Documente Academic

Documente Profesional

Documente Cultură

Electrical Signature Analysis

Încărcat de

Luis LongoDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Electrical Signature Analysis

Încărcat de

Luis LongoDrepturi de autor:

Formate disponibile

ELECTRICAL SIGNATURE ANALYSIS

Manoj Kumar Sah- Siemens

INTRODUCTION Electrical signature analysis is the procedure of acquiring the motor current & voltage signals, performing signal conditioning and analyzing the derived signals to identify the various faults. The three phase signals are collected either directly (for a LT motor) or through a CT (for a HT motor). Thus, motors can be tested from the control panel, enabling easy testing of remote, inaccessible or hazardous area motors. A FFT (Fast Fourier Transform) or DFLL (Digital Frequency Locked Looped) analyzer is required for converting the signals from the time domain to the frequency domain PREMISE Motor current acts as an excellent transducer for detecting faults in the motor. Spectrum analysis of the motors current & voltage signals can hence detect various faults without disturbing its operation. Typical faults detected are 1. Rotor bar damage 2. Misalignment/ unbalance 3. Foundation looseness 4. Static eccentricity 5. Dynamic eccentricity 6. Core damage 7. Loose wedges 8. Interturn shorts 9. Defective bearings 10. Torque Analysis

THEORY A motor current signal is ideally a perfect sinusoidal wave at 50 Hz. Pictorially; we can represent the current in terms of time as well as frequency . The amplitude of the peak in frequency is equal to the RMS amplitude of the sine wave. As this is a theoretical situation with no harmonics, we see only one peak in the frequency spectrum. The conversion of the current from time to the frequency domain is achieved using an algorithm called the Fast Fourier Transform (FFT) or DFLL. During actual operation, many harmonics will be present in the motor signal, thus an actual signal will show many peaks including line frequency and its harmonics This is known as the motors current signature. Analyzing these harmonics after amplification and signal conditioning will enable identification of the various motor faults. Certain harmonics come in on the supply & these are of little consequence. However, harmonics are also generated due to various electrical & mechanical faults. All faults cause a change in the internal flux distribution, thus generating the harmonics. Note that these are intermediate harmonics and cannot be detected by standard harmonic analyzers. As fault generated harmonics appear only in the current spectrum (but not in voltage), superimposition of current & voltage spectra can easily identify them.

ROTOR BAR DAMAGE In the current signature, the motor pole passing frequency (PPF = motor slip x no. of poles) will show up as a sideband to the line frequency, i. e. we will see peaks at FL PPF The difference in amplitude between the line frequency peak and the pole passing frequency sidebands is an indication of the rotor bar health. Empirical research has shown that a difference of over 60 dB indicates an excellent rotor bar condition

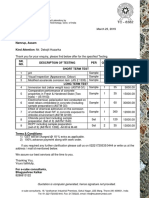

As the rotor bars start degrading (i. e. high resistance joints are present or a crack starts developing), the rotor impedance rises. Due to this, the current drawn at the PPF frequency rises, leading to an increase in the amplitude of the PPF peaks in the current spectrum. A difference of about 48 dB would indicate the presence of high resistance joints whereas a difference of about 35 dB would indicate multiple broken bars. Most cases lie somewhere in between and the exact damage level can be assessed in each case (see Table 1).

C A T 1 2 3 4 5 6 7

N dB O

Rotor Condition Assessment

>60 54 60 48 54 42 48 36 42 30 36 <30

Excellent Good Moderate High Resistant Connection or Cracked Bars Broken Rotor Bars Will Show in Vibration Multiple Cracked/Broken Bars, Poss. Slip Ring Problems Severe Rotor Faults

MISALIGNMENT/ UNBALANCE To identify these problems, it is required to perform another signal conditioning of the motor current signal. The process is known as RMS Demodulation, which is carried out in order to eliminate the line frequency.

Here, the motor running speed will show up as a peak. Based on its amplitude, we can judge whether any misalignment or unbalance is present. In the demodulated signature of a healthy motor, the motor running speed peak would be barely visible. In case the motor was to be misaligned or mechanically unbalanced, high peaks will show up at the motor running speed & its harmonics. FOUNDATION LOOSENESS.

Uneven foundations or loose foundation bolts will result in foundation looseness. This can by identified by looking at the RMS Demodulated spectrum. The looseness will show up as high peaks at half the running speed of the motor.

