Documente Academic

Documente Profesional

Documente Cultură

Coca Cola

Încărcat de

DW97Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Coca Cola

Încărcat de

DW97Drepturi de autor:

Formate disponibile

Coca-Cola

Revealing its Recipe for Low Carbon Products

Carbon footprinting case study

In 2007, Coca-Cola began working in partnership with the Carbon Trust to calculate the carbon footprint of some of its most popular products in Great Britain. As part of this work, Coca-Cola Enterprises (CCE) piloted the Carbon Trusts product carbon footprinting methodology (PAS 2050). In March 2009, the carbon footprint of four brands (Coca-Cola, Diet Coke, Coke Zero and Oasis Summer Fruits) was published at www.cokecorporateresponsibility.co.uk Coca-Cola is now using the Carbon Trusts Footprint Expert tool to extend this work to a further 36 products in 2011. Coca-Cola has launched Trace Your Coke, a new online tool to help consumers understand the journey and carbon footprint of some of its most popular products.

Taking a lead

In 2007, Coca-Cola was among a group of nine leading companies to pilot the Carbon Trusts draft product carbon footprinting standard now BSI PAS 2050. This included work to calculate the carbon footprint of some of its most popular soft drinks in Great Britain. This work was undertaken in order to: Undertake a detailed analysis of the greenhouse gas emissions that are embodied in selected products. Help identify cost effective opportunities to reduce emissions generated across the full product lifecycle. Support and guide the development of the Carbon Trusts product carbon footprinting methodology so that it could become an internationally recognised and agreed standard. Coca-Cola calculated the carbon footprint of four brands (Coca-Cola, Diet Coke, Coke Zero and Oasis Summer Fruits) in a variety of packaging formats. This was the first time that the carbon footprint of any brand of sparkling drink had been certified by the Carbon Trust.

What we learnt

The work has had a considerable impact in helping Coca-Cola Enterprises to take action to make its business more sustainable. In particular, the work helped to identify the opportunities for greenhouse gas emissions to be reduced across the full product lifecycle including the manufacturing of packaging, distribution and chilling of products, as well as the consumer use and disposal of the package. The work highlighted that: Packaging is responsible for between 30 to 70 percent of a soft drinks carbon footprint. The carbon footprint of soft drinks can be reduced by using more recycled content in primary packaging and by reducing the weight of primary packaging. Recycling a bottle or can will reduce the carbon footprint of the individual product by up to 40% and make a major difference to the environmental footprint of the product.

CTS287

Designing out emissions

Coca-Cola used the work to inform its corporate responsibility and sustainability (CRS) strategy and decision making related to packaging design, new product development and recycling. Specifically, Coca-Cola has: Introduced a new glass bottle design which reduces carbon emissions by up to 2,200 tonnes per year in Great Britain. Worked in partnership with WRAP and Beverage Can Makers Europe (BCME) to set a new standard and launch a new design for 300ml aluminium cans which will save approximately 78,000 tonnes of CO2 each year. Ensured that carbon footprint measurement and reduction is now a part of its packaging design and new product development process. Launched a comprehensive programme of work to encourage consumers to recycle their products. This work has included: a consumer advertising campaign in Great Britain. a partnership with WRAP and RECOUP to establish 120 on-the-go Recycle Zones by the end of 2011. Recycle Zones are located in busy places like shopping centres, sports arena, airports and universities. Launched a joint venture with ECO Plastics to develop a new purpose-built recycling facility in Lincolnshire. This initiative will mark a step change in the GB plastic reprocessing industry

and will more than double the amount of high-quality rPET (PET that is recycled to make food-grade, sustainable packaging) currently produced in Great Britain. The state-of-the-art plastics reprocessing plant will supply CCE with enough GB-sourced, high-quality rPET to help CCE achieve its target of including 25% recycled PET in all its plastic packaging in Great Britain by 2012. Engaged employees at Coca-Cola Enterprises on the topic of carbon emissions by running a 4-week employee Carbon Challenge in partnership with The Carbon Trust. As part of the project, CCE employees tracked and aimed to reduce their own personal carbon emissions for a month. Participants were invited to share their carbon reduction experiences online with other CCE employees.

