Documente Academic

Documente Profesional

Documente Cultură

Case

Încărcat de

dm1680Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Case

Încărcat de

dm1680Drepturi de autor:

Formate disponibile

CONSTRUCTION EQUIPMENT SERVICE TRAINING

1650K & 1850K SERIES CRAWLER TRACTORS

SECTION 5 UNDER CARRIAGE

(PRELIMINARY COPY) Form 5080

REV 01/2002

CASE CORPORATION 700 STATE STREET RACINE, WI 53404 U.S.A.

CASE CANADA CORPORATION 3350 SOUTH SERVICE ROAD BURLINGTON, ON L7N 3M6 CANADA

2000 Cas C!"#!"a$%!& A'' R%()$s R s "* + Printed in U.S.A.

TABLE OF CONTENTS

TABLE OF DEFINITIONS----------------------------------------------------------------------------------4 GENERAL INFORMATION---------------------------------------------------------------------------------5 UNDERCARRIAGE COMPONENTS-------------------------------------------------------------------------6 UNDERCARRIAGE WEAR LIMITS-----------------------------------------------------------------------22

UNDERCARRIAGE

OBJECTIVES

After completion of this section of the trainin man!al" the trainee #ill $e a$le to accomplish the follo#in %

&no# the location of the !ndercarria e dri'e components. &no# ho# the components f!nction.

&eep an e(e o!t for s(m$ols" #hich #ill alert (o! to special information.

Wait a Minute )his s(m$ol #ill preface a fre*!entl( as+ed *!estion. REMEMBER % )his s(m$ol #ill preface a tip that ma( ma+e (o!r ,o$ more efficient. IMPORTANT % )his s(m$ol #ill preface a tip that (o! sho!ld definitel( not i nore.

1650K & 1850K C !"#$

01%2002

5,3

UNDERCARRIAGE

TABLE OF DEFINITIONS

U&+ "-a""%a( C!.#!& &$s

SPECIFICATION

M!+ ' V "s%!& L%&/ P%$-) T"a-/ Ga0( D!01' 2'a& ( R!'' "

6 6 1 6 6

S%&(' 2'a& ( R!'' "s

6 6 6 6 6

1-50& 1850&

E.tra /on )rac+ /7P /on )rac+ E.tra /on )rac+ /7P

-.012 314- mm5 -.012 314- mm5 4.002 3202.0 mm5 4.002 3202.0 mm5 4.002 3202.0 mm5

452 31.00 m5 81.12 32.11 m5 452 31.00 m5 022 32.11 m5 022 32.11 m5

Se mented Sproc+ets /ife time l!$ricated $ottom rollers /ife time l!$ricated carrier rollers /ife time l!$ricated idlers rollers Sealed and l!$ricated trac+ chain #ith split master lin+

&650K & 1850K C !"#$

01%2002

5,4

UNDERCARRIAGE

GENERAL INFORMATION

)he information and specifications listed in this section are $ased aro!nd a 1850& cra#ler" the 1-50& cra#ler are 'er( similar. )o f!ll( !nderstand the !ndercarria e" it is important to !nderstand the p!rpose of each component. 8t is also 'er( important to +no# ho# that component f!nctions #ith the other components in the s(stem. R 3 " &- $) Cas 4U&+ "-a""%a( 20&+a. &$a's5 .a&0a' &0.1 " BUR 7,53670 3!" a++%$%!&a' 1a-/ ("!0&+ %&3!".a$%!&. 9ase 9orporation has the follo#in 'ideo tapes a'aila$le that are 'er( ed!cational on !ndercarria e operation" maintenance and #ear.

REMEMBER:

Ta# T%$' s

:

2!". N0.1 "

:

1650K & 1850K C !"#$

01%2002

5,5

UNDERCARRIAGE

UNDERCARRIAGE COMPONENTS

1 2 1 6

)rac+ Frame <ottom Rollers S!pport Rollers )ensioner =e'ice

5 4

8dler ;heel )rac+ 9hain =ri'e Sproc+et

&650K & 1850K C !"#$

01%2002

5,6

UNDERCARRIAGE

UNDERCARRIAGE COMPONENTS

T"a-/ 2"a. s, 89:

