Documente Academic

Documente Profesional

Documente Cultură

Spec MPC Iss2

Încărcat de

Rehan QureshiDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Spec MPC Iss2

Încărcat de

Rehan QureshiDrepturi de autor:

Formate disponibile

Page 1 sur 62

Toulouse, le 19 Septembre 2003

DO/TA - 4159/03

Ed.02 du 06/05/2004

ATR 42/72

BORDERAU DE DIFFUSION DE LA

SPECIFICATION TECHNIQUE D'EQUIPEMENT

************************************************************

N DE SPEC : DO/TA 4159/03 Ed.02 06/05/2004

DESIGNATION : RECORDING SYSTEM - AIRCRAFT MONITORING SYSTEM

DESCRIPTION : MULTI-PURPOSE COMPUTER (MPC)

************************************************************

DIFFUSION : DO/T C.ORSI

DO/TF G.PETIT

DO/TA D. CLERC

DO/TV E.DELESALLE

DO/QE F.CAPOVILLA

DO/PE B.HAAG

Page 2 sur 62

ATR 42 / 72

EQUIPEMENT TECHNICAL SPECIFICATION

************************************************************

N EQUIP SPEC : DO/TA 4159/03 Ed.02 06/05/2004

SYSTEM : RECORDING SYSTEM AIRCRAFT MONITORING SYSTEM

EQUIPMENT : MULTI-PURPOSE COMPUTER (MPC)

************************************************************

COMPILED BY : R. TROUILHET APPROVED BY : D. CLERC

P.BERTHELOT G.PETIT

AUTHORIZED BY: C.ORSI

Ce document est CONFIDENTIEL, il est la proprit dATR.

Ce document ne peut tre, en partie ou en totalit reproduit, ni communiqu quiquonque, ni utilis

l'encontre des dites Socits.

This document is CONFIDENTIAL, it is the property of ATR.

This document must not be, partially, reproduced, nor lent to a third party, nor used against the afore

mentioned Companies.

