Documente Academic

Documente Profesional

Documente Cultură

Unit4 MSH

Încărcat de

chandramohan muruganTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Unit4 MSH

Încărcat de

chandramohan muruganDrepturi de autor:

Formate disponibile

PROCESS CONTROL (IT62)

Chapter 4

CONTROLLERS, TRANSMITTERS, CONVERTERS AND RELAYS

by Dr. Mallikarjun S. Holi Professor & Head Department of Biomedical Engineering Bapuji Institute of Engineering & Technology Davangere-577004

Chapter 4 : Controllers, Transmitters, Converters and Relays

4.1 Introduction In this chapter we study the fundamental concepts, design and working of signal converters, signal generators, computing relays, transmitters and annunciators, which are the part of process control. One should have knowledge about different types such devices which will help designing appropriate control system based on the application. 4.2 Objectives At the end of this chapter you will be able to understand: Principle of signal conversions and working of different signal converters Fundamental concepts of signal generators and their design and working Principle and working of computing relays Basic concepts and working of different type of transmitters used in process control. Different types of annunciators and their working. 4.3 Converters The signal conversion refers to the modifications that must be made to the control signal to properly interface with the next stage in the control loop. Thus, if a valve control element is to be operated by an electric motor actuator, then a 4-20 mA dc control signal must be modified to operate the motor. If a dc motor is used, modification might be current to voltage conversion and amplification. The devices that perform such signal conversions are often called transducers because they convert control signals from one form to another, such as pneumatic to electronic (i.e. pressure to current), electronic to pneumatic (i.e. current to pressure), current to voltage, etc. The principal objective of signal conversion is to convert the low-energy control signal to a high-energy signal to drive the actuator. Pneumatic-to-Electronic Converters The pneumatic-to-electronic transducer is used wherever pneumatic signals must be converted to electronic signals for anyone of the following reasons: Transmission over large distances Input to an electronic logger or computer Input to telemetering equipment Instrument air not available at the receiver controller In principle, any of the electronic pressure transmitters could be used, but in practice, special devices are used to improve accuracy. The air signals are at low pressure levels (3-15 PSIG), and many of the pressure detectors are not sensitive or not linear enough at these pressures. A P/I transducer should be at least percent accurate and preferably percent to preserve the integrity of the initial signal. Since the total error is the square root of the mean squares or the individual component errors, the greater the precision of the P/I transducer, the better the signal. 2

Because of this need for accuracy, most P/I transducers use a bellows input and a motion balance sensor. A typical high-quality P/E converter is shown in Figure 4.1. When 3-15 PSIG input pressure is applied to pressure capsule or bellow, it leads to movement of the LVDT core between the primary and secondary coils. The primary coil has input excitation from a square wave oscillator. The movement of the core leads to generation of differential potential across two secondary which is demodulated to obtain dc voltage output, which will be directly proportional to applied input pressure.

Fig. 4.1 Pneumatic to electronic converter Millivolt-to-Current Converters Millivolt-to-current converters are widely used in the measurement of temperature, using thermocouples or other millivolt generating sensing elements. They are also utilized in converting the output signals of analyzers into higher level transmission signals. A typical millivolt-to-current converter is illustrated in Fig.4.2. When these devices are used to convert thermocouple outputs, they are also referred to as temperature transmitters. Voltage-to-Current Converters Voltage-to-Current Converters are used for conversion of higher voltages into transmission signals, preferably in the form of current. These circuits as shown in Fig. 4.3 usually consist of voltage dividers & rectifiers to reduce the voltages to a level compatible with the receivers.

Fig. 4.2 Millivolt to current converter

Fig. 4.3 Solid-state voltage to current converter

Current-to-Current Converters Current-to-Current transducers are available to convert AC signals to DC (or DC to DC) and to amplify or reduce their levels as necessary. Levels of alternating current can be changed, when necessary, by current transformers. A common signal levels in power industry is 0-5 amps. Direct currents are re-ranged by putting a series of resistors in the circuit and reading the voltage drop across it. A converter of AC to DC milliamperes is shown in Fig. 4.4. The figure shows three separate devices, a current transformer, an AC to DC milliampere converter, and a current-to-air converter. The function of the transformer is to scale down the current to the range normally used for direct AC metering. The AC/DC converter makes this signal compatible with the usual DC milliampere transmission system. DC to DC converters are sometimes used for isolation of electrical circuits, such as with intrinsically safe systems.

Fig. 4.4 AC to DC milliampere converter with integral I/P transducer Current-to-Air Converters Electro-pneumatic transmitters are also called converters and transducers. They are extremely important, since they form the link between electrical measurements and pneumatic control systems. They also convert electronic controller outputs into air pressures for operation of pneumatic valves. Figure 4.5 illustrates one of these converters and also lists the various electric devices with which it is commonly combined. The input is usually a DC current in the range of 1-5, 4-20, or 10-50 milliamperes. An permanent magnet creates a field that passes through the steel body of the transmitter and across a small air gap to the pole piece. A multi-turn, flexure-mounted voice coil is suspended in the air gap. The input current flows through the coil creating an electromagnetic force that tends to repel the coil and thus converts the current signal into a mechanical force. Since the total force obtainable in a typical voice coil motor with such small current

inputs is only in the order of some ounces, a different approach, namely, the use of a reaction nozzle, is employed to convert the force into a pneumatic output pressure. In this circuit, supply air flows through a restriction and out the detector nozzle. The reaction of the air jet as it impinges against the nozzle seat supplies the counterbalancing force to the voice coil motor. The nozzle back pressure is the transmitted output pressure. In order to make the transmitter insensitive to vibration, the voice coil is integrally mounted to a float, submerged in silicone oil. The float is sized so that its buoyant force equals the weight of the assembly, leaving a zero net force. Zero is adjusted by changing a leaf-spring force. Span is adjusted by turning the rangeadjusting screw to change the gap between the screw and the magnet, thus shunting some of the magnetic field away from the pole piece.

