Documente Academic

Documente Profesional

Documente Cultură

Id 800089 Exxonmobil Oil Corp - Engr Eval Ans 483736 483739 Completed

Încărcat de

api-242947664Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Id 800089 Exxonmobil Oil Corp - Engr Eval Ans 483736 483739 Completed

Încărcat de

api-242947664Drepturi de autor:

Formate disponibile

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

PAGES PAGE

42 1

APPL. NO. DATE

483736, 483739, 10/31/12

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

455135

PROCESSED

BY

CHECKED

BY

B. Chandan

TV

PERMIT-TO-OPERATE (PO)

&

PERMIT-TO-CONSTRUCT (PC)

COMPANY NAME AND ADDRESS

ExxonMobil Corporation

3700 W. 190

TH

Street

Torrance, CA 90509-2929

Contact : Valerie Tse

Telephone: (310) 212-1781

Email : valerie.b.tse@exxonmobil.com

EQUIPMENT LOCATION

ExxonMobil Torrance Refinery

3700 W. 190

th

Street

Torrance, CA 90509-2929

Facility ID: 47882

Unitized ID: 800089

SECTION D: EQUIPMENT DESCRIPTION

Equipment

ID

No.

Connected

To

RECLAIM

Source Type/

Monitoring

Unit

Emission`

And

Requirements

Conditions

Process 6: HYDROGEN PRODUCTION UNITS

System 3: HYDROGEN PRODUCTION UNITS HEATERS

HEATER, HYDROGEN

REFORMING, 24F-1,

NATURAL GAS, PSA

GAS, REFINERY GAS,

931 MMBTU/HR WITH

A/N: 440468 483736

BURNER, NATURAL

GAS, PSA GAS,

REFINERY GAS,

WITH LOW NOX

BURNER, 108

TOTAL; 931

MMBTU/HR

D925 C395 D926 NOX:

MAJOR

SOURCE**

SOX:

MAJOR

SOURCE**

CO: 88.54 LBS/HR (7) [RULE

1303(b)(2)-Offset, 5-10-1996];

CO: 2000 PPMV (5) [RULE 407,

4-2-1982]; NOX: 9 PPMV AT 15

MINS. (4) [RULE 2005,

5-6-2005]; NOX: 42 LBS/HR (7)

[RULE 2005, 5-6-2005]; PM: (9)

[RULE 404, 2-7-1986]; PM: 0.1

GRAINS/SCF (5) [RULE 409, 8-

7-1981]; PM10: 24.94 LBS/HR

(7) [RULE 1303(b)(2)-Offset, 5-

10-1996]; ROG: 62.35 LBS/HR

(7) [RULE 1303(b)(2)-Offset,

5-10-1996]; SO2: 20 PPMV (8)

[40CFR 60 Subpart 1, 6-24-

2008; CONSENT DECREE

CIVIL CASE No. 05 C 5809,

12-13-2005]; SOX: 17.03

LBS/HR (7) [RULE 2005,

5-6-2005]

A99.xx,

A195.1,

B61.1,

B61.3,

C1.12,

D28.23,

D82.1,

D90.xx,

D90.yy,

D182.3,

D182.4,

E54.xx,

E193.16,

H23.33,

K171.5

Continue on the Next Page

J. Pan

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

PAGES PAGE

42 2

APPL. NO. DATE

483736, 483739, 10/31/12

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

455135

PROCESSED

BY

CHECKED

BY

B. Chandan

TV

Process 6: HYDROGEN PRODUCTION UNITS

System 3: HYDROGEN PRODUCTION UNITS HEATERS

FUGITIVE EMISSIONS,

MISCELLANEOUS

A/N: 440468 483736

D1807 HAP: (10) [40CFR 63 Subpart

CC, #5A,5-25-2001]

H23.34

STACK, COMMON TO

GAS TURBINE 24J-01 &

HEATER 24F-1

A/N: 440468 483736

S1732 C395

SECTION H: EQUIPMENT DESCRIPTION

Equipment

ID

No.

Connected

To

RECLAIM

Source

Type/

Monitoring

Unit

Emission`

And Requirements

Conditions

Process 18: ELECTRICITY GENERATION

System 1: COGENERATION SYSTEM

S15.1,

S31.2

TURBINE, 24J-01,

COGENERATION

SYSTEM, (COMBINED

CYCLE), AIR

COMPRESSOR, BUTANE,

NATURAL GAS,

PROPANE, REFINERY

GAS, GE MODEL 52614P,

COMBUSTOR WITH

STEAM INJECTION, GAS

TURBINE, 316

MMBTU/HR WITH

A/N: 435110 483739

Permit to Construct Issued:

06/28/06 06/xx/2012

GENERATOR,

ELECTRIC, 22.83 MW

D926 D925 NOX: MAJOR

SOURCE**;

SOX: MAJOR

SOURCE**

CO: 88.54 LBS/HR (7) [RULE

1303(b)(2)-Offset, 5-10-1996];

NOX: 9 PPMV (4) [RULE

2005, 5-6-2005]; NOX: 42

LBS/HR (7) [RULE 2005, 5-6-

2005]; NOX: 210 160 PPMV

(8) [40CFR 60 Subpart GG, 2-

24-2006]; PM: 0.01

GRAINS/SCF (5) [RULE 475,

10-8-1976; RULE 475,8-7-

1978]; PM: 0.1

GRAINS/SCF (5B) [RULE

409, 8-7-1981]; PM: 11

LBS/HR (5A) [RULE 475,

10-8-1976; RULE 475,

8-7-1978]; PM10: 24.94

LBS/HR (7) [RULE 1303(b)(2)-

Offset, 5-10-1996]; ROG:62.35

LBS/HR (7) [RULE 1303(b)(2)-

Offset, 5-10-1996]; SO2: 20

PPMV (8A) [40CFR 60

Subpart 1, 6-24-2008];SO2:

150 PPMV (8) [40CFR 60

Subpart GG, 2-24-2006];SOX:

17.03 LBS/HR (7) [RULE 2005,

5-6-2005]

A99.xx,

A195.1,

A327.1,

B61.4,

B61.6,

D28.22,

D28.23,

D82.3,

D82.4,

D90.3,

D90.yy

D182.3,

D182.4,

H23.15,

K171.5

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

PAGES PAGE

42 3

APPL. NO. DATE

483736, 483739, 10/31/12

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

455135

PROCESSED

BY

CHECKED

BY

B. Chandan

TV

Process 18: ELECTRICITY GENERATION

System 1: COGENERATION SYSTEM

S15.1,

S31.2

TURBINE, 24J-2,

UNFIRED, STEAM

TURBINE WITH

A/N: 435110 483739

Permit to Construct Issued:

06/28/06 12/xx/2012

GENERATOR,

ELECTRIC, 19.3 MW

D2239 K171.5

DEVICE CONDITIONS

SECTION D

A. Emission Limits

A99.xx The 42 lbs/hr NOX limit(s) shall not apply during startup, shutdown or malfunction.

For purpose of this condition, start-up and shutdown shall be defined as the time

period during the startup and shutdown of the heater unit when the temperature of the

exhaust gas at the inlet to SCR is below 550 degree F.

[RULE 2005 , 5-6-2005]

[Devices subject to this condition : D925]

A195.1 The 9 PPMV NOX emission limit(s) is averaged over 15 minutes corrected to 15%

excess oxygen, dry basis.

For purpose of this condition, the limit applies at all times except during startup,

shutdown, or malfunction when the temperature of the exhaust gas at the inlet to the

SCR is below 550 degrees F.

[RULE 2005 , 5-6-2005]

[Devices subject to this condition : D925]

B. Material/Fuel Type Limits

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

PAGES PAGE

42 4

APPL. NO. DATE

483736, 483739, 10/31/12

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

455135

PROCESSED

BY

CHECKED

BY

B. Chandan

TV

B61.1 The operator shall only use fuel gas containing the following specified compounds:

Compound ppm by volume

total sulfur calculated as H2S less than 100

[RULE 2005, 5-9-2006]

[Devices subject to this condition : D925, D1236, D1239]

B61.3 The operator shall not use fuel gas containing the following specified compounds:

Compound ppm by volume

H2S greater than 160

[40CFR 60 Subpart J, 6-24-2008; CONSENT DECREE CIVIL CASE No. 05 C 5809,

12-13-2005]

[Devices subject to this condition : D925]

C. Throughput/Operating Limitation

C1.12 The operator shall limit the firing rate to no more than 931 MM Btu per hour.