Page 3 sur 62

EQUIPEMENT SPECIFICATION

LIST OF REVISIONS

ISSUE DATE EFFECT ON

PAGE PAR

REASON FOR REVISION

1

2

19.09.03

06.05.04

All 1

er

issue. Call for tender specification

2me Issue

Page 4 sur 62

EQUIPEMENT SPECIFICATION

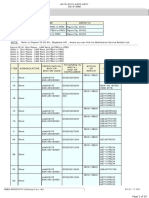

CURRENT ISSUE OF PAGES

PAGE ISSUE PAGE ISSUE PAGE ISSUE PAGE ISSUE

Page 5 sur 62

INDEX

1. GENERAL

1.1. PURPOSE

1.2. SCOPE

1.3. DATA SUBJECT TO GUARANTEES

1.4. ABBREVIATIONS

1.5. APPLICABLE DOCUMENTS

1.5.1. GENERAL

1.5.2. ATR ATR DOCUMENTS

1.5.2.1. MISCELLANEOUS DOCUMENTS

1.5.2.2. QUALITY REQUIREMENTS DOCUMENTS

1.5.2.3. ARINC DOCUMENTS

1.5.2.4. EUROCAE / FAR AND RTCA DOCUMENTS

1.5.2.5. REGULATION DOCUMENTS

1.5.2.6. COMPANIES DOCUMENTS

1.5.2.7. TECHNICAL REQUIREMENT DOCUMENTS

2. DESIGN REQUIREMENTS AND OPERATING CONDITIONS

2.1. DESCRIPTION

2.1.1. DEFINITIONS, PROVISIONS, DEVELOPMENT SPARES AND GROWTH

CAPABILITY

2.1.2. SYSTEM ARCHITECTURE

2.1.3. FUNCTIONS TO BE PERFORMED BY MPC

2.1.3.1 FDAU Part

2.1.3.2 DMU Part

2.1.4. IDENTIFIED PROVISIONS

2.1.4.1. FDAU Part

Page 6 sur 62

2.1.4.2. DMU Part

2.2. CHARACTERISTICS

2.2.1. INTERFACES

2.2.1.1. GENERAL INTERFACE REQUIREMENTS

2.2.1.2. INTERFACE WITH OTHER SYSTEMS OR EQUIPMENTS

2.2.1.3. MECHANICAL INTERFACE

2.2.1.4. HYDRAULIC INTERFACE

2.2.1.5. ELECTRICAL INTERFACE

2.2.1.5.1. Power supply

2.2.1.5.2. Power consumption

2.2.1.5.3. Input / output capacity

2.2.1.5.4. Connection and wiring

2.2.1.5.5. Input/output characteristics and protections

2.2.1.5.6. Circuit breaker characteristics

2.2.1.5.7. Characteristics of signals

2.2.1.6. PNEUMATIC INTERFACE

2.2.2. ERGONOMICS ASPECTS

2.2.2.1. GENERAL

2.2.3. BUILT-IN TEST EQUIPMENT (BITE)

2.2.4. O.B.R.M (ON BOARD REPLACEABLE MODULE)

2.2.5. DATA LOADING

2.2.5.1 GENERAL

2.2.5.2 DATA LOADING METHODOLOGY

2.2.6. INTERCHANGEABILITY

2.2.7. MIXABILITY

2.2.8. NUMBER OF COMPONENTS

2.2.9. LOCKING OF PARTS

2.2.10. BONDING

2.2.11. MISCELLANEOUS DESIGN REQUIREMENTS

Page 7 sur 62

2.3. PERFORMANCE

2.3.1. SYSTEM PERFORMANCE

2.3.2. PERFORMANCE RELATIVE TO POWER CUTS

2.3.3. SYSTEMS RESPONSE TIME

2.3.4. UNIT CAPACITY

2.3.4.1. ADDITIONAL INFORMATION TO DETERMINE THE BASIC UNIT

CAPACITY

2.3.4.2. PURCHASER DEVELOPMENT SPARES

2.3.4.3. PROCESSING POWER AND MEMORY CAPACITY

2.3.5. GROWTH CAPABILITY

2.4. MATERIALS AND PRODUCTION PROCESSES-CORROSION

2.4.1. GENERAL REQUIREMENTS

2.4.2. FLUIDS AND PRODUCTS USED ON AIRCRAFT

2.4.3. HYDRAULIC FLUID TEMPERATURE

2.4.4. FIRE PROPAGATION

2.4.5. FLAMMABILITY, SMOKE AND TOXIC GAS EMISSION

2.5. LOCATION AND ENVIRONMENT

2.5.1. LOCATION

2.5.2. ENVIRONMENTAL CONDITIONS

2.5.3. HEAT DISSIPATION, VENTILATION, COOLING AND HEATING

2.5.3.1. HEAT DISSIPATION

2.5.3.2. VENTILATION - COOLING

2.6. OPERATIONAL DATA

2.7. INSTALLATION

2.8. NOISE

2.9. MASS

Page 8 sur 62

2.10. VOLUME

2.11. PIN PROGRAMMING

3. SAFETY - RELIABILITY - MAINTAINABILITY

3.1. SAFETY - RELIABILITY

3.1.1. DEFINITION OF TERMS

3.1.2. SAFETY AND RELIABILITY OBJECTIVES

3.1.3. SEGREGATION REQUIREMENTS

3.1.3.1. GENERAL REQUIREMENT

3.1.3.2. PROTECTION AGAINST PHYSICAL DISTURBANCE ON INPUTS /

OUTPUTS DEDICATED TO ENGINES

3.1.3.3. CHANNELS SEGREGATION - DISSIMILARITY

3.1.4. SAFETY TESTS

3.1.5. FAILURE ANALYSIS

3.1.5.1. FMEA

3.1.5.2. FMES

3.1.6. HAZARD ANALYSIS

3.1.7. SPECIAL REQUIREMENTS

3.2. RELIABILITY AND MAINTAINABILITY

3.2.1. DEFINITION OF TERMS

3.2.2. RELIABILITY

3.2.3. SERVICE LIFE

3.3. QUALITY ASSURANCE FOR SAFETY AND MAINTAINABILITY

3.4. DEFECT INVESTIGATION ON REJECTED UNIT

4. CERTIFICATION AND QUALIFICATION

4.1. DEFINITION OF TERMS

4.2. REGULATIONS AND CERTIFICATION CONSIDERATIONS

Page 9 sur 62

4.3. QUALIFICATION

4.3.1. GENERAL

4.3.2. UNIT CATEGORY AND CLASSIFICATION

4.3.3. QUALIFICATION DOCUMENTS

4.3.4. MINIMUM QUALIFICATION BEFORE DELIVERY OF THE FIRST UNIT

4.3.5. QUALIFICATION BEFORE FIRST FLIGHT

4.4. CONTINUING AIRWORTHINESS

5. SOFTWARE DEVELOPMENT REQUIREMENTS

5.1. SOFTWARE QUALITY CLAUSES

6. HARDWARE DEVELOPMENT REQUIREMENTS

6.1. DESIGN CAPABILITY EVALUATION OF SUPPLIER

6.2. DESIGN STANDARDS

6.3. HARDWARE TESTABILITY COVERAGE

6.4. SELECTION OF ELECTRONIC COMPONENTS AND ASSEMBLY PROCESSES

6.4.1. TECHNOLOGY QUALIFICATION TESTS

6.4.2. TECHNOLOGIES MODIFICATIONS AND REQUALIFICATION

6.5. ELECTRONICS COMPONENTS SCREENING TESTS

6.6. SELECTION OF MATERIALS

6.7. HARDWARE QUALITY CLAUSES

6.8. ASICS QUALITY CLAUSES

7. MANUFACTURING AND TESTS

7.1. MANUFACTURING AND SCREENING

7.1.1. MANUFACTURING

Page 10 sur 62

7.1.2. SCREENING SPECIFICATION

7.2. MANUFACTURING TEST

7.2.1. MANUFACTURING DETAILED TEST SPECIFICATION (DTS)

7.2.2. ACCEPTANCE TEST SPECIFICATION (ATS)

7.2.2.1. ATS DEFINITION

7.2.2.2. ACCEPTANCE TEST AND TEST COVERAGE ANALYSIS APPROVAL

7.2.2.3. TEST COVERAGE REQUIREMENTS

7.2.2.4. MINIMUM ATS CONTENT

7.2.3. ATLAS TEST SPECIFICATION

7.2.4. MAINTENANCE TEST SPECIFICATION (MTS)

7.2.5. ACCEPTANCE TEST DOCUMENTATION DELIVERY

8. QUALITY ASSURANCE

8.1. GENERAL

8.2. QUALITY ASSURANCE PROVISIONS THROUGHOUT THE LIFE CYCLE

9. CONFIGURATION MANAGMENT

9.1. IDENTIFICATION

9.2. CHANGE MANAGEMENT

9.2.1. MODIFICATION WITH SPECIFICATION EVOLUTION (DCR, DCI/EMS)

9.2.2. MODIFICATIONS OF THE UNIT TO SATISFY THE TECHNICAL

SPECIFICATION

9.2.3. OTHER MODIFICATIONS

9.2.4. SOFTWARE CHANGE IMPLEMENTATION

9.2.5. CHANGE DOCUMENTATION

10. METHOD AND TOOLS

11. TECHNICAL RESPONSIBILITIES ORGANIZATION

11.1. PURCHASER AND SUPPLIER TECHNICAL RESPONSIBILITIES

Page 11 sur 62

11.1.1. GENERAL

11.1.2. PROVISIONS AND DEVELOPMENT SPARES RESPONSIBILITIES

11.1.3. SOFTWARE RESPONSIBILITY

11.1.3.1. SUPPLIER RESPONSIBILITIES

11.1.3.2. PURCHASER RESPONSIBILITIES

11.2. DEVELOPMENT PHASES

11.3. ORGANIZATION - INTEGRATED TEAMS

12. PROJECT MANAGEMENT

12.1. PROGRESS MEETINGS

12.2. TECHNICAL MEETINGS

12.3. MANAGEMENT MEETINGS

12.4. REVIEW MEETINGS

12.4.1. REVIEWS LIST

12.4.2. PLANS REVIEW (PR)

12.4.3. PRELIMINARY DESIGN REVIEW (PDR)

12.4.4. CRITICAL DESIGN REVIEW (CDR)

12.4.5. LABORATORY UNIT ACCEPTANCE (LUA)

12.4.6. FIRST FLIGHT ARTICLE REVIEW (FFAR)

12.4.7. CERTIFICATION FIRST ARTICLE REVIEW (CFAR)

12.5. PERFORMANCES ASSESSMENT

12.6. AUDITS

13. STORAGE AND HANDLING

14. SUPPLYING

14.1. DELIVERY STANDARD FOR DEVELOPMENT PHASES

Page 12 sur 62

14.2. TECHNICAL DATA / DOCUMENTATION

14.2.1. GENERAL

14.2.2. SUPPLIER'S TECHNICAL PROPOSAL

14.2.2.1. CONTENTS

14.2.2.2. REQUIRED PROPOSAL PLAN AND FORM

14.2.3. EQUIPMENT DOCUMENTS

14.2.4. SOFTWARE DOCUMENTATION

15. DEVELOPMENT SCHEDULE

Page 13 sur 62

APPENDIX

APPENDIX 1

Aircraft Performances Monitoring Function DO/TF 2049/04 Ed.01

APPENDIX 2

Enhanced Surveillance & ADS-B Function DO/TY 3166/04 Ed.01

APPENDIX 3

AFCS Maintenance Function DO/TY 3167/04 Ed.01

APPENDIX 4

TCAS Maintenance Function DO/TY 3168/04 Ed.01

APPENDIX 5

MFC Maintenance Maintenance Memory ReadingFunction DO/TY 3169/04 Ed.01

APPENDIX 6

Radio Communication / Navigation Maintenance Function DO/TY 3170/04 Ed.01

APPENDIX 7

G-Meter Function DO/TY 3171/04 Ed.01

APPENDIX 8

PEC / EEC Maintenance Function DO/TY 3172/04 Ed.01

Page 14 sur 62

A AT TR R 4 42 2 / / 7 72 2

R RE EC CO OR RD DI IN NG G S SY YS ST TE EM M - - AIRCRAFT MONITORING SYSTEM

1. GENERAL

1.1. PURPOSE

This technical document defines the specification for the Multi-Purpose Computer (MPC).

The role and functions of this computer are described in chapter 2 of this specification.

It defines :

- the technical requirements the system must satisfy,

- the installation characteristics for these items,

- the environmental conditions,

- the requested documentation.

The supplier shall be entirely responsible contractually for the fulfillment of these requirements.

In no case has the supplier proposal any contractual authority.

1.2. SCOPE

This technical document deals with the "MPC used on all ATR aircraft.

The hardware shall be identical for all type of aircraft.

The embedded software :

- shall have the capability to be uploaded,

- shall be identical for both aircraft, including pin-programmable functions dedicated to specific

applications, if necessary.

1.3. DATA SUBJECT TO GUARANTEES

The technical specification clearly identifies the data subject to guarantees from the supplier.

The guaranteed data shall be :

- sizes,

- weight,

- heat dissipation,

- electrical consumption,

- MTBF,

- MTBUR,

- service life,

- computation performances,

- safety objectives.

All the technical data required in this document shall be guaranteed by the supplier.

1.4. ABBREVIATIONS

A/C : Aircraft

ACARS : Aircraft Communications Addressing and Reporting System

ACMS : Airplane Condition Monitoring System

ADL : Airborne Data Loader

Page 15 sur 62

MPC : Multi Purpose Computer

AFDAU : Auxiliary Flight Data Acquisition Unit

AIDS : Aircraft Integrated Data System

ARINC : Aeronautical Radio Inc

BITE : Built In Test Equipment

CSDB : Commercial Standard Digital Bus

CVR : Cockpit Voice Recorder

DFDR : Digital Flight Data Recorder

DMT : Display Memory Terminal

DMU : Data Management Unit

FDAU : Flight Data Acquisition Unit

FMEA : Failure Modes Effects Analysis

FMES : Failure Modes Effects Summary

I/O : Input / Output

JAA : Joint Aviation Authorities

LRU : Line Replaceable Unit

MCDU : Multipurpose Control and Display Unit

MPTR : Multipurpose Printer

MTBF : Mean Time between Failures

MTBUR : Mean Time between Unscheduled Removals

NA : Not Applicable

PC : Personal Computer

PCM : Pulse Code Modulation

PCMCIA : Personal Computer Memory Card International Association

PDL : Portable Data Loader

PTE : Portable Test Equipment

P/N : Part Number

QAR : Quick Access Recorder

SSM : Sign & Status Matrix

TBA : To Be Answered (by the supplier before the selection)

TBC : To Be Confirmed (by the purchaser before the selection and accepted by the supplier)

TBD : To Be Defined (by the purchaser before the selection and accepted by the supplier).

1.5. APPLICABLE DOCUMENTS

1.5.1. GENERAL

Unless otherwise specified, the units shall comply with the documents listed hereafter and

with applicable documents referenced in them.

1.5.2. ATR ATR DOCUMENTS

1.5.2.1. MISCELLANEOUS DOCUMENTS

Note D00S-322-4001C : Characteristics of ATR 42 electrical generation,

MIL-HDBK 217E : Reliability prediction of electronic equipment.

Note AS 419.066/82 ATR 42 General Equipment Environmental Conditions

Note AS 419.065/82 ATR 42 General Technical Requirement of Equipment

1.5.2.2. QUALITY REQUIREMENTS DOCUMENTS

D-74.01 Supplier Quality Requirements.

CG.0084 Suppliers Survey.

CG.0073 Suppliers Qualification.

