Documente Academic

Documente Profesional

Documente Cultură

174-175 Technical A Boring Calculation of Cutting Forces

Încărcat de

janaaidaas1996Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

174-175 Technical A Boring Calculation of Cutting Forces

Încărcat de

janaaidaas1996Drepturi de autor:

Formate disponibile

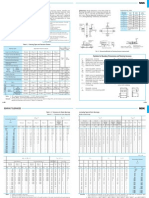

Tools with ISO elements | Technical appendix | Calculation of cutting forces, boring

Calculation of cutting forces, boring

(simplied)

Example calculation:

Boring tool 80 mm; Z = 5; pre-drilled 72 mm = 90

72 pre-drilled

80

Material: EN-GJL-250 kc1.1* = 1160 mc = 0.26 vc 200 m/min fz= 0.2 mm Blunting 30 % Result

Basic formula 1. Spindle speed

Calculation

Vc 1000 n = D (D d) ap = 2 A = ap f z

200 1000 n = 80 (80 72) ap = 2 A = 4 mm 0,2 mm 5

n = 800 1/min

2. Cutting depth

ap = 4 mm

3. Cutting cross section

A = 4 mm2

4. Chipping thickness

h = fz sin kc1.1 kc = h mc

h = 0,2 mm sin90 1160 kc = 0,2 0,26

h = 0,2 mm

5. Specic cutting force without blunting factor

kc = 1763 N/mm2

with 30 % blunting: 1763 N/mm2 1,3 = 2292 N/mm2

6. Cutting force

Fc = A kc = b h kc dm Mc = Fc 2 2 n Mc Pc = 60s

Fc = 4 mm2 2292 N/mm2 0,076 m Mc = 9167,3 N 2 2 800 min-1 348,3 Nm Pc = 60s

Note: The efficiency of the main spindle drive is not taken into account. Appropriate power calculations can be made by MAPAL.

Fc = 9,17 kN

7. Cutting torque dm = average diameter in metres

Mc = 348,3 Nm

8. Cutting power

Pc = 29,2 kW

* Value for cutting force calculation, WTO GmbH

174

Tools with ISO elements | Technical appendix | Calculation of cutting forces, boring

Machine tool selection:

Comparison with torque and output power of the machine tool There follow two spindle speed/power diagrams. The number of teeth and cutting parameters are to be dened as a function of the machine. In the example calculation the machine with the motor spindle is unsuitable, as here at a spindle speed of 800 1/min a torque of 187 Nm and a power of approx. 20 kW is achieved (Figure 1). Motor spindle (Figure 1)

Torque (Nm) Power (kW) 35 kW 100% 630 400 200 160 100 40 10 5 1000 1600 4000 10.000 40 30 20 10 8 5 3,15 2 0,6 1000 1600 4000 10.000 0,6 187 Nm 100% 40 30 20 10 8 5 3,15 2

Torque curve in Nm Power curve in kW Line to assist on reading the diagram

Spindle speed (1/min)

Solution: Either reduce number of teeth, reduce cutting speed and feed, divide cut between two tools or select more powerful machine (e.g. with geared spindle, (Figure 2).

Geared spindle (Figure 2)

Torque (Nm) Power (kW) 42 kW 100% 630 400 200 160 100 40 10 5 400 Nm 100%

The example diagrams are shown in a simplied form.

Spindle speed (1/min)

175

Technical appendix

S-ar putea să vă placă și

- Semi-Topping Shaper CuttersDocument4 paginiSemi-Topping Shaper CuttersalemarlonstosÎncă nu există evaluări

- Involute Spline Strength CalculationsDocument1 paginăInvolute Spline Strength CalculationsRjgandhi65Încă nu există evaluări

- As 2842-1986 Fluid Power - O-Rings and Housings - Inch Series Metric ConversionDocument6 paginiAs 2842-1986 Fluid Power - O-Rings and Housings - Inch Series Metric ConversionSAI Global - APACÎncă nu există evaluări

- Tools with ISO elements | Technical appendix | Calculation of cutting forces, boringDocument2 paginiTools with ISO elements | Technical appendix | Calculation of cutting forces, boringMohammed AlnasharÎncă nu există evaluări

- SPUD 604 ManualDocument37 paginiSPUD 604 ManualfbarrazaisaÎncă nu există evaluări