[RULE 1303(b)(2)-Offset, 5-10-1996; RULE 2005, 5-6-2005]

[Devices subject to this condition : D925]

D. Monitoring/Testing Requirements

D28.23 The operator shall conduct source test(s) in accordance with the following

specifications:

The test shall be conducted yearly after the initial performance test using the test

protocol approved by the District.

The test shall be conducted to determine the emission rates (lb/hr) of ROG, CO &

PM emissions at the outlet.

The District shall be notified of the date and time of the test at least 10 days prior to

the test.

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

PAGES PAGE

42 5

APPL. NO. DATE

483736, 483739, 10/31/12

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

455135

PROCESSED

BY

CHECKED

BY

B. Chandan

TV

[RULE 1303(b)(2)-Offset, 5-10-1996; RULE 3004(a)(4) - Periodic Monitoring,

12-12-1997]

[Devices subject to this condition : D925]

D82.1 The operator shall install and maintain a CEMS to measure the following parameters:

SOX concentration in ppmv

Oxygen concentration in percent volume

[RULE 2011, 5-6-2005; 40CFR 60 Subpart 1, 6-24-2008; CONSENT DECREE

CIVIL CASE No. 05 C 5809, 12-13-2005]

[Devices subject to this condition : D925, C952]

D90.xx The operator shall continuously monitor the total sulfur concentration in fuel gases

before being burned in this device according to the following specifications:

During times when the operator uses refinery fuel gas from 8C-5 (Device D500), the

operator will use Gas Chromatography (GC 33) to monitor total sulfur concentration

for the 8C-5 (Device D500) refinery fuel gas.

During times when the operator uses refinery fuel gas from 64C-4 (Device D838),

the operator will use a SOx CEMS on RECLAIM SOx reference source 75F-1

(Device D805) or 3F-3/4 (Device D930/D931 with common Device S1975) that

only use refinery fuel gas from fuel gas mix drum 64C-4 (Device D838) to calculate

total sulfur concentration in the 64C-4 (Device D838) refinery fuel gas.

For the purposes of this condition and with regards to total sulfur concentration,

natural gas and PSA waste gas used in 24F-1 (Device D925) shall be deemed to

meet SCAQMD Clean Fuels Policy BACT Guidelines (10-20-2000). As such, no

additional monitoring shall be required for these fuels.

The operator shall also install and maintain a device to continuously record the

parameter being monitored.

[SCAQMD Rule 2005, 5-6-2005]

[Devices subject to this condition: D925]

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

PAGES PAGE

42 6

APPL. NO. DATE

483736, 483739, 10/31/12

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

455135

PROCESSED

BY

CHECKED

BY

B. Chandan

TV

D90.yy The operator shall periodically monitor the H2S concentration at the inlet of this

device according to the following specifications:

The Alternative Monitoring Plan (AMP) approved by the United States

Environmental Protection Agency (USEPA) on June 2, 2009 for the periodic

monitoring and reporting of H2S concentration for the off-gas streams from Heater

24F-1 (D925) in P6/S3 and Gas Turbine Generator 24J-1 (D926) in P18/S1.

The operator shall maintain records in a manner approved by the District, to

demonstrate compliance with the requirements specified under this section.

[40CFR 60 Subpart A, 6-13-2007; 40CFR 60 Subpart 1, 6-24-2008; CONSENT

DECREE CIVIL CASE No. 05 C 5809, 12-13-2005]

[Devices subject to this condition : D925]

D182.3 The operator shall test this equipment in accordance with the following specifications:

To determine the control efficiency of the SCR, after June 29, 2006, the operator

shall, prior to the first physical modification where a permit to construct is required,

file a permit application for that modification and include with the application a

method for determining the control efficiency of the SCR

Such method may include, sampling port at the inlet of the SCR, monitor/analyzer for

NOx concentration at the inlet of the SCR, or other equivalent method to determine

SCR efficiency as approved by the Executive Officer

Until the above method(s) is approved, the operator shall keep record of the ammonia

injection rate and shall make it available upon AQMD request

Once the above method(s) is approved, the operator shall conduct the SCR control

efficiency determination and annually thereafter

[RULE 2005, 5-6-2005; RULE 3004(a)(4)-Periodic Monitoring, 12-12-1997]

[Devices subject to this condition : D925]

D182.4 The operator shall test this equipment in accordance with the following specifications:

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

PAGES PAGE

42 7

APPL. NO. DATE

483736, 483739, 10/31/12

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

455135

PROCESSED

BY

CHECKED

BY

B. Chandan

TV

To determine the PM10 emissions, after June 29, 2006, the operator shall, prior to the

first physical modification where a permit to construct is required, file a permit

application for that modification and include with the application a method for

determining the PM10 emissions. Such method shall be provided in compliance with

EPA or SCAQMD source test method

Until such time that a permit is issued for the modification, the PM10 emissions are

assumed to equal to the PM emissions

Once the above method(s) is approved, the operator shall conduct the PM10

emissions determination and annually thereafter

[RULE 1303(b)(2)-Offset, 5-10-1996; 3004(a)(4)-Periodic Monitoring, 12-12-

1997]

[Devices subject to this condition : D925]

E. Equipment Operation/Construction Requirements

E54.xx The operator is not required to vent this equipment to the following equipment if all

of the requirements listed below are met:

Device ID: C395 [SELECTIVE CATALYTIC REDUCTION REACTOR]

Requirement number 1: During startups and shutdowns. For the purpose of

this condition, start-up and shutdown shall be defined as the time period

during the startup and shutdown of the heater unit when the temperature of the

exhaust gas at the inlet to SCR is below 550 degree F.

Requirement number 2: The operator shall limit startups and shutdowns to no

more than 60 hours, not including the refractory dryout period. Refractory

dryout shall be permitted up to a total of 144 consecutive hours to allow the

curing of refractory materials.

Requirement number 3: During startup and shutdown, the operator shall use

244.05 lbs NOx per hour for reporting purposes under RECLAIM.

Requirement number 4: ExxonMobil shall submit a report to the District

annually with a summary of the number of hours for startups and shutdowns.

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

PAGES PAGE

42 8

APPL. NO. DATE

483736, 483739, 10/31/12

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

455135

PROCESSED

BY

CHECKED

BY

B. Chandan

TV

[RULE 2012, 5-6-2005]

[Devices subject to this condition : D925]

E193.16 The operator shall operate and maintain this equipment according to the following

specifications:

The operator shall comply with all applicable requirements specified in

Subpart A of the 40CFR60

[40CFR 60 Subpart A, 5-16-2007; CONSENT DECREE CIVIL CASE No. 05 C

5809, 12-13-2005]

[Devices subject to this condition :. D925.]

H. Applicable Rules

H23.33 This equipment is subject to the applicable requirements of the following rules or

regulations:

Contaminant Rule Rule/Subpart

SOX 40CFR60, SUBPART J

[40CFR 60 Subpart 1, 10-4-1991]

[Devices subject to this condition : D925]

H23.34 This equipment is subject to the applicable requirements of the following rules or

regulations:

Contaminant Rule Rule/Subpart

VOC District Rule 1173

VOC 40CFR60, SUBPART GGGa

This equipment was subject to the applicable requirements of 40CFR60 Subpart GGG

per Consent Decree Civil Case No. 05 C 5809 dated 12-13-2005. This equipment is

now subject to the applicable requirements of 40CFR60 Subpart GGGa per

ExxonMobil's notification to EPA dated 08-24-2009.

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

PAGES PAGE

42 9

APPL. NO. DATE

483736, 483739, 10/31/12

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

455135

PROCESSED

BY

CHECKED

BY

B. Chandan

TV

[Rule 1173, 5-13-1994; Rule 1173, 2-6-2009; 40CFR 60 Subpart GGGa, 6-2-2008;

CONSENT DECREE CIVIL CASE No. 05 C 5809, 12-13-2005]

[Devices subject to this condition : D1807.]

K. Recordkeeping/Reporting

K171.5 The operator shall provide to the District the following items:

Final designed P&ID within 60 days after construction is completed including, but

not limited to heating rate and fuel lines for heater 24F-1

[RULE 1301, 12-7-1995]

[Devices subject to this condition : D925]

Note: this is a P/C condition that is no longer applicable; same condition in Sec H still is tagged to Gas Turbine

device D926 and will remain as such

SECTION H

SYSTEM CONDITIONS

S15.1 The vent gases from all affected devices of this process/system shall be vented as

follows:

All emergency vent gases shall be directed to a blowdown flare system except

Devices IDs D35, D1250, D2145, D57 TO D62, D71, D68, D86-D91, D98, D152,

D237, D349, D360, D629, D630, D631, D657, D638, D668, D671 , D1503-D1505,

D1507 that vent to the atmosphere.