Looking ahead

The work that the Carbon Trust has undertaken with Coca-Cola in Great Britain is now being applied to a wider range of products and across European markets. The Carbon Trust has now licensed its Footprint Expert tool to Coca-Cola. During 2011 Coca-Cola will use the tool to repeat the carbon footprinting of the 14 products originally selected, as well as extending it to a further 36 products. The Chief Executive of the Carbon Trust, Tom Delay praised Coca-Colas efforts to measure and reduce their energy use. He said: CocaCola was one of the first companies to sign up for carbon footprinting with the Carbon Trust.

As part of its ongoing commitment to reducing its carbon impact, it has made an important contribution to our work to create the product carbon footprinting standard. Simon Baldry, Vice President General Manager of Coca-Cola Enterprises in Great Britain said: Sustainability is at the heart of everything we do and we are working hard to reduce the carbon footprint of both our business operations and our products, across the full

product lifecycle. Our ongoing partnership with the Carbon Trust has been instrumental in helping us to drive forward our carbon reduction agenda and inform our approach on sustainable packaging and recycling.

Find out more about the Carbon Trust Footprinting Certification Company http://www.carbontrustcertification.com

Coca-Cola

S-ar putea să vă placă și

- Improvement of Skills in the Green Economy through the Advanced Training Programs on Cradle to CradleDe la EverandImprovement of Skills in the Green Economy through the Advanced Training Programs on Cradle to CradleÎncă nu există evaluări

- Quality Enhancement in Voluntary Carbon Markets: Opening up for MainstreamDe la EverandQuality Enhancement in Voluntary Carbon Markets: Opening up for MainstreamÎncă nu există evaluări

- 121 Innovative: Supplier EngagementDocument6 pagini121 Innovative: Supplier EngagementIrfan YaqoobÎncă nu există evaluări

- Coca-Cola Most Common Littered Brand On UK Beaches, Says Study - Coca-Cola - The GuardianDocument3 paginiCoca-Cola Most Common Littered Brand On UK Beaches, Says Study - Coca-Cola - The GuardianLê Đức Anh NguyễnÎncă nu există evaluări

- Coca-Cola Sustainability Report 2013/14Document12 paginiCoca-Cola Sustainability Report 2013/14edienewsÎncă nu există evaluări

- Carbon Trust Certification OverviewDocument2 paginiCarbon Trust Certification OverviewMatt MaceÎncă nu există evaluări

- TESCO - The Customer Relationship Management ChampionDocument8 paginiTESCO - The Customer Relationship Management ChampionBulbul JainÎncă nu există evaluări

- Environmental AuditDocument4 paginiEnvironmental Auditbuson1100% (1)

- ExternalDocument12 paginiExternalVishnu VermaÎncă nu există evaluări

- C1Cocacola Goes GreenDocument2 paginiC1Cocacola Goes GreenAubrey JustineÎncă nu există evaluări

- Running Head: Coca-Cola'S Approach To Sustainability Measurement 1Document9 paginiRunning Head: Coca-Cola'S Approach To Sustainability Measurement 1DenizÎncă nu există evaluări

- Coca Cola Case StudyDocument2 paginiCoca Cola Case Studypuja bhatÎncă nu există evaluări

- Coca-Cola USA PESTLE Analysis (Presentation)Document8 paginiCoca-Cola USA PESTLE Analysis (Presentation)anabia19Încă nu există evaluări

- Global Citizens ProjectDocument13 paginiGlobal Citizens Projectapi-680435076Încă nu există evaluări

- Green 25 PartnersDocument7 paginiGreen 25 PartnersakenemidÎncă nu există evaluări

