Documente Academic

Documente Profesional

Documente Cultură

Jis G 3141 e 2005

Încărcat de

wokeooo100%(3)100% au considerat acest document util (3 voturi)

818 vizualizări31 paginiJIS G 3141 :2005 (JISF) Japanese Industrial Standard based on ISO 3574 : 1999 Cold-reduced carbon steel sheet of commercial and drawing qualities. Some parts of this Standard may conflict with a patent right, application for a patent after opening to the public, utility model right or application for registration of utility model after opening to public which have the said technical properties.

Descriere originală:

Titlu original

jis.g.3141.e.2005

Drepturi de autor

© Attribution Non-Commercial (BY-NC)

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentJIS G 3141 :2005 (JISF) Japanese Industrial Standard based on ISO 3574 : 1999 Cold-reduced carbon steel sheet of commercial and drawing qualities. Some parts of this Standard may conflict with a patent right, application for a patent after opening to the public, utility model right or application for registration of utility model after opening to public which have the said technical properties.

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

100%(3)100% au considerat acest document util (3 voturi)

818 vizualizări31 paginiJis G 3141 e 2005

Încărcat de

wokeoooJIS G 3141 :2005 (JISF) Japanese Industrial Standard based on ISO 3574 : 1999 Cold-reduced carbon steel sheet of commercial and drawing qualities. Some parts of this Standard may conflict with a patent right, application for a patent after opening to the public, utility model right or application for registration of utility model after opening to public which have the said technical properties.

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 31

JIS G 3141 (2005) (English): Cold-reduced carbon

steel sheet and strip

JIS G 3141 :2005

(JISF)

JAPANESE

INDUSTRIAL

STANDARD

Translated and Published by

Japanese Standards Association

Cold-reduced carbon steel sheets and

strips

ICS 77.140.50

Reference number: JIS G 3141 : 2005 (E)

PROTECTED BY COPYRIGHT

155

G 3141 : 2005

Foreword

This translation has been made based on the original Japanese Indus-

trial Standard revised by the Minister of Economy, Trade and Industry

through deliberations at the Japanese Industrial Standards Committee

as the result of proposal for revision of Japanese Industrial Standard

submitted by the Japan Iron and Steel Federation (JISF) with the draft

being attached, based on the provision of Article 12 Clause 1 of the In-

dustrial Standardization Law applicable to the case of revision by the

provision of Article 14 ..

Consequently JIS G 3141 : 1996 is replaced with this Standard.

This revision has been made based on ISO 3574 : 1999 Cold-reduced car-

bon steel sheet of commercial and drawing qualities for the purpose of

making it easier to compare this Standard with International Standard;

to prepare Japanese Industrial Standard conforming with International

Standard; and to propose a draft of an International Standard which is

based on Japanese Industrial Standard.

Attention is drawn to the possibility that some parts of this Standard

may conflict with a patent right, application for a patent after opening

to the public, utility model right or application for registration of utility

model after opening to the public which have technical properties. The

relevant Minister and the Japanese Industrial Standards Committee

are not responsible for identifying the patent right, application for a

patent after opening to the public, utility model right or application for

registration of utility model after opening to the public which have the

said technical properties.

Editor's notice: New JIS Mark Scheme went into effect on October 1st, 2005 according to the revi-

sion of the Industrial Standardization Law. so old JIS mark indication is omitted

from this English version. Uptodate information including list of JIS subject to

New JIS Marking SYAt.,.y, ;" ,),1 tt,(, ,H,l,;,jte of JISe (http://www.jisc.go.jp).

Date of Establishment: 1969-02-01

Date of Revision: 2005-02-20

Date of Public Notice in Official Gazette: 2005-02-21

Investigated by: Japanese Industrial Cammittee

'0 JSA 2006

Standards Board

Technical Committee on Iron and Steel

JIS G 3141 : 2005, First English edition published in 2006-03

Translated and published by: Japanese Standards Association

4-1-24, Akasaka, Minato-ku, Tokyo, 107-8440 JAPAN

In the event of any doubts arising as to the contents,

the original JIS is to be the final authority.

All reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized

in any fmm or by any electronic or mechanical, including photocopying and microfilm, without

in the publisher.

Printed in Japan

PROTECTED BY COPYRIGHT

G 3141 : 2005

Contents

Page

Introduction ........................................................ 1

1 Scope ...................................................... 1

2 Norlnative references1

3 Grade and symbols ............................................................................... 1

4 Chemical composition ........................................................................... 2

5 Mechanical properties 3

5.1 Yield point or proof stress, tensile strength and elongation .......... .... .. .. 3

5.2 Average ratio of plastic strain .. .. .............. .. .. .. .. ...... ...... .. 4

5.3 Hardness ......................................................................................... 4

5.4 Bendability ..................................................................................... 6

6 Expression of size 6

7 Standard dilnensions ............................................................................ 6

8 Dimensional tolerances ......................................................................... 7

8.1 Position of measurement on dimensions .... ........ .... .................. ............ 7

8.2 Thickness tolerances .... .......... ...... .... .. ................ .. .. ........ 7

8.3 Width tolerances ............................................................................... 8

8.4 Length tolerances ........................................................ 9

9 Shape .................................................................... .. .. .. .. .... .. 9

9.1 Flatness ....................................................................................... 9

9.2 Camber ...................................................................... 10

9.3 Squareness ......................................................................... 11

10 Mass ....................................................... 11

10.1 Mass of steel sheet ............................................................................. 11

10.2 Mass of steel coil 12

11 Oiling' .............................................................................................. 12

12 Appearance ....................................................................................... 12

13 Test ............................................................................................... 13

13.1 Chemical analysis .............................................................................. 13

13.2 Mechanical test 13

14 Inspection 14

14.1 Inspection 14

14.2 Retests 14

15 Packaging and marking ...................................... 14

PROTECTED BY COPYRIGHT

G 3141 : 2005

16 Report 15

Annex 1 (informative) Additional information .......................................... 16

Annex 2 (informative) Comparison table between JIS and corresponding

International Standard .............................................. 19

PROTECTED BY COPYRIGHT

JAPANESE INDUSTRIAL STANDARD

Cold -reduced carbon steel

sheets and strips

JIS G 3141 : 2005

Introduction This Japanese Industrial Standard has been prepared based on the

third edition of ISO 3574 Cold-reduced carbon steel sheet of commercial and drawing

qualities published in 1999 with some modifications of the technical contents.

The portions given sidelines or dotted underlines are the matters modified from the

original International Standard. A list of modifications with the explanations is given

in Annex 2 (informative).

1 Scope This Standard specifies the cold-reduced carbon steel sheets, coils and

strips (hereafter referred to as "steel sheet and coil"), including the cold rolled strip

steel (steel coils less than 500 mm in width during cold rolling) and also the cut lengths

therefrom.

Remarks: The International Standard corresponding to this Standard is as fol

lows.

In addition, symbols which denote the degree of correspondence in

the contents between the relevant International Standard and JIS are

IDT (identical), MOD (modified), and NEQ (not equivalent) according

to ISOfIEC Guide 21.

ISO 3574 : 1999 Cold-reduced carbon steel sheet of commercial and

drawing qualities (MOD)

2 Normative references The standards listed in attached table 1 contain provisions

which, through reference in this text, constitute provisions of this Standard. The most

recent editions of the standards (including amendments) given in the table shall be ap-

plied.

3 Grade and symbols The steel sheet and coil shall be classified into five categories

and their symbols shall be as given in table 1. __

.. __

PROTECTED BY COPYRIGHT

2

G 3141: 2005

Table 1 Symbol of grade

Symbol of grade Remarks

SPCC Commercial quality

SPCD Drawing quality

SPCE Deep drawing quality

SPCF Deep drawing quality, non-ageing

SPCG Extra deep drawing quality, non-ageing

Remarks 1 When the SPCC steel sheet and coil of stan-

dard temper grade and these as-annealed are

guaranteed for their tensile strength and

elongation upon request by the purchaser, T

shall be suffixed to the symbol so that it reads

SPCCT.

2 Usually SPCG is manufactured by IF steel.

_t;?Q 111 ti_Qn _ a.!_ XI})X _ a.B_

Table 2 Temper grade

Temper grade Symbol of temper grade

A

S

118 Jmrd .8

114 Jwxd 4,

1I2_ha.xd

Z

J

Table 3 Surface finish

Surface finish Symbol of surface finish Remarks

Dull finish D A matt finish produced with a roll roughened

its surface mechanically or chemically

Bright finish B A smooth finish produced with a roll finished

its surface smoothlv

Remarks: This table is not applicable to the steel sheet and coil that are as-annealed.