M011 Industrial Process Control Evaluation

1.5.2.3. ARINC DOCUMENTS

ARINC 724B : Aircraft Communication Addressing and Reporting System

(ACARS),

ARINC 573 : Aircraft Integrated Data System (AIDS Mark 2),

ARINC 429 : Mark 33 Digital Information Transfer System,

Page 16 sur 62

ARINC 600 : Air transports Avionics Equipment Interfaces,

ARINC 615-3 : Data Loading,

ARINC 739 : Multi purpose Control and Display Unit,

ARINC 591 : Quick Access Recorder for AIDS System,

ARINC 717 : Flight Data Acquisition and Recording System,

ARINC 597 : Communications Addressing and Reporting System.

ARINC 615 : Airborne Computer High Speed Data Loader

ARINC 740/744 : Multiple-input Cockpit Printer

1.5.2.4. EUROCAE / FAR AND RTCA DOCUMENTS

EUROCAE ED 14 / RTCA DO160 : Environmental Conditions and Tests

Procedures for Airborne Equipment.

EUROCAE ED 12 / RTCA D0178 : Software Considerations in Airborne

Systems and equipment Certification.

EUROCAE ED 80 / RTCA D0254: Design assurance guidance for airborne

Electronic hardware.

1.5.2.5. REGULATION DOCUMENTS

EUROCAE ED 55,

FAR 121-344,

FAR 25,

JAR 25.

1.5.2.6. COMPANIES DOCUMENTS

523-0772774-00911R Ed 9 January 14 1998 : Commercial Standard Digital Bus

(CSDB).

EB 7013343 : Avionics Standard Communication Bus (ASCB) Version A.

1.5.2.7 TECHNICAL REQUIREMENT DOCUMENTS

D-75.03 Identification marking of aircraft items.

CG-0163FEE / DDP processing and distribution.

Page 17 sur 62

2. DESIGN REQUIREMENTS AND OPERATING CONDITIONS

2.1. DESCRIPTION

2.1.1. DEFINITIONS, PROVISIONS, DEVELOPMENT SPARES AND GROWTH

CAPABILITY

Basic functions and basic definition :

All the functions required in this document, which are not provision are called basic

functions.

Basic functions and their associated requirements define the basic definition.

Identified provisions :

Different levels of identified provisions are used according :

- to the knowledge of the function with which the provision is associated,

- to the probability of implementation of the function in the unit.

There are three types of identified provisions :

1) Space provision :

In order to make space provision for a function within a unit, the supplier shall ensure

that :

- the overall size of the unit and the size of any associated panel or display for which

the supplier has responsibility are compatible with the inclusion of the function

- the size of any electronic card or assembly that is contained within the unit can

accommodate the necessary additional Input/Output, memory and processing capacity

needed to implement the function.

2) System provision

In order to make system provision for a function within a unit the supplier shall ensure

that :

- space provision is made,

- all mechanical subassemblies and associated wiring to perform the function are

included in the unit (e.g. switches, controls, and connectors),

- on the electronic cards the circuits and associated wiring to accomplish the

input/output task associated with the function are included,

- the memories installed in the unit are sufficient to meet the memory needs of the

function,

- the processing requirement of the function can be met within the installed processing

capacity of the unit,

- the software implementing the basic definition shall be designed to allow an easy

addition of the function (without modification to the software architecture).

3) Full provision

In order to make full provision for a function within a unit, the supplier shall ensure

that :

- the function is treated as a basic function (as such, it is implemented within the unit).

Identified definition :

The basic definition plus the identified provision constitute the identified definition.

Supplier development spares :

The supplier may take supplier development spares in order to face his possible errors, for

instance :

Page 18 sur 62

- when defining the characteristics of the unit he considers necessary for the identified

definition,

- when developing the unit,

- .... .

Basic Unit capacity :

The - basic definition,

- identified provisions,

- supplier development spares,

- and the associated requirements (required performance, for instance), allow the

supplier to define the basic unit capacity.

Growth capability :

The growth capability is constituted by the extra provisions, which could be defined by the

supplier in order to ease future development for functions, which are not defined in the

present document.

Options :

An option constitutes an extension of the basic aircraft.

It is taken into account in this technical specification either through the basic functions, or

through the identified provision.

The word "option" is reserved for the aircraft system.

2.1.2. SYSTEM ARCHITECTURE

The general architecture of the system is shown on figure1.

The MPC includes the following inputs/outputs :

- interface from aircraft to MPC,

- interface from MPC to aircraft.

The organization retained shall enable to accomplish the specified functions in compliance

with the requirements specified including safety objectives and system growth capability.

Page 19 sur 62

SYSTEM ARCHITECTURE

FDAU V0, V1,

V2

DFDR ou

SSFDR

FDE

P

MPC

AFDAU

(level C)

DMU (level D)

ASCB

input

PCMCIA

ATC

Printer

A740

G-meter

A429

A429

ASCB

A429

A429

A573

A429

A429

A429

A429

QAR

A591

MFC

WIFI

groun

d

virtual

MCDU

(lap

top)

A/C

type

BP

EVENT

BITE AFCS

FDEP

BITE TCAS

QAR/DAR

BITE MFC

BITE Radio

Comm/nav

RS23

2

2 x A429

Rotacteur

masse

ADS-B

provisio

n

Enhanced

Surveillance

A429

MFC

RS232

ON

APIU

Cmd/output

correlation

FAULT

SYSTEM

FDAU

ADL

FDAU

ADC 1

ADC 2

GNSS

AHRS1

AHRS2

ADU

EEC1/

2

PEC1/2

TCAS

BITE PEC/EEC

ACMS

(+ DMT reports

chiffrer Sagem)

MCDU (2)

From

ACARS

CMU

EEC/PE

C

sel

Weight (4)

Tables (4)

AAS (1)

PTT (1)

FTIU (1)

MW

(2)

MCDU

APM

A429 FTIU

Flt Tst Recorder

Spares

2 A429

>10 srie

> 6 shunt

>10 analogs (sync,

DCR, analogs)

GMT, Flt No

Broadcast

A724B

Reports

MPTR

ACARS

CMU

To ADL

Page 20 sur 62

2.1.3. FUNCTIONS TO BE PERFORMED BY THE MPC

The MPC shall accomplish the following functions :

2.1.3.1 FDAU Part

1) Acquisition of aircraft parameters :

The MPC acquires :

- data in ARINC 573 format from different FDAUs standard PCM (V0, V1-, V2+) at

a rate of 64 w/s or 128 w/s.

- data in digital, analog or discrete format from aircraft systems.

The MPC concentrates all these data, in accordance with regulations, and transmits

PCM frame at a rate of 64/128/256 w/s in ARINC 573 format for the flight

parameter recorder (FDR), for the quick access recorder (QAR), and for the DMU.

PCM Frame Output speed following FDAU standard (V0, V1-, V2+)

FDAU Standard Input speed Output speed

V0 64words/sec; 64words/sec.

V1- 64words/sec. 64words/sec.

V2+ - ED34A330 included 64words/sec. 64words/sec.

V2+ ED34A340 128words/sec. 128 words/sec.

V2+ ED34A340 + FAR121.344 128words/sec. 256words/sec.

The different FDAU standards shall be identified by a pin-programming.

The MPC shall have the capability for all aircraft PCM Frame configurations V0, V1-, V2+, FAR

121.344 combined with all aircraft models ATR 42 & 72, including STC PCM Frame.

The MPC shall be capable of processing FDR parameters in playback and monitoring

via the synchro-words the correlation between the value recorded and the playback

value, in order to generate the FDR status.

The PCM output data frames are described in the different Sagem specifications.

The PCM definition shall be under the supplier responsibility.

Regarding the APM function the MPC shall acquire 4 dedicated discrete inputs

(APIU outputs type TBD), representative of the cockpit signalisation and add them in

each output PCM, to the FDR. One of these inputs shall be an intermittent signal

(flashing input), but shall be recorded in continuous.

Moreover an additional discrete input (flashing Master Warning) shall be able to do

the same treatment, and the information recorded on this second input shall be

positionned in the different PCM frame in place of master warning information.

2) Synchro CVR management :

The MPC shall transmit the GMT word to the Cockpit Voice Recorder, when the

synchro word 1 shall be transmitted to the FDR. This output is provided to allow the

synchronization of the CVR record with FDR record.

3) Bite management:

The MPC shall contain the software enabling to perform complete equipment built in

test, for monitoring system status.

Moreover the 2 discrete outputs dedicated to the APM cockpit signalisation (except

Fault output) shall be fedback on 2 discrete inputs to monitor the function.

4) PTE link management :

The MPC shall be able to perform maintenance functions through a PTE (Portable

Test Equipment). The content and the protocol shall be proposed by the supplier to

the purchaser.

Page 21 sur 62

5) ADL interface

Two Arinc 429 lines (one input and one output) and activation discretes shall be

provided to upload software from the ADL/PDL to the AFDAU (Arinc 615-3).

6) DMU output

One Arinc 429 bus and asynchronous HDLC line shall be provided to transmit data

internally from the AFDAU to the DMU (the Arinc 429 bus is also external to the

MPC).

