Documente Academic

Documente Profesional

Documente Cultură

Presentation On Desert Cooler

Încărcat de

Anonymous BJ9omODescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Presentation On Desert Cooler

Încărcat de

Anonymous BJ9omODrepturi de autor:

Formate disponibile

Submitted to : Dr Amandeep Sharma

Prepared by: Rupinder singh (L-2k10-DT-23-B.Tech) Roshank (L-2k10-DT-22-B.Tech) Saglpreet singh ( L-2k10-DT-24-B.Tech) Simrat S. Bains (L-2k10-DT-29-B.Tech) Simranjit singh (L-2k10-DT-26-B.Tech) Sukhwinder S. (L-2k10-DT-28-B.Tech)

What is DESERT COOLER? It is a device that cools air through simple evaporation of water.

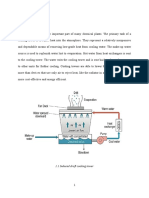

Principle Of Working: As the name implies , it is suitable for places where the humidity is quite low and temperature quite high. These conditions are in conformity with desert areas. Hence the coolers are called Desert coolers. The principle on which a desert cooler works is Evaporative cooling. Evaporative cooling is a process in which sensible heat is removed and moisture added to the air. When air passes through a spray of water it gives up heat to water, some of the water evaporated and picks up heat from the air equivalent to its latent heat . The vapour thus formed are carried along in stream. In this way air is cooled and humidified.

Contruction and working of a desert cooler: 1. Blower/ Fan 3. Water wetted pads 5. Float valve 2. water circulating pump 4. water tank

Working: The water is filled in the sump of the cooler from water supply mains , the level of which is controlled by a float valve. A water pump lifts the water and supplies it at the top of the cooler to the water distribution system which consists of small branches of copper pipe or so equipped with orifices which deliver equal amount of water to the troughs which in turns supply water to the wetted pads. The water which drops back from the pads is recirculated. The pump may be made of brass , stainless steel or even plastic. The blower pulls the air through the wetted pads and deliver it to space to be cooled through an opening in the fourth side of the cabinet of desert cooler. The air which is sucked through the pads is cooled by the principle of evaporative cooling . The blower gives adequate velocity to the air before it is delivered to the spaces to be cooled. To have long life of the desert cooler and better performance , pads should be changed every year and holes for water distribution system should be cleaned.The tank should be cleaned just after the season and coated with corrosion resisting paint .

Different parts of desert cooler :

Cooler pump

Float valve-

-Cooler pads

motor

On/off switch

Comparison of desert cooler and air conditioner.

S. No.

Particulars

Desert cooler

Window type air conditioner Quite high Complete referigeration unit Possible Less

1. 2. 3. 4.

Initial cost Main components Humidity control Power reqd per unit cooling Utility

Low Motor and fan Not possible More

5.

Can be used only to cool the air & that too in dry season Inside or in the window of room.

Can be used for both cooling and heating

6.

Location

Fitted either in the window or wall.

CLASSIFICATION: 1) Fan in the vertical plane: the arrangement of the components is shown in fig. there is a separate motor for the pump and fan so they can be used independently.The arrangement of the components in a box providing 3 pads. The pump , pumps the water from the bottom tank to the top and water trinkles through the holes provided on the top of tank and falls passing the pads to the bottom tank. Advantages of this type of cooler are: 1. The pump cannot be started without starting the fan , which prevents unwanted running of pump. 2. The system can be used as a cooler in hot summer and as a fan when cooling is not required.

2) Fan inhorizontal plane: the wox type of the cooler falls under this class. The arrangement of the basic component is shown in fig. this differs from the previous one in fan arrangement.The pump and fan are mounted on same vertical shaft and run by a common motor. Hence the fan and pump cannot be operated seperately as in the previous arrangement.

Advantages of this sytem are: 1) 4 cooling pads instead of 3 , hence cooling capacity is more. 2) Noise is less than other coolers. 3) Unique omni directional air flow provides better air distribution in the room.

3) Cooler without water pump: the majority of the users in india are facing three major problems: a) the coolers consume more electrical energy and hence not economical. b) the water pumps of the cooler are submerged in water tanks get damaged frequently . c)the khus pads need frequent replacement thereby causing inconveinence. To avoid such problems a new model known as Quality desert cooler is developed.

Type and size of fans recommended are:

Size RPM Area to be cooled

15

18

24

24

900

900

700

900

150ft

300ft

600ft

900ft

Advantages desert cooler

Less expensive to install because estimated cost is half that of central refrigerated air conditioning y Less expensive to operate because estimated cost of operation is that of refrigerated air y Ease of maintanance because only two main parts fan &water pump which repair at low cost

y

Manufacturers of desert coolers are : Symphony , Kenstar , Khaitan and other local brands.