Fig. 4.5 Electronic to pneumatic transducer transmitter with typical input sources

Resistance-to-Current Converters Resistance measurements are common in temperature measurements and in resistance or strain gauge sensors. The circuits used are similar to those of the millivolt-to-current converters, except that the front end is a resistance bridge instead of a voltage bridge as shown in Fig.4.6. In the strain gauge bridge, the strain gauge elements may take the place of two of the resistors in the resistance bridge shown in Fig.4.6.

Fig. 4.6 Resistance to current converter 4.4 Function Generators Time Function Generators (Programmers) The simplest and the least expensive analog time function generator is the cam-type programmer. These are assembled in large-case circular chart recorder housings as shown in Fig. 4.7, and consist of a motor-driven cam that moves the set-point index, to which a motion transmitter is connected. The output is usually a 3-15 PSIG pneumatic set-point signal. Electric outputs are also available. The time base is a function of motor speed, and a wide selection of speeds is available. The cams can be made of plastic or metal. It is also common to incorporate an integral controller, direct-sensing element, and circular chart recorder in the same housing. Cam programmers are usually applied to batch processes that are repeated time after time. These units are not as accurate as the profile tracer and line follower types of more recent manufacture. The cam rise is also limited for mechanical reasons to about 50degree cam rotation for full-scale movement of the index. Curvilinear coordinates make the cams more difficult to lay out as compared with programming a device with rectilinear coordinates.

Fig. 4.7 Cam type programmer Adjustable Ramp-and-Hold Programmers For batch processes in which the controlled variable must be made to rise at a controlled rate, then hold at some preset value and, possibly, fall at a controlled rate, programmers such as that in Fig. 4.8 are often preferable to cam types, particularly if the program must be changed periodically. These, too, are usually packaged as large-case circular chart recorders. In this type programmer, the set-point index is driven by a constant speed motor. The rate of rise is set by adjustment of an interrupter timer, which makes contact for a set percentage of the basic timer cycle time. The movement of the index is, therefore, actually in steps, hut the steps are so small that the operation is, for all practical purposes is continuous. The set point rises until it coincides with the hold point index, at which point hold timer is energized while the interrupter timer is de-energized. Controlled cooling rate requires driving the set-point index in reverse.

Fig. 4.8 Adjustable ramp-and-hold programmer Profile Tracer Programmers Profile tracer programmers come in 150 x 150 mm miniature pneumatic recorder type cases as shown in Fig. 4.9. The program is stored on a laminated, endless belt plastic master. It combines an analog set-point program with up to 25 synchronized digital tracks for operation of logic circuits, auxiliary equipment, solenoid valves, lights, etc. There is no limit to the slope the programmer can follow-even slopes of 90 degrees are accommodated. Since the master program can be quickly changed, these programmers are often used where the program does require periodic change and where accurate reproduction of the program is essential, as in textile dyeing processes. The complete program is stored on the master, thus eliminating the need for having an operator make various program settings for each change and, therefore, eliminating the chance for human error in setting the program. These programmers are accurate to within percent of full scale, which makes them applicable when accuracy alone is the critical requirement of the operation. The endless belt master is made up by plotting the desired analog program on the rectilinear chart and cutting the top portion away with scissors. The second layer serves as a backing and is also used to program the synchronized digital tracks. At any point of the program where a switch action is desired, a hole is punched in with a conductor's punch. The back of the analog program has a pressure-sensitive adhesive that joins the two sections. A splice finishes the make-up of the master,

In operation motor drives the master program. A cable-mounted tracer nozzle senses the step on the analog program profile. The back-pressure of the nozzle actuates a servo, which, through the cable drive, keeps the tracer following the profile. Operating from the same servo drive is an accurate force balance type motion detector. Sensing the back side of the digital master are a series of vertically aligned nozzles. Normally, their hack pressure is high since the master baffles the nozzles. However, if a punched hole presents itself, the hack pressure of that particular nozzle drops to zero, actuating the connected pressure switch.

Fig. 4.9 Pneumatic profile tracer programmer with synchronized on-off sequence control switches Electric Line and Edge Programmers Electric line and edge follower programmers will perform with less than percent error. In the electrostatic line follower type, Fig. 4.10, the desired program curve is etched into a conductive surface chart, dividing it into two electrically isolated surfaces. The surfaces are energized by oppositely phased AC voltages establishing a gradient across the gap. A non-contacting probe senses the electrostatic field developed by the surfaces and energizes a servo amplifier to keep the probe tracking the line, which is at zero potential. Attached to the servo drive is the wiper of a potentiometer whose output is proportional to line position. The photoelectric line follower type functions to keep the line centered between two slightly overlapping pickup heads. The detector must he manually set over the line at start-up, and slope rate is limited by the speed of the follower mechanism. The photoelectric edge follower consists of a chart which is divided into a transparent and an opaque section at the program line. A photocell detector senses the edge and a servo system tracks it. Up to eight digital tracks are available with the electric programmers. 10