4 Chemical composition The steel sheet and coil shall be tested in accordance with

13.1, and their cast analysis value shall be as given in table 4. The specification in ta-

ble 4 shall be applied to steel sheet and coil of as-anneal or standard temper only.

PROTECTED BY COPYRIGHT

Symbol of grade

SPCC

SPCD

SPCE

SPCF

SPCG (1)

Table 4 Chemical composition

C Mn P

0.15 max. 0.60 max.

0.12 max. 0.50 max. 0.040 max.

0.10 max. 0.45 max. 0.030 max.

0.08 max. 0.45 max. 0.030 max.

0.02 max. 0.25 max. 0.020 max.

3

G 3141: 2005

Unit: %

S

0.050 max.

0.040 max.

0.030 max.

0.030 max.

0.020 max.

Note (1) The upper limit value may be differ upon agreement between the

purchasC'l' and the supplier.

____

5 Mechanical properties

5.1 Yield point or proof stress, tensile strength and elongation The steel sheet and

coil of standard temper grade and those as-annealed shall be tested in accordance with

13.2, and their yield point or proof stress, tensile strength and elongation shall be as

given in table 5.

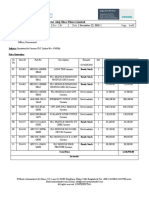

Table 5 Yield point or proof stress, tensile strength and elongation

Symbol Yield Tensile Elongation Tensile

of grade point or strength % test

proof N/mm

2

pIece

stress

N/mm

2

Division according to Division according to nominal thickness

nominal thickness mm

mm

0.25 or 0.25 or 0.25 or 0.30 or 0.40 or 0.6001' 1.0 or 1.6 or 2.5 or

over over ovel' to over to over to over to over to over to over

and and and and and and

excl. excl. excl. excl. 1.0 excl. 1.6 excl. 2.5

0.30 0.40 0.60

SPCC - - - - - - - - - No.5

SPCCT - 270 min. 28 min. 31 min. 34 min. 36 min. 37 min. 38 min. 39 min. test

(2) piece,

SPCD (240 max.) 270 min. 30 min. 33 min. 36 min. 38 min. 39 min. 40 min. 41 min.

rolling

SPCE (220 max.) 270 min. 32 min. 35 min. 38 min. 40 min. 41 min. 42 min. 43 min.

direc-

SPCF (210 max.) 270 min. - - 40 min. 42 min. 43 min. 44 min. 45 min.

tion (:1)

SPCG (190 max.) 270 min.

- -

42 min. 44 min. 45 min. 46 min. -

Notes (2) For SPCC that guarantees tensile strength and elongation.

(3) In the case that No.5 test piece can not be cut out, tensile strength and elongation shall

be agreed upon between the purchaser and the supplier.

Remarks 1 For those less than 0.60 mm in thickness, :-1. tensile test shall be omitted.

2 The eloncation specification in table 5 is not applied to steel sheet and coil of standard

temper grade that have been bright finished.

3 SPCF and SPCG shall be guaranteed for non-ageing property for six months after

shipment from the manufacturer's factory.

PROTECTED BY COPYRIGHT

4

G 3141: 2005

4 The upper limit of yield point or proof stl'ess in parenthesis is informative and can be

applied when agreed upon between the purchaser and the supplier.

5 1 Nlmm

2

= 1 MPa

5.2 Average ratio of plastic strain The steel sheet and coil of SPCG shall be tested in

accordance with 13.2. The average ratio of plastic strain r shall be as given in table 6.

Table 6 The average ratio of plastic strain r

Division according to nominal thickness mm

Symbol of grade

Under 0.50

0.50 or over up to Over 1.0 up to

Over 1.6

and incl. 1.0 and incl. 1.6

SPCG

-

1.4 min. 1.3 min.

-

5.3 Hardness The steel sheet and coil of grades 118 hard, 114 hard, 112 hard and full

hard (hereafter referred to as "hard material") shall be tested in accordance with 13.2

and their hardness shall be as given in table 7 or table 8. For those material so thin in

thickness that HRB hardnes.; <-ao 1)(" Imrdness may be measured by

HR30T, HR15T or HV, and may be converted to HRB by conversion table as given in

tables 9 to 11. Examples of HRB and minimum applied thickness are given in reference

table 2.

Hardness value which is not in the hardness conversion table shall be calculated by

in terpola tion.

Remarks: JIS Z 2245 specifies that "The thickness of the specimen shall be such

that the deformation of the test is not observed on the opposite side of

the specimen." and reference table 1 shows the equation to calculate

the minimum thickness of the specimen where spherical indenters are

to be used.

Reference table 1 Equation to calculate the minimum

thickness of the specimen

Indenter Rockwell hardness Rockwell superficial hardness

Spherical indenter 15 hoI' 0.03 (130- H) 15 h or 0.015 (100- H)

Where, h: Indentation's permanent deformation (mm)

H: Hardnc3s value

Table 7 Rockwell hardness of hard material (HRB)

Temper grade Temper symbol HRB

1/8 hard 8 50 to 71

1/4 hard 4 65 to 80

1/2 hard 2 74 to 89

Full hard 1 85 or over

PROTECTED BY COPYRIGHT

HR30T

35.0

36.0

37.0

38.0

39.0

40.0

41.0

42.0

43.0

44.0

45.0

46.0

Table 8 Vickers hardness of hard material

Temper grade Temper symbol HV

118 hard 8 95 to 130

114 hard 4 115 to 150

112 hard 2 135 to 185

Full hard 1 170 or over

Reference table 2 HRB and minimum applied thickness

HRB hardness 50 65 74 85

Minimum applied thickness

Table 9 Conversion table from HR30T to HRB

5

G 3141: 2005

Converted

HR30T

Converted

HR30T

Converted

HR30T

Converted

HRB HRB HRB HRB

28.1 47.0 46.0 59.0 63.9 71.0 81.9

29.6 48.0 47.5 60.0 65.4 72.0 83.4

31.1 49.0 49.0 61.0 66.9 73.0 84.9

32.5 50.0 50.5 62.0 68.4 74.0 86.4

34.0 51.0 52.0 63.0 69.9 75.0 87.9

35.5 52.0 53.5 64.0 71.4 76.0 89.4

37.0 53.0 55.0 65.0 72.9 77.0 90.8

38.5 54.0 56.5 66.0 74.4 78.0 92.3

40.0 55.0 58.0 67.0 75.9 79.0 93.8

41.5 56.0 59.5 68.0 77.4 80.0 95.3

43.0 57.0 60.9 69.0 78.9 81.0 96.8

44.5 58.0 62.4 70.0 80.4 82.0 98.3

Remarks Conversion table shown as table 9 is in accordance with table 2 of ASTM E140.

Hardness not in table of ASTM, is calculated by interpolation.

Table 10 Conversion table from HR15T to HRB

HR15T

Converted

HR15T

Converted

HR15T

Converted

HR15T

Converted

HRB HRB HRB HRB

70.0 28.8 76.0 47.3 82.0 65.8 88.0 84.3

70.5 30.3 76.5 48.8 82.5 67.3 88.5 85.8

71.0 31.9 77.0 50.4 83.0 68.8 89.0 87.3

71.5 33.4 77.5 51.9 83.5 70..1 89.5 88.9

72.0 35.0 78.0 53.4 84.0 71.9 90.0 90.4

72.5 36.5 78.5 55.0 84.5 73.5 90.5 92.0

73.0 38.0 79.0 56.5 85.0 75.0 91.0 93.5

73.5 39.6 79.5 58.1 85.5 76.6 91.5 95.0

74.0 41.1 80.0 59.6 86.0 78.1 92.0 96.6

74.5 42.7 80.5 61.1 86.5 79.6 92.5 98.1

75.0 14.2 81.0 62.7 87.0 81.2 93.0 99.7

75.5 45.7 81.5 64.2 87.5 82.7

Remarks Conversion table shown as table 10 is in accordance with table 2 of ASTM

E140. Hardness not in table of ASTM, is calculated by interpolation.

PROTECTED BY COPYRIGHT

6

G 3141: 2005

Table 11 Conversion table from HV to HRB

HV

Converted

HV

Converted

HV

Converted

HV

Converted

HRB HUB HRB HRB

85 41.0 115 65.0 145 76.6 175 86.1

90 48.0 120 66.7 150 78.7 180 87.1

95 52.0 125 69.5 155 79.9 185 88.8

100 56.2 130 71.2 160 81.7 190 89.5

105 59.4 135 73.2 165 83.1 195 90.7

110 62.3 140 75.0 170 85.0 200 91.5

Remarks Conversion table shown as table 11 is in accordance with table 1 of SAE J417.