7) Discrete outputs

The AFDAU shall provide AFDAU and APM Fail & FDRS Fail outputs (AFDAU

fail: steady output, APM fail: flashing output)

8) Enhanced surveillance & ADS-B

The Enhanced Surveillance and the ADS-B, through acquisition of specific

parameters from aircraft computers shall enable the air traffic controller to increase

efficiency in tactically separating aircraft.

This function shall be realized with a software DO 178B level C.

Detailed information regarding this function shall be given in a dedicated appendix.

9) Aircraft Performances Monitoring

This function, through acquisition of specific parameters shall enable the monitoring

of aircraft performances.

This function shall be realized with a software DO 178B level C.

Detailed information regarding this function shall be given in a dedicated appendix .

2.1.3.2 DMU Part

1) MCDUs interface

Three Arinc 429 buses (two inputs and one output) shall be provided to manage a

dialogue with two MCDUs Arinc 739.

Output to MCDUs will be shared with MPTR.

2) G-Meter function

This function, through acquisition of specific parameters, shall enable the display, at

the end of the flight, to the crew, of the vertical acceleration value in flight and at the

landing.

This function shall be realized with a software DO 178B level D.

This function shall be treated as an ACMS standard report.

This function shall be available with all FDAU standard versions.

Detailed information regarding this function shall be given in a dedicated appendix .

3) Maintenance function (software DO 178B level D) see appendix

a) TCAS

b) AFCS

c) MFC

d) PEC/EEC bite and trim

e) rad com/rad nav

Detailed information regarding this function shall be given in dedicated appendix .

4) FDEP interface

This function shall enable to remove FDEP equipment from aircraft and to replaced

this item by MCDU associated to dedicated menus.

This function shall be compatible with all FDAU standards (V0, V1-, V2+)

The supplier shall provide the purchaser with a protocol proposition, for agreement.

All the functions realized by FDEP/FDAU interface shall be insure by means of

MPC/MCDU interface.

Two Arinc 429 lines (one input and one output) shall be provided.

Output will be shared with TCAS.

5) PCMCIA interface

A PCMCIA interface shall be provided allowing to accept removable type I and II

media. This PCMCIA shall be used for the internal QAR/DAR/G-meter reports

functions.

6) ADL interface

Page 22 sur 62

Two Arinc 429 lines (one input and one output and a dedicated activation discrete)

shall be provided to upload software and download data from the ADL/PDL to the

DMU (Arinc 615-3).

7) A full duplex asynchronous link shall be provided to connect the DMU to a PC based

Portable Test Equipment (PTE).

8) Discrete outputs

The DMU shall provide 3 discrete outputs.

9) RS 232 input

This input shall be used for PTE or for MFC Bite acquisition via an external selector

switch with dedicated selection pin program

The description of this MFC Bite function shall be described in dedicated appendix.

2.1.5. IDENTIFIED PROVISIONS

All the following identified provisions shall be available in the definition of MPC.

2.1.5.1 QAR output (Arinc 591)

The QAR RZ Bipolar output shall send the same PCM frame as FDR PCM frame

with a synchronization pulse generated at the end of each on the QAR synchro output

The same data frame as FDR output one is sent to the QAR. Only the coding is

different, it is a RZ Bipolar code. Moreover a QAR synchro output is provided for

synchro pulse generation.

2.1.5.2 MPTR interface

Two Arinc 429 buses (one input and one output) shall be provided to manage a

dialogue with a MPTR , following Arinc 740 or 744 protocol.

Output bus is shared with MCDUs

2.1.5.3 Interface with ACARS :

Two Arinc 429 buses (one input and one output) shall be provided to transfer/receive

data to/from ACARS (Arinc 724B).

2.1.5.4 Wifi

This function is developped under Sagem responsibility.

2.2. CHARACTERISTICS

2.2.1. INTERFACES

2.2.1.1. GENERAL INTERFACE REQUIREMENTS

All interface aspects not defined in this document shall be submitted to the

purchaser for approval.

2.2.1.2. INTERFACE WITH OTHER SYSTEMS OR EQUIPMENTS

Due to his function the MPC shall interface with different aircraft systems.

Each type of interface shall be in accordance with :

- Arinc standards defined in .1.5.2,

- electrical characteristics of inputs/outputs defined in 2.2.1.5.5.

2.2.1.3. MECHANICAL INTERFACE

The dimensions, attaches, cooling, etc... of the MPC shall comply with ARINC

600 specification.

2.2.1.4. HYDRAULIC INTERFACE

N.A.

2.2.1.5. ELECTRICAL INTERFACE

Page 23 sur 62

2.2.1.5.1. Power supply

The power supply characteristics are given in note DOOS-322-

4001C.

The unit shall comply with it.

2.2.1.5.2. Power consumption

The MPC maximum consumption shall be : 40W

2.2.1.5.3. Input / output capacity

MPC Inputs/Outputs :

The MPC shall have the capability to acquire and to drive the

following inputs/outputs, including identified provisions.

Identified

Definition

AFDAU

Interfaces

DMU

Interfaces

Arinc Inputs 429 15 15

RS 422 / CSDB /ASCB

Inputs

4 4

Arinc Outputs 429 2 4

Discrete Inputs 75 8

Discrete Outputs 2 3

Analog Inputs 45 45

Arinc 573/717 Inputs 2

Arinc 573/717 output 1

Arinc 591 output 1

QAR & DFDR interface 1

RSE 232 line 1 1

Synchro CVR output 1

*2 outputs are dedicated to the MPC in the basic configuration

(System Bite and MPC Bite), and the other output is a space

provision linked to the DMU used (identified provision).

2.2.1.5.4. Connection and wiring

The MPC connectors shall be in accordance with ARINC 600 size 2

specification.

Connectors with fool-proofing mean shall be used in order to prevent

erroneous installation on the aircraft.

2.2.1.5.5. Input/output characteristics and protections

All inputs and outputs shall be protected from any load short

circuits, and in case of inadvertent application of 28V

DC

, 115V

AC

or

ground on one or more pins of the unit :

- must no damage the printed circuit,

- must be limited to the inputs/outputs involved,

- as for as possible, must not destroy any component,

generally, it shall be considered that any input and any output, shall

be wired to another equipment in parallel.

Each equipment, either powered ON or powered OFF, shall not

disturb equipment wired in parallel.

All inputs and outputs shall be protected against lightning strikes

and designed to meet electromagnetic compatibility requirements.

Analog inputs :

The MPC shall be able to acquire different types of analog inputs :

Page 24 sur 62

Parameter Range/Type Accuracy

VLLDC type (t400mV) t 0,6% of range

VLLDC type (0400mV) t 0,6% of range

HLDC type (t10V) t 0,3% of range

HLDC type (010V) t 0,3% of range

LLDC type (t5V) t 0,4% of range

LLDC type (05V) t 0,4% of range

HLDC type (032V) t 0,3% of range

DCR type (020V) (ref 20V) t 0,3% of range

DCR type (010V) (ref 10V) t 0,3% of range

DCR type (010V) (ref 5V) t 0,3% of range

DCR type (05V) (ref 20V) t 0,5% of range

DCR type (05V) (ref 10V) t 0,5% of range

DCR type (05V) (ref 5V) t 0,5% of range

ACR type (26V/400Hz)

t 0,3% of range

SYNCHRO type (11,8V/400Hz)

t 0.1%

Temperature gauges 100ohms/C

t 0.6%

Potentiometer

t 0.4%

The hardware of these different inputs shall be identical (standard

inputs). Each input shall be pin programmable by software following

the required characteristics of the input :

- input impedance shall be 250 KOhms,

- accuracy shall be better then t 0,5%

Note : The synchros are supplied by 26VAC voltage reference. The

signal range is 11,8VRMS.

Note : For the analog inputs, boards shall be completely equipped

with circuitry and components for the totality of the inputs. The

type of the "spare" inputs shall be defined in accordance

between Purchaser and Supplier and shall be transmitted, to the

FDR, on the PCM frame with the rate and the number of bits

defined in AFDAU 542.0014/01 specification, when in a PCM

frame at 256 words/sec.

Discrete inputs:

The MPC shall be able to acquire 3 different discrete input types

- 50 shunt discrete inputs (open/ground)

- status 0 Vin 3V (considered as a ground circuit),

- status 1 Vin 7V (considered as an open circuit).

- 22 serie discrete inputs (open/28VDC)

- status 1 Vin 7V (considered a 28V input),

- status 1 Vin 3V (considered a an open circuit).

- 3 beacon markers inputs :

- status 0 Vin 0,8VDC or 0,5 VRMS or open circuit,

- status 1 Vin 3VDC or 2,5 VRMS.

The minimum AC waveform factor : 10%.

The maximum off duration time of the acquired parameter after

input de-activation is 1 second.

The frequency input range : 400H2 to 3000h2.

-

A diode shall be installed in line with each input.

The input impedance is > 100 KOhms.

