Documente Academic

Documente Profesional

Documente Cultură

Lathe Rest Movement Control

Încărcat de

asdfasfDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Lathe Rest Movement Control

Încărcat de

asdfasfDrepturi de autor:

Formate disponibile

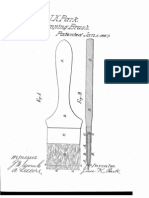

H. K. SMITH.

LATHE REST.

No. 60,950. Y.

Patented Jan. l, 1867.

me Noam: Farms co., wno?uurnn.. wAsHmGroN, o. c.

@einen tartes gaxttff?r.

...mk

HENRY K. SMITH, 0F N ORWICH, CONNECTICUT, ASSIGNOR TO HIMSELF AND CHARLES OSGOOD, CF THE SAME PLACE.

Letters Petentlio. 60,950, dated January 1, 1867.

IMPROVEMENT

LATE-RESTS.

v dite tlnhule refont. tu im that tetters @stent mit mating tart nf tigt smut.

TO .ALL WHOM IT MAY CONCERN: Be it known that I, HENRY K. SMITH, of Norwich, in the county of New London, and State of Connecticut,

have invented a new and useful Improvement in Rests for Turning-Lathes; and I do >hereby declare that the ` following is a full, clear, and exact description thereof, which will enable others skilled in the art to vmake and

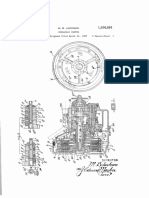

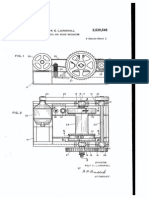

use the same, reference being had to the accompanying drawings, forming'part 'of this specification, in which-Figure 1 is a plan 'or top view of the lathe-rest, showing the rails 'upon which it moves or slides- in red. Figure 2, a central transverse vertical section through the rest and the bed-piece of the lathe upon which

it nieves, with the latter in red. n .

Figure 3, a vertical section taken in the plane of the linexsc, iig..1,'which section line extends in thedirection of the width of thc rest. '

Figure 4, a horizontal section taken in the plane of the line y y, iig. 3.

Figure 5, an elevation of the inner end of the rest with its upper portion in vertical sectionr

Figures 6 and 7, detail views.

Similar letters of reference indicate like parts. . _

The present invention consists, rst, in a novel arrangement of gearing whereby the movement of the rest

can be changed in direction at pleasure, that is, made to move either toward the right or left on the lathegand, second, in a novel manner of constructing the rest whereby it can be raised andlowered according as may he

desired. I I

A in'the drawings represents the framework of the rest, consisting of a. box-portion, B, tothe top or upper side of which is secured a- T-shaped frame, C, extending in a horizontal plane <therefrom andl in a. directionat

right angles thereto. rThis box~portion B comes upon the front side of the lathe, when the rest framework, by

its T-shaped frame C, is laid or placed upon the parallel pright bars or rails, D, of the lathe-bed, u-'s plainly shown in the drawings, iig. 2.`v E,.a pinion-wheel at one end of ' a hollowl sleevefor shaft F, arranged-"toturn Aupon a xed centre horizontal shaft of the front plate, J, of the box-portionlB, which pinon~wheel is in proper position for engaging with the toothed rack-bar kupon the under side of the Hauch L, atthe-upper . end of 'the front rail or bur, D, of the lathefbed, _this rack-bar 7c in the drawings being shown in red. To this hollow shaft F, hereinabove >referred to, a gear-wheel, N, is secured, with whichinterloqksor meshes a pinion-wheel, O, secured to' the inner end of a spindle, P, that, projecting beyond the front plate- J ofv the box B, has a handle, Q, there

secured to it for convenience 'in turning it. This gear~wheel upon one side inter-locks or meshes with a gear

wheel, R, which is one of a series of' gears, R, S, and T,'constituting or forming a part ofthe friction-clutch U. The construction and arrangement of the various parts composing thel clutchU are the same as that described in the schedule annexed to the Letters Patent 'granted to me on the 5th day of`December,;A. D. 1865, and there

fore needs no particular description herein, the gears R and T being the loose gears of the clutch, which, by' .the~ screwing in or out of the centreconieal-shaped spindle, V, thereof, are thrown' into or out of connection

with the other or intermediate gear S. _ With the centre gear S of the clutch U a gear-wheel, W, engages, form ing a connection between such clutchnd the centre gear-wheel, Y, of another clutch, X, of a similar const-ruc tion and arrangement of parts. With each ofthe outside or loose gear-wheels Z Z of the clutchV X similarvworm'

gears, upon its A?, inside, are engaged, and are both interlocked of which or are-hung connected and together turn in through suitable a bearings similar pinion-wheel of the frontBlof plateeach of worm-gear. the box