This process/system shall not be operated unless the blowdown flare system is in full

use and has a valid permit to receive vent gases from this system.

[RULE 1303(a)(1)-BACT, 5-10-1996; RULE 1303(b)(2)-Offset, 5-10-1996]

[Systems subject to this condition : Process 1, System 1 , 2 , 3 , 4 , 7; Process 2 ,

System 1 , 2 , 4 , 5; Process 3, System 1 , 5 , 7; Process 4, System 1 , 3 , 5; Process 5,

System 1 , 2; Process 6, System 1 , 2; Process 7, System 1; Process 8, System 1 , 2 , 3

,4 , 6; Process 9, System 1 , 2 , 5; Process 11, System 1 , 2 , 3 , 4 , 5 , 6 , 7 , 8 , 9 , 10 ,

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

PAGES PAGE

42 10

APPL. NO. DATE

483736, 483739, 10/31/12

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

455135

PROCESSED

BY

CHECKED

BY

B. Chandan

TV

11 , 12; Process 12, System 1 , 2 , 3; Process 13, System 1 , 2 , 3 , 4; Process 17 ,

System 5 , 8 , 11; Process 18, System 1; Process 19, System 3; Process 23, System 1]

S31.2 The following BACT requirements shall apply to VOC service fugitive components

associated with the devices that are covered by application number(s) 280605,

384499, 385155, 389291, 389292, 411508, 411586, 422931, 435110, 435111 &

471343:

All valves shall be bellow-sealed except in the following applications: valves in

heavy liquid service, control valves, instrument piping/tubing valves, valves

requiring torsional stem motion, situations where valve failure could pose safety

hazard (e.g., drain valves with stems in the horizontal position), retrofit/special

application valves with space limitation and valves not commercially available .

District shall approve all exceptions to this requirement.

All valves and new major components shall be physically identified in the field

With special markings that distinguish the components from nonBACT components.

Additionally, all new components shall be identified as BACT components in the

record.

All valves shall be inspected monthly using EPA Reference Method 21. The

operator may revert to quarterly inspection upon District approval, after two

consecutive monthly inspections in which only two percent or less are found to

be leaking above 500 ppmv. For leaks greater than 500 ppmv above background,

repair shall be attempted within five (5) days of detection. Repair or replacement

shall be completed within 15 days, unless demonstrated otherwise.

The operator shall keep records of the monthly inspections, subsequent repairs

and reinspections, if any, in a manner approved by the District.

The operator shall provide the following information to the District no later than

60 days after initial startup of the equipment in the system:

a ) Piping and instrumentation diagrams (or some other equivalent District-approved

diagrams) that identify all valves. The operator shall also provide a listing of all

valves (bellows and non-bellows) categorized by location, type, size, accessibility,

and service; and

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

PAGES PAGE

42 11

APPL. NO. DATE

483736, 483739, 10/31/12

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

455135

PROCESSED

BY

CHECKED

BY

B. Chandan

TV

b) Recalculation of fugitive emissions based on actual fugitive components installed

and removed from service. All valves shall be categorized by tag number, type, size,

body material, service, and reason(s) why bellow seal valves were not used.

[RULE 1303(a)(1)-BACT, 5-10-1996; RULE 1303(b)(2)-Offset, 5-10-1996]

[Systems subject to this condition : Process 4, System 1 , 3; Process 6, System 2 ;

Process 7, System 3; Process 9, System 6; Process 13, System 1 , 3 , 4 , 11; Process

18, System 1]

A. Emission Limits

A99.xx The 42 lbs/hr NOX limit(s) shall not apply during startup, shutdown or malfunction.

For purpose of this condition, start-up and shutdown shall be defined as the time

period during the startup and shutdown of the heater unit when the temperature of the

exhaust gas at the inlet to SCR is below 550 degree F.

[RULE 2005 , 5-6-2005]

[Devices subject to this condition : D925]

A195.1 The 9 PPMV NOX emission limit(s) is averaged over 15 minutes corrected to 15%

excess oxygen, dry basis.

For purpose of this condition, the limit applies at all times except during startup,

shutdown, or malfunction when the temperature of the exhaust gas at the inlet to the

SCR is below 550 degrees F.

[RULE 2005 , 5-6-2005]

[Devices subject to this condition : D925]

A327.1 For the purpose of determining compliance with District Rule 476, combustion

contaminant emissions may exceed the concentration limit or the mass emission limit

listed, but not both limits at the same time.

[RULE 475, 10-8-1976; RULE 475, 8-7-1978]

[Devices subject to this condition : D926.]

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

PAGES PAGE

42 12

APPL. NO. DATE

483736, 483739, 10/31/12

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

455135

PROCESSED

BY

CHECKED

BY

B. Chandan

TV

B. Material/Fuel Type Limits

B61.4 The operator shall not use fuel gas containing the following specified compounds:

Compound ppm by volume

Total sulfur compounds 30

calculated as H2S greater

than

[RULE 2005, 5-6-2005]

[Devices subject to this condition : D926]

B61.6 The operator shall not use fuel gas containing the following specified compounds:

Compound ppm by volume

H2S greater than 160

[40CFR 60 Subpart 1, 6-24-2008]

[Devices subject to this condition : D926]

D. Monitoring/Testing Requirements

D28.22 The operator shall conduct source test(s) in accordance with the following

specifications:

The test shall be conducted within 90 days from the complete modification of the fuel

gas optimization project using the test protocol approved by the District.

The test shall be conducted to determine the CO, NOx, SOx, SO2 & O2 concentration

at the outlet.

The test shall be conducted to determine the NH3 emissions at the outlet.

The test shall be conducted to determine the emission rates (lb/hr) of ROG, CO, PM,

NOx & SOx emissions at the outlet.

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

PAGES PAGE

42 13

APPL. NO. DATE

483736, 483739, 10/31/12

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

455135

PROCESSED

BY

CHECKED

BY

B. Chandan

TV

The District shall be notified of the date and time of the test at least 10 days prior to

the test.

[RULE 1303(b)(2)-Offset, 5-10-1996; RULE 2005, 5-6-2005; RULE 3004(a)(4)-

Periodic Monitoring, 12-12-1997]

[Devices subject to this condition : D926]

D28.23 The operator shall conduct source test(s) in accordance with the following

specifications:

The test shall be conducted yearly after the initial performance test using the test

protocol approved by the District.

The test shall be conducted to determine the emission rates (lb/hr) of ROG, CO & PM

emissions at the outlet.

The District shall be notified of the date and time of the test at least 10 days prior to

the test.

[RULE 1303(b)(2)-Offset, 5-10-1996; RULE 3004(a)(4)-Periodic Monitoring, 12-12-

1997]

[Devices subject to this condition : D926]

D82.3 The operator shall install and maintain a CEMS to measure the following parameters:

SOX concentration in ppmv.

Oxygen concentration in percent volume.

[RULE 2011, 5-6-2005; 40CFR 60 Subpart J, 6-24-2008]

[Devices subject to this condition : D926]

D82.4 The operator shall install and maintain a CEMS to measure the following parameters:

NOX concentration in ppmv

SOX concentration in ppmv

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

PAGES PAGE

42 14

APPL. NO. DATE

483736, 483739, 10/31/12

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

455135

PROCESSED

BY

CHECKED

BY

B. Chandan

TV

Oxygen concentration in percent volume

[RULE 2011, 5-6-2005; RULE 2012, 5-6-2005; 40CFR 60 Subpart GG, 2-24-2006]

[Devices subject to this condition : D926]

D90.3 The operator shall continuously monitor the H2S concentration in the fuel gases before

being burned in this device according to the following specifications:

The operator shall monitor the concentration of the total sulfur compounds at the

outlet of the fuel gas mix drum/knockout pot 24C-1 (Device D2234).

The operator shall use Gas Chromatography (GC 61) to monitor the parameter.

The operator shall also install and maintain a device to continuously record the

parameter being monitored.

[RULE 2005, 5-6-2005; RULE 3004(a)(4)-Periodic Monitoring, 12-12-1997]

[Devices subject to this condition : D926]

D90.yy The operator shall periodically monitor the H2S concentration at the inlet of this

device according to the following specifications:

The Alternative Monitoring Plan (AMP) approved by the United States

Environmental Protection Agency (USEPA) on June 2, 2009 for the periodic

monitoring and reporting of H2S concentration for the off-gas streams from Heater

24F-1 (D925) in P6/S3 and Gas Turbine Generator 24J-1 (D926) in P18/S1.