- How To Choose Cutting DataDocument31 paginiHow To Choose Cutting DataJose JacksonÎncă nu există evaluări

- Sheet No. 1 Design of GearsDocument3 paginiSheet No. 1 Design of GearssallyÎncă nu există evaluări

- Parametric Design On Internal Gear of Cycloid Gear Pump With NX10.0Document6 paginiParametric Design On Internal Gear of Cycloid Gear Pump With NX10.0PanagiotisÎncă nu există evaluări

- Splines: Key Components and Torque TransferDocument4 paginiSplines: Key Components and Torque TransferthirumalaikumaranÎncă nu există evaluări

- Small Commercial Vehicles India 2022Document26 paginiSmall Commercial Vehicles India 2022tussi_91100% (1)

- Important Hint: at Least One Warning Has Occurred During The CalculationDocument8 paginiImportant Hint: at Least One Warning Has Occurred During The CalculationDemir HamzicÎncă nu există evaluări

- Standards Development: Enclosed Drives: Agma VoicesDocument2 paginiStandards Development: Enclosed Drives: Agma VoicesRittik ChakrabortyÎncă nu există evaluări

- 6.4 Tooth-Bearings TechnicalData KGSTOCKGEARSDocument3 pagini6.4 Tooth-Bearings TechnicalData KGSTOCKGEARSLuis TestaÎncă nu există evaluări

- Grain SizeDocument12 paginiGrain SizeTejwinder S ChauhanÎncă nu există evaluări

- Iso 53 Indian StandardsDocument12 paginiIso 53 Indian StandardsErhan GencÎncă nu există evaluări

- AGMADocument7 paginiAGMADipakÎncă nu există evaluări

- TransmissionDocument24 paginiTransmissionRoyÎncă nu există evaluări

- 11.shafting and Associated Parts - V002Document64 pagini11.shafting and Associated Parts - V002Policarpo AlmeidaÎncă nu există evaluări

- Design of Transmission Systems Part ADocument32 paginiDesign of Transmission Systems Part Akannanviknesh086319Încă nu există evaluări

- Reverse EngineeringDocument27 paginiReverse Engineeringzeyadhr70Încă nu există evaluări

- Jis G 3466 - 2006 (JP)Document11 paginiJis G 3466 - 2006 (JP)HongHaiDuongÎncă nu există evaluări

- GEARBOX PART LISTDocument3 paginiGEARBOX PART LISTjosechr6Încă nu există evaluări

- A Method to Optimize Brass Synchronizer RingDocument6 paginiA Method to Optimize Brass Synchronizer RingaravindhÎncă nu există evaluări

- Me 581 Machine Tool Design Section 5 Design of Spindles and Spindle SupportsDocument54 paginiMe 581 Machine Tool Design Section 5 Design of Spindles and Spindle SupportsMlhhemreÎncă nu există evaluări

- Case DepthDocument2 paginiCase DepthSumeet SainiÎncă nu există evaluări

- ISO 1302 DIN 4768 Comparison of Surface Roughness Values Stainless Steel T PDFDocument2 paginiISO 1302 DIN 4768 Comparison of Surface Roughness Values Stainless Steel T PDFYohanes Wahyu TdÎncă nu există evaluări

- Broaching PDFDocument7 paginiBroaching PDFBalaji Karunakaran100% (1)

- Me-331 Design of Machine Elements Unit Iv Design of Basic ElementsDocument25 paginiMe-331 Design of Machine Elements Unit Iv Design of Basic ElementsMuthuvel MÎncă nu există evaluări

- Gearbox Design and Analysis - ProgramDocument4 paginiGearbox Design and Analysis - Programمحمد نتعيÎncă nu există evaluări

- KISSsoft ANSI B92.1 Involute Spline AnalysisDocument6 paginiKISSsoft ANSI B92.1 Involute Spline AnalysisDaggupati PraveenÎncă nu există evaluări

- Contact Pattern Analysis Training ProgramDocument4 paginiContact Pattern Analysis Training ProgramRAJIV GandhiÎncă nu există evaluări

- drwing-IIT Que-1 PDFDocument14 paginidrwing-IIT Que-1 PDFNur Alam100% (1)

- Reverse Engineering ExplainedDocument47 paginiReverse Engineering ExplainedMohannadÎncă nu există evaluări