Through one of the worm-gears', A, a shaft, C, extends, that, in the direction of its length, is grooved, and by a key-pin upon the inside of the worm-gear isconnectedwith the same,so that' as'the'saidshaft is revolved the said worm-gear A2 will be revolved with it, while at the _same time tlie'rsaid'lgear A? can -freely> slide forward and

backward upon the same. ' The friction-clutchX hereinabove referred to is'operated by turning its centre conical

shaped spindle, having a milled head Dz, in the- proper direction tozthrow either one or the other of the loose gears,`Z, of such clutch- into> connection with its centre'gear-wheel, Y." /The shaft C3 is connected with theA run ning gearing or driving power of the lathe, and by its revolution, according as either one or the other of the

loose and outside gear-wheels,-Z, of the frictiomclutch X is.~in connection with the centre g/oamvhecbY of the same, (with the connection through the loose gear-wheel R of the dlutch U and gearnrheehN establishcfh) thc

cow,

lathe-rest will be made to travel either toward thc right or left upon the lathe-bed, as the crise may be,- and at

my time may be changed by properly operating the spindle of the clutch X to throw either oneor the other of

the loose gear-wheels Z oi' the clutch X into connect-ion with the centrewheel Y of such clutch, as is> obvious without any further explanation. To the upper side of the T-shnpcd frame C a frame, A3, corresponding in general shape to that of the frame C, is arranged, as will be now described. This frame is made in two parts or sections, C3 and D3, placed one upon the other, with the upper, C, hung' to the lower at its front end, as .shown at i33 in the drawings, and the' lower one, D, arranged iso-slide upon dove-tail tenen strips, F3, of the

'upper side of the frame C. . In the upper side of the upper section of the frame', A3, a right-angular -r-shapedv way or groove G is made, in which is to be arranged the tool-rest of the lathe. Hf, a thumb-screw, screwing

-into and through a.-nut,I3, divided into two equal parts or sections in 'one direction, and in the other direction

suspended upon centre screws, J3, screwed into the tail portion of the upper section of the frame B3 from each 'side of the same. The lower end, Kfof the thumb-screw is formedoi' a doubletruncated conical shape, 'with

'the smaller bases' together, and turns by such ond >loosely in a nut, I", divided and hung to the lcwersection, D2'

of the frame B3 in a similar manner to .thatabove explained for the nut I. By means of the thumb-screw H3, 'in connection with the nuts Is and L3, it' is plain to be seen -that the upper section, G5', of the frame Bacan be .more or less inclined with regard to the lower section, D, according as may be found necessary inA the use of the ,tool-rest to present the tool to its work, the dividing of the nuts and the swivelling of them in the

'frame A3, as hereinabove described, obviating all strain upon the thumb-screw, and also enabling the wearing

.away of the parts to be compensated for by simply setting up the centre screws, J3, properly therefor. M3, a l

screw-shaft, screwing into and through a. lug, N3,upon- the under side of the lower section, D3, of the _frame B3,

extending loosely through the top of the boioportion B of the lathe-rest frame. O3, a handle on outer end 'ofscrewf

shaft M3 for convenience in turning it. By turning the-said screw-shaft N3 the frame Bais made to move either

'forward-or backward upon the main frame A, according to the direction in which the screw-shaft M3 is turned. On this screw-shaft M3 is a pinion-wheel, Pi', that engages with the loose geabwheel T of the friction-clutch U, l by means of which, when the said gear-wheel fl is in connection with the_iixed wheel S of said clutch, the forward and backward movement or cross-feed oi' the tool-rest frame can be accomplished thronghthe revolution -of the slotted shaft C2, as is obvious without any further explanation. For .tho purpose of chasing screw threads the vback or inner end of the lathe-rest 'frame is secured t'o and moves upon a horizontal screw-shaft, Q,

extending in the direction of the length of the lathe-bed by means of a. screw-threaded nut or sleeve, R5, divided