Different coolers of symphony with their specifications :

S-ar putea să vă placă și

- Cooling Load EstimationDocument69 paginiCooling Load EstimationkarimÎncă nu există evaluări

- Oral and Practical Review: Reflections on the Part 147 CourseDe la EverandOral and Practical Review: Reflections on the Part 147 CourseÎncă nu există evaluări

- Pipe Size CalcDocument19 paginiPipe Size Calcnitin_bir100% (1)

- Pipe Size CalcDocument19 paginiPipe Size Calcnitin_bir100% (1)

- Cummins Engine Room Ventilation RequirementDocument3 paginiCummins Engine Room Ventilation RequirementAnonymous BJ9omOÎncă nu există evaluări

- Design of Expansion TankDocument4 paginiDesign of Expansion TankKELVIN100% (2)

- Design of Expansion TankDocument4 paginiDesign of Expansion TankKELVIN100% (2)

- Basics of PipingDocument102 paginiBasics of PipingDawood Akram100% (1)

- Air-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&ADe la EverandAir-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&AEvaluare: 5 din 5 stele5/5 (1)

- Foam CalculationsDocument8 paginiFoam CalculationsAnonymous BJ9omO86% (7)

- Refrigeration and Air Conditioning Lab: Mansoura University Faculty of Engineering Mechanical Power Department 4 YearDocument9 paginiRefrigeration and Air Conditioning Lab: Mansoura University Faculty of Engineering Mechanical Power Department 4 YearKhaled HakimÎncă nu există evaluări

- Split Air ConditionerDocument13 paginiSplit Air ConditionerInzi Gardezi100% (1)

- Thermal Applications: Cooling Systems GuideDocument32 paginiThermal Applications: Cooling Systems GuideTinu Paul JepinÎncă nu există evaluări

- Split AC Guide: How They Work & System ComponentsDocument8 paginiSplit AC Guide: How They Work & System ComponentssadÎncă nu există evaluări

- Entropic Memes: One Easy Way to Build a BombDocument2 paginiEntropic Memes: One Easy Way to Build a Bombkimkiko100% (3)

- Cooling Tower REPORTDocument25 paginiCooling Tower REPORTSaroj KumarÎncă nu există evaluări

- Refrigeration System Components: - Vishakh GaneshDocument34 paginiRefrigeration System Components: - Vishakh GaneshS R Akhil KrishnanÎncă nu există evaluări

- Steam Condensers and Evaporators ExplainedDocument32 paginiSteam Condensers and Evaporators Explainedvipul sharma100% (1)

- List of Malaysian StandardDocument49 paginiList of Malaysian StandardPaklong Itm Perlis33% (3)

- HVACDocument72 paginiHVACvarshneyrk@rediffmail.comÎncă nu există evaluări

- Ice Plant ModelDocument12 paginiIce Plant ModelAtul Sartape100% (2)

- ECM216 BUILDING SERVICES Bab 2.2 Air ConditioningDocument8 paginiECM216 BUILDING SERVICES Bab 2.2 Air ConditioningAZUAN BIN AHMAD FAUZI100% (3)

- Cooling tower functionsDocument16 paginiCooling tower functionsPrasanna kumar subudhi100% (1)

- Condenser in Power PlantDocument20 paginiCondenser in Power PlantPrabir Kumar PatiÎncă nu există evaluări

- Cooling Towers: Cold Water BasinDocument13 paginiCooling Towers: Cold Water BasinmichsantosÎncă nu există evaluări

- Refrigration Saving HeatDocument39 paginiRefrigration Saving HeatTanviÎncă nu există evaluări

- By: Meet Shah & Arpit ThumarDocument27 paginiBy: Meet Shah & Arpit ThumarArpit ThumarÎncă nu există evaluări

- Cooling Tower: Refrigeration and Air Conditioning LabDocument40 paginiCooling Tower: Refrigeration and Air Conditioning LabEngr Saad Bin SarfrazÎncă nu există evaluări

- Air ConditionerDocument5 paginiAir ConditionerArun Pravin APÎncă nu există evaluări

- Merriam-Webster Dictionary Online: 12/09/2021 by Gilbert W Techer 1Document47 paginiMerriam-Webster Dictionary Online: 12/09/2021 by Gilbert W Techer 1Guilbert TecherÎncă nu există evaluări