- 3rd SlideDocument4 pagini3rd SlideSofia Mae FaeldoniaÎncă nu există evaluări

- CocaCola EditedDocument5 paginiCocaCola Editedkipkiruimathew131Încă nu există evaluări

- Coca ColaDocument17 paginiCoca ColaJeff Lester PiodosÎncă nu există evaluări

- CR Summary 2011Document8 paginiCR Summary 2011Johan HexÎncă nu există evaluări

- Submitted by Zain Ul AbideenDocument13 paginiSubmitted by Zain Ul AbideenTariq RehmaniÎncă nu există evaluări

- Coca Cola: Sustainability Marketing ofDocument5 paginiCoca Cola: Sustainability Marketing ofneeraj100% (1)

- CocaColaMarketingPlan PDFDocument12 paginiCocaColaMarketingPlan PDFNguyên NhiÎncă nu există evaluări

- Coco Cola Case Study 2 BELDocument1 paginăCoco Cola Case Study 2 BELHimanshi SharmaÎncă nu există evaluări

- Carbon Footprint Student Tutor Course DateDocument10 paginiCarbon Footprint Student Tutor Course DateFrank JohnÎncă nu există evaluări

- Social Responsibility Report 2009Document58 paginiSocial Responsibility Report 2009Anup VermaÎncă nu există evaluări

- Bus 5910 Written Assignment Unit 6Document10 paginiBus 5910 Written Assignment Unit 6Sheu BasharuÎncă nu există evaluări

- Group1 - MNC Report - CocaColaDocument17 paginiGroup1 - MNC Report - CocaColanguyen kinÎncă nu există evaluări

- Marketing Assignment - Coca Cola (Coke Life)Document3 paginiMarketing Assignment - Coca Cola (Coke Life)Akanksha Nagar-RM 20RM903Încă nu există evaluări

- Carbon Footprint StudyDocument11 paginiCarbon Footprint StudyconstructCO2Încă nu există evaluări

- Ecos CoDocument4 paginiEcos CoMaria Jose Mojica TobarÎncă nu există evaluări

- Navigating The Carbon Maze: Understanding The Problem What Can I Do? How Do I Do That? Will I Make A Difference?Document38 paginiNavigating The Carbon Maze: Understanding The Problem What Can I Do? How Do I Do That? Will I Make A Difference?J RobsonÎncă nu există evaluări

- Sibusiso SCM Assignment 1Document15 paginiSibusiso SCM Assignment 1Sibusiso ZuluÎncă nu există evaluări

- Revenue ModelDocument15 paginiRevenue ModelSibusiso ZuluÎncă nu există evaluări

- Environmental ReportDocument28 paginiEnvironmental ReportMickey BrownÎncă nu există evaluări

- Early CSR Initiatives by Coca Cola PDFDocument2 paginiEarly CSR Initiatives by Coca Cola PDFchetan pawarÎncă nu există evaluări

- A Case Study and Analysis of Coca Cola Company: Module Code: MAN00024I Module Title: Strategy, Management and SocietyDocument7 paginiA Case Study and Analysis of Coca Cola Company: Module Code: MAN00024I Module Title: Strategy, Management and SocietywarishaÎncă nu există evaluări

- Coca ColaDocument11 paginiCoca ColaSamael MorningstarÎncă nu există evaluări

- Shailesh (Coke Life)Document16 paginiShailesh (Coke Life)Shailesh Kukreja100% (1)

- Diet CokeDocument19 paginiDiet CokeMc ThitiÎncă nu există evaluări

- Coca-Cola Operations and Inventory Management - 1192 Words - Report ExampleDocument4 paginiCoca-Cola Operations and Inventory Management - 1192 Words - Report ExampleMohammed KhodaryÎncă nu există evaluări

- Tp4 Gbermic FerreraDocument4 paginiTp4 Gbermic Ferreramark florence B BrunoÎncă nu există evaluări