.in the ldirection of its length into two equal parts, both of which are arranged to slide by their _arms,-- S3, upon

the downward projecting piece T? of the lathe-rest, so as to open from or close upon each other; the two parts

of the nut R3, when closed `upon ,each other, 'embracing the said screw~shaft Q3 hereinbefore referred to, thereby placing the rest or carriage under. control of said screw-shaft, which in turn is connected to the turn ing gear lof the lathe inthe usual and well-known manner. The two parts of the nut R3 are both operated by turning a. shaft or spindle U3,_having a. handle, V3, which spindle is provided with two cams or eece?trics W3, (one for each part of the said nnt,) so attached to the same as .-tp move -one part of the nut upward, whilethe

other part moves downward, this arrangement of parts being _plainly and distinctly 'shown in iig., 2 of the

drawings. _ '

What I claim as 'i w, and desire to secure by Letters Patent, is--

1. The combination of the friction-clutch X, or its equivalent, .with the worm-gears A, connected v together

by pinion-wheels B2, slotted shaft C2, and intermediate gear-wheels' W, R, N, and E, with. the Vlatter engaging

with the toothed or geared rack-bar K of the lathe-bed, when all combined and arrangedftogcther so as to

oper-utc substantially in~the manner and for the purpose' described. l A

2. In combination with the above, the friction-clutch U, or its equivalent, connected through its loose gear wheel T with the pinion-wheel. P3 of a screw-shaft, MS, screwing into'and'throilghthe lug Na of -the sliding lathe

rest frame A3, substantially asidescribed for the purpose speciied.

3. The -combination of the divided nuts I3, L3, and thumb-screw, H3, with thetwo sections G3 and D3 of the' ' tool~rest frame A?, substantially as and for the purpose described. __

' HENRY K. SMITH.

Witnesses:

Gino. L. CLARK,

F. -IA.. SMITH.

S-ar putea să vă placă și

- Patented Jan. 1, I867 V: Z. SperryDocument3 paginiPatented Jan. 1, I867 V: Z. SperryasdfasfÎncă nu există evaluări

- Us 61009Document4 paginiUs 61009asdfasfÎncă nu există evaluări

- Us1446763 PDFDocument7 paginiUs1446763 PDFJin SongÎncă nu există evaluări

- Patented Oct, 17, 1882, No. 265,987,: G. S. ShieffieldDocument3 paginiPatented Oct, 17, 1882, No. 265,987,: G. S. ShieffieldJorge MosqueraÎncă nu există evaluări

- Us1866891 PDFDocument8 paginiUs1866891 PDFbelchior alvaroÎncă nu există evaluări

- Anti-Aircraft Fire Control Device (1937)Document10 paginiAnti-Aircraft Fire Control Device (1937)CAP History LibraryÎncă nu există evaluări

- U.S. Patent 652,520, Entitled Capotasto To Inventor T.M. Pletcher, Dated June 26, 1900.Document3 paginiU.S. Patent 652,520, Entitled Capotasto To Inventor T.M. Pletcher, Dated June 26, 1900.Anonymous a7S1qyXÎncă nu există evaluări

- Improved Machine for Making Tin CansDocument2 paginiImproved Machine for Making Tin CansasdfasfÎncă nu există evaluări

- Dec. 1, 1953 J. H. Allen: Filed Oct. 11, 1951Document8 paginiDec. 1, 1953 J. H. Allen: Filed Oct. 11, 1951Rezicky ImamÎncă nu există evaluări

- A Single ShontgunDocument3 paginiA Single ShontgunyuehanÎncă nu există evaluări

- Wollensak v. Reiher, 115 U.S. 96 (1885)Document6 paginiWollensak v. Reiher, 115 U.S. 96 (1885)Scribd Government DocsÎncă nu există evaluări

- No. 60,993. ' Patented Jan. 8, 1867.: F. Bru ADocument2 paginiNo. 60,993. ' Patented Jan. 8, 1867.: F. Bru AasdfasfÎncă nu există evaluări

- Variable-Speed Gearing Patent from 1901Document4 paginiVariable-Speed Gearing Patent from 1901belchior alvaroÎncă nu există evaluări

