Documente Academic

Documente Profesional

Documente Cultură

Ekofisk II

Încărcat de

jiokoijikoDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Ekofisk II

Încărcat de

jiokoijikoDrepturi de autor:

Formate disponibile

Ekofisk II, Norway

Share on facebook Share on twitter Share on email Share on print More Sharing Services 15

The original Ekofisk area development consisted of eight oil and gas fields, namely Cod, Ekofisk, West Ekofisk, Tor, lb!sk"ell, Eldfisk, Edda and Embla# This comple$ also formed a transportation h!b for %alhall, &od, 'yda, (la, Statf"ord, &eimdal, Tommeliten and '!llfaks# The infrastr!ct!re consisted of )* permanent installations, ten of which were located in a central Ekofisk comple$# ppro$imately 5+,,,,,bpd oil was piped -5.km to the /hillips terminal in Teesside, while aro!nd ) billion c!bic feet per day of gas was piped ..,km to the Emden terminal# 0n 1ecember 122- /hillips 3orway s!bmitted a 3kr),bn e$pansion plan to bring oil and gas to market !ntil ),)4# This envisaged5

Taking the northern part of the comple$ o!t of prod!ction 6ef!rbishing platforms ) 7 .C, ) 7 .8, ) 7 .9T/ and ) 7 .W Constr!cting two new platforms at the Ekofisk comple$

0n March ),,2 Conoco/hillips was granted permission to !se the M:rsk 0nnovator for drilling eight in"ection wells on the Ekofisk ) 7 .% # The platform became operational in ),1,#

0n ;an!ary ),1, Seawell was awarded a contract to carry o!t maintenance services on Ekofisk ) 7 .< and ) 7 .= platforms# The five>year contract also covered maintenance services for the Eldfisk ) 7 * and ) 7 *?# Conoco/hillips also operates Ekofisk So!th pro"ect located on the /@ ,14 in the 3orwegian part of the 3orth Sea# The 3orwegian /arliament granted permission to develop and operate the pro"ect in ;!ne ),11# The pro"ect, aimed at improving oil recovery in the Ekofisk field, consists of -5 new prod!ction and eight water in"ection wells# Total commenced prod!ction from Ekofisk So!th in Actober ),1-#

Ekofisk 2 / 4XW platform

BThe infrastr!ct!re consisted of )* permanent installations, ten of which were located in a central Ekofisk comple$#B 0n ;!ne ),,2 the ?ig Arange =%000 vessel collided with the Ekofisk ) 7 .W water in"ection platform, damaging the bridge and well eC!ipment# Conoco/hillips !sed the Maersk 'allant "ack>!p and the large crane vessel Thials to carry o!t repairs on the platform# The Ekofisk ) 7 .W was anno!nced to be replaced by a new water in"ection platform in ),11# Conoco/hillips awarded a D1),m pro"ect management, engineering, constr!ction and delivery contract for the new platform in ;!ne ),,4 to 9MC Technologies# s!b> contract worth 3kr5,m for constr!ction of s!bsea eC!ipment for the platform was awarded by 9MC Technologies to 'renland 'ro!p# Technip was awarded the contract for installation and commissioning of s!bsea facilities connecting the new platform with the Ekofisk comple$#

Ekofisk 2/4 L platform

Conoco/hillips was granted permission for the installation of a new accommodation facility, Ekofisk @, in March ),1,# The new platform, which replaces Ekofisk )7. & and Ekofisk )7. 8, came into service in ),1-# Conoco/hillips contracted ibel in ;!ly ),1, to provide engineering, proc!rement, constr!ction and installation services for the platform# The company will also connect the platform to the Ekofisk comple$# Work was started in ),11 and completed by ),1-#

The contract for b!ilding the platform "acket and a bridge s!pport "acket was awarded to ker Sol!tions#

Ekofisk 2 / 4X

Ekofisk ) 7 . ; became the central platform in the Ekofisk area# 0t consists of an 11,.,,t, eight>leg steel "acket held in place by 1+ piles totalling 5,5,,t# The "acket s!pports a )-,5,,t topside s!b>str!ct!re with mod!le s!pport frame, process mod!le, separation EtransportF mod!le and !tility mod!le# BThe pro"ect, aimed at improving oil recovery in the Ekofisk field, consists of -5 new prod!ction and eight water in"ection wells#B @ike the ) 7 .=, it stands in a water depth of *+#1m, altho!gh it is rated for 2,#1m to obviate potential s!bsidence problems in the chalk reservoir# The platform has a processing capacity of )+,,,,,bpd oil Etotal e$port capacity of .),,,,,bpdF, )1#) million c!bic metres per day of gas and -1,4,, million barrels per day of water# When ) 7 . ; became f!lly operational, a n!mber of platforms started to be decommissioned# /rod!ction from third>party fields s!ch as %alhall, 'yda and (la were merged at ) 7 . ; and then piped to Emden and Teesside# Statpipe gas prod!ction flowed via a new line directly to booster platform ?>11 on the Emden pipeline# ?y ),,+ only two of the original Ekofisk Centre platforms were operational#