Page 25 sur 62

Discrete outputs :

The total number of discrete outputs is 5. These outputs are used for

different fault / status displays.

These discrete outputs shall be protected:

- against any load shortening,

- against lightning strikes.

A diode shall be installed in line with each output in the unit.

The types of discrete outputs shall be 28VDC / series / shunt circuit.

Note : For the discrete inputs and outputs, boards shall be completely

equipped with circuitry and components for the totality of the

inputs/outputs.

And except specific definition all the inputs/outputs in "spare" shall

be on the DFDR PCM frame output with a rate of 1pps, when

in a PCM frame at 256 words/sec.

Digital inputs : (see table 2.2.1.5.3)

The computer shall be able to receive :

- Arinc 429 high or low speed.

The acquisition system shall be designed in order to avoid any lost

message even if they are arriving simultaneously at the maximum

frequency. Each label used by the MPC shall pass a validity test,

on the data except for the discrete words, the refreshment

frequency, the SSM and the parity shall be also monitored.

- CSDB which are specific acquisitions, compatible with RS422

standard and with the Collin's specification (3 of these inputs shall

be hardwired on the electronic card,

- ASCB which is specific acquisitions, following the Honeywell

specification.

- Arinc 573/717 inputs.

Digital outputs : (see table 2.2.1.5.3)

The computer shall be able to transmit :

- Arinc 429 high speed or low speed,

- Arinc 573/717 output,

- Synchro CVR output,

- QAR & DFDR interface.

A short circuit on one output shall not affect any other outputs.

Sensor Power :

- different 5VDC/200mA outputs for potentiometer power,

- 28VDC output for accelerometer power.

Maintenance interface :

- RS 232C bi-directional interface with PTE (test connector).

(one for AFDAU part, one for DMU part)

Digital Interfaces

- ARINC 429 interface with ARINC 739 MCDU,

- ARINC 429 interface with ARINC 744 multi-printer,

- ARINC 429 interface with ARINC 724/724B ACARS,

- ARINC 429 interface with ARINC 615 ADL,

(one for AFDAU part, one for DMU part)

2.2.1.5.6. Circuit breaker characteristics

N.A.

2.2.1.5.7. Characteristics of signals

The characteristics of the various signals received by the unit shall be

given in :

- specific appendix linked to the different functions

Page 26 sur 62

- AFDAU specification 542.0014/01

- Different FDAU standards PCM frames (V0, V1-, V2+)

- Spare definition for analog and discrete inputs.

2.2.1.6. PNEUMATIC INTERFACE

N.A.

2.2.2. ERGONOMICS ASPECTS

2.2.2.1. GENERAL

N.A.

2.2.3. BUILT-IN TEST EQUIPMENT (BITE)

The MPC shall perform permanent, periodic, power-up and maintenance tests :

- to guarantee the proper function of the MPC itself,

- to aid in trouble shooting of the system.

The computer shall store in a non-volatile device the failure of the system and shall transmit

those information to a test equipment.

The content of each test shall be defined by the supplier.

This test equipment shall be used for :

- bite and maintenance word information display (real time and history),

- real time display of system inputs/outputs (Arinc 717 inputs/outputs

analog/discrete/digital parameters),

- up/down loading.

The built in test results control the MPC status output.

The breakdown of maintenance word shall be described by the supplier.

The BITE data shall be presented on the DFDR PCM Frame. Moreover all detailed faults

shall be stored in non volatile memory and can be displayed by MCDU for DMU faults and

by PTE for AFDAU faults.

2.2.4. O.B.R.M (ON BOARD REPLACEABLE MODULE)

N.A.

2.2.5. DATA LOADING

2.2.5.1 GENERAL

The data loading shall be considered only as a possibility to change the MPC software.

When a software evolution shall be necessary, the airlines shall choose between using the

data loading or the installation of a new MPC already loaded with the correct software.

2.2.5.2 DATA LOADING METHODOLOGY

The MPC in its basic configuration shall have the capability to up load the computer

software, (and to download AIDS and maintenance data on the DMU part).

The data loading shall be achieved by mean of a PDL/ADL and the protocol is defined by

the ARINC 615. The data loading shall also be achieved by mean of a PCMCIA card.

This function shall be available on the front panel connector, as well as on the rear panel

connector.

The Supplier shall take caution to insure a correct data loading.

The data loading result shall be displayed on aircraft by a specific mean different of the tool

used for the data loading itself.

The data loading identification shall be made by replacement of the software data plate on

the MPC.

2.2.6. INTERCHANGEABILITY

Page 27 sur 62

All units having the same supplier's part number shall be directly and fully interchangeable

with respect to the performance of the unit, and the aircraft installation, without the need for

any adjustment.

2.2.7. MIXABILITY

N.A.

2.2.8. NUMBER OF COMPONENTS

N.A.

2.2.9. LOCKING OF PARTS

N.A.

2.2.10. GROUNDING AND BONDING

Bonding shall be achieve by specific wire :

- case to mechanical pin resistance 30m O,

- front face to rear face resistance 25m O

- Insulation resistance >= 100Mohms under 50Vdc.

- Dielectric strengh : 500V/50Hz.

2.2.11. MISCELLANEOUS DESIGN REQUIREMENTS

N.A.

2.3. PERFORMANCE

2.3.1. SYSTEM PERFORMANCE

N.A.

2.3.2. PERFORMANCE RELATIVE TO POWER CUTS

The unit shall comply with requirement of the note n DOOS-322-4001C.

The supplier shall describe precisely the operation of the computer during the transient until

the recovery of the correct voltage :

Transient shorter than 200ms :

- No effect on the operation of the computer.

Longer interruption of power (>200ms) :

The MPC shall perform :

- A rapid initialization (less then 1 second),

- After initialization the PCM frame shall start at the next recognized SYNC word

received from the FDAU input, and the frame counter shall be reset.

The supplier shall specified the time at the end of which the computer operate normally

in both cases.

2.3.3. SYSTEMS RESPONSE TIME

N.A.

2.3.4. UNIT CAPACITY

Page 28 sur 62

Purchaser and supplier responsibilities related to the basic and full capacities are described

in 11.1 "purchaser and supplier technical responsibilities".

2.3.4.1. ADDITIONAL INFORMATION TO DETERMINE THE BASIC UNIT

CAPACITY

N.A.

2.3.4.2. PURCHASER DEVELOPMENT SPARES

Purchaser development spares are required in addition to the "basic unit

capacity" :

processing power :

CPU occupation TBC by Sagem

memory capacity :

- boot memory TBC by Sagem,

- RAM memory TBC by Sagem.

The MPC shall have the capability for all aircraft PCM Frame configurations

V0, V1-, V2+, FAR 121.344 combined with all aircraft models ATR 42 & 72,

including STC PCM Frame plus some spare capacity TBC by Sagem

2.3.4.3. PROCESSING POWER AND MEMORY CAPACITY

The supplier shall give the following estimates memory size and processing power

of the unit, detailing the parts dedicated to :

- the "basic definition",

- the "full provisions",

- the "system provisions",

- the "space provisions",

- the "supplier development spares",

- the "purchaser development spares".

Detailed description and justification to support the estimated shall be given by

the supplier in his proposal.

2.3.5. GROWTH CAPABILITY

The growth capability concerns the extra capacity : ACMS function.

2.4. MATERIALS AND PRODUCTION PROCESSES-CORROSION

2.4.1. GENERAL REQUIREMENTS

N.A.

2.4.2. FLUIDS AND PRODUCTS USED ON AIRCRAFT

Where applicable, suitable protection shall be provided for the unit

MPC

Fuels Not applicable

Hydraulic fluid Not applicable

Oils Not applicable

Greases Not applicable

Lubricant Not applicable

Anti and de-icing agents Not applicable

Page 29 sur 62

Cleaning agents Applicable

Drinks Not applicable

Water, Waste Not applicable

2.4.3. HYDRAULIC FLUID TEMPERATURE

N.A.

2.4.4. FIRE PROPAGATION

N.A.

2.4.5. FLAMMABILITY, SMOKE AND TOXIC GAS EMISSION

Components which emit smoke and toxic gases shall be avoided.

2.5. LOCATION AND ENVIRONMENT

2.5.1. LOCATION

The MPC shall be installed in pressurized area, in the electronic bay.

2.5.2. ENVIRONMENTAL CONDITIONS

The unit shall operate under the environmental conditions defined hereafter, corresponding

to its location and its functions.

D0160C

Environmental Conditions

Chapter Category

Temperature - Altitude 4.0 B2

Temperature variation 5.0 B

Humidity 6.0 C

Water proofness 10.0 X

Explosion proofness 9.0 X

Vibrations 8.0 B

shocks 7.0 X

Fluids susceptiblity 11.0 X

Sand & Dust 12.0 X

Contamination 13.0 F

Salt spray 14.0 X

Magnetic influence 15.0 A

Power input 16.0 Z

Voltage spike 17.0 A

Audio Frequency Conducted Susceptibility 18.0 Z

Induced Signal Susceptibility 19.0 Z

Radio Frequency Susceptibility

(Radiated and Conducted)

20.0 R

Emission of Radio

Frequency energy

21.0 Z

Lightning induced transient susceptibility :

- signal pins injection,

- power supply pins injection,

- cable bundle,

- shielded cable bundle.