DYNAMIC AND STATIC Dynamic eccentricity is the phenomenon of a variable stator-rotor air gap, typically caused due to worn out bearing housings or end covers. This is a significant problem as it can damage the bearing & housing soon and can eventually lead to the rotor rubbing with the stator. Close trending is recommended on detection of this condition. It will show up as high peaks at principal rotor bar passing frequency and its harmonics along with the running speed sidebands around these. Dynamic eccentricity = RB x RS nFL RS

Static eccentricity = RB x RS nFL where RB= no. of rotor bars RS= running speed of the motor FL= line frequency n= odd harmonics of the line frequency

STATOR MECHANICAL FAULTS* These faults are typically loose wedges, laminations or core damage. Loose wedges damage the coil insulation mechanically and also erode the conducting varnish on the coil sides, leading to corona. The corona discharges then start degrading the motor insulation. Core damage results in shorted stator laminations, causing localized eddy currents and heating the core locally. This will eat away at the motor insulation and destroy it over time. * Detection of these faults & distinguishing between them is proprietary information and fault frequency calculations are hence not given over here.

INTERTURN SHORTS* Interturn shorts lead to excessive heating in the stator coil and also current imbalance. These will cause localized and uneven heating, reduced output and eventually resulting in a ground fault. The current spectrum can pick up interturn shorts as well as interturn insulation degradation (in severe cases). BEARING PROBLEMS* All bearings have a set of unique defect frequencies (as specified by the bearing manufacturer), which allow identification of bearing problems. When the current signature of a motor is examined, the presence of high peaks at these bearing defect frequencies can identify and pinpoint the problem (in terms of whether the damage is in the inner race, outer race, balls, rollers or cage). The degree of degradation can be assessed based on the amplitudes of these peaks.

TORQUE ANALYSIS* By capturing the real components of the current and deriving the flux generated from voltage a signal equal to air gap torque is developed. Mechanical information buried in a complex modulated current signal can now be easily accessed and interpreted for electrical and mechanical conditions.

ADDITIONAL APPLICATIONS The motor current is modulated by any form of vibration, which causes pulses in the torque & results in harmonics. Hence, current spectrum analysis can also be used to detect problems in the driven loads. Typical detectable problems include: Fan blade damage, Belt looseness, Gear tooth damage, Gear shaft unbalance, Load bearing problems, etc.

References: 1. Rubn Puche Panadero, Joan Pons Llinares, Vicente Climente Alarcony and Manuel Pineda Snchez, Review of Diagnosis Methods of Induction Electrical Machines based on Steady State Current. 2. Aditya Korde Diagnostic Technologies Online Condition Monitoring. 3. Thomson, W. T, On-Line MCSA to Diagnose Shorted Turns in Low Voltage Stator Windings of 3-Phase Induction Motors prior to Failure, Proceedings of IEEE Conference on Electrical Machines and Drives (IEMDC), 2001, Boston.

S-ar putea să vă placă și

- Electrical Signature AnalysisDocument25 paginiElectrical Signature AnalysisChandradeep BanerjeeÎncă nu există evaluări

- Knowledge is "Real Power": Introduction to Power QualityDe la EverandKnowledge is "Real Power": Introduction to Power QualityÎncă nu există evaluări

- Vibration Analysis Rolling Element BearingDocument20 paginiVibration Analysis Rolling Element BearingmilaÎncă nu există evaluări

- Motor Current SignatureDocument5 paginiMotor Current Signaturel1f3b00kÎncă nu există evaluări

- Nandi Infrastructure Corridor Enterprise Ltd. (NICE) - FinalDocument16 paginiNandi Infrastructure Corridor Enterprise Ltd. (NICE) - FinalJay Dhananjay ShahÎncă nu există evaluări

- Motor Current Signature Analysis TestDocument25 paginiMotor Current Signature Analysis Testmayur dhandeÎncă nu există evaluări

- Current Signature AnalysisDocument2 paginiCurrent Signature AnalysisawanrmbÎncă nu există evaluări

- Temperature Effects On DC Motor Performance 1Document10 paginiTemperature Effects On DC Motor Performance 1BabuÎncă nu există evaluări

- Tan Delta Test ReportDocument1 paginăTan Delta Test ReportRex007 90Încă nu există evaluări

- Harmonics Training May 2012 WebinarDocument35 paginiHarmonics Training May 2012 WebinarMarvin TejerinaÎncă nu există evaluări