- Make 3d CAD Model of Spiral Bevel.115110106Document14 paginiMake 3d CAD Model of Spiral Bevel.115110106Awidhi KresnawanÎncă nu există evaluări

- 05 StraightnessMeasurement90Document90 pagini05 StraightnessMeasurement90maddy_scribdÎncă nu există evaluări

- Diseños de EngranajesDocument26 paginiDiseños de EngranajesTarja Turunen MexicoÎncă nu există evaluări

- BEARING TOLERANCES TABLEDocument12 paginiBEARING TOLERANCES TABLESandeep MatetiÎncă nu există evaluări

- IS2048: Specifications for parallel keys and keywaysDocument12 paginiIS2048: Specifications for parallel keys and keywaysSagar GandhiÎncă nu există evaluări

- Straight Sided Serrations SpecificationsDocument2 paginiStraight Sided Serrations SpecificationsMarcel Dandaro100% (1)

- Analysis of The Yokeless and Segmented Armature MachineDocument7 paginiAnalysis of The Yokeless and Segmented Armature MachineSeksan KhamkaewÎncă nu există evaluări

- Creo Simulation Brochure - FinalDocument8 paginiCreo Simulation Brochure - FinalSrashmiÎncă nu există evaluări

- 0409 GearSolutionsDocument56 pagini0409 GearSolutionsAshish RajÎncă nu există evaluări

- Influence of Gear Geometry On Gearbox Noise Reduction - An Experimental InvestigationDocument7 paginiInfluence of Gear Geometry On Gearbox Noise Reduction - An Experimental InvestigationsamanaveenÎncă nu există evaluări

- Gear MotorDocument45 paginiGear Motorb3ltaÎncă nu există evaluări

- Tesi Poligono P3GDocument172 paginiTesi Poligono P3Ger_sor_magaraÎncă nu există evaluări

- Gears KinematicsDocument19 paginiGears Kinematicsavinashn12Încă nu există evaluări

- Tonnage Calculation General Formula For Press Tonnage RequiredDocument1 paginăTonnage Calculation General Formula For Press Tonnage RequiredsachinÎncă nu există evaluări

- Alwasy Step Ahead in TechnologyDocument6 paginiAlwasy Step Ahead in TechnologyDxFx100% (1)

- Catalog Strunguri Pentru Lemn - August 2013Document11 paginiCatalog Strunguri Pentru Lemn - August 2013Expert Masini UnelteÎncă nu există evaluări

- Gear Pumps: Product RangeDocument4 paginiGear Pumps: Product RangeEng-Mohammed SalemÎncă nu există evaluări

- Iso 2901 2016Document9 paginiIso 2901 2016Brandon Vicuña GalánÎncă nu există evaluări

- Advanced Concepts of GD&TDocument3 paginiAdvanced Concepts of GD&TPalani Trainer33% (3)

- A-313 - 98Document7 paginiA-313 - 98José Ramón GutierrezÎncă nu există evaluări

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987De la EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonÎncă nu există evaluări

- Calculation: Specification of MotorDocument7 paginiCalculation: Specification of MotorMahar Tahir Sattar MtsÎncă nu există evaluări

- Turning Problems - DR Saqib 2018Document11 paginiTurning Problems - DR Saqib 2018254Încă nu există evaluări

- Designing a Speed ReducerDocument12 paginiDesigning a Speed ReducerHannahÎncă nu există evaluări

- Example For Milling CalculationDocument3 paginiExample For Milling CalculationAbd Muhaimin AmmsÎncă nu există evaluări

- Contoh Soal MachiningDocument2 paginiContoh Soal MachiningNurhayati SitorusÎncă nu există evaluări

- HW 5 - Me 406-152 Plus SolutionDocument3 paginiHW 5 - Me 406-152 Plus SolutiontrishÎncă nu există evaluări

- Document Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking PlantDocument49 paginiDocument Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking Plantsusa2536Încă nu există evaluări

- 25 Things Managers Should Know About FEA - Digital EngineeringDocument3 pagini25 Things Managers Should Know About FEA - Digital Engineeringjanaaidaas1996Încă nu există evaluări

- Pro E Thickness ControlDocument1 paginăPro E Thickness Controljanaaidaas1996Încă nu există evaluări