Each trac+ frame is composed of a frame made #ith material #ith hi h mechanical specifications fa$ricated #ith $o.ed section $ars. 8nside" f!ll( enclosed trac+ tensioner de'ices are mo!nted" protected from the entr( of loose materials. )he t#o frames are hin ed" at the $ac+" on the P8V>) S?AF)S" #hereas" in the front" the connection is pro'ided $( a s!spended cross@mem$er" hin ed centrall( and to the frame of the machine on the sides. )h!s" each trac+ frame is allo#ed to pi'ot independentl( from the other one. )he ali nment of the trac+ frames is pro'ided $( !ides" the position of #hich is ad,!sted $( shims. )he follo#in components are mo!nted on the trac+ frames% <ottom Rollers )rac+ 9hain S!pport Rollers 8dler And )rac+ )ensioner =e'ice.

T"a-/ 2"a. B!$$!. R!'' "s, 82: )he rollers are do!$le flan e and sin le flan e" made of special steel" heat treated to $etter #ithstand #ear and a$rasion. )hese rollers" mo!nted in the lo#er side of each trac+ frame" s!pport the mass of the machine. )he shafts t!rn on l!$ricated $!shes. Aetal 3lon @life5 seals pro'ide the sealin .

T"a-/ C)a%& S0##!"$ R!'' "s, 83:

)he s!pport rollers s!pport the !pper part of the trac+ chain. Each roller is sec!red" $( s!pports" to the trac+ frames. )he shafts t!rn on l!$ricated $!shin s and metal 3lon @life5 seals pro'ide the sealin .

1650K & 1850K C !"#$

01%2002

5,7

UNDERCARRIAGE

UNDERCARRIAGE COMPONENTS

T"a-/ C)a%& T &s%!& " D *%- , 84:

)he trac+ tensioner de'ice pro'ides a d!al f!nction% +eep the trac+ chain tensionB a$sor$ the stress transferred $( the idler. )he trac+ chain tension is pro'ided $( a h(dra!lic de'ice" made of a c(linder and a piston connected to the idler (o+e $( a rod. )o stretch a trac+ chain" rease is p!mped inside the c(linder. )his ca!ses a for#ard mo'ement of the piston and the idler" connected to it. Please note that the sprin is normall( compressed" $!t it does not act!ate its action a ainst the trac+ chain.

I+' ", 85:

)he idler" of a sprin t(pe" located in the front side of each trac+ frame" is connected to the trac+ chain tensioner h(dra!lic de'ice $( a (o+e and a rod a ainst the ad,!stin c(linder piston. )he tensioner effort and the a$sorption of shoc+s recei'ed $( the trac+ chain #hile #or+in are transferred thro! h this s(stem. For this reason" the idler is not ri idl( connected to the trac+ frame $od(" $!t it is allo#ed to slide on !ides" #hich m!st $e properl( ali ned $( ad,!stin shims. )he shafts t!rn on l!$ricated $!shin s. Aetal 3lon @life5 seals pro'ide the sealin .

&650K & 1850K C !"#$

01%2002

5,6

UNDERCARRIAGE

UNDERCARRIAGE COMPONENTS

T"a-/ -)a%&, 86:

)he trac+ chain is essentiall(" made of% Pins /in+s <!shes Shoes

Pins and $!shes are the components of the trac+ chain most s!$,ect to #ear. )he s(mptoms characteriCin the #ear of pins and $!shes are #ear of the sides of the lin+s" fast #ear of the sproc+et teeth and e.cessi'e sa in of the trac+ chains. Shoes are sin le ri$$ed. )he ri$$in " $esides pro'idin traction" contri$!te to reinforcin the shoe. ;orn shoes" $esides facilitatin the slippin of the trac+ chains" are more easil( deformed. )he trac+ chain is permanentl( l!$ricated and the #ear $et#een pin and $!sh is reatl( red!ced. 8n fact" each pin 315 has an a.ial hole 325 and t#o radial holes 315 perpendic!lar to the first one" pro'idin a constant and contin!os l!$rication. )he mo'ement $et#een pin and $!sh" ens!res the distri$!tion of l!$ricant o'er all the contact s!rfaces. Seals 365 pro'ide the sealin " a'oidin the entr( of forei n materials and +eepin the l!$ricant. R!$$er pl! 325 allo#s the fillin #ith oil and pro'ides sealin . NOTE , O& '01"%-a$ + $"a-/ -)a%&, %$ %s " -!.. &+ + $! $0"& #%&s a&+ 10s) s, as ; ''. Fi .2 @ Permanent l!$rication 3SA/)5 trac+ chains 1. Pin #ith l!$e oil reser'e drillin 2. R!$$er pl! 1. Radial l!$e drillin s 6. Seal 5. )hr!st rin -. <!shin 4. /in+ 8. Pin