The operator shall maintain records in a manner approved by the District, to

demonstrate compliance with the requirements specified under this section.

[40CFR 60 Subpart A, 6-13-2007; 40CFR 60 Subpart 1, 6-24-2008; CONSENT

DECREE CIVIL CASE No. 05 C 5809, 12-13-2005]

[Devices subject to this condition : D926]

D182.3 The operator shall test this equipment in accordance with the following

specifications:

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

PAGES PAGE

42 15

APPL. NO. DATE

483736, 483739, 10/31/12

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

455135

PROCESSED

BY

CHECKED

BY

B. Chandan

TV

To determine the control efficiency of the SCR, after June 29, 2006, the operator

shall, prior to the first physical modification where a permit to construct is required,

file a permit application for that modification and include with the application a

method for determining the control efficiency of the SCR

Such method may include, sampling port at the inlet of the SCR, monitor/analyzer for

NOx concentration at the inlet of the SCR, or other equivalent method to determine

SCR efficiency as approved by the Executive Officer

Until the above method(s) is approved, the operator shall keep record of the ammonia

injection rate and shall make it available upon AQMD request

Once the above method(s) is approved, the operator shall conduct the SCR

control efficiency determination and annually thereafter

[RULE 2005, 5-6-2005; RULE 3004(a)(4)-Periodic Monitoring, 12-12-1997]

[Devices subject to this condition : D926]

D182.4 The operator shall test this equipment in accordance with the following

specifications:

To determine the PM10 emissions, after June 29, 2006, the operator shall, prior to the

first physical modification where a permit to construct is required, file a permit

application for that modification and include with the application a method for

determining the PM10 emissions. Such method shall be provided in compliance with

EPA or SCAQMD source test method

Until such time that a permit is issued for the modification, the PM10 emissions are

assumed to equal to the PM emissions

Once the above method(s) is approved, the operator shall conduct the PM10

emissions determination and annually thereafter

[RULE 1303(b)(2)-Offset, 5-10-1996; RULE 3004(a)(4)-Periodic Monitoring,

12-12-1997]

[Devices subject to this condition : D926]

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

PAGES PAGE

42 16

APPL. NO. DATE

483736, 483739, 10/31/12

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

455135

PROCESSED

BY

CHECKED

BY

B. Chandan

TV

H. Applicable Rules

H23.15 This equipment is subject to the applicable requirements of the following rules or

regulations:

Contaminant Rule Rule/Subpart

NOx 40CFR60, Subpart GG

SOx 40CFR60, Subpart GG

SOx 40CFR60, Subpart J

[40CFR 60 Subpart GG, 2-24-2006; 40CFR60 Subpart 1, 6-24-2008]

[Devices subject to this condition : D926]

K. Recordkeeping/Reporting

K171.5 The operator shall provide to the District the following items:

Final designed P&ID within 60 days after construction is completed including, but

not limited to heating rate and fuel lines for heater 24F-1.

[RULE 1301, 12-7-1995]

[Devices subject to this condition : D926, D2239]

BACKGROUND

The ExxonMobil Oil Corporation (ExxonMobil) operates a refinery in the City of Torrance.

The South Coast Air Quality Management District (District) currently classifies this facility as

a Sulfur Oxides (SOx) and Nitrous Oxides (NOx) Regional Clean Air Market Incentives

Market (RECLAIM) facility and a Title V facility. The District has issued the final Title V

permit to ExxonMobil on January 25, 2010.

On June 10, 2008, ExxonMobil submitted 2 applications for Change of Conditions for two

existing equipment located at its Torrance refinery. Specifically, the company requests that

the District add a condition to its Process Heater 24F-1 (D925) and its Cogeneration Turbine

24J-1 (D926) to clarify that during startup of its heater and turbine, they do not need to

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

PAGES PAGE

42 17

APPL. NO. DATE

483736, 483739, 10/31/12

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

455135

PROCESSED

BY

CHECKED

BY

B. Chandan

TV

operate its selective catalytic reduction (SCR) control (C395) identified in Process 6 of

System 4 of its facility permit and do not need to comply with the NOx concentration limit

imposed on its Turbine 24J-1 and Process Heater 24F-1 by permit condition A195.1.

ExxonMobil states in its applications that during startup its Process Heater 24F-1 needs time

to reach the 550 degrees Fahrenheit required by Condition E71.7 for Ammonia (NH3)

injection imposed on its SCR control. As a result, ExxonMobil requests that the District

clearly state that during startup NH3 cannot be injected (technologically infeasible) and that

the NOx concentration limit is not applicable during startup until the flue gas temperature of

the process heater reaches 550Fahrenheit and above. The two existing permit conditions that

implicitly allow the process heater to exceed the NOx limit during startup are as follows:

A195.1 The 9 PPMV NOX emission limit(s) is averaged over 15 minutes

corrected to 15% excess oxygen, dry basis.

[RULE 1303(a)(1)-BACT, 5-10-1996; RULE 1303(a)(1)-BACT,

12-6-2002]

[Devices subject to this condition : D925, D926]

E71.7 The operator shall only inject NH3 into this equipment if the flue gas

inlet temperature is at least 550 degrees F.

[RULE 1303(a)(1)-BACT, 5-10-1996]

[Devices subject to this condition: C301, C395, C916, C923, C1238, C1241]

Although the current permit allows ExxonMobil to bypass the SCR during start-up

(<550F), it does not implicitly states that ExxonMobil does not need to meet the NOx

limit in A195.1 during start-up, shut-down or malfunction when the SCR inlet

temperature is expected to be less than 550F. As a result, ExxonMobil has applied for a

Variance to the AQMD Hearing Board for planned start-ups and shutdowns, to allow

them to exceed the 9 ppmv limit in A195.1. Therefore, ExxonMobil submitted these

applications to allow them to exceed the NOx limits during start-ups or shutdown

without a variance.

PERMIT HISTORY

The ExxonMobils Process Heater 24F-1 and Turbine 24J-1 are existing devices that require

POs from the District for their operations. Therefore, the District has records of the permits

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

PAGES PAGE

42 18

APPL. NO. DATE

483736, 483739, 10/31/12

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

455135

PROCESSED

BY

CHECKED

BY

B. Chandan

TV

for both devices past operations. The following table gives the permits that the District has

issued for the two devices:

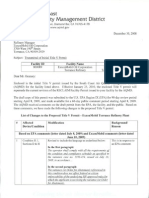

Table 1: Permit History

HEATER 24F-1 (APPLICATION NO. 483736)

Application

No.

Permit No.]

Date

Submitted or

Issued

Application

Type

Application

Status

Purpose

483736 6/10/2008 60 20 Subject application to allow SCR bypass

during start-up and shut-down

455135 4/16/2010 60 20

(will be

cancelled)

Applicant submitted the applications to

include Subpart J requirements as

required under its consent decree. This

application has been merged with the

483736 and will be cancelled.

440468

[F82841]

6/28/2006 PO Active ExxonMobil submitted the application

the application as part of its fuel

optimization project to increase the

amount of waste recovered for use from

its hydrogen plant.

298485

[D95235]

12/28/1995 PO Inactive ExxonMobil submitted the application to

increase the rating of the heater from 788

to 931 MMBTU/HR.

133686 4/16/1987 PC Inactive New construction.

COGENERATION SYSTEM/TURBINE 241-1 (APPLICATION NO. 483739)

Application

No.

Permit No.]

Date

Submitted or

Issued

Application

Type

Application

Status

Purpose

500502 7/9/2009 63 21 Subsequent application to 483739,

currently open will be process after P/C

is issued to 483739

483739 6/10/2008 60 20 Subject application to allow SCR bypass

during start-up and shut-down

435110 6/29/2006 PC Active ExxonMobil submitted the application

the application as part of its fuel

optimization project to increase the

amount of waste recovered for use from

its hydrogen plant.

298671

[D95326]

12/28/1995 PO Active ExxonMobil submitted the application to

replace the existing turbine to

accommodate the increased air flow

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

PAGES PAGE

42 19

APPL. NO. DATE

483736, 483739, 10/31/12

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

455135

PROCESSED

BY

CHECKED

BY

B. Chandan

TV

requirements from the increase in

capacity of Reformer Heater 24F-1.

175643 8/1/1989 PC Inactive ExxonMobil submitted the application to

modify combustor burner to have the

ability to burn natural gas, butane,

propane, and refinery gas.

139735 12/01/1987 PC Inactive New construction.