- Bioresources.: Kraft, BCTMP, and TMP Dewatering Behaviour Along The Axis of A Screw PressDocument16 paginiBioresources.: Kraft, BCTMP, and TMP Dewatering Behaviour Along The Axis of A Screw Pressjanaaidaas1996Încă nu există evaluări

- 13-12 BIBUS Ez-Wheel Catalogue - ENDocument20 pagini13-12 BIBUS Ez-Wheel Catalogue - ENjanaaidaas1996Încă nu există evaluări

- Drawing OptionDocument14 paginiDrawing Optionjanaaidaas1996Încă nu există evaluări

- Customer SatisfactionDocument6 paginiCustomer Satisfactionjanaaidaas1996Încă nu există evaluări

- Shear Stress in Beams NotesDocument4 paginiShear Stress in Beams NotesMubark Al-haidariÎncă nu există evaluări

- Rittal Price ListDocument60 paginiRittal Price Listdgrsri80% (5)

- Material Specification Sheet Saarstahl - C45: 1.0503 BS: Afnor: Sae: Material Group: Chemical Composition: ApplicationDocument2 paginiMaterial Specification Sheet Saarstahl - C45: 1.0503 BS: Afnor: Sae: Material Group: Chemical Composition: Applicationshankarjb100% (1)

- FMEA Priorities and ActionsDocument4 paginiFMEA Priorities and Actionsjanaaidaas1996Încă nu există evaluări

- Simulation Theory ManualDocument115 paginiSimulation Theory ManualAleksandar AcevskiÎncă nu există evaluări

- Van CFD: Boundery ConditionsDocument4 paginiVan CFD: Boundery Conditionsjanaaidaas1996Încă nu există evaluări

- Quick Reference CardDocument6 paginiQuick Reference Cardjanaaidaas1996Încă nu există evaluări

- IITK-GSDMA Wind Codes DocumentDocument105 paginiIITK-GSDMA Wind Codes DocumentMadusha Galappaththi100% (2)

- Mentorpaper 102589Document13 paginiMentorpaper 102589janaaidaas1996Încă nu există evaluări

- An Entrepreneur Rajesh Mandlik LinkedInDocument29 paginiAn Entrepreneur Rajesh Mandlik LinkedInjanaaidaas1996Încă nu există evaluări

- VBA Book PDFDocument121 paginiVBA Book PDFAriadiKetutÎncă nu există evaluări

- Head RestraintDocument14 paginiHead Restraintjanaaidaas1996100% (1)

- Ind Connectivity Study GuideDocument9 paginiInd Connectivity Study Guidejanaaidaas1996Încă nu există evaluări

- Corrosion Predict6 Sept2012 PinDocument3 paginiCorrosion Predict6 Sept2012 Pinjanaaidaas1996Încă nu există evaluări

- Jigs and Fixtures JoshiDocument252 paginiJigs and Fixtures JoshiVikram Govindarajan83% (6)

- Fundamentals of Resistance Welding PDFDocument8 paginiFundamentals of Resistance Welding PDFSuraj SinghÎncă nu există evaluări

- Creating A SolidWorks Add-InDocument7 paginiCreating A SolidWorks Add-Inkkozak99Încă nu există evaluări

- Five Habits of A Highly Successful Start-Up Employee Hari TDocument5 paginiFive Habits of A Highly Successful Start-Up Employee Hari Tjanaaidaas1996Încă nu există evaluări

- Review of The New Y14 5 2009 StandardDocument16 paginiReview of The New Y14 5 2009 StandardPhillip GrimÎncă nu există evaluări

- DATUMSDocument84 paginiDATUMSmaddy_scribd100% (2)

- Engineering Drawings IntrodroductionDocument39 paginiEngineering Drawings Introdroductionadnan100% (3)

- GD&T BasicsDocument33 paginiGD&T Basicsjanaaidaas1996Încă nu există evaluări

- Dimensional Tolerance ChartDocument1 paginăDimensional Tolerance Chartpushkar_k123Încă nu există evaluări

- Basic GD&T - Datums PDFDocument35 paginiBasic GD&T - Datums PDFtnchsgÎncă nu există evaluări

- CE6306 NotesDocument125 paginiCE6306 Noteskl42c4300Încă nu există evaluări

- 1 s2.0 S1110016822005646 MainDocument14 pagini1 s2.0 S1110016822005646 MainEss ZeeÎncă nu există evaluări