T!!$) + S (. &$ I+' ", 87:

)he idler transfers" directl(" to the trac+ chain the rotation recei'ed from the final dri'e. )he sproc+et is mo!nted on the final dri'e o!tp!t shaft. )here are nine toothed se ment $olted to the h!$" th!s the( are indi'id!all( replacea$le. )he profile of the teeth is of a self@cleanin t(pe. )he toothed se ments can $e replaced #itho!t remo'in the chains.

1650K & 1850K C !"#$

01%2002

5,7

UNDERCARRIAGE

UNDERCARRIAGE COMPONENTS

Each trac+ frame is composed of a frame made #ith material #ith hi h metal specifications. Fa$ricated #ith $o. section to f!ll( enclosed trac+ recoil sprin s" protected from the entr( of loose materials. All of the rac+ components e.cept the dri'e sproc+et are attached to the trac+ frames.

R a" 2"a. P%*!$s

)he trac+ frame is hin ed at the rear on a pi'ot shaft that transmits the ma,orit( of the forces into the rear ho!sin " the finial dri'e helps to s!pport the mo!ntin shaft. )he mo!ntin shaft is !nder c!t $et#een $!shin s to facilitate shaft remo'al. )he shaft is +ept from rotatin $( one of the mo!ntin $olts. Each frame 3ri ht or left side5 ma( pi'ot independentl( from each other.

T"a-/ 2"a.

1. Rear Frame S!pport 2. Pin

&650K & 1850K C !"#$

01%2002

5,90

UNDERCARRIAGE

UNDERCARRIAGE COMPONENTS

2"!&$ 2"a. P%*!$s

)he trac+ frame front connection is pro'ided $( a s!spended cross@mem$er" hin ed centrall( and to each trac+ frame. Phenol $!shin " hin e pins and trac+s are ali ned #ith shim at the pi'ot shaft.

1650K & 1850K C !"#$

01%2002

5,99

UNDERCARRIAGE

UNDERCARRIAGE COMPONENTS

L!; " T"a-/ R!'' "

)he trac+ rollers are life time l!$ricated and are mo!nted to the $ottom of the trac+ frame. )he rollers carr( the #ei ht of the cra#ler on the trac+ chain. Sealers are metal face seals and m!st $e free of an( fin er prints or d!st #hen assem$led.

V "s%!&

/on )rac+ E.tra /on )rac+ /7P

ROLLERS USED 9650<

8 D 6SF and 6=F 8 D 6SF and 6=F

9650<

4 D 6SF and 1=F 8 D 6SF and 6=F 8 D 6SF and 6=F

S# -%3%-a$%!& SPECI2ICATION

8tem Sin le Flan e =o!$le Flan e /!$ricate SAE 10/60 ;) 0.40 oC 30.1- & 5 >!ter Flan e 0.-82 326- mm5 Race 8.242 3210 mm5 ;ei ht 111 l$. 351.25 & 5 125 l$ 35-.65 & 5 Shaft end pla( ;hen re$!ilt the seals sho!ld hold 20E61 PS8 of air press!re for a minim!m of 15 seconds #ith o!t a press!re drop.

1 2 1 6 5 4 8 0 10 11

>FRin Sin le Flan e Roller Front Seal <!shin Seal Shaft <!shin <!shin ?o!sin /!$e Shaft /!$e Pl! S!pport Roller =o!$le Flan e Roller Retainin <olts

&650K & 1850K C !"#$

01%2002

5,92

UNDERCARRIAGE

UNDERCARRIAGE COMPONENTS

T"a-/ Ca""% " R!'' "

)he trac+ carrier rollers are mo!nted on the top of the trac+ frame to s!pport the trac+ chain $et#een the dri'e sproc+et and the idler. )his roller also helps maintain ali nment of the chain $et#een the idler and dri'e sproc+et. )he roller is life time l!$ricated. Sealers are metal face seals and $e free of an( fin er prints or d!st #hen assem$led.