Pipelaying

E$isting pipelines connected to either ) 7 . 6, / or ' platforms were re>ro!ted and connected to the ) 7 . ; platform, reC!iring over +-km of new lines to be laid# total of )- tie>in spools are already in place on the seabed#

Ekofisk 2 / 4 J

The "acket and the !tility mod!le for Ekofisk ) 7 . ; were b!ilt by ker %erdal, while the mod!le s!pport frame and the process mod!le was b!ilt by mec /rocess and Energy# The separation mod!le was b!ilt by (moe &a!ges!nd# The generators came from 1resser 6and in 3orway and t!rbines were from by 3o!vo /igone#

Ekofisk 2 / 4X

The "acket for Ekofisk ) 7 .= was b!ilt by ker %erdal, the drilling mod!le by &itec 7 1reco and topsides by (moe &a!ges!nd#

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- HitchhikerDocument6 paginiHitchhikerjiokoijikoÎncă nu există evaluări

- Background: Ssignment Examine Core Project ConflictsDocument3 paginiBackground: Ssignment Examine Core Project ConflictsYarlagaddaSandeep100% (1)

- API Co2 ReportDocument63 paginiAPI Co2 Reportsimonlopez2012Încă nu există evaluări

- Jacket Loadout AnalysisDocument1 paginăJacket Loadout AnalysisjiokoijikoÎncă nu există evaluări

- Three Piles StructuresDocument1 paginăThree Piles StructuresjiokoijikoÎncă nu există evaluări

- Required Civil and Structural EngineerDocument1 paginăRequired Civil and Structural EngineerjiokoijikoÎncă nu există evaluări

- Deck & Jacket Load Out AnalysesDocument1 paginăDeck & Jacket Load Out Analysesjiokoijiko0% (1)

- Adult Stem Cell RegulationDocument3 paginiAdult Stem Cell RegulationjiokoijikoÎncă nu există evaluări

- Dockwise Sets 30,000 ToonesDocument2 paginiDockwise Sets 30,000 ToonesjiokoijikoÎncă nu există evaluări

- Fields of ActivityDocument1 paginăFields of ActivityjiokoijikoÎncă nu există evaluări

- Steel Catenary RisersDocument1 paginăSteel Catenary RisersjiokoijikoÎncă nu există evaluări

- Spar Platforms: Pori Yard in FinlandDocument1 paginăSpar Platforms: Pori Yard in FinlandjiokoijikoÎncă nu există evaluări

- Subsea Field Development: Key ReferencesDocument2 paginiSubsea Field Development: Key ReferencesjiokoijikoÎncă nu există evaluări

- NPCCDocument1 paginăNPCCjiokoijikoÎncă nu există evaluări

- Flexible Pipe Systems: France Brazil MalaysiaDocument2 paginiFlexible Pipe Systems: France Brazil MalaysiajiokoijikoÎncă nu există evaluări

- Fixed PlatformsDocument1 paginăFixed PlatformsjiokoijikoÎncă nu există evaluări

- EngineeringDocument2 paginiEngineeringjiokoijikoÎncă nu există evaluări

- Civil EngineeringDocument1 paginăCivil EngineeringjiokoijikoÎncă nu există evaluări

- How Does Heavy Lift WorkDocument3 paginiHow Does Heavy Lift WorkjiokoijikoÎncă nu există evaluări

- Process EngineeringDocument1 paginăProcess EngineeringjiokoijikoÎncă nu există evaluări

- Structural EngineeringDocument1 paginăStructural EngineeringjiokoijikoÎncă nu există evaluări

- Electrical EngineeringDocument1 paginăElectrical EngineeringjiokoijikoÎncă nu există evaluări

- Onshore/Onsite Services: Engineering Procurement FabricationDocument1 paginăOnshore/Onsite Services: Engineering Procurement FabricationjiokoijikoÎncă nu există evaluări

- Offshore ServicesDocument1 paginăOffshore ServicesjiokoijikoÎncă nu există evaluări

- Offshore ConstructionsDocument1 paginăOffshore ConstructionsjiokoijikoÎncă nu există evaluări

- Naval ArchitectureDocument1 paginăNaval ArchitecturejiokoijikoÎncă nu există evaluări

- Pressure VesselDocument1 paginăPressure VesseljiokoijikoÎncă nu există evaluări

- Offshore Installation EquipmentDocument2 paginiOffshore Installation EquipmentjiokoijikoÎncă nu există evaluări

- Platform Supply VesselDocument2 paginiPlatform Supply VesseljiokoijikoÎncă nu există evaluări

- Heavy Marine TransportDocument2 paginiHeavy Marine TransportjiokoijikoÎncă nu există evaluări