FEE ANALYSIS

The following table presents the Districts analysis of the required processing fees for the

subject two applications:

Table 2: Fee Analysis

Equipment Type Fee

Schedule

Required

Fee

A/N 455135 - Process Heater 24F-1 > 50 MMBTU/hr

BCAT 019605

E $3,318.36

A/N 483736 - Process Heater 24F-1 > 50 MMBTU/hr

BCAT 019605

E $4,015.22

A/N 483739 - Congeneration Turbine 24J-1 < 50 MW,

Other Fuel; BCAT 053708

D $2,734.71

Total Required Processing Fee $10,068.29

Requested Expedited Fee (483736/483739 only) $3,374.97

Total Fee Required $13,443.26

Total Permit Processing Fees Paid $13,443.26

Refund (Deficit) $0.00 ($0.00)

Note that ExxonMobil submitted its two applications to the District prior to 1 July 2008. Therefore,

2007 fee schedules apply, which is used to calculate the required fees.

The Districts fee analysis shows that ExxonMobil has paid the exact permit processing fees.

No additional fee or refund is required.

COMPLIANCE RECORD REVIEW

The District conducted a 3-year search in its Compliance Database to determine whether any

of the devices has any any open Notice-to-Comply (NTCs) or Notice-of-Violation (NOVs).

The results indicate that there were 11 NOVs and 3 NCs issued to this facility, but only one

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

PAGES PAGE

42 20

APPL. NO. DATE

483736, 483739, 10/31/12

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

455135

PROCESSED

BY

CHECKED

BY

B. Chandan

TV

was issued to the subject Heater 24F-1. NOV #P56604 was issued on 12/30/09 to this heater

for operating contrary to condition #4, Section E, of the Facility Permit. This NOV has been

resolved and the equipment is in compliance. There are currently no open NTCs or NOVs for

any of the devices at this facility; they are either closed or in compliance. See Attachment A

for NOV/NC report.

PROCESS DESCRIPTION

The ExxonMobils cogeneration system is located in its hydrogen production/plant area of the

refinery. The companys cogeneration process has been recently upgraded and modified to

optimize the fuel/waste gas from that portion of the facility in ExxonMobils PC Application

No. 435110. This latest modification increases the amount of reclaimed hydrogen gas burned

in the turbine combustor and Heater 24F-1. ExxonMobil has completed its modification.

Because the PC is not converted to PO, a subsequent PC will be issued under A/N 483739.

The companys cogeneration process uses a combination waste gas from the hydrogen plant

area, refinery gas, and methane for both the turbine combustor and burners for Process Heater

24F-1. The process employs a gas turbine with a combustor that is rated at 316 mmBtu/hr

which drives an electric generator producing 22.83 megawatts electricity. This generated

electricity is used by compressors located in the hydrogen plant.

Once the gas is expanded through the gas turbine, it does not go directly to the atmosphere.

Instead, the hot gases from the gas turbine at 1,000F and 15% oxygen becomes the secondary

combustion air for the Process Heater 24F-1. This turbine exhaust eventually becomes part of

exhaust of Process Heater 24F-1 and flows to the SCR serving the heater. The following

process flow diagram shows the ExxonMobils cogeneration process.

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

PAGES PAGE

42 21

APPL. NO. DATE

483736, 483739, 10/31/12

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

455135

PROCESSED CHECKED

BY BY

B. Chandan

TV

Gas Turbine

241-01

Combustor

316 MMBTU/HR

Generator

22.83 MW

Refinery

Gas

Condenser &

Knockout Pot

Water

Steam

Steam Turbine

241-2

SCR

Control

CEMS

NH3

Process Heater

24F-1

931 MMBTU/HR

Air

PSA Recovered

Gas

Refinery

Fuel

Combustion Air

and Flue Gas

EMISSION SUMMARY

The ExxonMobils requested changes do not affect criteria pollutant emissions for the Heater

24F-1 and Turbine 24F-1. ExxonMobil only requests that the District explicitly states the

company is allowed to bypass its SCR, which controls the NOx emissions from the process,

during the startup of its turbine and process heater. This operational request is not new as the

District already has allowed ExxonMobil to bypass its SCR during startup and shutdown

(condition E71.1). However, the amount of emission during startup and shutdown was not

quantified, nor was a condition requiring ExxonMobil to determine start-up NOx emissions

incorporated into the permit.

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

PAGES PAGE

42 22

APPL. NO. DATE

483736, 483739, 10/31/12

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

455135

PROCESSED

BY

CHECKED

BY

B. Chandan

TV

Note that only start-up NOx emissions are affected by the requested start-up condition

emissions of all other criteria pollutants remain the same irrespective of start-up or normal

mode of operation.

The following table summarizes the emissions during startup (see next section for details on

the emission calculations):

Table 3: Emissions Summary

NOx

Hourly

Emissions

(lb/hr)

Daily

Emissions

(lb/day)

Annual

Emissions

(lb/yr)

30-Day Average

Emissions

(lb/day)

During Startup 244.05 5,857.2 14,643 --

During Normal Operations 42.03 1,008.7 365,654 1,016

Combined -- -- 380,297 1,056

ROG

Hourly

Emissions

(lb/hr)

Daily

Emissions

(lb/day)

Annual

Emissions

(lb/yr)

30-Day Average

Emissions

(lb/day)

During Startup 62.35 1,496.40 546,186.00 1,517.18

During Normal Operations 62.35 1,496.40 546,186.00 1,517.18

PM10

Hourly

Emissions

(lb/hr)

Daily

Emissions

(lb/day)

Annual

Emissions

(lb/yr)

30-Day Average

Emissions

(lb/day)

During Startup 24.94 598.56 218,474.40 606.87

During Normal Operations 24.94 598.56 218,474.40 606.87

SOx

Hourly

Emissions

(lb/hr)

Daily

Emissions

(lb/day)

Annual

Emissions

(lb/yr)

30-Day Average

Emissions

(lb/day)

During Startup 17.03 408.8 149,212 414.48

During Normal Operations 17.03 408.8 149,212 414.48

CO

Hourly

Emissions

(lb/hr)

Daily

Emissions

(lb/day)

Annual

Emissions

(lb/yr)

30-Day Average

Emissions

(lb/day)

During Startup 88.54 2,124.89 775,584.12 2,154.40

During Normal Operations 88.54 2,124.89 775,584.12 2,154.40

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

PAGES PAGE

42 23

APPL. NO. DATE

483736, 483739, 10/31/12

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

455135

PROCESSED

BY

CHECKED

BY

B. Chandan

TV

EMISSION CALCULATIONS:

Table 4: Operational Data

Operating Hours

Per Day

Operating Days

Per Year

Normal Operations 24 365

Startup-Requested Changes to Permit Conditions 24 2.5 (60 hrs)

Total Hours in Normal Operations 24 362.5

Note: The start-up hours requested by ExxonMobil are 60 hrs per start-up. Assumed 1 start-

up each year.

Data used in Emissions Calculations:

Max heating rates, MMBtu/hr: 1,247 (total), 316 (gas turbine, 25%), 931 (heater, 75%)

Fuel gas (refinery/natural gas) HHV, MMBtu/MMscf: 1020

F dry factor for natural gas = 8710/+E6 scf/Btu

The following Emissions factors were developed in the previous application 440468/440469

(see Attachment B for the entire evaluation; relevant pages for 24F-1 calculations are on pages

22 to 24):

Table 5: Emission Factors/Limits

NOx

Emission

Factor/Limit

SOx

Emission

Factor/Limit`

ROG

Emission

Factor/Limit

PM10

Emission

Factor/Limit

CO

Emission

Factor/Limit

9 ppmv

@ 15% O2

Rule 2005 Limit

(4-40-2001)

87.5 ppmv

@ 0% O2

(combined

GTG/Heater)

0.050 lb/mmBtu

(Determined by

District - see

Attachment B)

0.02 lb/mmBtu

(Determined by

District - see

Attachment B)

0.071 lb/mmBtu

(Determined by

District - see

Attachment B)

*30 ppmv H2S limit/gas turbine &100 ppmv H2S limit/ heater

30 ppmv x 25% = 100 ppmv x 75% = 82.5 ppmv

Total NOx Emissions During Normal Operations:

See Attachment B (A/N 440468_69 evaluation) for details on the following calculations

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

PAGES PAGE

42 24

APPL. NO. DATE

483736, 483739, 10/31/12

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

455135

PROCESSED

BY

CHECKED

BY

B. Chandan

TV

N0x _

lb

J

]

= FJ

sc

HHBtu

x ppm: x 1uc

-6

x

lbmolc

S79 c

x 46

lbN0x

lbmolc

x

HHBtu

br

x

sc

1u2u BIu

x 24

br

J

x

2u.9

2u.9 - %02

= 871u x 9x1uc

-6

x

46

379

x 1247 x

24

020 1

x

20.9

20.9-15

= 1,uu8.7

Ibs

du

= 42. 3 |hxhr

Total NOx Emissions During Startup When SCR Is Not Operating:

Based on source tests conducted during the 2009 start-up (w/o NH3 injection), the max NOx

concentration was determined to be 70 ppm uncontrolled (see Attachment C for CEMS data).