- Engineering Vol 69 1900-04-06Document35 paginiEngineering Vol 69 1900-04-06ian_new100% (1)

- L'il Wu" MM: Jan. 30, 1951 R, E - Ljungkull 2,539,545Document12 paginiL'il Wu" MM: Jan. 30, 1951 R, E - Ljungkull 2,539,545lfilippiniÎncă nu există evaluări

- H.M. Sprague's Folding Pistol Patent from 1912Document4 paginiH.M. Sprague's Folding Pistol Patent from 1912djsfÎncă nu există evaluări

- Post 6 38604 Reifgraber AutoDocument14 paginiPost 6 38604 Reifgraber AutoAoolf ManÎncă nu există evaluări

- Us2765819 PDFDocument8 paginiUs2765819 PDFAzri LunduÎncă nu există evaluări

- Feb. 4, 1941. E. T. Shaw 2,230,338: (3N 77. E. % 2 N% Ee3Document7 paginiFeb. 4, 1941. E. T. Shaw 2,230,338: (3N 77. E. % 2 N% Ee3ValBMSÎncă nu există evaluări

- Witnesses:: No. 628,142. @muted .My 4, - 899Document2 paginiWitnesses:: No. 628,142. @muted .My 4, - 899dgfsduuwioÎncă nu există evaluări

- Single screw actuated pivoted clampDocument2 paginiSingle screw actuated pivoted clampdevheadbot100% (1)

- US97821Document7 paginiUS97821ReggieÎncă nu există evaluări

- Howe MacHine Co. v. National Needle Co., 134 U.S. 388 (1890)Document8 paginiHowe MacHine Co. v. National Needle Co., 134 U.S. 388 (1890)Scribd Government DocsÎncă nu există evaluări

- Braiding MachineDocument7 paginiBraiding Machinejojaberi100% (1)

- ?. 22/22. Sering-?zc?ize.: XY2 ZA230 Pa?enie? 322/2 /346Document6 pagini?. 22/22. Sering-?zc?ize.: XY2 ZA230 Pa?enie? 322/2 /346Missy MaynardÎncă nu există evaluări

- Tel - Escope Mounting FDR Guns.: N0. 69 - , 248. V ' Patented Lan. I4, - 902Document4 paginiTel - Escope Mounting FDR Guns.: N0. 69 - , 248. V ' Patented Lan. I4, - 902Radim KadlecÎncă nu există evaluări

- Making Eyelets MachineDocument3 paginiMaking Eyelets MachineasdfasfÎncă nu există evaluări

- No. 748,348. PATENTED DEC. 29, 1903. Rotary'Fluid Engine.: J. F. GooleyDocument4 paginiNo. 748,348. PATENTED DEC. 29, 1903. Rotary'Fluid Engine.: J. F. Gooleymonem2014Încă nu există evaluări

- Us965386 PDFDocument6 paginiUs965386 PDFJin SongÎncă nu există evaluări

- Cash Reg. Co. v. Cash Indicator Co., 156 U.S. 502 (1895)Document13 paginiCash Reg. Co. v. Cash Indicator Co., 156 U.S. 502 (1895)Scribd Government DocsÎncă nu există evaluări

- Benet Mercie BreechDocument13 paginiBenet Mercie BreechAnonymous htRZ5zTMgÎncă nu există evaluări

- USD12839Document2 paginiUSD12839nmfzkwy2rÎncă nu există evaluări

- Torrent Arms Lumber Co. v. Rodgers, 112 U.S. 659 (1885)Document7 paginiTorrent Arms Lumber Co. v. Rodgers, 112 U.S. 659 (1885)Scribd Government DocsÎncă nu există evaluări

- US22753Document4 paginiUS22753vadimÎncă nu există evaluări

- Us1955360 PDFDocument8 paginiUs1955360 PDFRodrigoPomaÎncă nu există evaluări

- @341 A É'Wqkammm: Filed July 28-, 1944Document3 pagini@341 A É'Wqkammm: Filed July 28-, 1944devheadbotÎncă nu există evaluări

- M © JG) - B) John Garlic/9r.: Sept-3, 1959 J. Gallo, SR 2,902,815Document3 paginiM © JG) - B) John Garlic/9r.: Sept-3, 1959 J. Gallo, SR 2,902,815James LindonÎncă nu există evaluări