Hardness not in table of SAE, is calculated by interpolation.

5.4 Bendability The steel sheet and coil of hard materials and those of spec shall

be tested in accordance with 13.2 and the bendability shall be as given in table 12. In

this case, the test piece shall withstand being bent without cracking on the outside

surface of the bent portion. However, the bend test may be omitted unless requested by

the purchaser.

Table 12 Bendability

Temper grade

Symbol of temper Bend test

grade Bend angle Inside radius Bend test piece

As-annealed A 180

0

Flat on itself No.3 test piece,

Standard tern-

S 180" Flat on itself

in the rolling

per grade

direction

118 hard 8 180" Flat on itself

114 hard 4 180

0

Thickness X 0.5

112 hard 2 180

0

Thickness X

1.0

Full hard 1

- -

6 Expression of size The size of the steel sheet and coil shall be expressed as fol-

lows:

a) The size of the steel sheet shall be expressed by thickness, width and length in mil-

limetre.

b) The size of the steel coil shall be expressed by thickness and width in millimetre.

7 Standard dimensions The standard thickness of the steel sheet and coil 500 mm

or over in width during cold rolling shall be as given in table 13.

0.4

1.6

Table 13 Standard dimensions

0.5

1.8

0.6

2.0

0.7

2.3

0.8 0.9 1.0

2.5 (2.6) 2.8

Unit: mm

1.2 1.4

(2.9) 3.2

Remarks: The standard thickness not in parentheses should pl'eferably

be used.

PROTECTED BY COPYRIGHT

7

G 3141: 2005

8 Dimensional tolerances

8.1 Position of measurement on dimensions The position of measurement on dimen-

sions shall be as follows :

a) For the steel sheet and regular portion of the steel coil, measurement on thickness

shall be made at any point not less than 15 mm apart from both side edges. In the

case where the width is less than 30 mm, however, the measurement shall be made

at a mid-width position.

b) Measurement on width shall be made at regular portion for the steel coil and at

any place for the steel sheet.

c) Measurement on length shall be made at any place for the steel sheet.

8.2 Thickness tolerances The thickness tolerances shall be as follows:

a) The thickness tolerances shall be applied to the nominal thickness.

b) The thickness tolerances shall be classified into Classes A and B as given in table

14 and table 15, respectively. The thickness tolerances of Class A shall generally be

applied. However, tolerances of Class B may be applied as agreed between the

purchaser and the supplier.

Table 14 Thickness tolerances, Class A

Unit: mm

Division according to nominal Division according to nominal width

thickness Under 630 630 or over 1000 or 1 250 or 1600 or

to and excl. over to and over to and over

1000 excl. 1250 excl. 1600

Under 0.25 0.03 0.03 0.03

- -

0.25 or over to and excl. 0.40 0.04 0.04 0.04 - -

0.40 or over to and excl. 0.60 0.05 0.05 0.05 0.06 -

0.60 or over to and excl. 0.80 0.06 0.06 0.06 0.06 0.07

0.80 or over to and excl. 1.00 0.06 0.06 0.07 0.08 0.09

1.00 or over to and excl. 1.25 0.07 0.07 0.08 0.09 0.11

1.25 or over to and excl. 1.60 0.08 0.09 0.10 0.11 0.13

1.60 or over to and excl. 2.00 0.10 0.11 0.12 0.13 0.15

2.00 or over to and excl. 2.50 0.12 0.13 0.14 0.15 0.17

2.50 or over to and excl. 3.15 0.14 0.15 0.16 0.17 0.20

3.15 or over 0.16 0.17 0.19 0.20

-

PROTECTED BY COPYRIGHT

8

G 3141 : 2005

Table 15 Thickness tolerances, Class B

Unit: mm

Division according to nominal Division accordill! to nominal width

thickness Under 160 160 or over to 250 or over to 400 or over to

and excL 250 and excL 400 and excL 630

Under 0.10 0.010 0.020

- -

0.10 or over to and excL 0.16 0.015 0.020

- -

0.16 or over to and excL 0.25 0.020 0.025 0.030 0.030

0.25 or over to and excL 0.40 0.025 0.030 0.035 0.035

0.40 or over to and excL 0.60 0.035 0.040 0.040 0.040

0.60 or over to and excL 0.80 0.040 0.045 0.045 0.045

0.80 or over to and excL 1.00 0.04 0.05 0.05 0.05

1.00 or over to and excL 1.25 0.05 0.05 0.05 0.06

1.25 or over to and excL 1.60 0.05 0.06 0.06 0.06

1.60 or over to and excL 2.00 0.06 0.07 0.08 0.08

2.00 or over to and excL 2.50 0.07 0.08 0.08 0.09

2.50 or over to and excL 3.15 0.08 0.09 0.09 0.10

3.15 or over 0.09 0.10 0.10 0.11

8.3 Width tolerances The width tolerances shall be as follows :

a) The width tolerances shall be applied to the nominal width.

b) The width tolerances shall be classified into Classes A, Band C as given in table 16,

table 17 and table 18, respectively. Table 16 is applied to those by ordinary cutting

method, table 17 is applied to those re-cut or precision cut and table 18 is applied

to those slit.

Table 16 Width tolerances, Class A

Unit: mm

Division to nominal width

Under 1 250 1250 or over

+7 + 10

0 0

Remarks: The plus side tolerances

shall not be applied to the

stretcher-levelled steel

sheet.

Table 17 Width tolerances, Class B

Unit: mm

Division to nominal width

Under 1 250 1250 or over

+3 +4

0 0

Table 18 Width tolerances, Class C

Unit: mm

Division according to nominal Division according to nominal width

thickness

Under 160 160 or over to 250 or over to 400 or over to

and excL 250 and excL 400 and excL 630

Under 0.60 0.15 0.20 0.25 0.30

0.60 or over to and excL 1.00 0.20 0.25 0.25 0.30

1.00 or over to and excL 1.60 0.20 0.30 0.30 0.40

1.60 or over to and excL 2.50 0.25 0.35 0.40 0.50

2.50 or over to and excL 4.00 0.30 0.40 0.45 0.50

4.00 or over to and excL 5.00 0.40 0.50 0.55 0.65

PROTECTED BY COPYRIGHT

8.4 Length tolerances The length tolerances shall be as follows :

9

G 3141: 2005

a) The length tolerances shall be applied to the nominal length of the steel sheet.

b) The tolerances on length shall be classified into Classes A and B as given in table

19 and table 20, respectively. Table 19 is applied to those by ordinary cutting

method and table 20 is applied to those re-cut or precision cut.

Table 19 Length tolerances, Class A Table 20 Length tolerances, Class B

Unit: mm

Division according

Tolerances

to nominal length

Under 2 000 +10

a

2 000 or over to and + 15

excl. 4 000 a

4 000 or over to and + 20

excl. 6 000 a

Remarks The plus sIde tolerances

shall not be applied to the

stretcher levelled steel

sheet.

9 Shape

Unit: mm

Division according

Tolerances

to nominal length

Under 1 000 +3

0

1 000 or over to and +4

excl. 2 000 a

2 000 or over to and +6

excl. 3 000 a

3 000 or over to and +8

excl. 4 000 0

9.1 Flatness The flatness tolerances shall be classified into Class A and Class B as

given in table 21 and table 22, respectively. Table 22 generally applies to stretcher-

levelled steel sheets. The flatness specified shall apply only to the steel sheet of stan-

dard temper grade which is 500 mm or over in width during cold rolling.

Remarks 1 Flatness shall be measured by laying a steel sheet under its own maSS

on a flat surface plate, and the value of flatness shall be determined as

the difference between the maximum deviation of convex from the flat

surface and the nominal thickness of the steel sheet when its convex

side is upper-most. The flat surface plate shall be of a sufficient length

to measure the flatness of steel sheets.

2 According to its shape and initiation zone, strain is categorized as fol-

lows.

Bow: A sheet in which condition with curvature. There are curvature

in rolling direction and curvature in at a right angle to rolling direc-

tion.

Wave: A sheet in which condition with rippling in rolling direction.

Edge wave: A sheet in which condition with wavy on the edge (edge of

the width direction) and flat in the middle.

Centre buckle: A sheet in which condition with wavy in the middle

and flat on the edge.