Fig. 4.10 Electric line follower programmer

11

4.5 Computing Relays Relay: An electrical switch that allows a low power to control a higher one. A small current energizes the relay, which closes a gate, allowing a large current to flow through. In general, it is device that receives information in the form of one or more instrument signals, modifies the information or its form, or both, and if required, sends out one or more resultant signals. Electromechanical Relay: An electrically controlled mechanical device that opens and closes electrical contacts when a voltage (or current) is applied to a coil. A relay provides isolation of control signals from switched signals. Solid State Relay: A Solid State relay is a switching device that completes or interrupts a circuit electrically and has no moving parts. A Mechanical relay is an electromechanical device that closes contacts to complete a circuit or opens contacts to interrupt a circuit. Computing Relays: The relays which are able produce suitable output based on the fundamental formulation/equation on which they are designed in analog / digital / pneumatic form. Pneumatic Multiplying and Dividing In the force bridge multiplier-divider shown in Figure 4.11 input pressures act on bellows in chambers A, B, and D. The output is a feedback pressure in chamber C. The bridge consists of two weigh-beams that pivot on a common movable fulcrum, with each beam operating a separate feedback loop. Any unbalance in moments on the left-hand beam causes a movement of the fulcrum position until a moment-balance is restored. An unbalance in moments on the right-hand beam results in a change in output pressure until balance is restored. Equations which characterize the operation of the force bridge are A x a = B x b and Dxa=Cxb (4.1) The equation can be reduced to AxC=BxD (4.2) C = (B x D) / A (4.3) Multiplication results when the two input variables are connected to chambers B and D, Division results when the dividend is connected to either chambers B or D, with the divisor connected to A. Simultaneous multiplication and division results when B, D, and A chambers are used. Electronic Multiplying and Dividing In Fig. 4.12, inputs e1 and e2 are multiplied in the diode bridge. Conduction of the diodes in the bridge is dependent upon the relative magnitude of the inputs with respect to the constant slope of the sawtooth input. The output of the diode bridge is trapezoid, which has an area equivalent to Area = e1e2 tan (4.4) The angle is established by the constant slope of the sawtooth, and thus Area = Ke1e2 (4.5)

12

The output voltage, e0, is amplified and filtered to a DC signal, and its voltage level will. therefore be proportional to the area and, consequently, to the product of e1 and e2. Adding another diode bridge to the multiplier circuit produces a multiplier/divider as shown in Fig.4.13. The input to the amplifier is the output difference from the two bridge networks. e0 = A (K e1e2 - Ke3e0) where A = gain of the amplifier. Rearranging the terms we will get e1e2 = [(e0)/AK + e3e0] The term e0/AK is very small if the amplifier gain is high, and thus e0 = (e1e2)/e3 (4.6) (4.7) (4.8)

Fig. 4.11 Pneumatic force bridge multiplying and dividing relay

13

Fig. 4.12 Electronic multiplier

Fig. 4.13 Electronic multiplier-divider Pneumatic Adding, Subtracting, and Inverting In the force balance arithmetic computing relay as shown in Fig. 4.14, a signal pressure in chamber A acts downward on a diaphragm with unit effective area. A signal in chamber B also acts downward on an annular diaphragm configuration, likewise having an effective area of unity. Signal pressures in chambers C and D similarly act upward on unit effective diaphragm areas. Any unbalance in forces moves the diaphragm assembly with its integral nozzle seat. The change in nozzle seat clearance changes the nozzle back pressure and hence, changes the output pressure, which is fed hack into chamber D until force balance is restored. The basic equation which describes the operation of the relay is T=A+BCK (4.9) K is the spring constant, which is adjustable to give the required pressure.

14

Fig. 4.14 Pneumatic adding, subtracting, inverting, and biasing relay Electronic Adding, Subtracting, and Inverting In Fig.4.15, the two input potentials e1 and e2 are compared in the multiple comparator, which produces a proportional output to the amplifier. The current paths of the two inputs can be the same or opposite, resulting in either an adding or subtracting circuit, respectively. Inverting is accomplished by biasing the comparator to produce maximum output with no input. Applying a reverse input (i.e., a reverse current input with respect to bias current) causes the output to decrease with increasing input. The feedback signal is such that the amplifier acts as a unity gain network. Electronic Scaling and Proportioning Simple electronic scaling or proportioning involves combining a voltage divider circuit with an amplifier. The voltage divider circuit is connected to either the input or output side, depending upon whether the gain is to he greater or less than unity.

15

In Fig. 4.16, the amplifier comes to balance when ei equals zero. Since the voltage divider is on the output, only a portion of the amplifier output is fed back to counterbalance the input voltage. Therefore, the output will rise above eI, resulting in gains greater than one. The operation can be expressed as (4.10) e0 = eI (R1 + R2) / R1 Fig. 4.17 shows the electronic scalar with gain less than one. The operation can be expressed as e0 = eI R2/(R1 + R2) (4.11)

Fig.4.15 Electronic adder, subtracter, and inverter

Fig.4.16 Electronic scalar with gain greater than one

Fig.4.17 Electronic scalar with gain less than one

16

Electronic Differentiating The input amplifier in Fig.4.18 is capacitor coupled so that only the rate of change of the input signal is seen by the amplifier. Two diodes in the feedback of the amplifier allow its output to go positive or negative (depending on the direction of the rate of change) by an amount equal to the forward drop across the diodes (only a few tenths of a volt). The output amplifier inverts and amplifies this signal by its open loop gain. A small positive feedback is applied to the last amplifier to prevent output from "chattering" at the diodes' switching point.

