Documente Academic

Documente Profesional

Documente Cultură

Air Release Valve Selection & Sizing

Încărcat de

Mahmoud EldusokyDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Air Release Valve Selection & Sizing

Încărcat de

Mahmoud EldusokyDrepturi de autor:

Formate disponibile

Air Release Valve Selection & Sizing

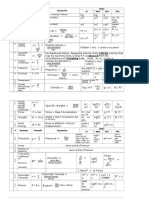

II. METHOD 2:

A. USING TABLE 2

If the specific venting rate is not known, Table 2 will assist in the selection of the correct type and proper size Air Release Valve. Determine the system maximum liquid flow rate (GPM) and maximum working pressure (PSIG). Select the orifice size and corresponding Air Release Valve Figure Number from the chart, noting the service on which the valves will function. Select a standard orifice size whenever possible. Long pipelines are vented more efficiently by Air Release Valves at frequent intervals than by larger orifice Air Release Valves widely spaced.

SMALL ORIFICE DIA. (INCHES)

AIR RELEASE VALVES

TABLE 2 (Air Release Valve Quick Selection Guide)

SERVICE FIGURE NUMBER INLET SIZES AVAILABLE WORKING PRESSURE (PSIG)* ORIFICE SIZE (IN) SYSTEM MAXIMUM FLOW RATE (GPM)** MAXIMUM VENTING CAPACITY (SCFM)**

CLEAN FLUIDS

STANDARD CAPACITY HIGH CAPACITY

SEWAGE SERVICE

STD.CAP. HIGH CAP. SHORT BDY.

901

1

905

1/2, 3/4

902

1

910

1/2, 3/4, 1 0-75 0-150 0-300 1/8 3/32 1/16 5,300 5,500 4,700 14.2 14.7 12.5

912

920

922

2, 3 0-75 0-150 0-300 1/2 3/8 7/32 85,200 88,000 57,200 227.3 234.8 152.6

923(4)

4

923(6)

6

925

2, 3, 4 0-75 0-150

927

2, 3, 4 0-75 0-150

929

2, 3, 4 0-75 0-150

1/2, 3/4, 1 1, 1-1/2, 2 0-75 0-150 0-300 5/16 3/16 1/8 33,300 22,000 18,700 89 59 50

0-150

0-150 0-200

0-150 0-300

0-150 0-300

0-150 0-300

0-150 0-300

1/16

3/32 1/16

3/32 1/16

1/8 3/32

1/2 3/8

1 11/16

5/16 3/16

1/2 7/16

5/16 3/16

2,400

5,500 3,100

5,500 4,700

9,800 10,500

156,500 168,000

626,000 565,000

13,300 8,800

34,100 47,900

13,300 8,800

6.5

14.7 8.5

14.7 12.5

26.1 28

417.3 448.6

1669.4 1507.7

88.8 58.7

227.3 319.5

88.8 58.7

BOLDFACE INDICATES STANDARD CONSTRUCTION. WORKING PRESSURE, ORIFICE SIZE, FLOW RATE & VENTING CAPACITY CORRESPOND FOR THE OTHER FIGURE NUMBERS AS INDICATED FOR THE FIG.929. *Specify if working pressure is below 10 PSI. **At maximum working pressure.

B. USING GRAPH 2 (For clean water systems only)

Where valve is to be selected on the basis of maximum system flow. (This graph assumes that clean water at standard conditions contains 2% dissolved air by volume and therefore will select an orifice diameter that will exhaust approximately 2% of the volume.) 1. Enter total maximum system flow at the bottom of Graph 2, draw a vertical line upward until you reach the line indicating maximum pressure. Draw a line horizontal left until you read minimum required orifice diameter. 2. Consult available Air Release Valve orifice diameter on Table 2 and select Valve with correct orifice diameter and pressure rating. SELECT A STANDARD ORIFICE WHENEVER POSSIBLE. 3. It is more efficient to install a greater quantity of Air Release Valves at strategic locations with smaller orifice than a lesser quantity with larger orifice. NOTE: Air Release Valves are commonly installed as a Combination Air Valve, (See Pages 38-61). Sizing and selection is the same as above when used in Combination Air Valves.