- Efficient loom let-off mechanism for maintaining even warp tensionDocument6 paginiEfficient loom let-off mechanism for maintaining even warp tensionDavictorÎncă nu există evaluări

- U.S. Patent 338,727, Entitled Guitar, Issued 1886.Document6 paginiU.S. Patent 338,727, Entitled Guitar, Issued 1886.Anonymous a7S1qyXÎncă nu există evaluări

- Siley ERS) .: No. 385,875, Patented July 10, 1888Document6 paginiSiley ERS) .: No. 385,875, Patented July 10, 1888Слэйтер Строительная компанияÎncă nu există evaluări

- USRX52Document3 paginiUSRX52nmfzkwy2rÎncă nu există evaluări

- (Patente 1) US1489458Document3 pagini(Patente 1) US1489458diegoÎncă nu există evaluări

- Pistol Nickl Us1427966Document11 paginiPistol Nickl Us1427966cll1968Încă nu există evaluări

- Us1517483 PDFDocument10 paginiUs1517483 PDFJin SongÎncă nu există evaluări

- Union Metallic Cartridge Co. v. United States Cartridge Co., 112 U.S. 624 (1884)Document16 paginiUnion Metallic Cartridge Co. v. United States Cartridge Co., 112 U.S. 624 (1884)Scribd Government DocsÎncă nu există evaluări

- June 24, 1969 R, Manterhelq 3,451,532: Med March 28, 1967 ', Sheet I OfaDocument5 paginiJune 24, 1969 R, Manterhelq 3,451,532: Med March 28, 1967 ', Sheet I OfabakkaÎncă nu există evaluări

- Hamilton Rifle ConstructionDocument5 paginiHamilton Rifle Constructionposchul2003Încă nu există evaluări

- July 8, 1924. 1,500,672: Y 7%Ale/Éa-Ac6-ÉzazaDocument3 paginiJuly 8, 1924. 1,500,672: Y 7%Ale/Éa-Ac6-Ézazakkd108Încă nu există evaluări

- 970,603. ' Patented Sept. 20, 1910.:, Winding Key Fob CamerasDocument4 pagini970,603. ' Patented Sept. 20, 1910.:, Winding Key Fob CamerasAndrei PoseaÎncă nu există evaluări

- No. 543,661. Patented July 30, 1895.: W. A. StowellDocument3 paginiNo. 543,661. Patented July 30, 1895.: W. A. StowellAlan PradanaÎncă nu există evaluări

- Hydraulically controlled tire changing machine patentDocument9 paginiHydraulically controlled tire changing machine patentMURALIPRAKASH.S 18BIT131100% (1)

- Data Originating From Sources Other Than The EPO May Not Be Accurate, Complete, or Up To DateDocument3 paginiData Originating From Sources Other Than The EPO May Not Be Accurate, Complete, or Up To DateJaymar ManualÎncă nu există evaluări

- Engineering Vol 72 1901-11-29Document31 paginiEngineering Vol 72 1901-11-29ian_newÎncă nu există evaluări

- No. 495,741. Patenfßd Apr. 1x8, 1893.: B'RBBGH Bolt For FirbarmsDocument3 paginiNo. 495,741. Patenfßd Apr. 1x8, 1893.: B'RBBGH Bolt For Firbarmscll1968Încă nu există evaluări

- SSntanv Engine.,: No. 630,648. - Pamnfed Aug.-A, - 899Document7 paginiSSntanv Engine.,: No. 630,648. - Pamnfed Aug.-A, - 899monem2014100% (1)

- Us 4207797Document7 paginiUs 4207797fghdfjerÎncă nu există evaluări

- 507 Mechanical Movements: Mechanisms and DevicesDe la Everand507 Mechanical Movements: Mechanisms and DevicesEvaluare: 4 din 5 stele4/5 (28)

- Scientific American Supplement, No. 441, June 14, 1884.De la EverandScientific American Supplement, No. 441, June 14, 1884.Încă nu există evaluări

- Clock Cleaning and Repairing - With a Chapter on Adding Quarter-Chimes to a Grandfather ClockDe la EverandClock Cleaning and Repairing - With a Chapter on Adding Quarter-Chimes to a Grandfather ClockEvaluare: 5 din 5 stele5/5 (1)