S# -%3%-a$%!& SPECI2ICATION

/!$ricate SAE 10/60 ;) 11 oC. 30.14 & 5 >!ter Flan e 8.52 321- mm5 Race 4.182 3184.5 mm5 ;ei ht 41.5 l$. 312.54 & 5 Shaft end pla( ;hen re$!ilt the seals sho!ld hold 20E61 PS8 of air press!re for a minim!m of 15 seconds #ith o!t a press!re drop.

1 2 1 6 5 4 8 0

/!$e Pl! 9o'er Seal )hr!st ;asher Roller <od( <earin s Elastic Rin Elastic Rin Shaft Seal Shaft

1650K & 1850K C !"#$

01%2002

5,93

UNDERCARRIAGE

&650K & 1850K C !"#$

01%2002

5,94

UNDERCARRIAGE

UNDERCARRIAGE COMPONENTS

T"a-/ T &s%!&%&(

)he trac+ tensionin s(stem !ses a rease filled h(dra!lic c(linder to maintain or ad,!st trac+ tension. )o chan e trac+ tension" add or release rease from the ad,!ster. A recoil sprin is !sed as a shoc+ a$sor$er that c!shions lar e impact loads or material $!ild !p in the trac+ chains. )rac+ tension sho!ld $e chec+ed dail(" and ma( re*!ire chec+in thro! h o!t the da( if #or+in in conditions that promote material $!ild !p.

Place a strai ht piece of stoc+ across the trac+ chain as sho#n at the left and meas!re the distance 3/5 $et#een the top of the pad and the $ottom of the strai ht ed e. )he distance sho!ld $e $et#een 1 G2 E 1 H2 310@60 mm5.

Vs

Press!re Relief Val'e

Vr

Press!re Release Val'e

7rease Fittin

1650K & 1850K C !"#$

01%2002

5,95

UNDERCARRIAGE

UNDERCARRIAGE COMPONENTS

P" ss0" R ' as Va'* 4I5 P" ss0" R '% 3 Va'* 4Vs5

T s$ 2%=$0" 3!" R '% 3 Va'* 4Vs5

1 2 1 6

R!$$er 9ap /oc+ I!t Sprin s <all

5 A

Val'e 9o'er 7rease Release 7ro'e )est )ool 45201541

< P Vs

)or*!e ;rench Fl!id ;ell Press!re Relief Val'e

&650K & 1850K C !"#$

01%2002

5,96

UNDERCARRIAGE

UNDERCARRIAGE COMPONENTS

8f the trac+ tension re*!ires ad,!stin " !se a standard rease !n to add rease to the tensionin c(linder thro! h fittin J82. 8f the trac+ is to ti ht d!e to material $!ild !p or o'er tensionin #ith rease" $ac+ o!t the press!re release 'al'e a co!ple of t!rns so that rease ma( escape thro! h the release ro'e 3-5. )he machine ma(

IMPORTANT: =o not remo'e the rease fittin . 8f the rease fittin is remo'ed or the press!re release 'al'e $ac+ed o!t too far $efore the press!re is released co!ld ca!se personal in,!ries. T s$%&( $) P" ss0" R ' as Va'*

=isassem$le all parts of the 'al'e and clean them from all traces of rease. Reassem$le the 'al'e and proceed as follo#s% sec!re tool 8A5 75279573 in a 'ice scre# 'al'e 3VS5 on the tool placin in $et#een the rele'ant >@Rin fill #ell 3P5 of the tool #ith asoline or alcohol act!ate tor*!e #rench 3<5 that the 'al'e m!st sta( closed" th!s the le'el of the li*!id inside #ell 3P5 m!st not chan e !ntil 'al!e JV12 > 64.24 to 50.50 ft l$s. 3-.61K -.8- daIm5 )he 'al'e sho!ld open and the #ell drain@ o!t #hen a tor*!e 'al!e 3V2 5D 50.50 to 56.21 ft l$s. 3-.8- E4.15 daIm5" is applied" e*!i'alent to a settin of 12"480 E 11600 PS8 3000 K 050 $ar5. S $$%&( 12480 to 11600 PS8 3000@050 $ar5 )o o$tain the settin 'al!e re*!ired" loosen loc+ n!t and rotate the end cap as re*!ired. )i hten loc+ n!t and fill !nit #ith rease. Reinstall the 'al'e on the c(linder and ti hten it to the prescri$ed tor*!e 3see chapt. 55.