HYDRAULIC GRADIENT WHEN EMPTYING OR FLUSHING LINE AT LEAST TWO AIR VALVES HYDRAULIC GRADIENT

PIPELINE PRESSURE, PSIG

PIPELINE FLOW IN U.S. GALLONS PER MINUTE

WHERE TO INSTALL AIR VALVES

LONG ASCENDING STRETCH WITHOUT SUMMIT LONG DESCENDING STRETCH WITHOUT SUMMIT LONG HORIZONTAL STRETCH WITHOUT SUMMIT

PARALLEL TO HYD. GRADIENT

CHANGE IN UPWARD SLOPE DATUM LINE

DOWNWARD GRADE APPROACHING THE HYD. GRAD. AIR VALVE AT PEAK

AIR VALVE AT CHANGE IN DOWNWARD SLOPE. VACUUM LIKELY WHEN EMPTYING LINE.

1. Peaks - Install Combination Air Valves. This is the foremost place where air valves are required. A peak is located by reference to the hydraulic gradient and not to a horizontal datum line. A section of the pipeline that is above the hydraulic gradient is under negative pressure and generally requires the use of a check to prevent air from being drawn into the pipeline. 2. Increased Down Slope - Install an Air Release Valve. If vacuum protection is required, install a Combination Air Valve. 3. Decrease in Upward Slope - Same as 2 4. 5. 6. 7. 8. Long Ascents - Install Air/Vacuum Valves @ 1/4 - 1/2 mile intervals. Long Descents - Install Combination Air Valves @ 1/4 - 1/2 mile intervals. Long Horizontals - Install Combination Air Valves @ 1/4 - 1/2 mile intervals. Pumps - Install Air Release on discharge as close as possible to check valve. Large Valve, Operating Cylinders & Piping Loops - Install Air Release Valves

NOTE: At points near the hydraulic gradient a negative pressure condition can occur after a pump trip or valve closure. Consider the use of a Surge Check or Vacuum Breaker/Air Release Valve. See pages 21, 26-28, 34, 40, 52, 53, 59 and 60 for further information.

Page 17

A Product of GA Industries

S-ar putea să vă placă și

- Theory Application and Sizing of Air ValvesDocument9 paginiTheory Application and Sizing of Air ValveskcplemmonsÎncă nu există evaluări

- A R INewDocument28 paginiA R INewBhavesh TandelÎncă nu există evaluări

- Air Valve 460Document6 paginiAir Valve 460amrezzatÎncă nu există evaluări

- Water Hammer Report 1Document74 paginiWater Hammer Report 1Ah Leng LauÎncă nu există evaluări

- 6206 Guide For Selection Installation andDocument32 pagini6206 Guide For Selection Installation andakbavra80% (5)

- Applied Hydraulic Transients Chaudhry PDFDocument266 paginiApplied Hydraulic Transients Chaudhry PDFcarlos100% (2)

- Air Vessel Sizing For Water Hammer Prevention in PipelinesDocument4 paginiAir Vessel Sizing For Water Hammer Prevention in PipelinesHeiner PalaciosÎncă nu există evaluări

- Hammer Quick Lessons PDFDocument19 paginiHammer Quick Lessons PDFsebasfarsaÎncă nu există evaluări

- Valve SizingDocument6 paginiValve SizingVaibhav KuraleÎncă nu există evaluări

- Transient Flow AnalysisDocument14 paginiTransient Flow Analysiscpsankar100% (1)

- Hydraulic Transient Analysis Case StudyDocument30 paginiHydraulic Transient Analysis Case StudyhutuguoÎncă nu există evaluări

- Water Hammer Analysis ReportDocument22 paginiWater Hammer Analysis ReportAh Leng LauÎncă nu există evaluări

- Air Valves ValmaticDocument28 paginiAir Valves Valmaticnimm1962100% (1)