Fig.4.18 Electronic differentiator Electronic Integrating The first amplifier in Figure 4.19, a Simple inverting type, performs the integration function as the charge accumulates across the capacitor of the RC network. The second amplifier is an inverting, general purpose type, which output directly to the input.

Fig.4.19 Electronic integrator

Electronic Square Root Extracting The square root converter, Fig. 4.20, combines a DC amplifier with a negative feedback diode network. As current into the amplifier increases, the amplifier gain decreases with decreased feedback resistance in the diode network. The gain varies according to, typically, seven straight line segments that approximate a square root function. This is accomplished by having seven diode-resistance paths in the feedback network automatically parallel each other with increasing input. The output stabilizes when the diode network modified feedback counterbalances the input.

17

Fig. 4.20. Electronic square root extractor Electronic High- and Low-Voltage Selector and Limiter The higher of the two positive inputs in Fig.4.21 causes a higher negative potential at the cathode of one of the diodes (CRl or CR2). The forward bias of this diode passes the higher input and reverse biases the other diode to isolate the lower input. Thus if signal e1 drops below signal e2, CR2 is forward-biased to pass signal e2 and CRI is reverse-biased to isolate signal e1. All the amplifiers are unity-gain inverter types. Substituting a fixed input for one of the variables produces a low-limit relay. To obtain a low-voltage selector as shown in Fig.4.22, the diodes are inverted and a negative supply (e) is used. Thus, the least positive input forward-biases one of the diodes (by the least negative potential applied to the anodes of the diodes). This automatically reverse biases the other diode and isolates the higher input from the output. Substituting a fixed input for one of the variables produces a high-limit delay.

Fig. 4.21. Electronic high-voltage selector

18

Fig. 4.22. Electronic low-voltage selector

4.6 Transmitters 4.6.1 Electronic and Intelligent Transmitters A transducer is a device that receives information in one form and generates an output in response to it. A transmitter is transducer that responds to a measurement variable and converts that input into a standardized transmission signal. An example of a simple transmitter or transducer is a thermocouple for measuring temperature. In the thermocouple, the temperature difference between the hot junction and the reference junction creates a DC voltage directly proportional to the temperature difference. Force-Balance Transmitters Fig.4.23 illustrates a force-balance differential pressure transmitter, in which the measurement that produces a force tends to move the top of the force bar. This tiny motion, acting through levers, moves the ferrite disc closer to the transformer, changing its output. This changes the amplitude output of the oscillator, which is rectified and then amplified to generate a DC milliampere transmitter signal. This output signal is fed back through the voice coil on the armature of the force motor, which is in series with the output terminals. When this feedback moment is equal to the moment created by the measurement force F2, the force bar is again in its original position and the amplifier signal stabilizes. The advantage of force-balance units over motion-balance devices is that by reducing motion, one minimizes the effect of pivot friction. Further, by always returning to the same position, hysteresis is minimized and greater accuracy can be obtained. In general, a force-balance cannot be used to produce digital signals without the use of a

19

supplementary device external to the transmitter, such as an analog-to-digital converter (ADC).

Fig.4.23 Motion-balance electronic transmitter Motion-Balance Transmitters In a motion-balance transmitter (Fig.4.24), the process measurement produces motion against a calibration spring, resulting in a change of position corresponding to a change in the process variable. This position is detected by a transducer. The output of the transducer is amplified and an electric feedback signal is used to stabilize the amplifier. Depending upon the type of transducer and the signal level it generates, the amplifier may not be required but may be a part of the receiver.

20

Fig.4.24 Motion-balance electronic transmitter Differential Transformer One of the most frequently used transducer principles is known as the differential transformer as shown in Fig.4.25. The linear variable differential transformer (LVDT), illustrated in of Fig. 4.25(a), consists of a transformer coil with a single primary winding and two symmetrically spaced secondary windings. The core or armature is a cylinder of magnetic material, such as ferrite, which can be moved within the "air gap" of the windings. When AC excitation is applied to the primary winding and the armature slug is centered, or is in the "null" position, the induced AC voltage in the secondary windings is equal and is in the same or opposite direction, depending on the method of winding. If the two secondary windings are connected in series with the voltages opposed (Fig. 4.25(b)), they will cancel out and give a zero or null reading when the slug is in the null position. As the slug is moved closer to coil A and further from coil B, as shown in Fig. 4.25(c), the output voltage increases in the direction of the coil A output, and this increase is proportional to the displacement of the slug. Another typical hookup is shown in Fig. 4.25(d), with a rectifier in the output of each secondary coil hooked up to a DC zero center meter. The meter will read zero at the null slug position and plus or minus for slug positions displaced from the center. The DC output of such a differential transformer can be amplified and used directly as a transmitted signal as shown in Fig. 4.24 or it can be used as a position detector of other devices as shown in Fig. 4.23. The excitation in a differential transformer must he supplied by an AC circuit. The AC source can be the receiving instrument using an AC transmitted signal or it can be a part of the amplifier in the transmission part of the transmitter, powered by a DC supply taken from the receiver.

21

Fig.4.25 Linear variable differential transformer Photoelectric Transducer Fig.4.26 shows a typical schematic of a photoelectric transducer where the position of the photocoder is proportional to the motion of a primary sensing element. Light from the source shines through perforations in the shutter to energize photoelectric cells. The output of these cells is scanned and the pulses are amplified to produce a digital signal, or they are rectified to produce DC analog signal.