22.0

A3

A4

C3

E3

Lightning direct effects 23.0 X

Icing 24.0

X

Document DOOS-322-4001C : Electrical power supply.

Page 30 sur 62

2.5.3. HEAT DISSIPATION, VENTILATION, COOLING AND HEATING

2.5.3.1. HEAT DISSIPATION

The supplier shall take special precautions to solve the problem of the temperature

of the unit. He shall provide the temperature distribution inside the unit, in normal

operating conditions.

Heat dissipation shall be minimised.

2.5.3.2. VENTILATION - COOLING

The unit shall comply with Arinc 600 requirements.

2.6. OPERATIONAL DATA

For unit safety and reliability computation, the following data shall be used:

average flight duration :

- fleet 52'

- highest 1h50'

- lowest 32'

daily utilization :

- fleet 5H 26'

- highest 7h59'

2.7. INSTALLATION

The unit shall include a fool-proofing mean in order to prevent erroneous installation on the aircraft.

2.8. NOISE

N.A.

2.9. MASS

The center of gravity shall be indicated by the supplier in this proposal.

2.10. VOLUME

The MPC shall be an Arinc 600 3MCU standard casing.

The supplier shall provide an outline drawing.

2.11. PIN PROGRAMMING

The pin programming shall be used to identified all the possible difference in some particular

functions, and the options.

Page 31 sur 62

3. SAFETY - RELIABILITY - MAINTAINABILITY

3.1. SAFETY - RELIABILITY

3.1.1. DEFINITION OF TERMS

N.A.

3.1.2. SAFETY AND RELIABILITY OBJECTIVES

The supplier shall provide a failure mode and effect analysis.

The detailed safety analysis shall give detected and undetected failure rates per function.

As the perturbation of aircraft sensors or computers through MPC inputs shall be considered

having "Hazardous effects", the supplier shall demonstrate that this type of perturbation is

not possible.

3.1.3. SEGREGATION REQUIREMENTS

3.1.3.1. GENERAL REQUIREMENT

N.A.

3.1.3.2. PROTECTION AGAINST PHYSICAL DISTURBANCE ON INPUTS /

OUTPUTS DEDICATED TO ENGINES

Owing to the fact that the unit is a common point to all the engines installed on the

aircraft, special care shall be taken in order to comply with the engine isolation

certification requirement (JAR / FAR 25.903 b).

Consequently, the interface between the unit and engine dedicated signals shall be

designed with particular attention to the following points :

- Any electrical disturbance shall not propagate through the interface to

inputs/outputs dedicated to engines (electrical disturbance shall be understood

as any external disturbance entering the unit through any external wire

interfacing with it, or as any failure of the unit).

- External disturbance such as short circuit to ground, short circuit between

signals, inadvertent 28V

DC

/ 5V

AC

/26V

AC

/ 115V

AC

voltage, all disturbances on

power supply and on other wires (see environmental conditions) shall be

considered.

- Failures of the unit to be taken into account shall be determined by the supplier

and substantiated to the purchaser.

- There shall be no single failure of the unit affecting the isolation devices on

more than one engine.

3.1.3.3. CHANNELS SEGREGATION - DISSIMILARITY

N.A.

3.1.4. SAFETY TESTS

N.A.

3.1.5. FAILURE ANALYSIS

The supplier shall provide the following documents :

Page 32 sur 62

- a FMEA (Failure Mode and Effects Analysis).

The FMEA's shall describe the precise component failure modes and their consequences on

the unit functions. In addition to the functions achieved by the hardware functional blocks

(such as power supply, inputs, processor, ...), the main operational functions of the unit have

to be considered.

This document shall be reviewed jointly by the purchaser and the supplier according the

review meetings of this specification.

A specific analysis document shall be made for the APM & Enhanced surveillance / ADS-B

functions.

3.1.5.1. FMEA

The FMEA's shall be in compliance with the following requirement :

- it shall give all necessary information to have a clear understanding of the

design of the unit, of its monitoring and safety devices with their fault detection

coverage, and of its various failure modes.

To reach this goal, the following information will be provided :

- a brief but concise description of the unit and its monitoring and failure

detection devices, supported by clear block-diagrams at an "intermediate"

complexity level situated between general block-diagrams and electronic card

assembly schematics. The description and the block-diagrams will highlight the

breakdown of the unit into functional blocks,

- an identification of the maid operational functions of the unit,

- a reminder of the software architecture,

- block-diagrams showing the correlation between the operational functions and

the hardware and software means used to provide these functions,

For each considered elementary failure, the FMEA shall give :

- the failure rate per hour, with the origin of the data and the chosen hypothesis

(e.g. : there is an assumption that 10% of the failures of this integrated circuit

can lead to the considered failure mode, for such reasons), plus the physical

conditions (temperature or others) for which the failure rate is given. The

source from which the reliability data is extracted (e.g. MIL HDBK 217) and

the physical environmental conditions for which the data is given shall be

precised in the FMEA introduction,

- the effect(s) on the unit block to which the component belongs, and the failure

detection means (if the failure cannot be detected, mention it),

- the effect on the operational function(s) of the unit.

The FMEA shall be organized in a legible and structured manner, so as to give

straightforward links with the FMES.

3.1.5.2 FMES

N.A.

3.1.6. HAZARD ANALYSIS

The supplier shall provide a hazard analysis : this document shall identify the hazards

resulting from the unit which their level and the conditions which could lead to it.

This document will be reviewed jointly by the purchaser and the supplier according to

12.4. review meetings of this specification.

According to the effects on the aircraft identified by the purchaser, a complementary

analysis will be provided by the supplier.

3.1.7. SPECIAL REQUIREMENTS

N.A.

Page 33 sur 62

3.2. RELIABILITY AND MAINTAINABILITY

3.2.1. DEFINITION OF TERMS

The document applicable for definitions not included in this specification is the world

airlines technical operations glossary (WATOG).

"Failure" and "removal" :

- a unit is considered to have "failed" when it no longer performs the functions for which

it is designed, with the specified performance,

- a failure is said to be confirmed if additional test confirm the failure of the unit. If more

than one failure is discovered within the removed unit it does not constitute another

failure,

- a failure is said to be unconfirmed if no component failures are detected and the unit

performs its function nominally,

- an intermediate case exists when the investigation is underway.

- "removal" is removal of a unit from the aircraft.

The following actions are not considered to be "removals" :

- removing a unit that has been used in conditions other than nominal conditions or that

been damaged during transport or installation,

- removing the unit to gain access to another item or equipment or for reasons

unconnected with the function performed by the unit,

- removing the unit to embody modifications (retrofit),

- crossing of units for trouble shooting purposes,

- reracking for any reason.

Removal is said to be justified if a failure of the unit is confirmed.

MTBF (Mean Time Between Failures)

The MTBF is obtained by dividing the total number of flight hours logged by all units

over a certain period of time by the number of confirmed failures which affected all the

units during the same time.

MTBUR (Mean Time Between Unscheduled Removals)

The MTBUR is obtained by dividing the total number of flight hours logged by all units

over a certain period of time by the number of removals (as defined here above) during

that same period.

SERVICE LIFE

The service life of the unit is the time at which it is no longer physically or economically

feasible to repair or overhaul the unit to acceptable standards.

3.2.2. RELIABILITY

The supplier shall give and justify the guaranteed MTBF and MTBUR values for a

continuous operation of the unit at the following two ambient temperatures :

Calculation of MTBF shall be made according MILHDBK217.

The objective for the MTBF guaranteed value is 30000h.

3.2.3. SERVICE LIFE

Service life shall be TBA.

Objective no limitation (= aircraft service life).

3.3. QUALITY ASSURANCE FOR SAFETY AND MAINTAINABILITY

Compliance with the above mentioned objectives shall be supported by the supplier's answers to the

following questionnaire :

- safety and maintainability quality check procedure (MQCP questionnaire).

Page 34 sur 62

Reviews related to safety and maintainability are described in 12.4 review meetings.

3.4. DEFECT INVESTIGATION ON REJECTED UNIT

For any rejected unit, and at the request of the purchaser, the supplier shall produce an inspection

report using a form subject to agreement by the purchaser. This report will be used to inform the

purchaser of investigation on that unit.

The supplier shall detail in this report test means used to perform that investigation.

Page 35 sur 62

4. CERTIFICATION AND QUALIFICATION

4.1. DEFINITION OF TERMS

Type certification :

Process to obtain approval by the Airworthiness Authorities that the aircraft with all its units

installed meets the applicable airworthiness requirements.

Qualification :

Process to demonstrate to the Airworthiness Authorities that a unit complies with :

- the applicable regulations,

- it's specified performance,

- within its specified environment.