- Cavitation-Pump-Pipe-Skid CalcDocument56 paginiCavitation-Pump-Pipe-Skid CalcOltun KAYAÎncă nu există evaluări

- CALCULATION COVER SHEET DETERMINATION OF WATER PRESSURE SURGE LOADDocument7 paginiCALCULATION COVER SHEET DETERMINATION OF WATER PRESSURE SURGE LOADJ A S JASÎncă nu există evaluări

- User ManualDocument135 paginiUser ManualRaghuveer Rao Pallepati100% (2)

- RO Water Treatment Process OptimizationDocument30 paginiRO Water Treatment Process Optimizationmiths_0087100% (1)

- Pressure Surges and Air Valve Specification PDFDocument22 paginiPressure Surges and Air Valve Specification PDFTONÎncă nu există evaluări

- Pump head calculation sheetDocument44 paginiPump head calculation sheetkdpmansi50% (2)

- Pump Selection - Teluk Kabung (07.10.2015) - With CommentDocument15 paginiPump Selection - Teluk Kabung (07.10.2015) - With CommentPriyo Jati WahyonoÎncă nu există evaluări

- Minor Loss Coefficients in Pipes and Tubes ComponentsDocument2 paginiMinor Loss Coefficients in Pipes and Tubes ComponentsSurendra ReddyÎncă nu există evaluări

- HDPE Vs GRPDocument14 paginiHDPE Vs GRPMariusÎncă nu există evaluări

- BURIED PIPE DEFLECTION AND BUCKLING CALCULATIONDocument4 paginiBURIED PIPE DEFLECTION AND BUCKLING CALCULATION9703422499Încă nu există evaluări

- Joukowsky EquationDocument1 paginăJoukowsky Equationvijay_jvÎncă nu există evaluări

- Me 2204 Fluid Mechanics and Machinery LiDocument8 paginiMe 2204 Fluid Mechanics and Machinery LiSheryll de GuzmanÎncă nu există evaluări

- Fluid Mechanics Tutorial 8C Pumped Piped Systems: Let's Start by Examining The Meaning of Specific Speed of PumpsDocument17 paginiFluid Mechanics Tutorial 8C Pumped Piped Systems: Let's Start by Examining The Meaning of Specific Speed of Pumps12Încă nu există evaluări

- Design of Surge Tank For Water Supply Systems UsinDocument9 paginiDesign of Surge Tank For Water Supply Systems Usinmohamed hindawiÎncă nu există evaluări

- Line SizingDocument14 paginiLine SizingSaif MujawarÎncă nu există evaluări

- Compute Time To Drain or Empty A Tank, Pond, or ReservoirDocument5 paginiCompute Time To Drain or Empty A Tank, Pond, or ReservoirJayakrishnan RadhakrishnanÎncă nu există evaluări

- Head Loss Pipe Fitting ValveDocument14 paginiHead Loss Pipe Fitting ValvePhạm Quang HuyÎncă nu există evaluări

- Intro To TBE For PumpDocument2 paginiIntro To TBE For PumpMuhammad RidhwanÎncă nu există evaluări

- AVK Resilient Seated Gate ValvesDocument36 paginiAVK Resilient Seated Gate ValvesCarel De JagerÎncă nu există evaluări

- Hydraulic Calculation of Pipelines ReportDocument91 paginiHydraulic Calculation of Pipelines Reportkanokwan jaruek100% (1)

- NEOPRSP001WI017 - Rev. 01 - Pages 07 - Cleaning in Place of RO System Work InstructionsDocument7 paginiNEOPRSP001WI017 - Rev. 01 - Pages 07 - Cleaning in Place of RO System Work Instructionsalialharbi021Încă nu există evaluări

- ECONOMIC SURGE TANK DESIGN WITH REVERSE FLOW THROTTLEDocument6 paginiECONOMIC SURGE TANK DESIGN WITH REVERSE FLOW THROTTLEcsimsekÎncă nu există evaluări

- Water Hammer Report (With Vacuum Air Valves)Document11 paginiWater Hammer Report (With Vacuum Air Valves)Ah Leng LauÎncă nu există evaluări