Fig.4.26 Photoelectric encoder transducer 22

Other popular transducers which are used in process control are capacitance type, potentiometric type and piezoelectric type transducer. Intelligent Transmitter An intelligent transmitter incorporates a microcontroller or a microprocessor in which not only the measurement signal is transferred from the transmitter to a receiver, such as an indicator or controller, but also the microprocessor implements the smart functions and provides a communication facility. This enables data specific to the transmitter itself, such as its type, serial number, etc, to be stored at the transmitter and accessed via the measurement loop in which it is installed, as shown in Fig.4.27. Other functions, such as setting or resetting the zero and span, details of the location and application, and running diagnostic routines to give warning of malfunctioning, can also be implemented. The term "intelligent" has come to be used to identify such transmitters. A further evolution which is now under way is to multiplex the transmitter outputs onto a network or "fieldbus" instead of connecting the transmitters via individual circuits to the control room.

Fig.4.27 General schematic of an intelligent transmitter 4.6.2 Fiber Optic Transmitters Electricity and pneumatics are commonly used to measure, control, and transmit information among process, controller, and operator. Fiber optics provides an alternate method of process measurement and information transmission. Although fiber optic (FO) transmission hardware and systems are readily available to the user, FO instruments are not yet available in the same broad spectrum as are electrical or pneumatic instruments. This is because the efforts of the FO industry have been primarily directed toward 23

meeting the needs of their prime customers, namely AT&T (commercial FO communication) and the military (special purpose FO instrumentation). Today the industrial and commercial world lags behind the military in FO instrumentation development. Instrumentation and Fiber Optics Fiber optics technology provides the instrument engineer with analog and digital sensors that measure process variables, operator actuation devices, interfaces to instrument (pneumatic, electrical, electronic, mechanical) sensors (hybrid devices), and communication capability between system analog or digital controllers. One of fiber optic's most compelling features for the instrumentation engineer is its intrinsically safe characteristics for use in hazardous environments. Moreover, the advent of digital electronics, the microprocessor, and distributed control systems has resulted in all awareness of problems associated with electronics in an industrial environment. These problems include voltage isolation between equipment, ground isolation, EMI, RFI, noise, lightning susceptibility, and EMP susceptibility. Since FO cable is a nonconductor and does not radiate energy, it can provide a built-in solution to these problems. Fiber optics are also being used today in the analog realm to transmit 0-10V and 0-20mA information, thus minimizing use of shielded cables. The microprocessor is now implanted in all levels of the instrument born system building block (i. e., process, controller, and operator interface). Information interchange between these blocks is implemented by various methods of communication, including 20mA two-wire loops, serial, parallel, baseband, and broadband communication. The ability of fiber optics to meet high information throughput requirements, while maintaining its advantages in its operating and environmental capabilities is making FO an attractive alternate in communication applications. Conventional instrumentation can be converted or expanded utilizing fiber optics because of the advances in optoelectronics. The marriage of conventional sensors and transmitters with fiber optics via optoelectronics is common and is sometimes referred to as a hybrid fiber optic link. Fiber Optic Principles Optical fiber bandwidth (dispersion) is one of the basic parameters considered in all applications. When analyzing dispersion in an optical fiber, the index of refraction (n) is considered as follows: n=C/V (4.12) C = speed of light in a vacuum (3 x 108 m/sec), and V = speed of light within the optical fiber, selected. The index profile of an optical fiber defines how the index of refraction varies as a function of radial distance from the fibers center, Step index profile refers to a fiber having an index of refraction with an abrupt change (step) at the core radius. The optical fiber divides into two sections, with the inner light-carrying optical conductor called the core and the outer jacket called the cladding, as shown in Fig.4.28. Optical energy is inserted into the core and travels along the core through internal reaction at the core through internal reflection at the core cladding interface. Reviewing

24

the figure, the comparative index of refraction for core (n1) and cladding (n2) is shown in Fig.4.29. Note the index of refraction for the cladding (n2) is less than that of the core (nl)

Fig.4.28 Fiber optic cable cross section and light transmission through fiber.

Fig.4.29 Index of refraction comparison. The core to cladding index ratio is a prime factor in defining optical transmission dispersion. To, illustrate this, a discussion of multimode propagation characteristics is required. In a multimode fiber, Fig.4.28 might be modified as illustrated in Fig. 4.30. Two factors must be recognized in this figure. First, not all, of the light travels down the core. Some of the light is lost in the cladding. The amount of light loss (dispersion) is a function of the angle that the light within the core hits the cladding, Snells law provides the minimum angle that supports internal reflection, as follows: Sin min = n2 / n1 (4.13) min depends on the cable selected and the indexes of refraction of the cladding and the core. Rays striking the core-cladding interface at angles less than min will he lost in the cladding (Fig.4.31).

25

Fig. 4.30 Light transmission in a multimode fiber

Fig. 4.31 Minimum angle for internal reflection depends upon the indexes of refraction of cladding and core Referring to Fig.4.30 note that many rays are traveling down the core, varying from the axial ray to various rays striking the cladding at various acceptance angles. Because each ray travels a different distance at the same speed, their arrival times will vary. Fig.4.30 illustrates a cable that has numerous propagation modes and an abrupt change in index profile; this fiber is called a multimode step index type fiber. Characteristically, multimode step index fibers can cause bit smearing or intersymbol interference in a digital data system and delay distortion in an analog-modulated system. To decrease mode volume, small glass fibers with n1/n2 as small as practical are constructed. If "V" is less than 2.405 m/sec, only a single-mode (axial ray) can propagate. Called a single-mode fiber, this design exhibits no modal dispersion at all. Single-mode construction offers the best bandwidth features but provides design challenges in injecting light into the small-diameter core as well as fiber-to-fiber splicing. Fig.4.32 illustrates single-mode transmission.