Based on this, the NOx emissions during start-up are calculated to be 244.05 lbs/hr (see

Attachment C for the details on start-up NOx calculations).

Rule 2012 for RECLAIM NOx, Protocol Chapter 2, Section G allows using source test data to

estimate the emission during start-up, in lieu of emissions factors established in Table 3-D.

Total Combined NOx Emissions:

Hourly Emissions during s/u = 244.05 lbs/hr

Daily Emissions during s/u = 5,857 lbs/day

Max allowed s/u hours = 60 hrs = 2.5 days

Yearly Emissions during s/u = = 14,643 lbs/yr

Hourly Emissions during Normal Operations = 42.03 lbs/hr

Daily Emissions during Normal Operations = 1,008 lbs/day

Normal operating hours = 362.5 days

Yearly Emissions during Normal Operations = 365,654 lbs/yr

Combined NOx Emissions (30 Day Average) = 380,297 12 mo/yr 30 days/mo

= 1056 lbs/day

Total S x Emissions Durin mal O tions a tup: O g Nor pera nd Star

S0x _

lb

J

] = ppm:x1uc

-6

x

lbmolc

S79 c

x64

lbS0x

lbmolc

x1247

HHBtu

br

x1uc

6

sc

1u2u BIu

x24

br

J

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

PAGES PAGE

42 25

APPL. NO. DATE

483736, 483739, 10/31/12

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

455135

PROCESSED

BY

CHECKED

BY

B. Chandan

TV

= 82.Sx1uc x

379

-6

64

x 1247x1uc

6

x

24

1020

= 4u8.8 lbsJoy

Total ROG Emissions During Normal Operations and Startup:

ROG Emissions = 0.050 lb/mmBtu x 1247 mmBtu/hr

= 62.35 lb/hr x 24 hr/day

= 1,496.4 lb/day x 365 day/yr

= 546,186 lb/yr x 1 yr/12 months x 1 month/30day

= 1,517.18 lb/day (30-day avg.)

Total CO Emissions During Normal Operations and Startup:

CO Emissions = 0.071 lb/mmBtu x 1247 mmBtu/hr

= 88.54 lb/hr x 24 hr/day

= 2,124.89 lb/day x 365 day/yr

= 775,584.12 lb/yr x 1 yr/12 months x 1 month/30day

= 2,154.40 lb/day (30-day avg.)

Total PM10 Emissions During Normal Operations and Startup:

PM10 Emissions = 0.02 lb/mmBtu x 1247 mmBtu/hr

= 24.94 lb/hr x 24 hr/day

= 598.56 lb/day x 365 day/yr

= 218,474.40 lb/yr x 1 yr/12 months x 1 month/30day

= 606.87 lb/day (30-day avg.)

RULES AND REGULATORY ANALYSIS

California Environmental Quality Act (CEQA):

No Formal CEQA Document Is Required. CEQA applies to all applicants who apply with

the District for permits for their planned projects that may have significant environmental

impacts. If these significant impacts arise, CEQA requires project proponents to perform

formal analyses to identify the impacts, propose mitigation measures to minimize them,

and formalize the results as a CEQA document for the public to review and comment.

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

PAGES PAGE

42 26

APPL. NO. DATE

483736, 483739, 10/31/12

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

455135

PROCESSED

BY

CHECKED

BY

B. Chandan

TV

To determine if a project must meet CEQA requirements, an applicant must perform a

prescreening analysis of its proposed project to determine whether or not that it may have

the potential to cause significant environmental impacts. To facilitate this prescreening

process, the District currently uses the 400-CEQA form as a tool to determine whether an

applicants project requires the preparation of a formal CEQA document. Based on the

ExxonMobils prescreening results for its turbine and process heater, no formal CEQA

document is required because the startup emissions was preexisting condition that wasnt

quantified, but allowed under the previous permit.

Regulation II: Permits

Rule 212: Standards for Approving Permits

The Districts Rule 212 specifies the conditions under which the District can issue a

requested permit to an applicants new or modified equipment. These conditions are set

in terms of the amount of air emission increase, the sources proximity to a public school,

and the level of health risk increases that arise from a toxic emission increase. These

requirements are specified in Rule 212, Subdivision (c).

When the applicants new or modified source triggers any of the conditions in Rule 212,

Subdivision (c), the applicants proposed new or modified emission source must undergo

public notification and review for a period of 30 days in advance of the Districts final

action on the requested permit as stated in Subdivision (d) of Rule 212. These specific

requirements of Subdivision (c) and the Districts analysis of compliance for

ExxonMobils turbine and process heater are as follows:

Rule 212 (a): Denial of Permit-to-Construct (PC) and Permit-to-Operate (PO)

Requirement

An equipment that requires a Permit-to-Construct (PC) or a Permit-to-Operate (PO)

must demonstrate that it can operate in compliance with all applicable District rules,

and Division 26 of the State Health Safety Code. If an applicant can not demonstrate

that his equipment can operate in compliance, the District needs to deny the requested

permit. The rules and regulatory analysis section in this evaluation report determines

whether ExxonMobil complies with the Rule 212, Subdivision (a), requirements. The

conclusion on the Districts regulatory analysis appears in the Recommendation

section of this evaluation report.

Rule 212 (b)(1): Conversion of PCs to POs

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

PAGES PAGE

42 27

APPL. NO. DATE

483736, 483739, 10/31/12

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

455135

PROCESSED

BY

CHECKED

BY

B. Chandan

TV

Not applicable. None of ExxonMobils applications are a PC to PO conversion.

Rule 212 (c)(1): Minimum Distance to a Public School Requirement, and Rule 212

(c)(3): Increases in Toxic Air Contaminants Requirements

No Public Notification Is Required. Any new or modified source with an emission

increase that requires a District permit may need to go through public notification

before the District grants the requested permit, if the source is located within 1000

feet from the outer perimeters of any public schools. This notification requirement

only applies to new or modified sources that result in an emission increase, and/or

increase in health risks.

Although the ExxonMobils applications are for changes to its operating conditions,

these changes result in no change in toxic emissions. There are also no emission

increases from the ExxonMobils proposed operational changes since the company

does not propose changes to the fuels used by the two devices, nor increases in the

two devices heat ratings. Therefore, no public notification is required.

Rule 212 (c)(2): Emission Increase Limits/Requirements

No Public Notification Is Required. The Paragraph (c)(2) of Rule 212 establishes the

emission thresholds of Rule 212, the net increases in emissions that would trigger

public notification requirements in Subdivision (d). The following table, which is

from Rule 212 (g), gives the amount of emission increase for each criteria pollutant

that would require public notification before the District can issue an applicants

requested permit, and this table also includes the net emissions from ExxonMobils

turbine and process heater:

Table 8: Net Emission Summary

Air Pollutant Daily Maximum

(lb/day)

Net Emissions Increase From Turbine and

Process Heater (lb/day)

VOC 30 0

NOx 40 0

PM

10

30 0

SOx 60 0

CO 220 0

Lead 3 0

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

PAGES PAGE

42 28

APPL. NO. DATE

483736, 483739, 10/31/12

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

455135

PROCESSED

BY

CHECKED

BY

B. Chandan

TV

There is no emissions increase from the proposed changes in condition for the two

applications. Therefore, no public notification is required.

Regulation IV: Prohibitions

Rule 401: Visible Emissions

Expect to Comply. Paragraph (b)(1) sets the opacity standards for emission sources. The

current standard is a shade that is equal or greater than No.1 on the Ringelmann Chart, or

any emission that causes the same degree of opacity as that of shade No.1 for more than

three minutes in any one hour. If ExxonMobil properly operates and maintains its turbine

and process heater, and only burns the gaseous fuels allowed in the permit, then District

expects ExxonMobil to comply with the requirements of Rule 401.

Rule 402: Nuisance

Expect to Comply. The Districts Rule 402 requirements prohibits emission source from

discharging pollutants that may cause injury or damage to persons or property, and public

nuisance. If ExxonMobil properly operates and maintains its turbine and process heater,

and only burns the gaseous fuels allowed in the permit, then District expects ExxonMobil

to comply with the requirements of Rule 402.