- Town Water Supply - Pump, Pumping Main: Delivery PipeDocument2 paginiTown Water Supply - Pump, Pumping Main: Delivery PipeJohn BandaÎncă nu există evaluări

- System design: Calculating pipe expansion and contractionDocument3 paginiSystem design: Calculating pipe expansion and contractionreach_arindomÎncă nu există evaluări

- Oily Water Separator Calculation ParametersDocument2 paginiOily Water Separator Calculation ParametersTun Naing WinÎncă nu există evaluări

- Pump Calculation - Rev 0Document6 paginiPump Calculation - Rev 0m khaeron100% (1)

- Acceleration Head For Reciprocating PumpsDocument2 paginiAcceleration Head For Reciprocating PumpsEng Alf100% (1)

- Separator Design Guide PDFDocument36 paginiSeparator Design Guide PDFAdam RizkyÎncă nu există evaluări

- Hydraulic TransientsDocument58 paginiHydraulic TransientsjulianvillajosÎncă nu există evaluări

- Water Hammer in Gravity LinesDocument12 paginiWater Hammer in Gravity LinesMuhammad Ehtsham0% (1)

- Total Dynamic HeadDocument2 paginiTotal Dynamic Headrajbhar_sÎncă nu există evaluări

- Pump Intake Design - ANSIDocument79 paginiPump Intake Design - ANSIrizkboss8312Încă nu există evaluări

- Plant Air SystemDocument7 paginiPlant Air SystemAnuj ShahiÎncă nu există evaluări

- ELMO-F Vacuum Units with Vacuum Pumps, Range 2BE Selection GuideDocument17 paginiELMO-F Vacuum Units with Vacuum Pumps, Range 2BE Selection GuideDSdds0% (1)

- Pump hydraulic calculationDocument1 paginăPump hydraulic calculationJk KarthikÎncă nu există evaluări

- Gas Pressure Reduction StationDocument2 paginiGas Pressure Reduction StationMathias OnosemuodeÎncă nu există evaluări

- Water Hammer: Values For CalculationDocument3 paginiWater Hammer: Values For CalculationEng-CalculationsÎncă nu există evaluări

- Estimation of Pump Moment of Inertia - NeutriumDocument8 paginiEstimation of Pump Moment of Inertia - NeutriumbcshendeÎncă nu există evaluări

- Air Release Valve Sizing Chart - How To Choose The Right ValveDocument8 paginiAir Release Valve Sizing Chart - How To Choose The Right Valvemyself_riteshÎncă nu există evaluări

- Optimized Air Distribution DesignDocument9 paginiOptimized Air Distribution DesignAbhay SinghÎncă nu există evaluări

- Apco Air Valve GuideDocument12 paginiApco Air Valve Guideanon_711152122Încă nu există evaluări

- Compressed Air Generation & Distribution SystemDocument6 paginiCompressed Air Generation & Distribution SystemSnehalkumar GhaytadkarÎncă nu există evaluări

- Compressed Air Piping-Economic PipingDocument5 paginiCompressed Air Piping-Economic PipingMOHAMMAD ASIFÎncă nu există evaluări

- OM-12_SDocument43 paginiOM-12_SalgmenezesÎncă nu există evaluări

- LMW Lakshmi Latest Machines: Pneumatic Air CompressorDocument8 paginiLMW Lakshmi Latest Machines: Pneumatic Air CompressorMuhammad JunaidÎncă nu există evaluări

- Astm D 2665 PDFDocument7 paginiAstm D 2665 PDFfayaz khan100% (2)

- Technical Data Sheet PPR (Green Color)Document1 paginăTechnical Data Sheet PPR (Green Color)Mahmoud EldusokyÎncă nu există evaluări

- QPF Plastic Products CatalogueDocument28 paginiQPF Plastic Products CatalogueMohamedAlamiÎncă nu există evaluări

- Institute of PlumbingDocument249 paginiInstitute of PlumbingPatel Kalinga100% (1)