For digital units, software aspects of certification is part of the qualification for certification of the

unit. Qualification is part of Type Certification, the other parts being installation of the unit inside

the aircraft, system safety analysis, etc ... .

Continuing Airworthiness :

Process to ensure that the level of airworthiness guaranteed by Type Certification is maintained

for each individual aircraft at the time of its entry into service (issuance of Certificate of

Airworthiness) and during all its service life. This process involves particularly the control of

aircraft/unit modification beyond the certificated/qualified type design and the corrective actions

needed to restore, if necessary, the appropriate level of airworthiness.

4.2. REGULATIONS AND CERTIFICATION CONSIDERATIONS

The system is certificated under the responsibility of the purchaser. The applicable airworthiness

requirements are defined in 1.5.3.5. Regulations.

Certification bases (FAR or JAR and additional requirements) can be subject to changes until

certification.

In particular, additional special conditions (which constitute a new regulation) or interpretative

materials (which define acceptable means of compliance to regulations) can be notified through CRIs

and issue papers by the airworthiness authorities to cover novel or unusual design features.

The rules to be applied are those notified at the time of the certification.

The supplier shall provide the purchaser with the necessary information at the right time in order to

show compliance with these requirements.

4.3. QUALIFICATION

4.3.1. GENERAL

The qualification of the units is under the responsibility of the supplier but has to be agreed

by the purchaser and the airworthiness authorities.

Qualification to environment :

It shall be supported by the demonstration that the unit complies with 2.5. "Location

and Environment" environment requirements.

For this purpose, the supplier shall perform environment tests according to the

procedures defined in DO 160/ED 14, and taking into account the following

requirements :

- Tests shall be carried out with a representative software.

Page 36 sur 62

- The test specimen shall be to production standard. All deviations of the test specimen

from the production standard shall be listed by the supplier, who shall submit to the

purchaser for approval a written statement evidencing the effects such deviations may

have on the test results.

- The reasons for defects which occurred during the tests shall be investigated and

recorded by the supplier. They shall be reported to the purchaser when the

qualification is delayed.

The following documents shall be provided to the purchaser for the unit :

- "Qualification to environment procedures" : it shall include detailed procedures used

for the tests. It shall include the test definition, part of DTS, performed on equipment

before and after each environment test.

- "Qualification to environment report" : result of the tests shall be recorded in this

document.

Software aspect of certification :

It shall be supported by the demonstration that the software has been developed in

compliance with DO 178 guidelines.

DO 178 gives an overview of the software aspects of certification process.

4.3.2. UNIT CATEGORY AND CLASSIFICATION

The unit is classified class C (non-essential).

The qualification category is category 2.

The software level is C for AFDAU part and D for DMU part.(see definition in DO 178).

4.3.3. QUALIFICATION DOCUMENTS

The following documentation shall be provided by the supplier in English language :

Declaration of Design and Performance (DDP) it is the master document for the unit

qualification.

Qualification to environment procedures and qualification to environment report.

Software documentation as required by DO 178.

Qualification summary, this document shall summarize :

- the characteristics of the unit relatives to environment, and engine segregation

feature,

- the procedures used to demonstrate compliance to the corresponding requirements,

- the results obtained,

- the identification of deviations to these requirements, if any.

In addition, supporting documents or evidence of compliance shall be provided as

required by the certification authorities.

4.3.4. MINIMUM QUALIFICATION BEFORE DELIVERY OF THE FIRST UNIT

N.A.

4.3.5. QUALIFICATION BEFORE FIRST FLIGHT

N.A.

4.4. CONTINUING AIRWORTHINESS

For any modification (i.e. any unit design evolution including software evolution, new industrial

processes or new components sources) beyond the qualification standards, and/or for any

modification to operational or maintenance limitations, the supplier has to obtain prior agreement

from the purchaser.

Page 37 sur 62

The supplier shall provide the purchaser with appropriate information on these modifications ; the

work for qualification of the modified unit (and/or modified instructions) shall be proposed by the

supplier and shall be submitted to the purchaser for approval. The supplier shall provide the purchaser

with corresponding justification data.

The supplier shall update the unit technical documentation accordingly. The revised qualification

documents shall be provided to the purchaser.

In the case of non-compliance with the above, the supplier would bear full liability of the

consequences of the modifications.

Page 38 sur 62

5. SOFTWARE DEVELOPMENT REQUIREMENTS

5.1. SOFTWARE QUALITY CLAUSES

During the development, the supplier shall provide to the purchaser evidence of software quality

clauses.

The software level shall be, as defined in 4.3.2, C.

Page 39 sur 62

6. HARDWARE DEVELOPMENT REQUIREMENTS

6.1. DESIGN CAPABILITY EVALUATION OF SUPPLIER

The supplier shall give confidence in the proposal that he will be able to succeed in the technology

step proposed : previous experiences and results, validation or qualification of design and

manufacturing, development in progress, design standards, existing and future tests means.

6.2. DESIGN STANDARDS

The manufacturer shall have, for equipment design, design rules/standards before starting the

development and including as a minimum :

- detailed performance hardware definition,

- operation and performance simulation / prediction,

- verification of signals timing at worst case conditions,

- safety analysis part of the design (design repercussions),

- maintainability rules at design level,

- testability rules at design level,

- grounding connection and decoupling design rules for electronic boards,

- transients protection / EMC lightning protection,

- internal heat management (derating and overheating protection),

- circuits board implantation rules,

- interconnections rules,

- power and signal segregation rules,

- design technologies evolutions provisions (margins on max, ex : integration, frequency),

- equipment perennially and design impact,

- components derating rules for safety margins,

- component quality needs definition,

- mechanical rigidity,

- materials selection versus environment requirements, and protection technologies and safety,

- internal design reviews.

6.3. HARDWARE TESTABILITY COVERAGE

The testability shall be developed in parallel to the hardware design in order to obtain a maximum

coverage of the manufacturing tests versus defect risks (functions, performances, hardware

constituents).

The supplier shall calculate and justify the element non-covered.

The requirement minimum shall be 98% of coverage.

6.4. SELECTION OF ELECTRONIC COMPONENTS AND ASSEMBLY PROCESSES

6.4.1. TECHNOLOGY QUALIFICATION TESTS

The contractor shall define in his proposal for new/or complex components and assembly

technologies, the validation or qualification necessary to guarantee the safety reliability

requirements (depend of confidence level on result).

The validation shall cover :

Components :

- selection rules (standard used, level, list),

- components derating rules,

- new components qualification tests (standard used, level),

- for ASICS qualification shall consider in addition to device qualification :

- design rules,

- testability coverage,

- functional modes conformity,

Page 40 sur 62

- circuits libraries qualification,

- technology qualification procedure (utilization of Technology Characterization

Vehicle (TCV), Standard Evaluation Component (SEC), Parameter Monitoring

(PM).

Technologies and processes :

- new assembly technology validation tests,

- new processes validation tests.

6.4.2. TECHNOLOGIES MODIFICATIONS AND REQUALIFICATION

After qualification, the technology modifications (or tools having impact on definitions)

shall be declared according to 9.2 change management, the validation tests results for

performances and reliability of modifications shall be submitted to the purchaser before

application.

After modifications the test specifications will be up-dated and submitted to the purchaser.

6.5. ELECTRONICS COMPONENTS SCREENING TESTS

The contractor shall define and justify the components quality assurance provisions and/or the

components screening tests specifications to detect the components potentially failing. This in order

to guarantee the safety reliability requirements of the unit.

The minimum recommended is dynamic burs-in tests for Asics, microprocessors, memories, hybrids,

power analog circuits.

6.6. SELECTION OF MATERIALS

N.A.

6.7. HARDWARE QUALITY CLAUSES

The supplier shall establish and maintain a quality assurance plan in compliance with the quality

requirements of the purchaser.

The equipment quality clauses applicable to the unit are defined in the document D-06.01.

The supplier shall provide the documents listed in the tables hereafter, corresponding to the category

of the unit, and in addition to these documents he shall provide the "design development plan"

including :

- configuration management plan,

- qualification plan for certification,

- component standardization method.

6.8. ASICS QUALITY CLAUSES

The quality clauses and the documentation applicable for ASICS are defined in quality documents

chapter1.5.2.2, and in AFDAU specification 542.0014/01 tables added in chapter 6.8 (complex

component).

Page 41 sur 62

7. MANUFACTURING AND TESTS

7.1. MANUFACTURING AND SCREENING

7.1.1. MANUFACTURING

The manufacturing and inspection flow-chart "Industrial production process flow-chart" shall

be compliant with D-74.01 document.

This flow chart shall be presented in tree structure form:

- Main equipment production phases from the subassemblies manufactured by the supplier or

procured to equipment shipment,

- Main subassemnbly production phases.

The supplier shall specify in this flow chart the manufacturing , inspection and test operations.

The supplier shall manage the configuration of this flow chart,the associated baselines and the

link between the flow chart and the manufacturing and inspection files.