1650K & 1850K C !"#$

01%2002

5,97

UNDERCARRIAGE

UNDERCARRIAGE COMPONENTS

I+' " W) '

)he idler carries the trac+ chain aro!nd the front of the trac+ frame. )he idler is life time l!$ricated. )his assem$l( can slide for#ard or rear#ard on the trac+ frame a ainst the recoil sprin to a$sor$ an( shoc+ loads. )hese shoc+ loads can $e from chan es in the terrain or temporar( material $!ild !p in the trac+ chains or sproc+ets. )he idler assists in +eepin the trac+ in ali nment #ith the trac+ frame. )he idler does not carr( the #ei ht of the machine as the $ottom rollers do.

1 2 1 6 5 S1 71 72

Front Seal 8dler ;heel 8dler S!pport <!shin s 8dler S!pport Pads Shims End 9learance 0.022 30.5mm5 Slide 9learance 0.022 30.5mm5

1 2 1 6

S!pport Shims 9o'er Plate 7!ide

&650K & 1850K C !"#$

01%2002

5,96

UNDERCARRIAGE

UNDERCARRIAGE COMPONENTS

D"%* S#"!-/ $

)he dri'e sproc+ets transmit en ine po#er to the trac+s. )he dri'e sproc+ets do not s!pport the #ei ht of the machine.

1 2 1 6

)oothed Sector <olt ?!$ Final =ri'e

1650K & 1850K C !"#$

01%2002

5,97

UNDERCARRIAGE

UNDERCARRIAGE COMPONENTS

T"a-/ C)a%&

A n!m$er of trac+ lin+s ma+e !p the trac+ chain assem$l(. Each lin+ assem$l( consists of a ri ht and left hand lin+" trac+ pin that is hollo#" $!shin s and l!$ricant.

S# -%3%-a$%!& SPECI2ICATION

Aaster /in+ )or*!e 221 ft. /$. Pl!s H t!rn =e rease the threads and appl( 261 /octite 7ro!ser Pad )or*!e 221 ft. l$. Pl!s 1/1 t!rn 9lean the threads and l!$ricated #ith en ine oil Each lin+ assem$l( is $ored at each end to hold the pins and $!shin s that connect the lin+s to ether. )he $!shin is pressed into each lin+. A pin is inserted thro! h the $!shin s and the ne.t set of lin+s is pressed into the pin. /in+ seals are assem$led into each lin+ so l!$ricatin oil can $e maintained in each ,oint. /!$ricatin oil is in,ected into each pin then a r!$$er pl! is p!shed into the pin to retain the l!$rication.

1 2 1 6 5 4 8

Pin" /!$e Reser'oir Pin Radial /!$e =rillin Seal )hr!st Rin <!shin /in+ R!$$er Pl!

&650K & 1850K C !"#$

01%2002

5,20

UNDERCARRIAGE

UNDERCARRIAGE COMPONENTS

Mas$ " L%&/

1 2 1

Aaster /in+ <olts Aaster /in+ 7ro!ser Pad 7ro!ser Pad <olts

1650K & 1850K C !"#$

01%2002

5,29

UNDERCARRIAGE

UNDERCARRIAGE WEAR LIMITS

I$ .

Pitch

M as0"%&( P"!- +0"

N!.%&a' D%. &s%!&s

11.042 3812 mm5

W a" L%.%$

/in+

5.062 3128 mm5

6.-12 3114 mm5

<ottom Roller

4.182F 3184.5 mm5

-.812 3141.5 mm5

S!pport Roller

8.242 3210 mm5

4.682 3100 mm5

<!shin s

2.842 341 mm5

2.-62 3-4 mm5

8dler

1.462 305 mm5

6.162 3105 mm5

0.402 320 mm5

1.082 324.5 mm5

7ro!sers

2.812 341.5 mm5

0.812 320.5 mm5

Sproc+et

0.112 38 mm5

&650K & 1850K C !"#$

01%2002

5,22

UNDERCARRIAGE

1650K & 1850K C !"#$

01%2002

5,23

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Simply Learn Hebrew! How To Lea - Gary Thaller PDFDocument472 paginiSimply Learn Hebrew! How To Lea - Gary Thaller PDFsuper_gir95% (22)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Pranayama Breathing ExcercizeDocument80 paginiPranayama Breathing Excercizedm1680100% (2)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Hamlet's Seven Soliloquies AnalyzedDocument3 paginiHamlet's Seven Soliloquies Analyzedaamir.saeedÎncă nu există evaluări