PROTECTED BY COPYRIGHT

10

G 3141: 2005

Table 21 Maximum deviation from flatness, Class A

Unit: mm

Division according to nominal Classification of shape-irregularity

width Bow, wave Edge wave Centre buckle

Under 1 000 12 8 6

1 000 or over to and excl. 1 250 15 9 8

1 250 or over to and excl. 1 600 15 11 8

1600 or over 20 13 9

Table 22 Maximum deviation from flatness, Class B

Unit: mm

Division according to nominal Classification of shape-irregularity

width Bow, wave Edge wave Centre buckle

Under 1000 2 2 2

1 000 or over to and excl. 1 250 3 2 2

1 250 or over to and excl. 1 600 4 3 2

1600 or over 5 4 2

9.2 Camber The camber for the steel sheet and coil shall be as given in figure 1. The

maximum of camber, classified into A and B, shall be as shown in table 23 and

table 24, respectively. Table 24 shall be applied as agreed between the purchaser and

the supplier.

The camber values specified shall not apply to the irregular parts of steel coils. The

measurement of the camber shall be conducted only when requested by the purchaser.

Steel sheets less than

2 000 mm in length

-,

(Any 2 000 mm length)

Steel sheets 2 000 mm

or greater in length

(Any 2 000 mm length)

Steel coils

Figure 1 Application of camber for steel sheets and coils

Table 23 Maximum value of camber, A

Unit: mm

Division according to nomi- Product form

nal width Steel sheets I Steel coils

Under 2 000 in length 2 000 or over in length I

30 or over up to and excl. 40 8 8 in any 2 000 length

40 or over up to and excl. 630 4 4 in any 2 000 length

630 or over 2 2 in any 2 000 length

PROTECTED BY COPYRIGHT

11

G 3141: 2005

Table 24 Maximum value of camber, B

Unit: mm

Division according to nomi- Product form

nal width

Steel sheets I Steel coils

Under 2 000 in length 2 000 or over in length I

30 or over up to and excL 40 25 25 in any 2 000 length

40 or over up to and excL 630 10 10 in any 2 000 length

630 or over 2 2 in any 2 000 length

9.3 Squareness Drop a perpendicular line from a corner and find a deviation (A)

from the opposite corner and the line as shown in figure 2, which ratio (AlB) with

width (B) is specified as out of square, that shall not be more than 1.0 %.

B(width)

_ ~ ~

'I,

- -- - -- -- - -- -- - -- -- - -- -- - -- -- ~ ....

\

V'igure 2 Squareness of steel sheet

10 Mass

10.1 Mass of steel sheet The mass of the steel sheet shall be as follows :

a) The mass of the steel sheet shall be expressed in kilogrammes. The theoretical

mass shall generally be applied for the steel sheet 500 mm or more in width during

cold rolling, and the actual mass shall be applied for the steel sheet under 500 mm

in width during cold rolling.

b) The method for calculation of mass of the steel sheet shall be in accordance with

table 25 using the nominal dimensions.

c) The standard mass of a single bundle of the steel sheets 500 mm or more in width

shall be 2 000 kg, 3 000 kg and 4 000 kg.

PROTECTED BY COPYRIGHT

12

G 3141: 2005

Table 25 Calculation procedure of theoretical mass

Sequence of calculation

Calculation method

Rounding off rule of calcu-

lated result

Basic mass kg/mm'm

2

7.85 (mass per millimetre thickness

-

per square metre area)

Unit mass kg/m2 Basic mass (kg/mm' m2) X thick- Rounded off to 4 significant

ness (mm) figures.

Area of steel sheet m

z

Width (m) X length (m) Rounded off to 4 significant

figures.

Mass of single sheet kg Unit mass (kg/m2) X area (m

2

) Rounded off to 3 significant

figures.

Mass of single bundle kg Mass of single sheet (kg) X number Rounded off to integer in kg.

of sheets per bundle of same size

Total mass kg Sum of mass of each bundle Integer in kg

Remarks 1 The total mass may be calculated by multiplying the mass of a single sheet

(kg) by the total number of sheets.

2 Rounding off of the numerical values shall be in accordance with rule A of JIS

Z 8401.

10.2 Mass of steel coil The mass of the steel coil shall be as follows:

a) The mass of the steel coil shall be the actual one expre!'<sed in kilogrammes.

b) For the mass of the steel coil, the maximum mass of each coil shall generally be

designated, and the specified maximum mass shall usually be not less than the fol-

lowing value;;;.

1) For the steel coils of 500 mm or more in width: 3 kg/mm of width

2) For the steel coils less than 500 mm in width: 1 kg/mm of width

11 Oiling The steel sheet and coil shall be oiled, unless otherwise specified.

12 Appearance The appearance shall be as follows:

a) The steel ~ h e e t and coil shall be free from such defects as holes, lamination and

other imperfections that are detrimental to practical use. Provisions on defects

other than holes and lamination, however, shall generally be applied to one side of

the surface (4) of the steel sheet and coil.

For the steel coil, however, some irregular portions and welds may be included

therein, since generally the steel coil is afforded no opportunity to inspect and to

remove such defective parts.

Note (4) The term "one side of the surface" means, as a rule, the top of each

package for the st.a6J .;heGt and the \Jl.itside surface for the steel coil.

b) For the steel sheet and coil of as-annealed grade, the coil break, edge wave, etc.

PROTECTED BY COPYRIGHT

13

G 3141: 2005

caused by omission of skin pass shall not be regarded as detrimental defects.

c) For the unoiled steel sheet and coil, the rust, scratch, caused by omission of

oiling shall not be regarded as detrimental defects.

13 Test

13.1 Chemical analysis

13.1.1 General requirements and sampling method for chemical analysis The

chemical composition of the steel sheet and coil shall be determined by cast analysis,

and the general requirements for chemical analysis and the sampling method of

specimen for analysis shall be as specified in clause 8 of JIS G 0404.

13.1.2 Test method The method for chemical analysis shall be in accordance with

JIS G 0320.

13.2 Mechanical test

13.2.1 General requirements for mechanical test The general requirements for me-

chanical testing shall be in accordance with the specifications in clause 9 of JIS G 0404.

With this respect, the sampling method of specimen shall conform to Class A of 7.6 in

JIS G 0404, and the number of test pieces and the sampling position shall be as fol-

lows:

a) Number of test pieces One test piece shall be taken from each steel coil defined in

cold rolling process (hereafter referred to as "coil").

In the case where the mass of the single coil is less than 3 t, one test piece shall

be taken from each lot of the same heat, rolled to the same thickness under the

same rolling conditions and the same heat treatment conditions.

b) Sampling position of test piece The centre of each test piece shall be at a quar-

ter-width. When it is infeasible, however, the sampling should be made as close to

the aforementioned position as possible. The tensile and bend test pieces shall be

taken parallel to the rolling direction.

13.2.2 Test piece and test method

a) Tensile test The tensile test shall be carried out as follows:

1) As to a test piece, .NQ .. shall be used. When this

is infeasible, the test piece shall be as agreed between the purchaser and the sup-

plier.

2) The test method shall be as specified in JIS Z 2241.

b) Plastic strain ratio determination The method of sampling and determination

shall be as specified in JIS Z 2254.

c) Hardness test The test shall be as specified in JIS Z 2244 or JIS Z 2245.

d) Bend test The bend test shall be carried out as follows:

PROTECTED BY COPYRIGHT

14

G 3141: 2005

1) As to a test piece, No.3 test piece specified in JIS Z 2204 shall be used.

2) The test method shall be as specified in JIS Z 2248.

14 Inspection

14.1 Inspection The inspection shall be carried out as follows:

a) General requirements for inspection shall be as specified in JIS G 0404.

b) The chemical composition shall conform to the requirements specified in clause 4.

c) The mechanical properties shall conform to the requirements specified in clause 5.

d) The dimensional tolerances shall conform to the requirements specified in clause 8.

e) The shape shall conform to the requirements specified in clause 9.

f) The mass shall conform to the requirements specified in clause 10.

g) The appearance shall conform to the requirements specified in clause 12.

14.2 Retests The <"lteel sheets and coils which have failed in the mechanical test may

be subjected to a retest as specified in 9.8 of JIS G 0404 for final acceptance.