- Mcquay CAC Model AHU Catalog - VisionDocument92 paginiMcquay CAC Model AHU Catalog - VisionStephen Lim0% (1)

- FLSmidth Pfister For Slideshare PDFDocument29 paginiFLSmidth Pfister For Slideshare PDFMalik Israr HussainÎncă nu există evaluări

- Presentation On Desert CoolerDocument17 paginiPresentation On Desert Coolersantaclaus99100% (1)

- Desert CoolerDocument17 paginiDesert CoolerMahaManthraÎncă nu există evaluări

- Presentation On Desert CoolerDocument17 paginiPresentation On Desert CoolerSooraj srjÎncă nu există evaluări

- GSUJ Vertical Geothermal Unit Features and BenefitsDocument2 paginiGSUJ Vertical Geothermal Unit Features and Benefitsapi-21574340Încă nu există evaluări

- Centralized AC System in 40 CharactersDocument11 paginiCentralized AC System in 40 CharacterskareemulllahÎncă nu există evaluări

- Screw Type of CompressorDocument9 paginiScrew Type of CompressorAnish KumarÎncă nu există evaluări

- Energy Conservation in Cooling TowersDocument13 paginiEnergy Conservation in Cooling TowersMohamad ChaudhariÎncă nu există evaluări

- Dasar Teori PendinginDocument64 paginiDasar Teori PendinginsuhandywÎncă nu există evaluări

- Computer-linked bench top cooling towerDocument9 paginiComputer-linked bench top cooling towerMuhammad Suleman AttariÎncă nu există evaluări

- CondensorDocument20 paginiCondensorLaka 98Încă nu există evaluări

- Guide to the 6 Main Types of Air Conditioning SystemsDocument9 paginiGuide to the 6 Main Types of Air Conditioning SystemskimÎncă nu există evaluări

- Cooling systems for I.C. EnginesDocument33 paginiCooling systems for I.C. EnginesRachitÎncă nu există evaluări

- KIET Group of Institutions, GhaziabadDocument8 paginiKIET Group of Institutions, GhaziabadSandeep ChhabraÎncă nu există evaluări

- Presentation Report-Converted 1Document11 paginiPresentation Report-Converted 1S.k. YadavÎncă nu există evaluări

- System ComponentsDocument35 paginiSystem ComponentsCharan Reddy AbbadiÎncă nu există evaluări

- VAMDocument21 paginiVAMpowergopsÎncă nu există evaluări

- WAC and VCRSDocument8 paginiWAC and VCRSShubham MishraÎncă nu există evaluări

- Central Air ConditioningDocument14 paginiCentral Air ConditioningHashim MuhammedÎncă nu există evaluări

- Study of Single Stage Air CompressorDocument28 paginiStudy of Single Stage Air CompressorRealKimJongUnÎncă nu există evaluări

- Split AC Guide: Indoor & Outdoor Unit PartsDocument4 paginiSplit AC Guide: Indoor & Outdoor Unit PartsMuhammad Jamshaid KhanÎncă nu există evaluări

- UNIT I - Air ConditionDocument62 paginiUNIT I - Air ConditionNeha JojanÎncă nu există evaluări

- Air Conditioning EfficiencyDocument3 paginiAir Conditioning EfficiencyVed PrakashÎncă nu există evaluări

- Air ConditioningDocument25 paginiAir ConditioningSiva Chandran SÎncă nu există evaluări

- Shivani Project ReportDocument20 paginiShivani Project ReportShivaniÎncă nu există evaluări

- University of Engineering and Technology: AssignmentDocument11 paginiUniversity of Engineering and Technology: AssignmentMuhammad NaumanÎncă nu există evaluări

- Assignement 2 AEDocument14 paginiAssignement 2 AEd purnachandraÎncă nu există evaluări

- Grou5 AirConditioner Assignment5Document17 paginiGrou5 AirConditioner Assignment5AnkurMahantyÎncă nu există evaluări

- Central Air Conditioning PlantsDocument8 paginiCentral Air Conditioning PlantsNilesh PatilÎncă nu există evaluări

- Thermal Engineering-CondenserDocument17 paginiThermal Engineering-CondenserJayÎncă nu există evaluări

- Cooling Towers: Definition: # in Power Plants The Hot Water From Condenser IsDocument27 paginiCooling Towers: Definition: # in Power Plants The Hot Water From Condenser IsUsman SheriffÎncă nu există evaluări

- Steam CondenserDocument16 paginiSteam CondenserAtharv MarneÎncă nu există evaluări

- Operation of Geothermal Cooling TowersDocument11 paginiOperation of Geothermal Cooling TowersAksanul KhalisÎncă nu există evaluări