Fig. 4.32 Single-mode (monomode) fiber The fiber core can be constructed with an index of refraction that decreases parabolically from the center of the fiber. Light propagation now occurs through refraction, a continual bending of the ray toward the fibers optical axis. This manufacturing technique provides a large-diameter fiber than single mode and a wider bandwidth fiber than multimode step 26

index, thus reducing the coupling problem while enhancing the distance handling capability. This product is called graded index fiber. Fiber Optic Components: Fig.4.33 illustrates components in a simple fiber optic system. These are identified as source, connector, cable and detector.

(d) Fig.4.33 Components of a fiber optic system (a) Source (LED) emission profile. (b)Acceptance cone for step-index fiber. (c) Source/fiber interface. (d) fiber optic link Source: Light emitting diode (LED) or Injection laser diode (ILD) Connector: Fiber optic Cable: Single mode, multimode step index, multimode graded index Detector: PIN diode or Avalanche photodiode (APD)

27

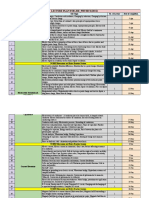

4.7 Annunciators and Alarms Principle of Operation The basic annunciator system consists of multiple individual alarm points, each connected to a trouble contact (alarm switch), a logic module, and a visual indicator (Fig.4.34). The individual alarm points are operated from a common power supply and share a number of annunciator system components, including an audible signal generator (horn), a flasher, and acknowledge and test push buttons. In normal operation the annunciator system and individual alarm points are quiescent. The trouble contact is an alarm switch that monitors a particular process variable and is actuated when the variable exceeds preset limits. In electrical annunciator systems it is normally a switch contact that closes (makes) or opens (breaks) the electrical circuit to the logic module and thereby initiates the alarm condition. In the alert stage the annunciator turns on the visual indicator for the particular alarm point and the audible signal and the flasher for the system. The visual indicator is usually a backlighted nameplate engraved with an inscription to identify the variable and the abnormal condition, but it can also be a bulls-eye light with a nameplate. The audible signal can be a horn, a buzzer, or a bell. The flasher is common to all individual alarm points and interrupts the circuit to the visual indicator as that point goes into the alert condition. This causes the light to continue to flash intermittently until either the abnormal condition returns to normal or it is acknowledged by the operator. The horn acknowledgment pushbutton is provided with a momentary contact; when it is operated, it changes the logic module circuit to silence the audible signal, stop the flasher, and turn the visual indicator on "steady." When the abnormal condition is corrected, the trouble contact returns to normal and the visual indicator is automatically turned off. The lamp test pushbutton with its momentary contact tests for burned-out lamps in the visual indicators. When activated, the pushbutton closes a common circuit (bus) to each visual indicator in the annunciator system, turning on those lamps that are not already on as a result of an abnormal operating condition. Operating Sequences The operation of an individual alarm point in the normal, alert, acknowledged, and return-to-normal stages is the annunciator sequence. A wide variety of sequences can be developed from commercially available logic components; many special sequences have been designed to suit the requirements of particular process applications. The most commonly used annunciator sequences is given below in the Table

28

Fig. 4.34 Elements of basic electronic type annunciator system

Pneumatic annunciators Pneumatic annunciators consist of air-operated equivalents of the trouble contact, logic module, and visual indicator stages of an electrical annunciator system. A single-point system furnishing high tank level monitoring is shown in Fig.4.35. Power supply to the system is instrument air at 80 to 100 PSIG, which is reduced to the required operating pressure by pressure regulator (1). The operating pressure is indicated on pressure gauge (2). A 3 to 15 PSIG analog input signal from a direct-acting level transmitter (LT-9) enters high-pressure limit relay (4), which is normally closed and set to open when the high level limit is exceeded. When this happens (alert condition), an input at supply pressure from (4) turns on a pneumatic visual indicator (3), and a normally open highpressure limit relay (6) allows supply air flow to air horn (7), turning it on. Simultaneously, the air output from (4) enters normally closed high-pressure limit relay (5) and momentary contact pushbutton (8), which is a normally open acknowledgment pushbutton for the system. In the alert condition, the pneumatic indicator and horn are both on. One acknowledges the alert condition by pushing button (2), closing it, and thereby opening high pressure limit relay (5). Supply air pressure from (5) closes high-pressure limit relay (6), which cuts off the operating air to the horn, thereby turning it off. Simultaneously, operating air pressure from (5) is fed back to the inlet of (5). The feedback pressure locks up (5) so that it will not close when the acknowledgment pushbutton (8) is released. In the acknowledged condition, the pneumatic indicator is on and the horn is off. The system returns to normal when the 3 to 15 PSIG analog input falls below the set point. This closes high-pressure limit relay (4) which turns off the pneumatic indicator (3). It also closes high pressure limit relay (5) by venting the lock-in circuit through relay (4). Pneumatic annunciators are used when one or two alarm points are needed but electrical 29

power is not readily available and in hazardous electrical areas where an electrical annunciator might not be practical. Pneumatic annunciator require a substantial amount of installation space and are expensive to manufacture.