15 Packaging and marking The steel sheet and coil which have passed the inspec-

tion shall, R-.f2 .. 0-.. . :-tntl dBOJJy marked with the following details by suit-

able means specified in clause 14 of JIS G 0404. According to the agreement between

the purchaser and the supplier, however, a part of the details given below may be

omitted.

a) Classification symbol

b) Symbol of temper grade

c) Symbol of surface finish

d) Manufacture number 01' inspection number

e) Dimensions

f) Number of sheets or mass (this may be omitted for the strip steel and cut lengths

therefrom which are cold-rolled under 500 mm in width)

g) Manufacturer's name or its identifying brand

Remarks: An example of marking on symbols of quality, temper grade and sur-

face finish

SPCCT-S D

I

e Surface fmish (Dull finisW

Temper grade (Standard temper grade)

L.. -------Classification <Commercial quality, mechanical

properties are guaranteed)

PROTECTED BY COPYRIGHT

15

G 3141: 2005

16 Report The report shall be in accordance with clause 13 of JIS G 0404. When

requested by the purchaser in advance, the manufacturer shall submit an inspection

document including the test results, the method of manufacture, ordered size and

quantity, and record of manufacture in accordance with JIS G 0415. __ t'y'p'?'j!Lin-_

__ __ __ __ .. _:? __ 9.r __ a,JJ? __ __ l_Qf_JJS __ Q

O_,Hel,

Attached Table 1 Normative references

JIS G 0320 Standard test methods for heat analysis of steel products

JIS G 0404 Steel and steel products-General technical delivery requirements

JIS G 0415 Steel and steel products-Inspection documents

JIS Z 2201 Test pieces for tensile test for metallic materials

JIS Z 2204 Bend test pieces for metallic materials

JIS Z 2241 Method oftensl1e test for metallic materials

JIS Z 2244 Vickers hardness test-Test method

JIS Z 2245 Rockwell hardness test-Test method

JIS Z 2248 Method of bend test for metallic materials

JIS Z 2254 Method of determining the plastic strain ratio for metallic sheet and strip

JIS Z 8401 Guide to the rounding ofnumbers

PROTECTED BY COPYRIGHT

16

G 3141: 2005

Annex 1 (informative) Additional information

This Annex describes the reference values for the agreement between the supplier

and the purchaser concerning the hardness of the standard temper grade and

as-annealed grade, tensile strength and elongation of hard materials, as well as the

matters to be attended at the time of contract, and is not to constitute the provisions of

this Standard.

1 Hardness of the standard temper grade and as-annealed grade Hardness of the

standard temper gl'&d0 lind ao-linnea16d grade shall be in accordance with either An-

nex 1 table 1 or Annex 1 table 2. However, the hardness values of HR30T , HR15T and

HV may be converted to HRB hardness values according to the conversion tables 9 to

11 of the text. Test method shall be in accordance with 13.2 of the text.

Remarks 1 JIS Z 2245 specifies that "The thickness of the specimen shall be such

that the deformation of the test is not observed on the opposite side of

the specimen." Since the influence of the test can be detected on the

back side of the test piece for the standard temper grade and

as-annealed grade easier than for the hard materials, sufficient atten-

tion is required in selecting the scales for Rockwell hardness.

2 HRB should not be used because the deformation of the test can easily

be observed on the back side of the specimen.

Annex 1 table 1 Rockwell hardness of the standard temper

grade and as-annealed grade

Temper grade Symbol of Hardness

temper grade HRB HR30T

As-annealed A 57 max. 54 max.

Standard temper grade S 65 max. 60 max.

Annex 1 table 2 Vickers hardness of the standard temper

grade and as-annealed grade

Tempel" grade Symbol of temper grade HV

As-annealed A 105 max.

Standard temper grade S 115 max.

PROTECTED BY COPYRIGHT

HR15T

79 max.

82 max.

17

G 3141: 2005

2 Tensile strength and elongation of hard materials Tensile strength and elongation

of hard materials shall be in accordance with Annex 1 table 3. Test method shall be in

accordance with 13.2 of the text.

Annex 1 table 3 Tensile strength and elongation of hard materials

Temper grade Symbol of temper gTade Tensile strength Elongation Tensile test piece

1/8 hard 8 290 to 410 25 min. No.5 test piece,

1/4 hard 4 370 to 490 10 min. rolling direction

1/2 hard 2 440 to 590

-

Full hard 1 550 min.

-

Remarks Annex 1 table 3 applies to steel sheets and strips 0.25 mm or greater in thick-

ness and 30 mm or greater in width.

3 Matters to be attended at the time of contract It is recommended that the pur-

chaser specifies the following items at the times of contract.

a) General matters to be specified at the time of ordering

1) Product form: coil or cut lengths (1)

2) Classification symbol

3) Symbol of temper grade

4) Symbol of surface finish

5) Dimensions

6) Quantity

7) Mass of bundled steel sheets (if required)

8) Allowable range on total quantity of shipment in comparison with ordered quan-

tity

9) Date and method of delivery and destination

10) Maximum mass of single coil

11) Inside diameter of coil (if required)

12) Designation of unoiling (if required)

13) Use

Note (1) For the steel in coil form and cut lengths therefrom which have been

cold rolled under 500 mm in width, they shall be designated as the "cold

rolled strip steel" at the time of ordering.

b) Temper rolling and surface finish The steel sheet and coil are supplied in the fol-

lowing conditions, unless otherwise specified.

1) The coil cold rolled 500 mm or more in width and cut lengths:

PROTECTED BY COPYRIGHT

18

G 3141: 2005

Standard temper grade and dull finish

2) The strip cold rolled under 500 mm in width and cut lengths:

Standard temper grade and bright finish

c) Dimensional tolerance and flatness Unless otherwise specified, the dimensional

tolerancl-)':; .1[(.1 Oato(-:",:; below are applied. In oth'H f-pocific

Class(es) shall be designated.

1) The coil cold rolled 500 mm or more in width and cut lengths:

Thickness tolerance, Class A, width tolerance, Class A, length tolerance, Class A,

and flatness, Class A

2) The strip cold rolled under 500 mm in width and cut lengths:

Thickness tolerance, Class B, width tolerance, Class B, and length tolerance,

Class B

d) Others Where denotation of the date of skin pass for the standard temper grade is

necessary, this matter shall be specifically designated.

PROTECTED BY COPYRIGHT

'1:1

?:J

o

>-'3

t'J

o

>-'3

t'J

tJ

t:d

o

o

'1:1

?:J

>-'3

Annex 2 (informative)

Comparison table between JIS and corresponding International Standard

JIS G 3141 : 2005 Cold-reduced carbon steel sheets and strips ISO 3574 : 1999 Cold-reduced carbon steel sheet of commercial and dra w-

ing qllalities

( I ) Requirements in JIS (n) Inter- (III) Requirements in (IV) Classification and details of techni- (V) Justification for the tech-

national International Standard cal deviation between JIS and t he In- nical deviation and future

Standard ternational Standard by clause measures

number

Clause Content Clause Content Classification Detail of technical

by clause deviation

1 Scope Cold-reduced carbon 1 Cold-reduced car- IDT

steel sheets and strips bon steel sheets

for commercial and and strips for

drawing use commercial and

drawing use

2 Norma- JIS Z 2241 2 ISO 6892 IDT In JIS, JIS necessary In JIS, JIS for analytical tests

tive refer- JIS shown in attached

-

MOD/addition for analytical tests is necessary and since hardness

ences table (excluding JIS Z and JIS for hardness tests and bend tests are speci-

2241) tests and for bend fied, JIS concerning them are

tests are added. required as the normative ref-

erences.

3 Grade Five types of classifica- 1 Five types of MOD/addition In JIS, temper grade In JIB. temper grade and sur

and sym- tions, temper grades and qualities are and surface finish are face finish are added because

boIs surface finishes are speci- specified. added. wider range of cold-reduced

fied. carbon steel sheets are speci-

fied in JIS than in ISO.

4 Chemical Chemical compositions of 5.2 Chemical compo- MOD/alteration Composition of P in SPCC requires higher compo-

composition four elements C, Mn, P, S sitions of five ele- SPCC is higher than sition of P than in ISO because

are specified for each five ments C, Mn, P, S, in ISO. it is often applied to hard ma-

classifications. Ti are specified for Ti is not specified for terials not specified in ISO.

each five classifi- SPCG, while speci- It is specified in JIS that al-

cations. fied in ISO. loying elements such as Ti or

other elements can be added as

necessary for SPCG.

o

Ci:!

f-'

....

f-'

o

Of-'

Ql<:.O

f-d

~

o

>-3

~

()

>-3

~

t:I

td

...,q

()

o

f-d

...,q

~

~

Q

~

>-3

( T ) Requil'ements in JIS

Clause Content

5Me" Yield point or proof

chanical stress, tensile strength,

properties elongation, average ratio

of plastic strain, hm'dness

and bendability are speci"

fied.