- Condenser and It's TypesDocument6 paginiCondenser and It's Typeskaacho piece pieceÎncă nu există evaluări

- Research 1 - Mechanical System BU2Document17 paginiResearch 1 - Mechanical System BU2Zachary Yassir GonzalezÎncă nu există evaluări

- Steam Condensers: 3/28/2015 1 Footer TextDocument23 paginiSteam Condensers: 3/28/2015 1 Footer TextKumari YehwaÎncă nu există evaluări

- Engine Cooling System and Servicin1Document37 paginiEngine Cooling System and Servicin1Emmanuel KutaniÎncă nu există evaluări

- Airconditioning and Ventilation SystemsDocument6 paginiAirconditioning and Ventilation SystemsJohn Kenneth Santiago PaulinoÎncă nu există evaluări

- Operating Instructions Refrigerated Air Dryers Models D-300 Through D-7500Document13 paginiOperating Instructions Refrigerated Air Dryers Models D-300 Through D-7500janessa ilaganÎncă nu există evaluări

- Rac Lab FileDocument28 paginiRac Lab FileGovind AtwalÎncă nu există evaluări

- Types of Air Conditioning: Qus 3206 / MDM Nurul AiniDocument56 paginiTypes of Air Conditioning: Qus 3206 / MDM Nurul AiniMalik MussaÎncă nu există evaluări

- Ppe Activity 6Document3 paginiPpe Activity 6Marycris Bautista RosarioÎncă nu există evaluări

- Additional GraphsDocument20 paginiAdditional GraphsAnonymous BJ9omOÎncă nu există evaluări

- Unit Conversion Sheet - Beta 1Document2 paginiUnit Conversion Sheet - Beta 1Anonymous BJ9omOÎncă nu există evaluări

- By Douglas C. Hittle, PH.D., Fellow ASHRAEDocument5 paginiBy Douglas C. Hittle, PH.D., Fellow ASHRAENiong DavidÎncă nu există evaluări

- VAV System ComponentsDocument12 paginiVAV System ComponentsBoonchai JaideeÎncă nu există evaluări

- Elite Software - PsyChartDocument5 paginiElite Software - PsyChartsyedkaleem55Încă nu există evaluări

- Brink S Body Building RevealedDocument135 paginiBrink S Body Building RevealedAnonymous BJ9omOÎncă nu există evaluări

- Sanitary and Plumbing Systems and EquipmentDocument117 paginiSanitary and Plumbing Systems and EquipmentJustine Policarpio Fabian100% (5)

- Hvac Control in The New MillenniumDocument388 paginiHvac Control in The New MillenniumPrecisionetica100% (2)

- Calculation of Fire Water Tank CapacityDocument2 paginiCalculation of Fire Water Tank Capacitymunim87100% (1)

- Hazen Williams EquationDocument5 paginiHazen Williams EquationAnonymous BJ9omOÎncă nu există evaluări

- Rules and Rules of Thumb For Duct SystemsDocument1 paginăRules and Rules of Thumb For Duct SystemsNguyễn Xuân ĐiệpÎncă nu există evaluări

- Q&A PlumbingDocument14 paginiQ&A PlumbingHenry SuarezÎncă nu există evaluări

- Exporting HAP Hourly Simulation Data To Spreadsheets.: QB Tip 001Document4 paginiExporting HAP Hourly Simulation Data To Spreadsheets.: QB Tip 001Anonymous BJ9omOÎncă nu există evaluări

- Rules and Rules of Thumb For Duct SystemsDocument1 paginăRules and Rules of Thumb For Duct SystemsNguyễn Xuân ĐiệpÎncă nu există evaluări

- TIGERFLOW Booster Sizing Worksheet: I. Pressure RequiredDocument3 paginiTIGERFLOW Booster Sizing Worksheet: I. Pressure RequiredAnonymous BJ9omOÎncă nu există evaluări

- Pressure Drop Calculation FactDocument6 paginiPressure Drop Calculation FactadehriyaÎncă nu există evaluări

- Hap Ehelp 007Document6 paginiHap Ehelp 007Anonymous BJ9omOÎncă nu există evaluări

- BTMP-B Hvac Upgrading Project: System Loss CalculationDocument3 paginiBTMP-B Hvac Upgrading Project: System Loss Calculationaa112311Încă nu există evaluări

- Economizer and Mixed AirDocument23 paginiEconomizer and Mixed AirAnonymous BJ9omOÎncă nu există evaluări