- Predicting Package Performance: September 1999 NumberDocument6 paginiPredicting Package Performance: September 1999 NumberPatrick AdamsÎncă nu există evaluări

- PESTEL Analysis For CokeDocument3 paginiPESTEL Analysis For CokeAyesha SohailÎncă nu există evaluări

- Reducing Your Carbon Footprint: A Guide For SmesDocument8 paginiReducing Your Carbon Footprint: A Guide For SmesGauresh BagayatkarÎncă nu există evaluări

- Environment and GucciDocument2 paginiEnvironment and GucciJuliana Arias UranÎncă nu există evaluări

- Company and Product Sustainability Analysis - The Coca Cola CompanyDocument7 paginiCompany and Product Sustainability Analysis - The Coca Cola CompanyMuhammad TalhaÎncă nu există evaluări

- Brewing GreenDocument10 paginiBrewing GreenHang U LieÎncă nu există evaluări

- Carbon FootprintDocument24 paginiCarbon FootprintsriramÎncă nu există evaluări

- Submitted By: Group - 5 Submitted To-Prof. Abhay Kardeguddi Date of Submission - 27th January 2022Document26 paginiSubmitted By: Group - 5 Submitted To-Prof. Abhay Kardeguddi Date of Submission - 27th January 2022Vishal MarhattaÎncă nu există evaluări

- Coca ColaDocument2 paginiCoca ColaArooj FatimaÎncă nu există evaluări

- Submitted By: Nitin Katoch Sabhyata MarwahDocument18 paginiSubmitted By: Nitin Katoch Sabhyata Marwahn.tÎncă nu există evaluări

- 1 Coca-Cola SocialDocument20 pagini1 Coca-Cola SocialAnne D'souzaÎncă nu există evaluări

- Executive Summary EnglishteztDocument3 paginiExecutive Summary EnglishteztMaryam AbÎncă nu există evaluări

- CocaCola GroupPresentationDocument30 paginiCocaCola GroupPresentationSharanya RamasamyÎncă nu există evaluări

- CUEGISDocument7 paginiCUEGISshrikanthÎncă nu există evaluări

- Coca ColaDocument4 paginiCoca ColaDanica Toledo PagoboÎncă nu există evaluări

- Carlsberg Group Business Model Review ReDocument4 paginiCarlsberg Group Business Model Review Reakshita ramdasÎncă nu există evaluări

- Group 1 CocaCola BDGDocument6 paginiGroup 1 CocaCola BDGKristine JarinaÎncă nu există evaluări

- Case Study of Coca - Cola CompanyDocument4 paginiCase Study of Coca - Cola CompanyMelrose Lopez100% (1)

- APA Reeferencing StyleDocument10 paginiAPA Reeferencing StyleDW97Încă nu există evaluări

- Making Decisions in The Oil and Gas Industry - CoopersmithDocument8 paginiMaking Decisions in The Oil and Gas Industry - CoopersmithSuta Vijaya100% (1)

- Madoff CaseDocument19 paginiMadoff CaseDW97100% (1)

- NESTLE-FinancialReport2012 & SummaryReport2012Document121 paginiNESTLE-FinancialReport2012 & SummaryReport2012kogul92Încă nu există evaluări

- PM OverviewDocument25 paginiPM Overviewmohitamitabh20Încă nu există evaluări

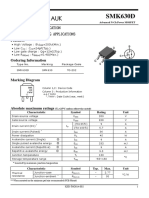

- SMK 630 DDocument8 paginiSMK 630 DMuhammad Chaidir FhadlyÎncă nu există evaluări

- 8.5 Final Review Key PDFDocument4 pagini8.5 Final Review Key PDFAlex VongÎncă nu există evaluări

- Tad 722 GeDocument2 paginiTad 722 GePaulo César Managó100% (1)

- Expt 8.7 Finding The Formula of Copper OxideDocument2 paginiExpt 8.7 Finding The Formula of Copper OxideIra Munirah0% (2)