Fig.4.35 Pneumatic annunciator circuit Summary: In this chapter the fundamental concepts about the converters, function generators, computing relays and annunciators are discussed along with their design and working principle. 1. The signal conversion refers to the modifications that must be made to the control signal to properly interface with the next stage in the control loop. The devices that perform such signal conversions are often called transducers because they convert control signals from one form to another. The principal objective of signal conversion is to convert the low-energy control signal to a high-energy signal to drive the actuator. 2. Function generators can provide an output as per the requirement of a process. The function generators can be designed and programmed in both analog and digital form. 3. Relay is device that receives information in the form of one or more instrument signals, modifies the information or its form, or both, and if required, sends out one or more resultant signals The relays which are able produce suitable output based on the fundamental formulation/equation on which they are designed in analog / digital / pneumatic form. 4. A transmitter is transducer that responds to a measurement variable and converts that input into a standardized transmission signal. 5. Annunciators and alarms provide an indication about the process condition either

30

in the form of visual or audible signal. Suggested Readings and Websites: 1. Instrument Engineers Handbook: Volume 2-Process Control, by Bela J. Liptak, Chilton Book Company. 2. Computer based industrial control by Krishna Kant, PHI, 2002 3. Computer Aided Process Control by S.K.Singh, PHI 4. www. controlmagazine.com 5. www. icsmagazine.com 6. www.honeywell.com 7. www.controlguru.com/ 8. www.processautomationcontrol.com Glossary: Absolute Alarm: An alarm caused by the detection of a variable which has exceeded its high or low limit condition. Adder: A device whose output is a representation of the sum of the inputs. Alarm: An audible or visible signal that indicates an abnormal or out-of-limits condition in the plant or control system. Computing relay: A device that performs one or more calculations or logical functions or both, and sends out one or more resultant signals. Error squared: The technique of using the square of the error on which to make the control calculation so as to produce a non-linear correction. Relay: An electrical switch that allows a low power to control a higher one. A small current energizes the relay, which closes a gate, allowing a large current to flow through. Signal Conversion: The signal conversion refers to the modifications that must be made to the control signal to properly interface with the next stage in the control loop. Switch: A device that connects, disconnects or transfers one or more circuits and is not designated as a controller, a relay, or a control valve. Keywords: Signal conversion, converters, function generators, relays, computing relays, transmitters, annunciators, alarms.

31

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- ASHRAE Fundamentals Handbook (2009)Document2 paginiASHRAE Fundamentals Handbook (2009)Luís Fernando Ferreira Silva50% (2)

- Process Design P-001Document39 paginiProcess Design P-001Yohanes Silaen100% (1)

- Tom Henry - Electrical Formulas and Calculations (2005 National Electrical Code - Nfpa 70 - Nec) PDFDocument14 paginiTom Henry - Electrical Formulas and Calculations (2005 National Electrical Code - Nfpa 70 - Nec) PDFgoodshepered90% (10)

- Huawei Embedded Power System ETP48150-A3 DataSheetDocument2 paginiHuawei Embedded Power System ETP48150-A3 DataSheetGuilherme Leite VasconcelosÎncă nu există evaluări

- Budget PlanDocument8 paginiBudget Planchandramohan muruganÎncă nu există evaluări

- (1402-3V1310) R410A DC Inverter VRF V4 Plus K Series 50Hz (V4+K, Mini VRF) PDFDocument46 pagini(1402-3V1310) R410A DC Inverter VRF V4 Plus K Series 50Hz (V4+K, Mini VRF) PDFnarimeneÎncă nu există evaluări

- Development of Manufacturing Industries in OMANDocument152 paginiDevelopment of Manufacturing Industries in OMANchandramohan muruganÎncă nu există evaluări

- PyramidsDocument14 paginiPyramidschandramohan muruganÎncă nu există evaluări

- Speed Management StrategyDocument38 paginiSpeed Management Strategychandramohan muruganÎncă nu există evaluări

- GCC Waste To Energy 2018 PDFDocument16 paginiGCC Waste To Energy 2018 PDFchandramohan muruganÎncă nu există evaluări

- Fusion of Thermal Infrared and Visible Spectrum ViDocument13 paginiFusion of Thermal Infrared and Visible Spectrum Vichandramohan muruganÎncă nu există evaluări

- Mounting StructureDocument1 paginăMounting Structurechandramohan muruganÎncă nu există evaluări

- Piping Design Training - Piping Codes and Standards - OilandgasclubDocument4 paginiPiping Design Training - Piping Codes and Standards - Oilandgasclubchandramohan murugan100% (2)

- Construction Project Controls Cost Schedule and Change ManagementDocument20 paginiConstruction Project Controls Cost Schedule and Change ManagementFederico BrigatoÎncă nu există evaluări

- Mes Pocket GuideDocument36 paginiMes Pocket Guidechandramohan muruganÎncă nu există evaluări

- CVGASDocument1 paginăCVGASrarunr1Încă nu există evaluări

- P&ID DiagramsDocument18 paginiP&ID DiagramsSakthipriya Shanmugham100% (1)

- Plant Floor Ethernet Best Practice MeetingDocument2 paginiPlant Floor Ethernet Best Practice Meetingchandramohan muruganÎncă nu există evaluări

- Electrical Online CalculationsDocument5 paginiElectrical Online Calculationsdarsh2001patelÎncă nu există evaluări

- Gas Flow Rate Calculation From Wellhead PressuresDocument1 paginăGas Flow Rate Calculation From Wellhead Pressureschandramohan murugan100% (1)

- Requirements EngineeringDocument4 paginiRequirements Engineeringchandramohan muruganÎncă nu există evaluări

- Orifice CalculationDocument3 paginiOrifice Calculationchandramohan muruganÎncă nu există evaluări

- Mesatutorial - Isa95 Enterprise IntegrationDocument64 paginiMesatutorial - Isa95 Enterprise Integrationchandramohan murugan100% (1)