- GunshotDocument2 paginiGunshotasdfasfÎncă nu există evaluări

- US60942 PageDocument1 paginăUS60942 PageasdfasfÎncă nu există evaluări

- Socket Programing GuideDocument101 paginiSocket Programing GuideAnurag AggarwalÎncă nu există evaluări

- Us 60954Document2 paginiUs 60954asdfasfÎncă nu există evaluări

- 01V96 ManualDocument334 pagini01V96 ManualDario Luna Popunjeni ProfilÎncă nu există evaluări

- US60932 Page 1Document1 paginăUS60932 Page 1asdfasfÎncă nu există evaluări

- Us 60951Document2 paginiUs 60951asdfasfÎncă nu există evaluări

- Us 60953Document3 paginiUs 60953asdfasfÎncă nu există evaluări

- Us 60941Document2 paginiUs 60941asdfasfÎncă nu există evaluări

- @értitrh .. Tstrs Gaunt @ffirn.: Amor Smith, 0F Cincinnati, OhioDocument1 pagină@értitrh .. Tstrs Gaunt @ffirn.: Amor Smith, 0F Cincinnati, OhioasdfasfÎncă nu există evaluări

- Gems "Tetra GM": Ffinr.: John '1 . Sohenck, JR, or ' Matteawan, New YorkDocument1 paginăGems "Tetra GM": Ffinr.: John '1 . Sohenck, JR, or ' Matteawan, New YorkasdfasfÎncă nu există evaluări

- Us 60945Document2 paginiUs 60945asdfasfÎncă nu există evaluări

- Us 60946Document2 paginiUs 60946asdfasfÎncă nu există evaluări

- Us 60947Document2 paginiUs 60947asdfasfÎncă nu există evaluări

- F. F. Reynolds.: No. 60,938. ' Patented Jan. Ì, - 867Document2 paginiF. F. Reynolds.: No. 60,938. ' Patented Jan. Ì, - 867asdfasfÎncă nu există evaluări

- Improved Sheepskin Mitten ConstructionDocument3 paginiImproved Sheepskin Mitten ConstructionasdfasfÎncă nu există evaluări

- N. Puckett. - : Centering ToolDocument2 paginiN. Puckett. - : Centering ToolasdfasfÎncă nu există evaluări

- Us 60933Document2 paginiUs 60933asdfasfÎncă nu există evaluări

- Us 60943Document2 paginiUs 60943asdfasfÎncă nu există evaluări

- Chemical Preservation of Butter and MeatsDocument1 paginăChemical Preservation of Butter and MeatsasdfasfÎncă nu există evaluări

- Instant railroad car brake from 1867 patentDocument2 paginiInstant railroad car brake from 1867 patentasdfasfÎncă nu există evaluări

- Refrigerator.: 2 Sheets Sheet 1.' C. F. Pike"Document5 paginiRefrigerator.: 2 Sheets Sheet 1.' C. F. Pike"asdfasfÎncă nu există evaluări

- Making Eyelets MachineDocument3 paginiMaking Eyelets MachineasdfasfÎncă nu există evaluări

- Us 60935Document2 paginiUs 60935asdfasfÎncă nu există evaluări

- Nitrii Tetra Gaunt Ffirr.: Adolphe Roque, of Brire, France, Assignor To Jacques Guedin, ofDocument1 paginăNitrii Tetra Gaunt Ffirr.: Adolphe Roque, of Brire, France, Assignor To Jacques Guedin, ofasdfasfÎncă nu există evaluări

- No. 60,932. - Patented Jan: 1, "1867.: S. J . PEETDocument2 paginiNo. 60,932. - Patented Jan: 1, "1867.: S. J . PEETasdfasfÎncă nu există evaluări

- Us 60959Document2 paginiUs 60959asdfasfÎncă nu există evaluări

- Us 60931Document2 paginiUs 60931asdfasfÎncă nu există evaluări

- Experimental stress analysis improves gondola wagon designDocument2 paginiExperimental stress analysis improves gondola wagon designrentizahariaÎncă nu există evaluări