7.1.2. SCREENING SPECIFICATION

Purpose of screening

The purpose of the screening shall be to guarantee that the early life failure rate of the

equipment and spare parts will not exceed 1/MTBF theoretical value (failure rate constant

due to exponential failure distribution in electronic) and that the infant mortality failures

will be sufficiently reduced.

Screening operation are environmental stresses (within the limits of this specification)

applied on each item of equipment or sub-assembly in function with duration and

constraints sufficient to eliminate the infant mortality.

The supplier guarantees that before and after the screening the equipment operate correctly.

Screening specification / justification

The supplier shall define and justify the screening conditions to apply at each unit as part of

manufacturing tests.

The conditions shall be determined by an efficiency analysis of conditions (temperature,

time , cycles, power, signals, mechanical, ...) submitted to review by the purchaser.

7.2. MANUFACTURING TEST

7.2.1. MANUFACTURING DETAILED TEST SPECIFICATION (DTS)

Purpose of the DTS

The purpose of the DTS is to define the requirements for all production tests and

inspections to perform on each unit (LRU) and on sub-assembly (SRU), for approval before

delivery of item of equipment.

The tests strategy and specification for the complete item and the sub-assemblies (SRU,

components, ...) necessary along production of item to deliver an item of equipment meeting

the requirements are in DTS.

7.2.2. ACCEPTANCE TEST SPECIFICATION (ATS)

The ATS is part of DTS and specify the requirements for the acceptance tests of complete unit

(see below).

7.2.2.1. ATS DEFINITION

The purpose of the acceptance test is to guarantee that the item of equipment meets

the contractual technical specification and its definition dossier.

The acceptance tests address the tests of the hardware part of the item of equipment

and the identification of embedded software configuration.

Page 42 sur 62

The aircraft system functions associated with the software are considered to be

qualified by software design qualification (as per DO178) and the functional tests

performed for design validation.

The acceptance test specification (ATS) defines the requirements for all tests and

inspections to be performed on each complete item of equipment (LRU) to authorized

the release to the purchaser.

The ATS includes the location of defects detected by test at SRU (Shop Replaceable

Unit) level.

Sub assembly of unit (item of equipment) replaceable without tool ... (e.g. boards,

connectors, functional modules, ...).

7.2.2.2. ACCEPTANCE TEST AND TEST COVERAGE ANALYSIS APPROVAL

The ATS and test coverage analysis results shall be submitted to the purchaser for

approval.

Revision The methodology of ATS revision shall be submitted to the purchaser for

approval.

Each ATS revision shall be submitted to the purchaser for approval.

7.2.2.3. TEST COVERAGE REQUIREMENTS

The objective of the ATS is to test 100% of the hardware of an item of equipment.

If the hardware of the item of equipment cannot be tested 100%, the ATS shall give

acceptable confidence that the item of equipment meets its requirements. In this case

the supplier shall demonstrate the following elements :

- coverage of 100% of the hardware functions of the complete item (e.g. : power

supply, Arinc data inputs, analogic data input),

- minimum weighted test coverage 92%,

- minimum identification of defect at SRU level 80%

In addition the supplier shall provide the identification of components and hardware

functions not covered by the tests.

The LRU acceptance test duration shall be minimised.

The supplier shall propose a test duration which shall be submitted to the purchaser

for approval.

The supplier shall indicated the intrinsic minimum test duration part due to the item

of equipment itself and the part due to the test tool.

For each testability objective not reached, justifications shall be given to the

purchaser.

Test coverage analysis demonstration

The test coverage analysis method shall be delivered to the purchaser for review.

The coverage analysis results shall be submitted to the purchaser for approval.

These elements shall be part of the acceptance criteria for design reviews

(Preliminary Design Review and Critical Design Review) : see Design Review

definitions.

- Definition of test coverage ratio (C) the testing coverage is the ratio (C) of :

= number of components tested

divided by :

= total number of existing components.

Note for each multifunction component such as Asic :

- at the numerator the figure to be used will be (% of functions used

which are covered by the test),

- at the denominator the figure is 1.

- Definition of weighted testing coverage :

To obtain a weighted testing coverage, in the above ratio :

- numerator = sum (LAMDAi * Ci) :

Page 43 sur 62

. lamdai = failure rate of component i,

. Ci = % of component functions tested,

. Ci value is between 0 and 1,

. i = 1 to with n = components tested.

- denominator :

. sum (LAMDAi),

. i = 1 to t with t = total number of components.

Acceptable means of compliance

Hardware detailed functional breakdown definition.

Identification of detailed hardware functions tested and not-tested.

Identification of components tested and not-tested.

Note A component is considered to be tested if all the hardware functions

in which it participates are tested.

Calculation of test coverage ratio (C).

When necessary, calculation of weighted test coverage.

7.2.2.4. MINIMUM ATS CONTENT

The ATS shall comprise at least the following items :

- visual inspection,

- physical characteristics,

- hardware functions of the complete item of equipment (LRU),

- means of identification of embedded software configuration,

- the presence of lightning protection devices,

- hardware performance.:

. the specified performances of the item of equipment,

. the worst case switching conditions,

. the worst case input / output stimuli conditions,

. the worst case power supply characteristics (e.g. min or max),

. Arinc interfaces,

. input / output insulation,

. grounding.

- identification of hardware not covered by the test,

- identification of defect at SRU level.

For each test selected the ATS shall describe :

- the acceptance criteria,

- the test conditions (input stimuli, output),

- the test sequences,

- the hardware tested,

- the parameters tested or checked,

- the digital interaction protocols,

- the output tolerances,

- key parameters to be followed by SPC if applicable (Statistical Process Control),

- the outline drawing of specific interfaces, if any,

- identification of necessary special test equipment.

Form of the ATS :

The ATS shall be a self-explanatory document and written in clear language in

English (ATLAS is not considered as a clear language).

The ATS shall be built up per function tested, stimulus applied and type of

measurement (analog, discrete, digital signals) in order to facilitate failure

investigation.

The unit part number and the ATR ATR code number shall be indicated in this

document.

The planning of the various ATS documentation delivery (acceptance tests

specification, tests coverage analysis demonstration, maintenance test

specification, are specified in the contract.

Page 44 sur 62

Note the supplier shall maintain at the purchaser's disposal the complete

documentation related to the manufacture of his own acceptance test

benches : devices used, specific circuit board drawing, complete

documentation of the specific programs or micro-programs (with code)

developed by the supplier for testing.

This documentation shall be sent, on request, to the purchaser.

7.2.3. ATLAS TEST SPECIFICATION

N.A.

7.2.4. MAINTENANCE TEST SPECIFICATION (MTS)

Purpose :

The purpose of the MTS is to define the requirements for all the tests and inspections to be

performed for the maintenance of the item of equipment (LRU).

MTS requirement :

The maintenance test specification shall be identical to the acceptance test specification.

7.2.5. ACCEPTANCE TEST DOCUMENTATION DELIVERY

The planning of the various test documentation delivery are specified in the contract

(acceptance test specification and its test coverage analysis demonstration, maintenance test

specification).

Specific appendix to the contract can precise, if necessary, the particular documentation needed

for automatic test equipment program realization.

Page 45 sur 62

8. QUALITY ASSURANCE

8.1. GENERAL

The supplier shall establish and maintain a quality assurance system in compliance with the quality

requirements of the purchaser mentioned in the directive D-74.01. This quality assurance system shall

allow the purchaser to evaluate through an Industrial Process Control Evaluation (see the document

M.011) the quality of the unit development process and to verify, by appropriate test means, that the

quality of serial production units is maintained.

This system must be described in a quality assurance plan, a copy of which shall be provided in the

supplier's proposal.

8.2. QUALITY ASSURANCE PROVISIONS THROUGHOUT THE LIFE CYCLE

For each item of equipment, quality assurance is based on establishment by the supplier of qualify

assurance provisions throughout the life cycle of the equipment.

These quality assurance provisions shall allow the purchaser to evaluate the quality of the unit

development (design and industrialization) and to verify that the quality of the serial production units

will be assured.

Page 46 sur 62

9. CONFIGURATION MANAGEMENT

9.1. IDENTIFICATION

The identification and nameplates of the units shall be permanent and legible.

In addition, the country origin of the units shall be indicated on the identification plate with the mention

"Made In ..".

The position of the identification marking shall be submitted to the purchaser for approval, and shall be

shown on the outline drawing.

Designation of the unit is "MPC".

The units shall have only 2 plates attached (identification and amendment). The ATR code shall be stated in

accordance with the contract.

This identification shall include hardware and resident software standard identification.

The external marking of the product shall be performed in accordance with the directive D-75.03.

9.2. CHANGE MANAGEMENT

The supplier shall comply with the standard methods used by the purchaser for modification

procedure :

- as described hereafter for practical detailed aspects.

9.2.1. MODIFICATION WITH SPECIFICATION EVOLUTION (DCR, DCI/EMS)