Rule 404: Particulate Matter (PM)-Concentration

Expect to comply. The Districts Rule 404 establishes limits on PM emissions. These PM

limits depend on the exhaust flow rate of the equipment and are listed in Table 404 (a).

Those limits are based on 15 minute averages. To determine if the ExxonMobils boiler

can comply with the PM limits of Rule 404, the PM concentration for the boiler was

calculated based on its maximum rating:

PM Emissions = 24.94 lb/hr x 1 hr/60 min x 7000 grains/lb = 2,909.667 grains/min

Boiler = 1247 mmbtu/hr

Fd = 8710 scf/mmbtu

Flue gas flowrate = 1247 mmbtu/hr x 8710 scf/mmbtu x 1 hr/60 min

= 181,022.83 scf/min

PM Conc. = (2,909.667 grains/min)/(181,022.83 scf/min) = 0.0161 grain/scf

Rule 404 Limit 0.0253 > PM Conc of 0.0161

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

PAGES PAGE

42 29

APPL. NO. DATE

483736, 483739, 10/31/12

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

455135

PROCESSED

BY

CHECKED

BY

B. Chandan

TV

The Districts calculation shows that ExxonMobils process heater is expected to comply

with the limit established by Rule 404.

Rule 407: Liquid and Gaseous Contaminants

Expect to Comply. The Districts Rule 407 establishes the maximum limits for Carbon

Monoxide (CO), and Sulfur Oxides (SOx) for any equipment that discharges air

pollutants in the Districts jurisdiction. The following table gives the emission limits that

currently apply to any equipment:

CO (ppmv) SOx (ppmv)

2000 ppm (dry basis, 3% O2)

at 15 minute average

500 ppm (dry basis, 3% O2)

at 15 minute average

Because ExxonMobil is a RECLAIM facility for both NOx and SOx, the company only

has to comply with the CO concentration limit as it is exempt by Rule 2001 (j)(2) for

SOx. Therefore, the District only imposes a condition for CO under the Equipment

Description section of the permit under the emissions requirements. If ExxonMobil

properly operates and maintains its turbine and process heater, the District expects the

company to comply with the CO limit.

Rule 409: Combustion Contaminants

Expect to comply. The Districts Rule 409 imposes an overall pollutant limit of 0.10

grain per cubic foot of combustion contaminants from a combustion source at 12% CO2

(0 % O2). ExxonMobil complies with this limit, as shown in the annual source test reports

(see Attachment E for 2009 source test results).

Rule 429: Start-up & Shutdown Exemption Provisions for NOx

Not Applicable. Although the Districts Rule 429 specifically governs the startup and

shutdown of heaters and boilers, ExxonMobil is RECLAIM facility subject to the

Districts Regulation XX and therefore not subject to Rule 429 by Rule 2001 (j).

Rule 475: Electric Generating Equipment

Expect to Comply. ExxonMobils cogeneration unit is subject to the Districts Rule 475.

This rule imposes limits of 0.01 grain/scf and 11 lb/hr of PM emissions which has been

imposed as emission limits on the turbine and heater. ExxonMobil complies with this

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

PAGES PAGE

42 30

APPL. NO. DATE

483736, 483739, 10/31/12

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

455135

PROCESSED

BY

CHECKED

BY

B. Chandan

TV

limit, as shown in the annual source test reports (see Attachment E for 2009 source test

results). Note that condition A327.1 has been added to indicate that only the mass or the

concentration limit apply at a given, not both. Compliance expected.

Regulation IX: Standards of Performance for New Stationary Sources (NSPS)

40CFR60, Subpart J: Standards of Performance for Petroleum Refineries

Expect to Comply. The ExxonMobils turbine and process heater run on fuel gas/waste

gas from the hydrogen plant area. Because both burn fuel/process gas, ExxonMobil must

comply with the requirements of Subpart J which has a limit of 160 ppmv H2S at the

inlet or 20 ppmv SO2 @ 0% at the outlet. Since ExxonMobil has a RECLAIM

continuous emission monitoring system for SOx at the outlet of the SCR, it has applied

for and received approval from EPA for an Alternative Monitorin Plan (AMP) to use the

RECLAIM monitor for Subpart J compliance determination. District will impose

condition D90.yy to indicate that ExxonMobil has an AMP for Subpart J monitoring and

compliance. Since the CEMS monitors SOx concentration at the common discharge

stack for both of the devices, the District has imposed outlet limit of 20 ppmv SO2 (0%

O2) for both permits at the stack of the SCR. Compliance expected.

40CFR60, Subpart GG: Standards of Performance for Stationary Gas Turbines

Expect to Comply. 40CFR, Subpart GG applies to stationary gas turbines. The regulation

sets standards for NOx and SOx emissions based on the combustor and turbine size.

Based on the size of ExxonMobils cogeneration unit, the NOx standard is determined by

60.322 (a)(2). See Attachment D for calculation details. The NOx emission calculated is

160 ppmv. The permit currently has 210 ppmv under the Emissions & Requirements.

This will be corrected to 160 ppm, as agreed by ExxonMobil (see their letter dated

October 27, 2010 in Attachment D).

In addition to NOx standards, Subpart GG also requires SOx emissions to be below

0.015% by volume @ 15% O2. Because ExxonMobils cogeneration unit is subject to

Subpart J which has a limit of 20 ppmv @ 0% O2 and is lower than the required limit for

Subpart GG (see calculation below). Therefore, ExxonMobil is expected to comply.

0.015 scf/100 scf x (20.9 -15)/(20.9) = 42 ppmv @ 0% O2

Since ExxonMobil is a RECLAIM facility, it already has a SOx and NOx CEMS that

meets the requirements.

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

PAGES PAGE

42 31

APPL. NO. DATE

483736, 483739, 10/31/12

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

455135

PROCESSED

BY

CHECKED

BY

B. Chandan

TV

The District has imposed a condition on the turbine (condition H23.15) that requires the

company to comply with applicable requirements of Subpart GG. Compliance is

therefore expected.

40CFR60, Subpart GGG/GGGa: Standards of Performance for Equipment Leaks of VOC

in Petroleum Refineries for which Construction, Reconstruction, or Modification

Commenced after 1-4-83 and on or before 11-7-06 [GGG]; after 11-7-06 [GGGa]

Expected to Comply. ExxonMobil was subject to Subpart GGG during the previous

modifications see page 27 of the previous engineering evaluation in Attachment B. This

equipment was also subject to the applicable requirements Subpart GGG per Consent

Decree Civil Case No. 05 C 5809 dated 12-13-2005. Permit condition stating that

Subpart GGG was applicable was imposed in the prior permits. However, ExxonMobil

has voluntarily accepted Subpart GGGa for all equipment previously subject to Subpart

GGG (per ExxonMobil's notification to EPA dated 08-24-2009). Therefore, this

equipment is no longer subject to Subpart GGG but rather it is now subject to the

applicable requirements of Subpart GGGa. Adding start-up condition does not affect

Subpart GGGa applicability.

Condition H23.34 has been tagged to the heater process 6, system 3. EM is expected to

continue to follow the inspection, leak reporting, and repair protocols described in this

regulation. Continued compliance is expected.

Regulation X: National Emission Standards for Hazardous Air Pollutants

40CFR63, Subpart CC: National Emission Standards for Hazardous Air Pollutants from

Petroleum Refineries

Not Applicable. The cogeneration section is not in organic hazardous pollutants (HAPs)

service. The only HAP in the fuel gas stream is hexane, but its concentration is less than

5% by weight (see material balance in PC Application No.435110).

Regulation XI: Source Specific Standards

Rule 1173: Control of Volatile Organic Compound Leaks and Releases from

Components at Petroleum Facilities and Chemical Plants

Expect to Comply. ExxonMobils cogeneration process is in VOC service. It is therefore

subject to the applicable requirements of Rule 1173. The District will impose a permit

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

PAGES PAGE

42 32

APPL. NO. DATE

483736, 483739, 10/31/12

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

455135

PROCESSED

BY

CHECKED

BY

B. Chandan

TV

condition requiring ExxonMobil to comply with all applicable requirements of Rule

1173. Compliance is expected.

Regulation XIII: New Source Review (NSR)-Emission Offsets, Modeling, and Best Available

Control Technology (BACT)

Not Applicable. The Districts NSR requirements only apply to sources with an increase in

emissions. The requested Change of Condition to allow for bypassing the SCR during startup

of the turbine and heater, does not affect any criteria pollutants, except NOx. Because

ExxonMobil is a NOx and SOx RECLAIM facility, the company does not need to comply

with Regulation XIII for NOx by Rule 1301 (b)(1) rather it need to comply with the NSR

requirements under Rule 2005 (see below for this rule evaluation). Since there is no other

emission increases from the requested changes, this rule does not apply.