- 2 - Slow Speed Vibration Signal AnalysisDocument9 pagini2 - Slow Speed Vibration Signal AnalysisSasi NimmakayalaÎncă nu există evaluări

- The Electrical Portal: Testing of DC MotorDocument2 paginiThe Electrical Portal: Testing of DC MotorGayathri Devi Yadav NakanaboyinaÎncă nu există evaluări

- Synchronous Motor: Ethiopia Maritime Training InstituteDocument21 paginiSynchronous Motor: Ethiopia Maritime Training InstitutetesfuÎncă nu există evaluări

- Chandra Gupt Porwal, CMD, NIMDC PVT LTD.Document13 paginiChandra Gupt Porwal, CMD, NIMDC PVT LTD.CHANDRA GUPT PORWALÎncă nu există evaluări

- Power Quality AnalyzerDocument4 paginiPower Quality AnalyzerVinod KumarÎncă nu există evaluări

- Measure Motor Efficiency To Understand VFDDocument5 paginiMeasure Motor Efficiency To Understand VFDGeorge MarkasÎncă nu există evaluări

- Hot Spot AllowanceDocument4 paginiHot Spot AllowanceCarlosÎncă nu există evaluări

- 8MS Three-Phase Synchronous MotorsDocument163 pagini8MS Three-Phase Synchronous MotorsrrrÎncă nu există evaluări

- Crest FactorDocument3 paginiCrest FactorjavadÎncă nu există evaluări

- THD Total Harmonic DistortionDocument3 paginiTHD Total Harmonic DistortionVenkateshÎncă nu există evaluări

- Vibration Analysis - Center of Electrical MachinesDocument12 paginiVibration Analysis - Center of Electrical MachinesmortezaÎncă nu există evaluări

- Improving Electrical System Reliability With Infrared ThermographyDocument5 paginiImproving Electrical System Reliability With Infrared ThermographyMohd Shawal100% (1)

- Finial Report PDFDocument33 paginiFinial Report PDFdurgaÎncă nu există evaluări

- T19101 118Document18 paginiT19101 118Chintan Raval100% (1)

- Air GapDocument20 paginiAir GapSurabhi MattaÎncă nu există evaluări

- AC Motor Name Plate - Terms & MeaningsDocument2 paginiAC Motor Name Plate - Terms & Meaningsavandetq15Încă nu există evaluări

- Avoiding Flashover in Medium-Voltage SwitchgearDocument7 paginiAvoiding Flashover in Medium-Voltage SwitchgearJuvencio MolinaÎncă nu există evaluări

- Turbovisory System: By: Oliver AdakDocument40 paginiTurbovisory System: By: Oliver AdakKrishna KumarÎncă nu există evaluări

- Phase Analysis: Part 1Document27 paginiPhase Analysis: Part 1Shawn RuhlÎncă nu există evaluări

- Vibration Assessment Quiz To Determine Entry Vs Analysis IDocument2 paginiVibration Assessment Quiz To Determine Entry Vs Analysis IAhmad DanielÎncă nu există evaluări

- Module3 - Induction MotorDocument45 paginiModule3 - Induction MotorRevki 'Exiit'Încă nu există evaluări

- Motor Temperature RatingsDocument5 paginiMotor Temperature RatingsFaizan Tahir ButtÎncă nu există evaluări

- Vib - AccelerometerDocument16 paginiVib - AccelerometerMahmoud SobhyÎncă nu există evaluări

- Vibration Analysis: How Does It Work?Document18 paginiVibration Analysis: How Does It Work?Rahul TaleÎncă nu există evaluări

- CM3152 en SKF Idler Sound MonitorDocument4 paginiCM3152 en SKF Idler Sound MonitorLuisSilvaÎncă nu există evaluări

- Installation of Vibration SensorsDocument8 paginiInstallation of Vibration SensorsnmguravÎncă nu există evaluări

- Transmission Line Signature AnalysisDocument6 paginiTransmission Line Signature AnalysisLalit KumarÎncă nu există evaluări

- Case Studies On VibrationsDocument36 paginiCase Studies On VibrationsAHMEDSAEED013Încă nu există evaluări

- Analysis of Permanent Magnet Synchronous MotorDocument15 paginiAnalysis of Permanent Magnet Synchronous Motormalini72Încă nu există evaluări

- 71951B LeonovaDiamond SpreadDocument8 pagini71951B LeonovaDiamond SpreadRajesh BeheraÎncă nu există evaluări

