncă nu există evaluări

- 2.5L 4-CYL - VIN (P) : 1993 Jeep CherokeeDocument19 pagini2.5L 4-CYL - VIN (P) : 1993 Jeep CherokeeAlberto DelcastillooÎncă nu există evaluări

- Manual Transmàssion 6 Speed PDFDocument55 paginiManual Transmàssion 6 Speed PDFIvan Alex Escobar100% (1)

- ZT 6000 VSDocument14 paginiZT 6000 VSdesign_artÎncă nu există evaluări

- General Information: To IndexDocument9 paginiGeneral Information: To IndexandriÎncă nu există evaluări

- The Visual Inspection Includes Removal of Inspection Cover Plates As Necessary To Do A Thorough JobDocument6 paginiThe Visual Inspection Includes Removal of Inspection Cover Plates As Necessary To Do A Thorough JobBenjamin HidalgoÎncă nu există evaluări

- Sebu7173-12 BDocument7 paginiSebu7173-12 BSantos Junnior Hipolito SandovalÎncă nu există evaluări

- ABS Jacking Survey Guide 2016 11Document9 paginiABS Jacking Survey Guide 2016 11Foad MirzaieÎncă nu există evaluări

- Optima 2001 2.5L Service-ManualDocument923 paginiOptima 2001 2.5L Service-Manualmuhammad nidzwanÎncă nu există evaluări

- Optima 2001 2.4L Service-ManualDocument917 paginiOptima 2001 2.4L Service-Manualmuhammad nidzwanÎncă nu există evaluări

- Weekly Monthly Press InspectionDocument5 paginiWeekly Monthly Press InspectionSathish PSKÎncă nu există evaluări

- 924F Pruebas y AjustesDocument26 pagini924F Pruebas y AjustesSan Gabriel Representaciones100% (1)

- w650 Service ManualDocument433 paginiw650 Service ManualEthan White100% (4)

- LHB Maintenance PraticesDocument28 paginiLHB Maintenance Praticesnaveenkumarvasili100% (1)

- Maintenances Schedules (LHB)Document11 paginiMaintenances Schedules (LHB)Parthaprotim Nath100% (3)

- PPD Lab 10Document12 paginiPPD Lab 10Ramil SalundagaÎncă nu există evaluări

- 7-1. Minimum Maintenance Activities For Engine Intake and Exhaust SystemsDocument10 pagini7-1. Minimum Maintenance Activities For Engine Intake and Exhaust SystemsegrabuanaÎncă nu există evaluări

- Amt 22013 Prelim HWDocument8 paginiAmt 22013 Prelim HWBoom RenegadesÎncă nu există evaluări

- C014 Assembly-Disassembly ManualDocument21 paginiC014 Assembly-Disassembly Manualwillyan100% (2)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisDe la EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisEvaluare: 4 din 5 stele4/5 (2)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideDe la EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideEvaluare: 4.5 din 5 stele4.5/5 (8)

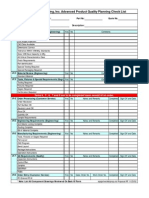

- Voisard Manufacturing, Inc. Advanced Product Quality Planning Check ListDocument1 paginăVoisard Manufacturing, Inc. Advanced Product Quality Planning Check ListzaheermechÎncă nu există evaluări

- Training Schedule PWIDocument1 paginăTraining Schedule PWIzaheermechÎncă nu există evaluări

- Modified RapidseqDocument8 paginiModified RapidseqzaheermechÎncă nu există evaluări

- Cswip 3.1 Welding Inspector - Multiple Choice Question, Dec 7, 2007Document43 paginiCswip 3.1 Welding Inspector - Multiple Choice Question, Dec 7, 2007claytoninf87% (30)

- Total Quality Management Must Know" Concepts For EngineersDocument28 paginiTotal Quality Management Must Know" Concepts For EngineerszaheermechÎncă nu există evaluări

- Functional Configuration Audit (FCA) Checklist: RequirementsDocument2 paginiFunctional Configuration Audit (FCA) Checklist: RequirementszaheermechÎncă nu există evaluări

- CSWIP Plate Tr5. WPK Rev2Document4 paginiCSWIP Plate Tr5. WPK Rev2razormeback100% (1)

- Pca Checklist: RestrictedDocument3 paginiPca Checklist: RestrictedzaheermechÎncă nu există evaluări

- Passive and Low Frequency RadarDocument11 paginiPassive and Low Frequency RadarzaheermechÎncă nu există evaluări

- Physical Configuration Audit (PCA) ChecklistDocument2 paginiPhysical Configuration Audit (PCA) ChecklistzaheermechÎncă nu există evaluări

- Guide To Insulation Product Specifications: ASTM Guides, Practices and Test MethodsDocument24 paginiGuide To Insulation Product Specifications: ASTM Guides, Practices and Test MethodszaheermechÎncă nu există evaluări

- FCA Checklist (NASA)Document2 paginiFCA Checklist (NASA)zaheermechÎncă nu există evaluări