6 Expres" Expression of size is

sion of size specified.

7 Stan" Standard thickness is

dard di" specified.

mensions

(Tf) Inter- (m) Requirements in

national International Standard

Standard

number

Claug!', Content

5,6 Yield point or

proof stress, ten"

sile strength,

elongation, aver"

a ~ c ratio of plastic

strain, and tensile

strain hardening

exponent are

specified.

15 Dimensions to be

supplied by the

purchaser are

specified.

-

(TV) Classification and details of techni"

cal deviation between JIS and the In"

ternational Standard by clause

Classification Detail of technical

by clause deviation

MOD/addition In ISO, hardness and

bendability were de"

leted at the levision.

MOD/alteration JIS and ISO differ in

tensile strength and

elongation. ISO

specifies tensile

strength by the UP"

pel' limit, contrary to

the lower limit in

JIS.

MOD/deletion In JIS, tensile strain

hardening exponent

was deleted.

IDT

MOD/addition In JIS, the thickness

used normally is

specified as the

standard thickne,>,>.

(V) Justification for the tech"

nical deviation and future

measures

Although bendability was de"

leted in ISO, JIS specified that

it shall be applied when reo

quested.

Provisions of hardness is nec"

essary for hard materials of

JIS.

JIS and ISO differ in the shape

of the test piece and the tensile

direction. Further, the lower

limit of the tensile strength in

JIS is the same as the refer-

ence value in ISO.

Tensile strain hardening ex"

ponent is used rarely for

cold "reduced carbon steel

sheet.

JIS products are for general

use and the standard thick"

ness IS necessary.

~

eN

r--'

fI:o-

r--'

I:-:i

o

o

01

"0

?:J

o

fo-,3

[rj

o

fo-,3

[rj

t;I

td

K'1

o

o

"0

K'1

?:J

@

fo-,3

( I ) Requil'ements in JIS

Clause Content

8 Dimen' Tolerances for thickness,

sional tol' width and length are

erances specified.

9 Shape Flatness and camber are

specified.

10 Mas8 Mass is specified.

11 Oiling Oiling is specified.

12Ap' Appearance is specified.

pearance

13 Test Analytical test, tensile

test, hardness test, bend

test and plastic strain

ratio determination are

specified.

(II) Intel'- (III) Requirements in

national International Standard

Standard

numbel'

Clause Content

6 Tolerances for

thickness, width,

length, flatness,

squareness and

camber are speci'

fied.

6 Tolerances for

thickness, width,

length, flatness,

squareness and

camber are speci'

fied.

-

4.6 Oiling is specified.

4.4 Appearance is

11 specified.

5.3 Analytical test

7 and tensile test

8 are specified.

(IV) Classification and details oftechni'

cal deviation between JIS and the In'

ternational Standard by clause

Classification Detail of technical

by clause deviation

MOD/alteration Tolerances in JIS are

stricter than in ISO.

MOD/alteration Tolerances in JIS are

stricter than in ISO.

MOD/addition In JIS. theo: . .'ctical

mass and actual

mass are specified.

IDT

IDT

MOD/addition In JIS, hardness

test, bend test and

plastic strain ratio

determination are

added.

(V) Justification for the tech'

nical deviation and future

measures

Proposal of tolel'ances of JIS

will be submitted to ISO.

Proposal of tolerances of JIS

will be submitted to ISO.

Two types of mass are required

by commercial custom and

thp.y are specified in JIS.

In ISO, bendability and hard'

ness were deleted at the revi'

sion, and there is no provision

for plastic strain ratio delH"

mination. In JIS, provisions

for hardness test, bend test

and plastic strain ratio deter-

mination are added.

o

Ci:!

f-'

....

f-'

~

o

~

Qlf-'

f-d

~

o

>-3

~

()

>-3

~

t:I

td

...,q

()

o

f-d

...,q

~

~

Q

~

>-3

( T ) Requirements in JIS

Clause Content

14,1 In- Inspection is specified.

spection

14,2 Re- Reinspection and the

tests judgment are specified.

15 Pack- Packaging and s",ven

aging and items to be marked are

marking specified.

16 Report Report is submitted

when requested by the

purchaser.

Annex 1 Hardness of the standard

temper grade and

as-annealed grade, ten-

sile strength of hard

materials, as well as the

matters to be attended at

the time of contract are

described for reference.

(Tf) Inter

national

Standard

number

(m) Requirements in

International Standard

Claus!', Content

-

No clause in ISO.

9 Reinspection is

specified.

10 Judgment ofthe

reinspection is

specified.

14 Seven items to be

marked are speci-

fied.

15 Report is submit-

ted on the items

requested by the

purchasl'T.

13 It is required to

specify the inside

diameter, the

maximum outside

diameter of the

coil and the

maXlmum mass.

15 Matters to be

supplied by the

purchaser are

specified.

(TV) Classification and details of techni-

cal deviation between JIS and the In-

ternational Standard by clause

Classification Detail of technical

by clause deviation

MOD/addition JIS specifies inspec-

tion in one integrated

clause, while ISO

specifies it in each

clause.

IDT

IDT

MOD/addition In JIS, packaging is

added.

IDT

MOD/addition In JIS, hardness of

the standard temper

grade and

as-annealed grade

and tensile strength

of hard materials al'e

added.

(V) Justification for the tech-

nical deviation and future

measures

This is the unique configura-

tion of JIS and is kept as it is.

Since packaging is required by

commercial custom, it is speci-

fied in JIS.

Since the hardness of the

standard temper grade and

as-annealed grade and the

tensile strength of hard rna te-

rials can be used by commer-

cial custom, they are added in

JIS.

~

~

eN

r--'

fI:o-

r--'

~

o

o

01

co

o

>-3

M

(1

>-3

M

t;I

to

K1

(1

o

co

K1

Q

>-3

( [ ) Requirements in JIS (II) Inter- (III) Requirements in (IV) Classification and details of techni- (V) Justification for the tech-

national International Standard cal deviation between JIS and the In- nical deviation and future

Standard ternational Standard by clause measures

number

Clause Content Clause Content Classification 1 )etail of technical

by clause deviation

3 Terms and defini- MOD/deletion In JIS, terms and Since terms are defined in JIS

tions are speci- definitions are de- G 0203, it is kept as it is.

fied. leted.

12 Acceptance in- MOD/deletion In JIS, acceptance Since JIS products are foy

spection prior to inspection is deleted. general use and acceptance

shipment is speci- inspection prior to shipment is

fied. not carried out normally, it is

deleted_

Designated degree of correspondence between JIS and International Standard: MOD

Remarks 1 Symbols in sub-columns of classification by clause in the above table indicate as follows:

IDT: Identical in technical contents_

MOD/deletion: Deletes the specification itemf\(s) or content(s) in International Standard_

MODI addition: Adds the specification item(s) or content(s) which are not included in International Standard_

MODI alteration: Alters the specification content(s) which are included in International Standard_

2 Symbol in column of designated degree of correspondence between JIS and International Standard in the above table

indicates as follows:

- MOD: Modifies International Standard.

Q

CJJ

""""'

""""'

t-o

0

ot-o

01 CJJ

Errata for JIS (English edition) are printed in S.' . liIi",J::.:;tjon Journal, published monthly by

the ,Japanese Stand31'ds Association, and also provided to subscribers of JIS (English edition)

in JI;[onthly Inforll1:iliun.