- Unit2 MSDocument43 paginiUnit2 MSchandramohan murugan100% (1)

- Analysis and Design of Cryogenic Ball ValveDocument6 paginiAnalysis and Design of Cryogenic Ball Valvechandramohan muruganÎncă nu există evaluări

- Project Manufacturing - Full PaperDocument7 paginiProject Manufacturing - Full Paperchandramohan muruganÎncă nu există evaluări

- Calificación+sismica+de+equipos+por+analisis DesbloqueadoDocument23 paginiCalificación+sismica+de+equipos+por+analisis DesbloqueadoRobert GalarzaÎncă nu există evaluări

- 03 LTHDocument41 pagini03 LTHchandramohan muruganÎncă nu există evaluări

- 446Document26 pagini446chandramohan muruganÎncă nu există evaluări

- Automating Knowledge TemplatesDocument0 paginiAutomating Knowledge Templateschandramohan muruganÎncă nu există evaluări

- Pre-MES Assessment - Cigarette ManufacturerDocument2 paginiPre-MES Assessment - Cigarette Manufacturerchandramohan muruganÎncă nu există evaluări

- Datasheet MultiPlus II 120V ENDocument2 paginiDatasheet MultiPlus II 120V ENAlamdar HassnainÎncă nu există evaluări

- Temp Rise Dry Type TransformerDocument8 paginiTemp Rise Dry Type TransformerAnonymous sAmJfcVÎncă nu există evaluări

- 4 App Physics 22EL Q I VDocument17 pagini4 App Physics 22EL Q I VRizwan MÎncă nu există evaluări

- Valve Catalogue General Imsubs Pvt. Ltd.Document20 paginiValve Catalogue General Imsubs Pvt. Ltd.Spark MeditechÎncă nu există evaluări

- Elecrical SystemDocument25 paginiElecrical SystemAshutosh ShuklaÎncă nu există evaluări

- Alspa MV3000 Buyers Guide PDFDocument68 paginiAlspa MV3000 Buyers Guide PDFAlejandro ZanellaÎncă nu există evaluări

- 50 PC 55 ZBDocument53 pagini50 PC 55 ZBVali IgnatÎncă nu există evaluări

- 200 Series FBM PartsDocument24 pagini200 Series FBM Partsñao manaoÎncă nu există evaluări

- 185 - Penawaran Harga Peralatan Parkir DPSDocument6 pagini185 - Penawaran Harga Peralatan Parkir DPSMuhammad Ibnu FahmiÎncă nu există evaluări

- Info Iec62055-31 (Ed1.0) enDocument8 paginiInfo Iec62055-31 (Ed1.0) enDaysi Ivonne Ortega MonteroÎncă nu există evaluări

- Commander SE: User GuideDocument76 paginiCommander SE: User GuidegmdeucsÎncă nu există evaluări

- Duty Cycle 1Document9 paginiDuty Cycle 1Susmita DasÎncă nu există evaluări

- Manual LinkuDocument8 paginiManual LinkufatjonÎncă nu există evaluări

- Spare Parts ListDocument2 paginiSpare Parts Listasdsd dsdaÎncă nu există evaluări

- Color TV: Service ManualDocument22 paginiColor TV: Service ManualAdlpal AccountÎncă nu există evaluări

- As Standard! Peace of Mind: ABB Drives For HVAC ApplicationsDocument8 paginiAs Standard! Peace of Mind: ABB Drives For HVAC ApplicationsPrakash RaoÎncă nu există evaluări

- Lecture Planner - Physics - LAKSHYA JEE 2022 PLANNER - PhysicsDocument7 paginiLecture Planner - Physics - LAKSHYA JEE 2022 PLANNER - PhysicsprekshaÎncă nu există evaluări

- Lab 3 MachineryDocument21 paginiLab 3 MachineryNazreen KamaruddinÎncă nu există evaluări

- Powerway Systems CatalogDocument6 paginiPowerway Systems CatalogSuraj SinghÎncă nu există evaluări

- SUN2000 330KTL H1 DatasheetDocument2 paginiSUN2000 330KTL H1 DatasheetNasiru BelloÎncă nu există evaluări

- PartLow MRC7700 Operqating ManualDocument74 paginiPartLow MRC7700 Operqating ManualLeandro CostaÎncă nu există evaluări

- Project InverterDocument67 paginiProject InverterKeshavGargÎncă nu există evaluări

- 03 MiniatureCircuitBreakers LV10 102021 EN 202111301144382742Document94 pagini03 MiniatureCircuitBreakers LV10 102021 EN 202111301144382742Omar Alfredo Del Castillo QuispeÎncă nu există evaluări

- Converter Circuits University of Colorado, Boulder Prof. Robert EricksonDocument4 paginiConverter Circuits University of Colorado, Boulder Prof. Robert EricksonThinh NguyenÎncă nu există evaluări

- Coil-Lock ... Hold-in-Device: From Power Quality Solutions IncDocument2 paginiCoil-Lock ... Hold-in-Device: From Power Quality Solutions IncvelizarkoÎncă nu există evaluări

- Unit-1, Electrical Power Quality 4-1, June 2019Document129 paginiUnit-1, Electrical Power Quality 4-1, June 2019Naga AnanthÎncă nu există evaluări

- UBM1511 BMI Lab ManualDocument57 paginiUBM1511 BMI Lab ManualAbiramiÎncă nu există evaluări

- TPSDocument2 paginiTPSFreddie MendezÎncă nu există evaluări