- Bending Moment Normal Forces in Tunnel Linings PDFDocument8 paginiBending Moment Normal Forces in Tunnel Linings PDFhendrawanÎncă nu există evaluări

- Structure Chap-7 Review ExDocument7 paginiStructure Chap-7 Review Exabenezer g/kirstosÎncă nu există evaluări

- Cast Iron DampingDocument5 paginiCast Iron Dampinggabs88Încă nu există evaluări

- Calculus SyllabusDocument7 paginiCalculus SyllabusRumarie de la CruzÎncă nu există evaluări

- Subsea Control Systems SXGSSC PDFDocument6 paginiSubsea Control Systems SXGSSC PDFLimuel EspirituÎncă nu există evaluări

- A RANS-based Analysis Ool For Ducted Propeller Systems in Open Water ConditionDocument23 paginiA RANS-based Analysis Ool For Ducted Propeller Systems in Open Water ConditionLeonardo Duarte MilfontÎncă nu există evaluări

- 9abs304-Probability & StatisticsDocument5 pagini9abs304-Probability & StatisticssivabharathamurthyÎncă nu există evaluări

- World-GAN - A Generative Model For MinecraftDocument8 paginiWorld-GAN - A Generative Model For MinecraftGordonÎncă nu există evaluări

- Minimum Cost Flow: A Minimum Cost Flow Problem Is A Optimization and Decision Problem To Find TheDocument3 paginiMinimum Cost Flow: A Minimum Cost Flow Problem Is A Optimization and Decision Problem To Find Thebishal maharjanÎncă nu există evaluări

- Assignment / Tugasan - Mathematics For ManagementDocument7 paginiAssignment / Tugasan - Mathematics For ManagementKetz NKÎncă nu există evaluări

- Radix 64 ConversionDocument13 paginiRadix 64 ConversionRajendra Prasad100% (1)

- Chapter 3. Drag Force and Its CoefficientDocument47 paginiChapter 3. Drag Force and Its Coefficientsmyeganeh100% (1)

- CV Dr Mohammad ShahzadDocument5 paginiCV Dr Mohammad ShahzadTarique WaliÎncă nu există evaluări

- Relation between resolution III and confounded responsesDocument50 paginiRelation between resolution III and confounded responsesrohitrealisticÎncă nu există evaluări

- ICCM2014Document28 paginiICCM2014chenlei07Încă nu există evaluări

- Mechanical Vibration NotesDocument56 paginiMechanical Vibration NotesYadanaÎncă nu există evaluări

- 6 Noise and Multiple Attenuation PDFDocument164 pagini6 Noise and Multiple Attenuation PDFFelipe CorrêaÎncă nu există evaluări

- RF Energy Harvesting in Relay NetworksDocument44 paginiRF Energy Harvesting in Relay NetworksYeshwanthSuraÎncă nu există evaluări

- EGA Revisited: Key Concepts in Grothendieck's Foundational WorkDocument50 paginiEGA Revisited: Key Concepts in Grothendieck's Foundational WorkTomás CampoÎncă nu există evaluări

- Decision Modeling Using SpreadsheetDocument36 paginiDecision Modeling Using SpreadsheetamritaÎncă nu există evaluări

- Determine Beam Deflection Using Integration and Geometric MethodsDocument8 paginiDetermine Beam Deflection Using Integration and Geometric MethodsNadiaÎncă nu există evaluări

- Stability Analysis-Control SystemDocument29 paginiStability Analysis-Control SystemNanmaran RajendiranÎncă nu există evaluări

- Unit 4 DeadlocksDocument14 paginiUnit 4 DeadlocksMairos Kunze BongaÎncă nu există evaluări

- ΔΣ Modulator with Low power Using Charge- Pump Based Switched-Capacitor IntegratorDocument5 paginiΔΣ Modulator with Low power Using Charge- Pump Based Switched-Capacitor IntegratorIPASJÎncă nu există evaluări

- Angle Pair Relationships: Name The Relationship: Complementary, Linear Pair, Vertical, or AdjacentDocument2 paginiAngle Pair Relationships: Name The Relationship: Complementary, Linear Pair, Vertical, or Adjacent何睿恩Ryan HoÎncă nu există evaluări

- Trigonometry Worksheet with 15 ProblemsDocument2 paginiTrigonometry Worksheet with 15 ProblemsChandrasegran NargesÎncă nu există evaluări