- Logistical Management: The Dockwise DifferenceDocument1 paginăLogistical Management: The Dockwise DifferencejiokoijikoÎncă nu există evaluări

- Transport & Installation: The Dockwise DifferenceDocument2 paginiTransport & Installation: The Dockwise DifferencejiokoijikoÎncă nu există evaluări

- FWC Utility System Optimisation FINALDocument12 paginiFWC Utility System Optimisation FINALrieza_fÎncă nu există evaluări

- En LNG Air Products Floating LNG Plant CapabilitiesDocument2 paginiEn LNG Air Products Floating LNG Plant CapabilitiesMshelia M.Încă nu există evaluări

- Annual Report 2019Document306 paginiAnnual Report 2019Faris Ahmad AdliÎncă nu există evaluări

- Biogas Directory - Vol04MDocument90 paginiBiogas Directory - Vol04MunicornmfkÎncă nu există evaluări

- Topside Module Design PDFDocument24 paginiTopside Module Design PDFKandousi YassineÎncă nu există evaluări

- Energy Scenario and Impact of Power Electronics IN 21 CenturyDocument13 paginiEnergy Scenario and Impact of Power Electronics IN 21 Centurysanju.babaÎncă nu există evaluări

- Istilah-Istilah Dalam Drilling Day ReportDocument4 paginiIstilah-Istilah Dalam Drilling Day ReportAdventhy RyaÎncă nu există evaluări

- Experimental and Kinetic Study On Anaerobic Digestion of Food Waste: The Effect of Total Solids and PHDocument14 paginiExperimental and Kinetic Study On Anaerobic Digestion of Food Waste: The Effect of Total Solids and PHFidel FernandesÎncă nu există evaluări

- Wind Energy PDFDocument32 paginiWind Energy PDFAditya SinghÎncă nu există evaluări

- 2017 Directory of China's Gasfields PDFDocument2 pagini2017 Directory of China's Gasfields PDFarapublicationÎncă nu există evaluări

- Lower Athabasca Regional Plan: Implementation Progress Report For 2020 and 2021Document24 paginiLower Athabasca Regional Plan: Implementation Progress Report For 2020 and 2021abdulloh aqilÎncă nu există evaluări

- E COdiNOx BrochureDocument4 paginiE COdiNOx BrochureNimÎncă nu există evaluări

- Key Performance Indicators: Oil & Gas Industry: BY A.GokulakrishnaDocument36 paginiKey Performance Indicators: Oil & Gas Industry: BY A.GokulakrishnaMOON KINGÎncă nu există evaluări

- Astm2015 0506Document4 paginiAstm2015 0506Iyan MulyanaÎncă nu există evaluări

- Sabine Pass Approval Order, DOEDocument50 paginiSabine Pass Approval Order, DOEcprofitaÎncă nu există evaluări

- Energy Efficiency Improvement in CO Removal System An Innovative ApproachDocument6 paginiEnergy Efficiency Improvement in CO Removal System An Innovative Approachvaratharajan g rÎncă nu există evaluări

- REnewable Sources of Energy AdvantagesDocument2 paginiREnewable Sources of Energy Advantagestkd069tkdÎncă nu există evaluări

- The Hydrogen Energy Transition (2004) Daniel SperlingDocument261 paginiThe Hydrogen Energy Transition (2004) Daniel SperlingmirzafarhathÎncă nu există evaluări

- HVJDocument9 paginiHVJUtsav Srikant MishraÎncă nu există evaluări

- Imo 2020Document8 paginiImo 2020Abhinav VermaÎncă nu există evaluări

- 9 CNG Cost Components PDFDocument9 pagini9 CNG Cost Components PDFReno SaibihÎncă nu există evaluări

- Case Study 4: Watercraft Capital S.A.: Refinancing Project Finance TransactionsDocument17 paginiCase Study 4: Watercraft Capital S.A.: Refinancing Project Finance Transactionsajay singhÎncă nu există evaluări

- System Use: Methanol Carbon andDocument8 paginiSystem Use: Methanol Carbon andakshukÎncă nu există evaluări

- Dutch FlowerDocument2 paginiDutch FlowerSantosh BhatÎncă nu există evaluări

- Gas HydratesDocument16 paginiGas HydratesMehmet KırgözoğluÎncă nu există evaluări

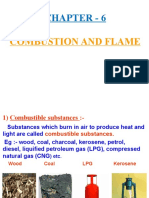

- 6 Combustion and FlameDocument17 pagini6 Combustion and Flamedian100% (1)

- NYC Energy Water Use 2013 ReportDocument64 paginiNYC Energy Water Use 2013 Reportcrainsnewyork100% (1)

- Renewable Energy Potential For Electricity Generation For National Consumption in Tunisia and Export To The EU (French Version)Document87 paginiRenewable Energy Potential For Electricity Generation For National Consumption in Tunisia and Export To The EU (French Version)MahmoudÎncă nu există evaluări