- Loss Prevention StandardDocument14 paginiLoss Prevention StandardMahmoud EldusokyÎncă nu există evaluări

- QPF Plastic Products CatalogueDocument28 paginiQPF Plastic Products CatalogueMohamedAlamiÎncă nu există evaluări

- Charlotte Plastics Tech Manual PDFDocument132 paginiCharlotte Plastics Tech Manual PDFMahmoud EldusokyÎncă nu există evaluări

- Water Installation CodeDocument34 paginiWater Installation CodeDăňĩêĺ RăĵăÎncă nu există evaluări

- NEMA Ratings and IP Equivalency Chart PDFDocument8 paginiNEMA Ratings and IP Equivalency Chart PDFMahmoud EldusokyÎncă nu există evaluări

- NEMA Ratings and IP Equivalency Chart PDFDocument8 paginiNEMA Ratings and IP Equivalency Chart PDFMahmoud EldusokyÎncă nu există evaluări

- NEMA Enclosure Types 11-05-2Document9 paginiNEMA Enclosure Types 11-05-2Duron SaavedraÎncă nu există evaluări

- Fm200 Data SheetDocument10 paginiFm200 Data SheetMahmoud EldusokyÎncă nu există evaluări

- NEMA Enclosure Types 11-05-2Document9 paginiNEMA Enclosure Types 11-05-2Duron SaavedraÎncă nu există evaluări

- Ashghal Guide-Qatar Sewerage & Drainage Design ManualDocument60 paginiAshghal Guide-Qatar Sewerage & Drainage Design Manualmounir89% (36)

- Auto Roll Towel Dispenser-EnDocument2 paginiAuto Roll Towel Dispenser-EnMahmoud EldusokyÎncă nu există evaluări

- 32 Balance Tank Design For Deck Level PoolsDocument2 pagini32 Balance Tank Design For Deck Level Poolschbane100% (2)

- Air Release Valves DetailsDocument16 paginiAir Release Valves DetailsMahmoud EldusokyÎncă nu există evaluări

- Air Release Valves DetailsDocument16 paginiAir Release Valves DetailsMahmoud EldusokyÎncă nu există evaluări

- QCS 2010 Part 14 Road DrainageDocument8 paginiQCS 2010 Part 14 Road DrainageRotsapNayrb100% (4)

- BS 864-2-1983Document24 paginiBS 864-2-1983Mahmoud EldusokyÎncă nu există evaluări

- Bubblers & Micro-Spray DevicesDocument2 paginiBubblers & Micro-Spray DevicesMahmoud EldusokyÎncă nu există evaluări

- Reference Data: Schedule 40 Steel Pipe DataDocument1 paginăReference Data: Schedule 40 Steel Pipe DataMustafaÎncă nu există evaluări

- PMP 8th Ed 8th Printing Updates EnglishDocument2 paginiPMP 8th Ed 8th Printing Updates EnglishLuizaecindyÎncă nu există evaluări

- PPR Pipes SpecificationsDocument32 paginiPPR Pipes SpecificationsMahmoud EldusokyÎncă nu există evaluări

- PROCESS GAS SOLUTIONS: AERZEN'S RELIABLE COMPRESSORS AND BLOWERSDocument26 paginiPROCESS GAS SOLUTIONS: AERZEN'S RELIABLE COMPRESSORS AND BLOWERSWesley andrade martins100% (1)

- Erapol E83ADocument2 paginiErapol E83ALucas NievaÎncă nu există evaluări

- Laboratory Manual Machine Shop 1 PDFDocument59 paginiLaboratory Manual Machine Shop 1 PDFVinz Bryan AlmacenÎncă nu există evaluări

- Module 2: Problem Set CH148/A32: Camacho, Ocampo, Patuto, Rodenas, TizonDocument5 paginiModule 2: Problem Set CH148/A32: Camacho, Ocampo, Patuto, Rodenas, TizonZhane TizonÎncă nu există evaluări

- Report Gas Adsorption Refrigeration Unit - 2020452596 - Eh2436Document7 paginiReport Gas Adsorption Refrigeration Unit - 2020452596 - Eh2436Nurul Syahida SyafikaÎncă nu există evaluări