- Using PeakVue Plus Technology For Detecting Anti Friction Bearing FaultsDocument11 paginiUsing PeakVue Plus Technology For Detecting Anti Friction Bearing Faultseko bagus sunaryo100% (1)

- Condition Monitoring and Fault Diagnosis of Electrical MachineDocument8 paginiCondition Monitoring and Fault Diagnosis of Electrical Machinemurthy237Încă nu există evaluări

- Electrical MachinesDocument50 paginiElectrical MachinesTanvi SuryawanshiÎncă nu există evaluări

- Vertical Motor Case History Shurafa IIR Rotate 2012Document4 paginiVertical Motor Case History Shurafa IIR Rotate 2012aal_shurafa100% (1)

- Up9000 ManualDocument33 paginiUp9000 Manualho-faÎncă nu există evaluări

- BHmag User ManualDocument40 paginiBHmag User ManualRamzanÎncă nu există evaluări

- Basics Vibration MeasurementDocument5 paginiBasics Vibration MeasurementMohan Arumugavallal100% (1)

- Solution Handbook: Harmonic MitigationDocument40 paginiSolution Handbook: Harmonic MitigationAngela TienÎncă nu există evaluări

- SM101 Life Expectancy Analysis Program (LEAP) Rev ADocument2 paginiSM101 Life Expectancy Analysis Program (LEAP) Rev Aashish0011Încă nu există evaluări

- Analysis ExamplesDocument53 paginiAnalysis ExamplesAbdelrahman KassmÎncă nu există evaluări

- A I RS: David G. Dorrell, William ThomsonDocument11 paginiA I RS: David G. Dorrell, William ThomsonEng Bagaragaza RomualdÎncă nu există evaluări

- Motor Bearing Failure Analysis by Vibration MonitoringDocument180 paginiMotor Bearing Failure Analysis by Vibration MonitoringGeert Henk Wijnants100% (1)

- IRTLevel1 3TrainingBrochureDocument12 paginiIRTLevel1 3TrainingBrochuregedearthanaÎncă nu există evaluări

- Shock Pulse MeasuringDocument4 paginiShock Pulse MeasuringyancÎncă nu există evaluări

- Pitfalls in The Analysis of Machinery Vibration MeasurementsDocument7 paginiPitfalls in The Analysis of Machinery Vibration MeasurementsTheerayoot PoomchaiÎncă nu există evaluări

- Mcsa PDFDocument12 paginiMcsa PDFdurgaprasad reganiÎncă nu există evaluări

- Motor Current Signature Analysis and InterpretationDocument6 paginiMotor Current Signature Analysis and InterpretationJayant KumarÎncă nu există evaluări

- SPM TrainingDocument106 paginiSPM TrainingBhaskar Reddy0% (1)

- Fault DiagnosisDocument29 paginiFault DiagnosisAnish PaiÎncă nu există evaluări

- Electricity Magnetism Appendix BDocument17 paginiElectricity Magnetism Appendix BLuis LongoÎncă nu există evaluări

- Multi Degree of FreedomDocument67 paginiMulti Degree of FreedomSrinath Gudur100% (1)

- Dirac Delta FuctionDocument4 paginiDirac Delta Fuctionreky_georgeÎncă nu există evaluări

- Harmonics and How They Relate To Power Factor - POWERFACDocument8 paginiHarmonics and How They Relate To Power Factor - POWERFACtatacpsÎncă nu există evaluări

- Dirac Delta FuctionDocument4 paginiDirac Delta Fuctionreky_georgeÎncă nu există evaluări

- ZigZag TransformersDocument3 paginiZigZag Transformerssukonna20040% (1)

- User Manual OptiPoint 500 For HiPath 1220Document104 paginiUser Manual OptiPoint 500 For HiPath 1220Luis LongoÎncă nu există evaluări

- Advanced Spectral AnalysisDocument9 paginiAdvanced Spectral AnalysisDamir KapidzicÎncă nu există evaluări

- User Manual OptiPoint 500 For HiPath 1220Document104 paginiUser Manual OptiPoint 500 For HiPath 1220Luis LongoÎncă nu există evaluări

- 63787Document13 pagini63787Luis LongoÎncă nu există evaluări

- Good Painting PracticeDocument1.673 paginiGood Painting PracticeLuis Longo60% (5)

- ,, Detyra, DinamikDocument17 pagini,, Detyra, DinamikVissarosÎncă nu există evaluări

- Accelerometer, IcpDocument2 paginiAccelerometer, IcpLuis LongoÎncă nu există evaluări