- EPSRC Thermal Management Sheffield Drying Tech Feb 2010 PDFDocument50 paginiEPSRC Thermal Management Sheffield Drying Tech Feb 2010 PDFVampireSuicideÎncă nu există evaluări

- NR-210803-Material and Energy BalanceDocument8 paginiNR-210803-Material and Energy BalanceSrinivasa Rao G100% (1)

- Exoterm Dan EndotermDocument19 paginiExoterm Dan EndotermZakiyahÎncă nu există evaluări

- Sulfuric AlkylationDocument18 paginiSulfuric AlkylationRaghunath Venkatramanan100% (1)

- Approximation Methods: Physics 130B, UCSD Fall 2009Document90 paginiApproximation Methods: Physics 130B, UCSD Fall 2009Luz PeñaÎncă nu există evaluări

- TurbochargerDocument8 paginiTurbochargersudheeshÎncă nu există evaluări

- Generic Requirements Specification of Design For EnvironmentDocument6 paginiGeneric Requirements Specification of Design For EnvironmentAxel CornaloÎncă nu există evaluări

- CATERPILAR3516 1550-2200 BHPDocument6 paginiCATERPILAR3516 1550-2200 BHPNadia AnandaÎncă nu există evaluări

- Capability Statement WGIM Integrity Operating WindowsDocument3 paginiCapability Statement WGIM Integrity Operating WindowsRomainKabs100% (2)

- Tabla Cargas Grua F4C-892Document4 paginiTabla Cargas Grua F4C-892Juan Carlos Callas GarayÎncă nu există evaluări

- Aula Balancim DifusaoDocument29 paginiAula Balancim DifusaoGabrielAntoniazziÎncă nu există evaluări

- Dipen Baroda Follo-Up SheetDocument92 paginiDipen Baroda Follo-Up Sheetanon-272209100% (1)

- PIPEPHASE Application BriefsDocument219 paginiPIPEPHASE Application Briefsarmando0212-1Încă nu există evaluări

- Valves and Nozzles Rosco Maximizer IIDocument3 paginiValves and Nozzles Rosco Maximizer IIalfredo torresÎncă nu există evaluări

- How To Avoid Wastage of EnergyDocument1 paginăHow To Avoid Wastage of EnergyNazrawi IJobsÎncă nu există evaluări

- The Hazards of Pork ScratchingsDocument1 paginăThe Hazards of Pork ScratchingsSteve ForsterÎncă nu există evaluări

- Header SizeDocument1 paginăHeader SizeNaufal HadiÎncă nu există evaluări

- Electrical All Sizing CalculationDocument123 paginiElectrical All Sizing Calculationvijaydev7594% (18)

- York YFM Fan-Coil UnitsDocument16 paginiYork YFM Fan-Coil UnitsInviairÎncă nu există evaluări

- Cleaning of Pipes by Gas Discharge Back PuffingDocument1 paginăCleaning of Pipes by Gas Discharge Back PuffingVamsi MahantiÎncă nu există evaluări

- PHYSICS/FILIPINODocument2 paginiPHYSICS/FILIPINOMaLou Temblique EscartinÎncă nu există evaluări

- UTP - Fluid Mechanics Course - September 2012 Semester - Chap 3 Bernoulli EquationsDocument35 paginiUTP - Fluid Mechanics Course - September 2012 Semester - Chap 3 Bernoulli EquationswhateveroilÎncă nu există evaluări

- GT ManualDocument10 paginiGT Manualsoldatbr4183Încă nu există evaluări

- Merit-Order Effect of Wind Generation in The Philippines: Is Wind Integration Related To Lower Electricity Spot Market Clearing Price?Document1 paginăMerit-Order Effect of Wind Generation in The Philippines: Is Wind Integration Related To Lower Electricity Spot Market Clearing Price?Trei KremmeasÎncă nu există evaluări

- CMG StarsDocument2 paginiCMG StarsSedighi100% (1)