- Gant ChartDocument2 paginiGant ChartzaheermechÎncă nu există evaluări

- ACCP Professional Level III Initial Qualification RequirementsDocument1 paginăACCP Professional Level III Initial Qualification RequirementszaheermechÎncă nu există evaluări

- ISO Standards Collection - CranesDocument4 paginiISO Standards Collection - CranesJosé Rezende0% (1)

- A Powerpoint Training Presentation: by Keith H. CooperDocument38 paginiA Powerpoint Training Presentation: by Keith H. CooperzaheermechÎncă nu există evaluări

- EXAMPLE CalculationsDocument4 paginiEXAMPLE CalculationszaheermechÎncă nu există evaluări

- Exercise 8 BeveragewareDocument9 paginiExercise 8 BeveragewareMae Cleofe G. SelisanaÎncă nu există evaluări

- Kenwood Report FinalDocument43 paginiKenwood Report Finaltooba siddiquiÎncă nu există evaluări

- RNP Rnav PDFDocument31 paginiRNP Rnav PDFhb2enbjxÎncă nu există evaluări

- D05 Directional Control Valves EngineeringDocument11 paginiD05 Directional Control Valves EngineeringVentas Control HidráulicoÎncă nu există evaluări

- Recipe: Patisserie Method: Eclair Cake RecipeDocument3 paginiRecipe: Patisserie Method: Eclair Cake RecipeEisha BibiÎncă nu există evaluări

- PaintballDocument44 paginiPaintballGmsnm Usp MpÎncă nu există evaluări

- 51 - Methemoglobin ProducersDocument20 pagini51 - Methemoglobin ProducersCabinet VeterinarÎncă nu există evaluări

- Macroscopic Physics Chemistry HW #1Document11 paginiMacroscopic Physics Chemistry HW #1Akash ModyÎncă nu există evaluări

- Preservation and Collection of Biological EvidenceDocument4 paginiPreservation and Collection of Biological EvidenceanastasiaÎncă nu există evaluări

- Capstone-ModDocument25 paginiCapstone-ModMohammad Ryyan PumbagulÎncă nu există evaluări

- The Superhero LifestyleDocument9 paginiThe Superhero LifestyleDerp Blood0% (3)

- Mobil Delvac 1 ESP 5W-40Document3 paginiMobil Delvac 1 ESP 5W-40RachitÎncă nu există evaluări

- TDS Shell Spirax s6 Gxme 75w-80Document2 paginiTDS Shell Spirax s6 Gxme 75w-80rstec pyÎncă nu există evaluări

- Biology 2 Chapter 4Document61 paginiBiology 2 Chapter 4Malas Nak TaipÎncă nu există evaluări

- Kern County Sues Governor Gavin NewsomDocument3 paginiKern County Sues Governor Gavin NewsomAnthony Wright100% (1)

- Latihan Soal Bahasa Inggris 2Document34 paginiLatihan Soal Bahasa Inggris 2Anita KusumastutiÎncă nu există evaluări

- Assistive TechnologyDocument3 paginiAssistive Technologyapi-547693573Încă nu există evaluări

- Cheap TBE Inverter TeardownsDocument33 paginiCheap TBE Inverter TeardownsWar Linux92% (12)

- Traditional vs. Enterprise Risk Management - How Do They DifferDocument4 paginiTraditional vs. Enterprise Risk Management - How Do They DifferJaveed A. KhanÎncă nu există evaluări

- Transmission Line Loading Sag CalculatioDocument25 paginiTransmission Line Loading Sag Calculatiooaktree2010Încă nu există evaluări

- Complete Renold CatalogueDocument92 paginiComplete Renold CatalogueblpÎncă nu există evaluări

- Harmonized Household Profiling ToolDocument2 paginiHarmonized Household Profiling ToolJessa Mae89% (9)

- Pengaruh Penambahan Lateks Pada Campuran Asphalt Concrete Binder Course (AC-BC)Document10 paginiPengaruh Penambahan Lateks Pada Campuran Asphalt Concrete Binder Course (AC-BC)Haris FirdausÎncă nu există evaluări

- CPhI Japan InformationDocument22 paginiCPhI Japan InformationctyvteÎncă nu există evaluări

- Capacity Requirement PlanningDocument17 paginiCapacity Requirement PlanningvamsibuÎncă nu există evaluări

- Refrigerator: Service ManualDocument119 paginiRefrigerator: Service ManualMihaela CaciumarciucÎncă nu există evaluări

- Soil Chapter 3Document67 paginiSoil Chapter 3Jethrone MichealaÎncă nu există evaluări

- Capacitor BanksDocument49 paginiCapacitor BanksAmal P RaviÎncă nu există evaluări

- Chan v. ChanDocument2 paginiChan v. ChanjdpajarilloÎncă nu există evaluări

- 5L ReductionsDocument20 pagini5L ReductionsCarlos Javier Orellana OrtizÎncă nu există evaluări