- 41 Assignment Worksheets For SchoolDocument26 pagini41 Assignment Worksheets For Schoolsoinarana456Încă nu există evaluări

- 2020 ROTH IRA 229664667 Form 5498Document2 pagini2020 ROTH IRA 229664667 Form 5498hk100% (1)

- Compartment SyndromeDocument14 paginiCompartment SyndromedokteraanÎncă nu există evaluări

- Royal British College IncDocument5 paginiRoyal British College IncLester MojadoÎncă nu există evaluări

- Benzil PDFDocument5 paginiBenzil PDFAijaz NawazÎncă nu există evaluări

- Art of Facing InterviewsDocument15 paginiArt of Facing Interviewskrish_cvr2937100% (2)

- Sustainable Development at British Petroleum: Presented by Amardeep Kulshrestha 09BS0000172 Section-EDocument20 paginiSustainable Development at British Petroleum: Presented by Amardeep Kulshrestha 09BS0000172 Section-EAmar KulshresthaÎncă nu există evaluări

- Pioneer PDP 5071 5070pu Arp 3354Document219 paginiPioneer PDP 5071 5070pu Arp 3354Dan Prewitt100% (1)

- Eric Koech CV - Docx..bakDocument7 paginiEric Koech CV - Docx..bakPeter Osundwa KitekiÎncă nu există evaluări

- Heat Transfer ExampleDocument4 paginiHeat Transfer Examplekero_the_heroÎncă nu există evaluări

- Epo-Fix Plus: High-Performance Epoxy Chemical AnchorDocument3 paginiEpo-Fix Plus: High-Performance Epoxy Chemical Anchormilivoj ilibasicÎncă nu există evaluări

- PEOPLE V JAURIGUE - Art 14 Aggravating CircumstancesDocument2 paginiPEOPLE V JAURIGUE - Art 14 Aggravating CircumstancesLady Diana TiangcoÎncă nu există evaluări

- Gender, Slum Poverty and Climate Change in Flooded River Lines in Metro ManilaDocument53 paginiGender, Slum Poverty and Climate Change in Flooded River Lines in Metro ManilaADBGADÎncă nu există evaluări

- Discharge PlanDocument3 paginiDischarge PlanBALOGO TRISHA MARIEÎncă nu există evaluări

- Refinería Kirkuk PDFDocument11 paginiRefinería Kirkuk PDFcesarinarragaÎncă nu există evaluări

- QA-QC TPL of Ecube LabDocument1 paginăQA-QC TPL of Ecube LabManash Protim GogoiÎncă nu există evaluări

- ATI Respiratory PowerpointDocument90 paginiATI Respiratory PowerpointAnn KelseaÎncă nu există evaluări

- Introduction and Vapour Compression CycleDocument29 paginiIntroduction and Vapour Compression Cycleمحسن الراشدÎncă nu există evaluări

- DyslexiaDocument19 paginiDyslexiaKeren HapkhÎncă nu există evaluări

- Meat Plant FeasabilityDocument115 paginiMeat Plant FeasabilityCh WaqasÎncă nu există evaluări

- Chemical Reaction Engineering-II - R2015 - 10-04-2018Document2 paginiChemical Reaction Engineering-II - R2015 - 10-04-201818135A0806 MAKKUVA BHAVYAÎncă nu există evaluări

- PPR Soft Copy Ayurvedic OkDocument168 paginiPPR Soft Copy Ayurvedic OkKetan KathaneÎncă nu există evaluări

- Dungeon World ConversionDocument5 paginiDungeon World ConversionJosephLouisNadeauÎncă nu există evaluări

- PolydactylyDocument43 paginiPolydactylyWara Samsarga GedeÎncă nu există evaluări

- Minyak Atsiri Sereh WangiDocument4 paginiMinyak Atsiri Sereh Wangicindy paraditha kasandraÎncă nu există evaluări

- Birding The Gulf Stream: Inside This IssueDocument5 paginiBirding The Gulf Stream: Inside This IssueChoctawhatchee Audubon SocietyÎncă nu există evaluări

- Q1. (A) The Diagram Shows A Microphone Being Used To Detect The Output From ADocument10 paginiQ1. (A) The Diagram Shows A Microphone Being Used To Detect The Output From ASivmi MalishaÎncă nu există evaluări

- Cover Letter UchDocument1 paginăCover Letter UchNakia nakia100% (1)