- Root Cause Failure Analysis Rev 2Document69 paginiRoot Cause Failure Analysis Rev 2clcoolleo100% (1)

- FS2 Learning Experience 1Document11 paginiFS2 Learning Experience 1Jona May BastidaÎncă nu există evaluări

- BVOP-Ultimate Guide Business Value Oriented Portfolio Management - Project Manager (BVOPM) PDFDocument58 paginiBVOP-Ultimate Guide Business Value Oriented Portfolio Management - Project Manager (BVOPM) PDFAlexandre Ayeh0% (1)

- Swedenborg's Formative Influences: Jewish Mysticism, Christian Cabala and PietismDocument9 paginiSwedenborg's Formative Influences: Jewish Mysticism, Christian Cabala and PietismPorfirio MoriÎncă nu există evaluări

- ! Sco Global Impex 25.06.20Document7 pagini! Sco Global Impex 25.06.20Houssam Eddine MimouneÎncă nu există evaluări

- Office of The Court Administrator v. de GuzmanDocument7 paginiOffice of The Court Administrator v. de GuzmanJon Joshua FalconeÎncă nu există evaluări

- Human Resource Development's Evaluation in Public ManagementDocument9 paginiHuman Resource Development's Evaluation in Public ManagementKelas KP LAN 2018Încă nu există evaluări

- CylinderDocument39 paginiCylinderapi-3854910100% (1)

- 201-Mhz RF Cavity Construction (Plan) For Mice: Derun Li Center For Beam Physics Lawrence Berkeley National LaboratoryDocument20 pagini201-Mhz RF Cavity Construction (Plan) For Mice: Derun Li Center For Beam Physics Lawrence Berkeley National Laboratorydm1680Încă nu există evaluări

- Mohrs CircleDocument76 paginiMohrs Circlersarunprasath0% (1)

- Quality Casting ManualDocument27 paginiQuality Casting ManualvisitabhinavÎncă nu există evaluări

- Knowledge Base: Joint DesignDocument7 paginiKnowledge Base: Joint Designdm1680Încă nu există evaluări

- Sec11 SilverBrazing WebDocument8 paginiSec11 SilverBrazing Webdm1680Încă nu există evaluări

- Silver Brazed Stainless Steel Cable: Presented byDocument26 paginiSilver Brazed Stainless Steel Cable: Presented bydm1680Încă nu există evaluări

- Welding, Cutting and Brazing: 29 CFR 1910.251 & 1926.350 Subpart Q & JDocument40 paginiWelding, Cutting and Brazing: 29 CFR 1910.251 & 1926.350 Subpart Q & JSudhakar VarmaÎncă nu există evaluări

- IE 337 W10 Lecture 3 Alloys&Heat - TreatDocument62 paginiIE 337 W10 Lecture 3 Alloys&Heat - Treatdm1680Încă nu există evaluări

- Superior Flux & Prince & Izant Co. Mfg. CoDocument15 paginiSuperior Flux & Prince & Izant Co. Mfg. Codm1680Încă nu există evaluări

- Design For Manufacture in Cost-Effective and Recyclable BrassDocument69 paginiDesign For Manufacture in Cost-Effective and Recyclable Brassdm1680Încă nu există evaluări

- Superior Flux & Mfg. CoDocument15 paginiSuperior Flux & Mfg. Codm1680Încă nu există evaluări

- Ultrasonic Machining ProcessDocument44 paginiUltrasonic Machining ProcessSaravanan KumarÎncă nu există evaluări

- Cast Iron Properties and Types in 40 CharactersDocument34 paginiCast Iron Properties and Types in 40 CharactersMKPashaPasha100% (1)