Errata will be provided upon request, please contact:

Standardization Promotion Department, Japanese Standards Association

4-1-24, Akasaka, Minato-ku, Tokyo, 107-8440 JAPAN

TEL. 03-3583-8002 FAX. 03-3583-0462

PROTECTED BY COYYRIGHT

S-ar putea să vă placă și

- Jis G 3131-2010Document16 paginiJis G 3131-2010christian210789Încă nu există evaluări

- Jis G 3141 2011Document30 paginiJis G 3141 2011Balamurugan P50% (2)

- JIS G 3302:: Hot-Dip Zinc-Coated Steel Sheet and StripDocument47 paginiJIS G 3302:: Hot-Dip Zinc-Coated Steel Sheet and StripAhmad KhreisatÎncă nu există evaluări

- Jis G 3507-2 - 2005Document14 paginiJis G 3507-2 - 2005Harold_katzerÎncă nu există evaluări

- Jis.g.3507.2.e.2005 Carbon Steel For Cold Heading Part 2 WiresDocument11 paginiJis.g.3507.2.e.2005 Carbon Steel For Cold Heading Part 2 WiresAnonymous gQyrTUHX38Încă nu există evaluări

- Jis B 1054-1 2001Document26 paginiJis B 1054-1 2001mattroidenÎncă nu există evaluări

- Astm B209 B209M (2001)Document26 paginiAstm B209 B209M (2001)Asif ChougleÎncă nu există evaluări

- Iso 15330 en PDFDocument6 paginiIso 15330 en PDFScube engineersÎncă nu există evaluări

- Aisi 1018Document1 paginăAisi 10188085roÎncă nu există evaluări

- Standard GB - T1804-m & ISO 2768-1 - 2 - Advanced CeramicsDocument5 paginiStandard GB - T1804-m & ISO 2768-1 - 2 - Advanced CeramicsMohd DanishÎncă nu există evaluări

- Is Iso 16160 2005Document11 paginiIs Iso 16160 2005Amber HudsonÎncă nu există evaluări

- MIL-I-24768 (Insulation, Plastics, Laminated, Thermosetting General Specification For)Document35 paginiMIL-I-24768 (Insulation, Plastics, Laminated, Thermosetting General Specification For)ccorp0089Încă nu există evaluări

- Methods For'Measuring Case Depth of Steel: Indian StandardDocument7 paginiMethods For'Measuring Case Depth of Steel: Indian Standardsingaravelan narayanasamyÎncă nu există evaluări

- Is 1730Document11 paginiIs 1730maheshkbandari0% (1)

- Jis G0561 1983Document10 paginiJis G0561 1983TUAN NGUYEN VANÎncă nu există evaluări

- Jis D0201 1995Document23 paginiJis D0201 1995Mahardika Kurnia DewantaraÎncă nu există evaluări

- Astm A653-06a - SGCC StandardDocument13 paginiAstm A653-06a - SGCC Standardcremsky100% (1)

- Jis G3113 1990Document11 paginiJis G3113 1990TUAN NGUYEN VANÎncă nu există evaluări

- JisDocument23 paginiJisĐào_hải_10100% (1)

- Sampling Plan PDFDocument3 paginiSampling Plan PDFamitÎncă nu există evaluări

- JIS Standards Conv2Document26 paginiJIS Standards Conv2johnnyquest_86Încă nu există evaluări

- JIS H5302 2000 Japanese Industrial StandardDocument15 paginiJIS H5302 2000 Japanese Industrial StandardHeri Sudarmaji100% (3)

- Hardox 500 Sheet: General Product DescriptionDocument2 paginiHardox 500 Sheet: General Product DescriptionDylkanWingsÎncă nu există evaluări

- Tolerance of Position (TOP) - 1Document34 paginiTolerance of Position (TOP) - 1maddy_scribdÎncă nu există evaluări

- BS en 10017-2004Document18 paginiBS en 10017-2004Bravo Rd75% (4)

- Iso 8015 - 1985-12-15Document7 paginiIso 8015 - 1985-12-15Ionut FarcasÎncă nu există evaluări

- ASTM B883Standard Specification For Metal Injection Molding (MIM) Ferrous Materials1Document5 paginiASTM B883Standard Specification For Metal Injection Molding (MIM) Ferrous Materials1David VegaÎncă nu există evaluări

- 513-Part 1-2016Document17 pagini513-Part 1-2016Shaheen MaveÎncă nu există evaluări

- Tol Geom Ansi y 14.5Document33 paginiTol Geom Ansi y 14.5Rebecca TurnerÎncă nu există evaluări

- (Bolt Science) BOLTCALC Program Brochure PDFDocument3 pagini(Bolt Science) BOLTCALC Program Brochure PDFAbdulrahman Al HuribyÎncă nu există evaluări

- Finish Method P90 1. Scope: Finishing Methods 7.0 FM100 7/9/2019Document5 paginiFinish Method P90 1. Scope: Finishing Methods 7.0 FM100 7/9/2019JoshÎncă nu există evaluări

- NES-M2032 - 2021 - (ColdRoll-High Tensile)Document13 paginiNES-M2032 - 2021 - (ColdRoll-High Tensile)dpfloresÎncă nu există evaluări

- Foreword: ISO 7044:2012 (En) Prevailing Torque Type All-Metal Hexagon Nuts With Flange, Style 2 - Product Grades A and BDocument4 paginiForeword: ISO 7044:2012 (En) Prevailing Torque Type All-Metal Hexagon Nuts With Flange, Style 2 - Product Grades A and BMarcelo KleinÎncă nu există evaluări

- GBT 1299-2014 Tool and Mould SteelsDocument68 paginiGBT 1299-2014 Tool and Mould SteelsPhong Tong100% (1)

- JIS G3445 STKM 11A Steel TubesDocument11 paginiJIS G3445 STKM 11A Steel TubesshantyÎncă nu există evaluări

- JIS B0419-1991 (Dung Sai Kich Thuoc)Document1 paginăJIS B0419-1991 (Dung Sai Kich Thuoc)Giang Nguyễn BáÎncă nu există evaluări

- ASCOMETAL Steel Grades ENDocument8 paginiASCOMETAL Steel Grades ENasad144Încă nu există evaluări

- ASTM Reference RadiographsDocument3 paginiASTM Reference RadiographsAkbar ShaikÎncă nu există evaluări

- Astm 653Document13 paginiAstm 653Alejandro Garza100% (1)

- 7 Coatings PDFDocument3 pagini7 Coatings PDFŽarko MočnikÎncă nu există evaluări

- Cold-Rolled EN 10268Document9 paginiCold-Rolled EN 10268charssxÎncă nu există evaluări

- High-Strength Low-Alloy Steel Shapes of Structural Quality, Produced by Quenching and Self-Tempering Process (QST)Document4 paginiHigh-Strength Low-Alloy Steel Shapes of Structural Quality, Produced by Quenching and Self-Tempering Process (QST)indityoÎncă nu există evaluări

- A 108 - 03 - Qtewoa - PDFDocument7 paginiA 108 - 03 - Qtewoa - PDFHanifiantoÎncă nu există evaluări

- As 1897-1976 Electroplated Coatings On Threaded Components (Metric Coarse Series)Document11 paginiAs 1897-1976 Electroplated Coatings On Threaded Components (Metric Coarse Series)SAI Global - APACÎncă nu există evaluări

- Jis Tieu Chuan NhatDocument2 paginiJis Tieu Chuan Nhatanhhoack3Încă nu există evaluări

- Sfa-5 8 PDFDocument24 paginiSfa-5 8 PDFgst ajahÎncă nu există evaluări

- Iso 7412 PDFDocument9 paginiIso 7412 PDFnate anantathatÎncă nu există evaluări

- BS-970!3!1991-Specification For Wrought Steels For Mechanical and Allied Engineering PurposesDocument38 paginiBS-970!3!1991-Specification For Wrought Steels For Mechanical and Allied Engineering PurposesEric Mellier100% (1)

- Is 209 - 1992 Zinc Ingot - SpecificationDocument5 paginiIs 209 - 1992 Zinc Ingot - SpecificationRam NiwasÎncă nu există evaluări

- Al - 1050ADocument2 paginiAl - 1050Adejo1986100% (1)

- Aisi 1008 Carbon Steel (Uns g10080)Document3 paginiAisi 1008 Carbon Steel (Uns g10080)parasite01100% (1)

- Astm F788MDocument6 paginiAstm F788MDaniel Velázquez100% (1)

- F 1789 - 17Document15 paginiF 1789 - 17Acilasac 2018Încă nu există evaluări

- Jdma17 2Document8 paginiJdma17 2qualidadesider0% (1)

- JIS-G3455 - Carbon Steel Pipes For High Pressure ServiceDocument27 paginiJIS-G3455 - Carbon Steel Pipes For High Pressure ServiceHoang Tan100% (1)

- Jis G 3125-2010Document16 paginiJis G 3125-2010Mehdi Mokhtari67% (3)

- 283057842 JIS G4053 2003 Low Alloyed Steels for Machine Structural Use 英文版 PDFDocument21 pagini283057842 JIS G4053 2003 Low Alloyed Steels for Machine Structural Use 英文版 PDFDewi Lanjarsari Purnama Sastri100% (1)

- Jis G 4304-2012Document57 paginiJis G 4304-2012marjan banoo75% (4)

- JIS G 0551:: Japanese Industrial StandardDocument54 paginiJIS G 0551:: Japanese Industrial StandardJohnLoyd DY100% (1)

- Jis G4051-2016Document27 paginiJis G4051-2016ALEX MURPHY67% (3)