- Cultivation Vaderstad Manual 2017Document128 paginiCultivation Vaderstad Manual 2017deroryÎncă nu există evaluări

- Rooftop Rain Water Harvesting in An Educational CampusDocument9 paginiRooftop Rain Water Harvesting in An Educational CampusAkshay BoratiÎncă nu există evaluări

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterDe la EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterÎncă nu există evaluări

- A Practical Handbook for Drilling Fluids ProcessingDe la EverandA Practical Handbook for Drilling Fluids ProcessingÎncă nu există evaluări

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesDe la EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesEvaluare: 4.5 din 5 stele4.5/5 (21)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentDe la EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentEvaluare: 4.5 din 5 stele4.5/5 (21)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDe la EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialÎncă nu există evaluări

- Shorting the Grid: The Hidden Fragility of Our Electric GridDe la EverandShorting the Grid: The Hidden Fragility of Our Electric GridEvaluare: 4.5 din 5 stele4.5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressDe la EverandNuclear Energy in the 21st Century: World Nuclear University PressEvaluare: 4.5 din 5 stele4.5/5 (3)

- Introduction to Power System ProtectionDe la EverandIntroduction to Power System ProtectionEvaluare: 5 din 5 stele5/5 (1)

- A Pathway to Decarbonise the Shipping Sector by 2050De la EverandA Pathway to Decarbonise the Shipping Sector by 2050Încă nu există evaluări

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsDe la EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsEvaluare: 4.5 din 5 stele4.5/5 (2)

- Heat Transfer Engineering: Fundamentals and TechniquesDe la EverandHeat Transfer Engineering: Fundamentals and TechniquesEvaluare: 4 din 5 stele4/5 (1)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsDe la EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsÎncă nu există evaluări

- Practical Reservoir Engineering and CharacterizationDe la EverandPractical Reservoir Engineering and CharacterizationEvaluare: 4.5 din 5 stele4.5/5 (3)

- Smart Power Distribution Systems: Control, Communication, and OptimizationDe la EverandSmart Power Distribution Systems: Control, Communication, and OptimizationÎncă nu există evaluări

- Power Electronics Diploma Interview Q&A: Career GuideDe la EverandPower Electronics Diploma Interview Q&A: Career GuideÎncă nu există evaluări

- Well Integrity for Workovers and RecompletionsDe la EverandWell Integrity for Workovers and RecompletionsEvaluare: 5 din 5 stele5/5 (3)

- Handbook on Battery Energy Storage SystemDe la EverandHandbook on Battery Energy Storage SystemEvaluare: 4.5 din 5 stele4.5/5 (2)

- Flow Analysis for Hydrocarbon Pipeline EngineeringDe la EverandFlow Analysis for Hydrocarbon Pipeline EngineeringÎncă nu există evaluări

- Renewable Energy: A Very Short IntroductionDe la EverandRenewable Energy: A Very Short IntroductionEvaluare: 4.5 din 5 stele4.5/5 (12)

- Live Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerDe la EverandLive Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerÎncă nu există evaluări

- The Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceDe la EverandThe Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceÎncă nu există evaluări

- Global Landscape of Renewable Energy FinanceDe la EverandGlobal Landscape of Renewable Energy FinanceÎncă nu există evaluări

- Solar Electricity Basics: Powering Your Home or Office with Solar EnergyDe la EverandSolar Electricity Basics: Powering Your Home or Office with Solar EnergyEvaluare: 5 din 5 stele5/5 (3)

- Photovoltaic Solar Energy: From Fundamentals to ApplicationsDe la EverandPhotovoltaic Solar Energy: From Fundamentals to ApplicationsÎncă nu există evaluări

- An Introduction to Renewable Energy Sources : Environment Books for Kids | Children's Environment BooksDe la EverandAn Introduction to Renewable Energy Sources : Environment Books for Kids | Children's Environment BooksÎncă nu există evaluări

- Electric Motor Control: DC, AC, and BLDC MotorsDe la EverandElectric Motor Control: DC, AC, and BLDC MotorsEvaluare: 4.5 din 5 stele4.5/5 (19)

- Renewable Energy Sources - Wind, Solar and Hydro Energy Revised Edition : Environment Books for Kids | Children's Environment BooksDe la EverandRenewable Energy Sources - Wind, Solar and Hydro Energy Revised Edition : Environment Books for Kids | Children's Environment BooksÎncă nu există evaluări

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsDe la EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsÎncă nu există evaluări