Note that conditions D28.22 and D28.23 were added (in the previous permit) for initial source

test and yearly source test, respectively, to demonstrate compliance with the offset limits

imposed in the permit. Initial Source Test was completed on August 21, 2008 and a Source

Test report was submitted to the District showing compliance with this condition (included in

the folder); therefore, condition D28.22 is no longer applicable and was already removed from

the permit for the heater device D925 (section D), and will be removed for the turbine device

D926 upon conversion to P/O. The facility has been performing the annual source tests under

condition D28.23 to show compliance with the offset limits for ROG, CO and PM (see

Attachment E for source test results from the 2009 tests). Continued compliance is expected.

Regulation XIV: Toxic Air Contaminants

Rule 1401: New Source Review of Toxic Air Contaminants (3/7/08)

Not Applicable. This rule specifies limits for MICR, cancer burden, and noncancer

acute/chronic hazard index for new permit units, relocations, or modifications to existing

permit units which emit toxic air contaminants listed in Table I of this rule. These applications

are subject to the Rule 1401 version dated 3/7/08 (the current version at the time the

application was deemed complete on 6/30/08).

Since there is no increase in toxics emissions from the proposed changes, this rule does not

apply and health risk assessment is not required.

Regulation XVII: Prevention of Significant Deterioration (PSD)-Standard Prepared Statement

by the District

The goal of PSD is to ensure that air quality in clean areas does not significantly deteriorate

while maintaining a margin for future industrial growth. It applies to net emission increases of

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

PAGES PAGE

42 33

APPL. NO. DATE

483736, 483739, 10/31/12

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

455135

PROCESSED

BY

CHECKED

BY

B. Chandan

TV

criteria air pollutants that are currently in attainment. The District recently signed a new

Limited PSD Delegation agreement with EPA (effective July 26, 2007) that gives the District

limited responsibility for PSD. The South Coast Air Basin is currently in attainment for NO2,

SO2, CO, and lead.

A recent EPA Endangerment Finding for greenhouse gases (GHG) means that emissions of

GHG need to be evaluated under PSD. Note that ambient air quality standards have not yet

been released for GHG. Therefore, as the South Coast Air Basin is not in nonattainment, GHG

emissions are also subject to PSD in South Coast.

The recently promulgated Tailoring Rule specifies that GHG emissions must be evaluated

under PSD for projects at existing PSD or Title V sources in South Coast according to a

phased-in applicability time frame. The subject equipment is located at a Title V facility. The

Tailoring Rule Step 2 is currently in effect, which means that a significant emission increase

of GHGs can itself trigger PSD for modifications (rather than only being evaluated as a part of

"anyway" modifications that trigger PSD due to increases in other regulated pollutants).

This application does not involve increases of any attainment air pollutant, and thus Reg XVII

does not apply.

Regulation XX: Regional Clean Air Incentive Market (RECLAIM)

Expect to Comply. The ExxonMobils requested changes do not add any additional or new

RECLAIM pollutants. The company requests that the a condition specifically states that

during startup and shutdown that the District allows the bypassing of the SCR when the flue

gas at the inlet of the SCR drops below 550 Fahrenheit in which the control is useless because

ammonia will not react with NOx at temperatures below 550 Fahrenheit. Permit condition

E71.7 already states this.

Although the current permit allows ExxonMobil to bypass the SCR during start-up (<550F),

it does not implicitly states that ExxonMobil does not need to meet the NOx limit in A195.1

during start-up, shut-down or malfunction when the SCR inlet temperature is expected to be

less than 550F. As a result, ExxonMobil has applied for a Variance to the AQMD Hearing

Board for planned start-ups and shutdowns, to allow them to exceed the 9 ppmv limit in

A195.1. Therefore, ExxonMobil submitted these applications to allow them to exceed the

NOx limits during start-ups or shutdown without a variance. The District will impose new

permit conditions for startup and shutdown and the method for reporting of NOx emissions

(conditions D99.xx, D195.1 and E54.xx).

The current RECLAIM CEMS used to monitor NOx emissions from the heater and turbine is

a single range monitor with a certified range of 0-25 ppmv. Since the NOx emissions during

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

PAGES PAGE

42 34

APPL. NO. DATE

483736, 483739, 10/31/12

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

455135

PROCESSED

BY

CHECKED

BY

B. Chandan

TV

the start-up of the heater and turbine are expected to exceed the range of the current monitor,

ExxonMobil needs to use alternate methods for reporting, as described in Rule 2012, Protocol

Chapter 2. Section G allows using source test data to estimate the emission during start-up, in

lieu of emissions factors established in Table 3-D.

As shown in the Emissions Calculations section above, the NOx emissions during start-up are

based on source tests conducted during the 2009 start-up (w/o NH3 injection). The tests

showed that the max NOx concentration during start-up was 70 ppm uncontrolled (see

Attachment C for CEMS data). Based on this, the NOx emissions during start-up are

calculated to be 244.05 lbs/hr (see Attachment C for the details on start-up NOx calculations).

This limit has been incorporated in condition E54.xx.

Rule 2005 New Source Review for RECLAIM

As discussed above, adding conditions to allow ExxonMobil to start-up their heater and

turbine does not result in any increase of NOx emissions, as this was already allowed under

condition E71.7. The current NOx BACT limit in the permit is 9 ppmv at 15% O2.

It is also important to note that it is technologically not feasible to reduce NOx when the

temperature of the flue gas at the inlet to the SCR is below 550F (if ammonia is injected

during start-up, when the temperature is below 550F, it will not react with NOx and will

mostly come out of the stack, unreacted). The heaters are already equipped with low-NOx

burners. Thus, the District needs to allow ExxonMobil to exceed the 9 ppmv BACT limit

during start-up, when the temperature is expected to be below 550F. The District is

proposing to add a condition that will limit the start-up time to no more than 60 hours to

minimize the time that this equipment will exceed the 9 ppmv NOx BACT limit. This

alternate limit is expected to comply with the federal LAER requirements during the start-up

of the heater and turbine. The District also proposes to specify 244.05 lbs NOx/hr that

ExxonMobil will be required to use for its RECLAIM reporting, as shown in the calculation

above. Thus, compliance with the provision of this rule is expected.

Regulation XXX: Title V Permits

Applicable and Comply. Because ExxonMobil has received its final Title V permit on January

25, 2010, it has to comply with the requirements for facilities that have been issued final Title

V permits. Under Regulation XXX, there are different classifications for changes to Title V

permits. For ExxonMobil, the following revision applies to the subject applications:

Applicable and Comply. Minor Permit Revision: This type of revision is for

changes that do not result in any emission increases regulated by Regulation

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

PAGES PAGE

42 35

APPL. NO. DATE

483736, 483739, 10/31/12

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

455135

PROCESSED

BY

CHECKED

BY

B. Chandan

TV

XXX, and hazardous air pollutants and rules, federal and local, and is not for

modification or reconstruction. Because ExxonMobils devices are existing

sources that are not being modified and has no increase of pollutants, the

changes are, therefore, considered a minor revision of its Title V permit.

Public notice is not required; however, the proposed permit and the

engineering evaluation will be submitted to the USEPA for a 45-day review as

required by Rule 3003(j)(1)(A).

RECOMMENDATIONS

Based on the evaluation above, ExxonMobils turbine and process heater are currently in

compliance and expected to remain in compliance with all applicable permit conditions and

AQMD, State, and Federal Rules and Regulations. Permit to Construct (turbine) and Permit to

Operate (heater) are recommended with the conditions listed in the Conditions Section of this

evaluation.

Following a summary of actions recommended under this evaluation:

A/N Equipment Description Device ID Recommended Action

483736 Heater 24F-1, hydrogen reforming D925 Approve P/O

483739 Turbine 24J-1, Cogen D926 Approve P/C

455135 Heater 24F-1, hydrogen reforming D925 Cancel application

TV Permit Amendment Minor TV Amendment

SOUTH COAST AIR QUALITY MANAGEMENT

DISTRICT

ENGNEERING AND COMPLIANCE

APPLICATION PROCESSING AND CALCULATIONS

PAGES PAGE

42 36

APPL. NO. DATE

483736, 483739,

455135

10/31/12

PROCESSED

BY

CHECKED

BY

B. Chandan

TV

Attachments

A.

Compliance Data

B.

Engineering Evaluation for Fuel Optimization Project

A/N 440468_69

C.

Start-up NOx Emissions Data and Calculations

D.