- Pressure Drop Calculation FactDocument6 paginiPressure Drop Calculation FactadehriyaÎncă nu există evaluări

- NonstandardDocument39 paginiNonstandarda04205Încă nu există evaluări

- Bostrig Type P VFD 2kVDocument3 paginiBostrig Type P VFD 2kVEnrique MartínezÎncă nu există evaluări

- Midea Klima Katalogus Midea Main 2008 EngDocument43 paginiMidea Klima Katalogus Midea Main 2008 EngJoao NogueiraÎncă nu există evaluări

- Carbolite CSF BOF RHF Oven ManualDocument12 paginiCarbolite CSF BOF RHF Oven ManualJim SmithÎncă nu există evaluări

- Signet 2714-2717 Twist-Lock pH/ORP Electrodes: FeaturesDocument4 paginiSignet 2714-2717 Twist-Lock pH/ORP Electrodes: FeaturesHuuDuydluÎncă nu există evaluări

- Sunpower Panel SpecDocument2 paginiSunpower Panel SpecRishi JainÎncă nu există evaluări

- PNOZ X2 8P enDocument9 paginiPNOZ X2 8P enHamed MokhtariÎncă nu există evaluări

- Sodium Chlorate Civilizations EndDocument3 paginiSodium Chlorate Civilizations EndlunicyÎncă nu există evaluări

- Recommendations For Assessment Eurocodes For Bridges: Chris R HendyDocument12 paginiRecommendations For Assessment Eurocodes For Bridges: Chris R Hendymicael_89100% (1)

- D3377-04 (2013) Standard Test Method For Weight Loss of Solventless VarnishesDocument3 paginiD3377-04 (2013) Standard Test Method For Weight Loss of Solventless Varnishesjose floresÎncă nu există evaluări

- GMK4115Document28 paginiGMK4115SeksiÎncă nu există evaluări

- CortadorDocument7 paginiCortadorMarco DiazÎncă nu există evaluări

- General Information - Diagnostic Trouble Code (DTC) Indexdtc: Auxiliary Heater Control Module (Ahcm)Document6 paginiGeneral Information - Diagnostic Trouble Code (DTC) Indexdtc: Auxiliary Heater Control Module (Ahcm)Jim LiebÎncă nu există evaluări

- Unol 6Document1 paginăUnol 6mhaeducationÎncă nu există evaluări

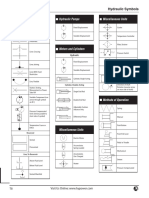

- Fluid Power Symbols PDFDocument4 paginiFluid Power Symbols PDFsanisah1245100% (1)

- SEO-91SEO001PO/002PO-OM-C-18/04/2011Document81 paginiSEO-91SEO001PO/002PO-OM-C-18/04/2011ibrahim100% (1)

- TDS - MBrace LaminatesDocument2 paginiTDS - MBrace LaminatesVenkata RaoÎncă nu există evaluări

- Mohanty ThesisDocument231 paginiMohanty ThesisbaloochybÎncă nu există evaluări

- Q.15. Derive Expression For Ratio of Tension On Tight Side and Slack SideDocument8 paginiQ.15. Derive Expression For Ratio of Tension On Tight Side and Slack SideVishal RajÎncă nu există evaluări

- Architectural Woodwork Specification GuideDocument8 paginiArchitectural Woodwork Specification GuideRonnell RepilÎncă nu există evaluări

- Honda's Secret MotoGP Transmission Revealed - Sport Rider Magazine - MobileDocument2 paginiHonda's Secret MotoGP Transmission Revealed - Sport Rider Magazine - Mobilelusso9567Încă nu există evaluări

- Hexion Starting Formulation 8014Document4 paginiHexion Starting Formulation 8014uzzy2Încă nu există evaluări

- 1 s2.0 S2351978919305803 MainDocument8 pagini1 s2.0 S2351978919305803 Mainjbasura69Încă nu există evaluări

- Harvel - Linha de Produtos em Vinis PVC e CPVCDocument126 paginiHarvel - Linha de Produtos em Vinis PVC e CPVCdanilobossuÎncă nu există evaluări

- Premium Water Treatment Solutions ManufacturerDocument6 paginiPremium Water Treatment Solutions ManufacturerUttaraHomesÎncă nu există evaluări

- NIIR List of DatabasesDocument61 paginiNIIR List of DatabasesRITESH RATHODÎncă nu există evaluări

- Curriculum For Hvac: Toll Free-1800-8333-999 (From Any Network)Document1 paginăCurriculum For Hvac: Toll Free-1800-8333-999 (From Any Network)iplusÎncă nu există evaluări