- The Loader Specialist: System 180Document8 paginiThe Loader Specialist: System 180dm1680Încă nu există evaluări

- AS 90tele: The Loader SpecialistDocument8 paginiAS 90tele: The Loader Specialistdm1680Încă nu există evaluări

- The Loader Specialist: System 180Document8 paginiThe Loader Specialist: System 180dm1680Încă nu există evaluări

- The Loader Specialist: System 180Document8 paginiThe Loader Specialist: System 180dm1680Încă nu există evaluări

- Mecalac Ahlmann As 210Document8 paginiMecalac Ahlmann As 210ForomaquinasÎncă nu există evaluări

- Af 60 eDocument8 paginiAf 60 edm1680Încă nu există evaluări

- Chemistry Sample Paper 2021-22Document16 paginiChemistry Sample Paper 2021-22sarthak MongaÎncă nu există evaluări

- Prep - VN: Where Did The Polo Family Come From?Document1 paginăPrep - VN: Where Did The Polo Family Come From?Phương LanÎncă nu există evaluări

- FOL Predicate LogicDocument23 paginiFOL Predicate LogicDaniel Bido RasaÎncă nu există evaluări

- Barnett Elizabeth 2011Document128 paginiBarnett Elizabeth 2011Liz BarnettÎncă nu există evaluări

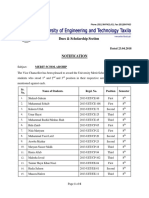

- Dues & Scholarship Section: NotificationDocument6 paginiDues & Scholarship Section: NotificationMUNEEB WAHEEDÎncă nu există evaluări

- Derivatives 17 Session1to4Document209 paginiDerivatives 17 Session1to4anon_297958811Încă nu există evaluări

- CV Finance GraduateDocument3 paginiCV Finance GraduateKhalid SalimÎncă nu există evaluări

- Opportunity Seeking, Screening, and SeizingDocument24 paginiOpportunity Seeking, Screening, and SeizingHLeigh Nietes-GabutanÎncă nu există evaluări

- Motivation and Emotion FinalDocument4 paginiMotivation and Emotion Finalapi-644942653Încă nu există evaluări

- Miss Daydreame1Document1 paginăMiss Daydreame1Mary Joy AlbandiaÎncă nu există evaluări

- Walter Horatio Pater (4 August 1839 - 30 July 1894) Was An English EssayistDocument4 paginiWalter Horatio Pater (4 August 1839 - 30 July 1894) Was An English EssayistwiweksharmaÎncă nu există evaluări

- Zeng 2020Document11 paginiZeng 2020Inácio RibeiroÎncă nu există evaluări

- Lab 5: Conditional probability and contingency tablesDocument6 paginiLab 5: Conditional probability and contingency tablesmlunguÎncă nu există evaluări

- Complete BPCL AR 2022 23 - English Final 9fc811Document473 paginiComplete BPCL AR 2022 23 - English Final 9fc811Akanksha GoelÎncă nu există evaluări

- Character Interview AnalysisDocument2 paginiCharacter Interview AnalysisKarla CoralÎncă nu există evaluări

- Puberty and The Tanner StagesDocument2 paginiPuberty and The Tanner StagesPramedicaPerdanaPutraÎncă nu există evaluări

- Bhikkhuni Patimokkha Fourth Edition - Pali and English - UTBSI Ordination Bodhgaya Nov 2022 (E-Book Version)Document154 paginiBhikkhuni Patimokkha Fourth Edition - Pali and English - UTBSI Ordination Bodhgaya Nov 2022 (E-Book Version)Ven. Tathālokā TherīÎncă nu există evaluări

- Inflammatory Bowel DiseaseDocument29 paginiInflammatory Bowel Diseasepriya madhooliÎncă nu există evaluări

- Financial Accounting and ReportingDocument31 paginiFinancial Accounting and ReportingBer SchoolÎncă nu există evaluări

- HRU Stowage and Float-free ArrangementDocument268 paginiHRU Stowage and Float-free ArrangementAgung HidayatullahÎncă nu există evaluări

- Corti Et Al., 2021Document38 paginiCorti Et Al., 2021LunaÎncă nu există evaluări

- Cincinnati LaserNst PDFDocument204 paginiCincinnati LaserNst PDFedrf sswedÎncă nu există evaluări