- Concrete Design Excel SheetDocument16 paginiConcrete Design Excel SheetCleth Hiren Santos25% (4)

- AnalysisbySTAAD PROandDesignofStructuralElementsbyMATLAB PDFDocument21 paginiAnalysisbySTAAD PROandDesignofStructuralElementsbyMATLAB PDFIsha PatelÎncă nu există evaluări

- Integrated Finite Elements Analysis and Design of StructuresDocument50 paginiIntegrated Finite Elements Analysis and Design of Structuresaeiou321Încă nu există evaluări

- Presentasi 2Document9 paginiPresentasi 2wokeoooÎncă nu există evaluări

- 244 457 1 SMDocument10 pagini244 457 1 SMAnonymous LsTEoBoTKÎncă nu există evaluări

- D ConcreteStruc N27Document8 paginiD ConcreteStruc N27Uriel Vélez OrejuelaÎncă nu există evaluări

- GRL WeapDocument1 paginăGRL WeapSACHIN H. DHAMAPURKARÎncă nu există evaluări

- Eth 1068 01 PDFDocument6 paginiEth 1068 01 PDFRedouane TebbouneÎncă nu există evaluări

- 18 Appendix ADocument23 pagini18 Appendix AHardik PrajapatiÎncă nu există evaluări

- Design of Structural Steel Joints and Connections 007Document16 paginiDesign of Structural Steel Joints and Connections 007henreng100% (6)

- 18 Appendix ADocument23 pagini18 Appendix AHardik PrajapatiÎncă nu există evaluări

- SCD Aisc 360 10Document25 paginiSCD Aisc 360 10ஆனந்த் கிருஷ்ணன்Încă nu există evaluări

- AASHTO Flexible Pavement DesignDocument9 paginiAASHTO Flexible Pavement DesignLandon MitchellÎncă nu există evaluări

- Teacher Manual R3Document54 paginiTeacher Manual R3George KaridisÎncă nu există evaluări

- Mechanical Anchoring TruBoltDocument3 paginiMechanical Anchoring TruBoltwokeoooÎncă nu există evaluări

- Design of Structural Steel Joints and Connections 007Document16 paginiDesign of Structural Steel Joints and Connections 007henreng100% (6)

- Use of SBEDS For Blast Resistant Design in Accordance With UFC 3 340 02Document38 paginiUse of SBEDS For Blast Resistant Design in Accordance With UFC 3 340 02wokeoooÎncă nu există evaluări

- Comparison of Response From Combined Axial and Blast Loads Calculated With SDOF and Finite Element MethodsDocument37 paginiComparison of Response From Combined Axial and Blast Loads Calculated With SDOF and Finite Element MethodswokeoooÎncă nu există evaluări

- The Design, Analysis and Construction of Tensile Fabric StructuresDocument26 paginiThe Design, Analysis and Construction of Tensile Fabric Structurespradeep vermaÎncă nu există evaluări

- Ada 571166Document17 paginiAda 571166wokeoooÎncă nu există evaluări

- MN KarstDocument4 paginiMN KarstwokeoooÎncă nu există evaluări

- Acceleration of A Plate Subject To Explosive Blast Loading - Trial ResultsDocument21 paginiAcceleration of A Plate Subject To Explosive Blast Loading - Trial ResultswokeoooÎncă nu există evaluări

- 7 Mistakes To Avoid As A New ClimberDocument15 pagini7 Mistakes To Avoid As A New ClimberwokeoooÎncă nu există evaluări

- Smokeview Technical Reference Guide PDFDocument84 paginiSmokeview Technical Reference Guide PDFwokeoooÎncă nu există evaluări

- Rii 4Document19 paginiRii 4wokeoooÎncă nu există evaluări

- Smokeview User GuideDocument205 paginiSmokeview User GuidewokeoooÎncă nu există evaluări

- Smokeview Verification GuideDocument102 paginiSmokeview Verification GuidewokeoooÎncă nu există evaluări

- Safir - Modelling Software For Construction Under Fire PDFDocument3 paginiSafir - Modelling Software For Construction Under Fire PDFwokeoooÎncă nu există evaluări

- Rii 4Document19 paginiRii 4wokeoooÎncă nu există evaluări

- Course Outline ENTR401 - Second Sem 2022 - 2023Document6 paginiCourse Outline ENTR401 - Second Sem 2022 - 2023mahdi khunaiziÎncă nu există evaluări

- LC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Document2 paginiLC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Mahadi Hassan ShemulÎncă nu există evaluări

- My BaboogDocument1 paginăMy BaboogMaral Habeshian VieiraÎncă nu există evaluări

- 23 Ray Optics Formula Sheets Getmarks AppDocument10 pagini23 Ray Optics Formula Sheets Getmarks AppSiddhant KaushikÎncă nu există evaluări

- Uniform Motion WorksheetDocument8 paginiUniform Motion Worksheetnikhil patro100% (1)

- For Accuracy and Safety: Globally ApprovedDocument4 paginiFor Accuracy and Safety: Globally ApprovedPedro LopesÎncă nu există evaluări

- Engineering Management: Class RequirementsDocument30 paginiEngineering Management: Class RequirementsMigaeaÎncă nu există evaluări

- Title: Smart Monitoring & Control of Electrical Distribution System Using IOTDocument27 paginiTitle: Smart Monitoring & Control of Electrical Distribution System Using IOTwaleed HaroonÎncă nu există evaluări

- str-w6754 Ds enDocument8 paginistr-w6754 Ds enAdah BumbonÎncă nu există evaluări

- KK AggarwalDocument412 paginiKK AggarwalEnrico Miguel AquinoÎncă nu există evaluări

- Cause Analysis For Spun Pile Crack and BrokenDocument11 paginiCause Analysis For Spun Pile Crack and BrokenRony LesbtÎncă nu există evaluări

- 11-Rubber & PlasticsDocument48 pagini11-Rubber & PlasticsJack NgÎncă nu există evaluări

- MATM1534 Main Exam 2022 PDFDocument7 paginiMATM1534 Main Exam 2022 PDFGiftÎncă nu există evaluări

- The Essence of Technology Is by No Means Anything TechnologicalDocument22 paginiThe Essence of Technology Is by No Means Anything TechnologicalJerstine Airah SumadsadÎncă nu există evaluări

- Table of Reinforcement Anchorage Length & Lap Length - Eurocode 2Document7 paginiTable of Reinforcement Anchorage Length & Lap Length - Eurocode 2NgJackyÎncă nu există evaluări

- TIA Guidelines SingaporeDocument24 paginiTIA Guidelines SingaporeTahmidSaanidÎncă nu există evaluări

- English Test For Grade 7 (Term 2)Document6 paginiEnglish Test For Grade 7 (Term 2)UyenPhuonggÎncă nu există evaluări

- Ficha Técnica Panel Solar 590W LuxenDocument2 paginiFicha Técnica Panel Solar 590W LuxenyolmarcfÎncă nu există evaluări

- VOTOL EMController Manual V2.0Document18 paginiVOTOL EMController Manual V2.0Nandi F. ReyhanÎncă nu există evaluări

- Blake Mouton Managerial GridDocument3 paginiBlake Mouton Managerial GridRashwanth Tc100% (1)

- BIOAVAILABILITY AND BIOEQUIVALANCE STUDIES Final - PPTX'Document32 paginiBIOAVAILABILITY AND BIOEQUIVALANCE STUDIES Final - PPTX'Md TayfuzzamanÎncă nu există evaluări

- Wine TourismDocument9 paginiWine Tourismyarashovanilufar1999Încă nu există evaluări

- How To Install Metal LathDocument2 paginiHow To Install Metal LathKfir BenishtiÎncă nu există evaluări

- Inverter 2 chiềuDocument2 paginiInverter 2 chiềuKhánh Nguyễn MinhÎncă nu există evaluări

- Sabian Aspect OrbsDocument8 paginiSabian Aspect Orbsellaella13100% (2)

- Pam8610 PDFDocument15 paginiPam8610 PDFRaka Satria PradanaÎncă nu există evaluări

- Pyramid Type Plate Bending MachineDocument10 paginiPyramid Type Plate Bending MachineAswin JosephÎncă nu există evaluări

- Dog & Kitten: XshaperDocument17 paginiDog & Kitten: XshaperAll PrintÎncă nu există evaluări

- Object Oriented ParadigmDocument2 paginiObject Oriented ParadigmDickson JohnÎncă nu există evaluări

- JO 20221109 NationalDocument244 paginiJO 20221109 NationalMark Leo BejeminoÎncă nu există evaluări