- (Unit 1&2) PDFDocument41 pagini(Unit 1&2) PDFJaiPrakashÎncă nu există evaluări

- Evaluation of Steam Jet EjectorsDocument11 paginiEvaluation of Steam Jet EjectorsRajeh Somrani100% (3)

- CentrifugationDocument12 paginiCentrifugationVytheeshwaran Vedagiri100% (16)

- All India Aakash Test Series For NEET - 2021 TEST - 6 (Code-C)Document32 paginiAll India Aakash Test Series For NEET - 2021 TEST - 6 (Code-C)Kavyatharsheni S XI-B 46Încă nu există evaluări

- Applications of Isotopes C11!3!01&C11!3!02Document12 paginiApplications of Isotopes C11!3!01&C11!3!02Olivia M OliverÎncă nu există evaluări

- Bricks PDFDocument86 paginiBricks PDFSai DasaradharamÎncă nu există evaluări

- Jin Shuren: 1. The Present Situation of Chinese Modified StarchDocument13 paginiJin Shuren: 1. The Present Situation of Chinese Modified StarchTatiana AlvaradoÎncă nu există evaluări

- Synthesis of Cesium Octacyanomolybdate (V) - and Cesium Cyanotungstate (V) Dihydrate: A More Successful Method OctaDocument3 paginiSynthesis of Cesium Octacyanomolybdate (V) - and Cesium Cyanotungstate (V) Dihydrate: A More Successful Method OctaDabasish DekaÎncă nu există evaluări

- Magnesia Carbon Refractories Product GuideDocument35 paginiMagnesia Carbon Refractories Product GuideSiddhartha BogawatÎncă nu există evaluări

- How to Set Up a New Aquarium in 7 Easy StepsDocument40 paginiHow to Set Up a New Aquarium in 7 Easy StepsAndrew HardcastleÎncă nu există evaluări

- Presentation On Forged Mill Balls Production in South AfricaDocument23 paginiPresentation On Forged Mill Balls Production in South AfricaRamoutar (Ken) SeecharranÎncă nu există evaluări

- Chapter 1 IntroductionDocument20 paginiChapter 1 IntroductionKaoru AmaneÎncă nu există evaluări

- Artal Catalogue PDFDocument72 paginiArtal Catalogue PDFArtalÎncă nu există evaluări

- Experiment 1Document5 paginiExperiment 1ain sufizaÎncă nu există evaluări

- TestDocument94 paginiTestmutiaraÎncă nu există evaluări

- Maintain Your BRH 501 Demolition HammerDocument46 paginiMaintain Your BRH 501 Demolition HammerRomán Arturo Guerrero Uc100% (3)

- Practice Problems - Electrochemical CellDocument5 paginiPractice Problems - Electrochemical CellYehia IbrahimÎncă nu există evaluări

- Advantage and Disadvantage of Using Nanoparticles in AgricultureDocument13 paginiAdvantage and Disadvantage of Using Nanoparticles in AgricultureAmjadRashidÎncă nu există evaluări

- Phase I document covers states of matter basicsDocument41 paginiPhase I document covers states of matter basicsdivakarsÎncă nu există evaluări

- Preliminary - Welding Procedure Specification (WPS)Document1 paginăPreliminary - Welding Procedure Specification (WPS)Rudi DaÎncă nu există evaluări

- Activated CarbonDocument34 paginiActivated CarbonSanjeeva YedavalliÎncă nu există evaluări

- Progress in Polyethylene Terephthalate RecyclingDocument24 paginiProgress in Polyethylene Terephthalate RecyclingyuppeÎncă nu există evaluări

- Main Pump PDFDocument36 paginiMain Pump PDFElia MekdadÎncă nu există evaluări

- Construction Materials For Marine Diesel EnginesDocument5 paginiConstruction Materials For Marine Diesel EnginesVijay AÎncă nu există evaluări

- Salt HydrolysisDocument3 paginiSalt Hydrolysisna_napanda100% (1)