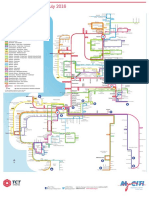

- 697 System MapDocument1 pagină697 System Mapanon_b186Încă nu există evaluări

- Clapham Junction Case Study - Safety ImportanceDocument18 paginiClapham Junction Case Study - Safety Importancebhagirath61Încă nu există evaluări

- Signal Reverser For Railway SignalingDocument23 paginiSignal Reverser For Railway SignalingVikas Srivastav100% (1)

- IQPC OmanDocument7 paginiIQPC OmanAshish LoyaÎncă nu există evaluări

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Document2 paginiIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Abhishek MishraÎncă nu există evaluări

- All Lines TimetableDocument17 paginiAll Lines TimetableAnthony WilcherÎncă nu există evaluări

- TMPC 111Document6 paginiTMPC 111MARITONI MEDALLA100% (1)

- Bar Hill Cambridge MapDocument1 paginăBar Hill Cambridge Maphalosunyrtimr6Încă nu există evaluări

- Curitiba's Bus System Is Model For Rapid TransitDocument3 paginiCuritiba's Bus System Is Model For Rapid TransitPlanting JusticeÎncă nu există evaluări

- Telangana Current Affairs 2019 by AffairsCloudDocument22 paginiTelangana Current Affairs 2019 by AffairsCloudSoumyasri MeruguÎncă nu există evaluări

- Urban Transportation ProblemsDocument10 paginiUrban Transportation ProblemsJoshuaÎncă nu există evaluări

- Maryland USA (In English)Document175 paginiMaryland USA (In English)DreamsAvenue.comÎncă nu există evaluări

- Katalog Ggu Leega Razdel 13 G-02Document8 paginiKatalog Ggu Leega Razdel 13 G-02JoseLuisAramayoÎncă nu există evaluări

- Regional Transportation for Raipur, Bhilai & DurgDocument25 paginiRegional Transportation for Raipur, Bhilai & DurghimanshusonberÎncă nu există evaluări

- Eight Wagon Design IR EDWagonDocument24 paginiEight Wagon Design IR EDWagonVeeru KumarÎncă nu există evaluări

- Bridge Engineering Presentation (General)Document69 paginiBridge Engineering Presentation (General)yyanan1118Încă nu există evaluări

- Alexander Purves The Persistence of Formal PatternsDocument27 paginiAlexander Purves The Persistence of Formal PatternsDanicaGanÎncă nu există evaluări

- Train ScheduleDocument3 paginiTrain ScheduleSiby ThomasÎncă nu există evaluări

- Datasheet M Relays V2.4Document16 paginiDatasheet M Relays V2.4Insan AzizÎncă nu există evaluări

- Consumer Perception Towards Thomas CookDocument93 paginiConsumer Perception Towards Thomas CookHarsh parasher (PGDM 17-19)Încă nu există evaluări

- Steel Weight Chart: Comprehensive Guide to Metal Sizes and WeightsDocument6 paginiSteel Weight Chart: Comprehensive Guide to Metal Sizes and WeightsNitin LendeÎncă nu există evaluări

- BNSF Crew ChangeDocument1 paginăBNSF Crew ChangeEMDGP382Încă nu există evaluări

- IRSEM-Version3-June-2021 CBTC RAMS Indian RailwwaysDocument551 paginiIRSEM-Version3-June-2021 CBTC RAMS Indian RailwwaysCarlos FloresÎncă nu există evaluări

- Question No 1 Discuss Harbour Classification Based On Protection and Utility NeedsDocument15 paginiQuestion No 1 Discuss Harbour Classification Based On Protection and Utility NeedsWahaj KhanÎncă nu există evaluări

- A Study On Passenger Satisfaction of Kochi MetroDocument20 paginiA Study On Passenger Satisfaction of Kochi MetroV& A VENTURES 2017Încă nu există evaluări

- MastEr Plan BrasiLiaDocument12 paginiMastEr Plan BrasiLiaLiam PotterÎncă nu există evaluări

- DG 95 111-E 09-03 Priamos IIIDocument43 paginiDG 95 111-E 09-03 Priamos IIIalfredohdnÎncă nu există evaluări

- Ipss HandbookDocument45 paginiIpss HandbookSarbendu PaulÎncă nu există evaluări

- Prezentare Charles DickensDocument8 paginiPrezentare Charles DickensFlori Maria0% (1)