Documente Academic

Documente Profesional

Documente Cultură

Purified Water European Pharmacopeia

Încărcat de

venki_beeTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Purified Water European Pharmacopeia

Încărcat de

venki_beeDrepturi de autor:

Formate disponibile

Water, purified EUROPEAN PHARMACOPOEIA 6.

3

Aluminium (2.4.17) : maximum 10 ppb, if intended for use in

the manufacture of dialysis solutions.

Prescribed solution. To 400 ml of the water to be examined

add 10 ml of acetate buffer solution pH 6.0 R and 100 ml of

distilled water R.

Reference solution. Mix 2 ml of aluminium standard

solution (2 ppm Al) R, 10 ml of acetate buffer solution

pH 6.0 R and 98 ml of distilled water R.

Blank solution. Mix 10 ml of acetate buffer solution

pH 6.0 R and 100 ml of distilled water R.

Bacterial endotoxins (2.6.14) : less than 0.25 IU/ml.

LABELLING

The label states, where applicable, that the substance is

suitable for use in the manufacture of dialysis solutions.

01/2009:0008

WATER, PURIFIED

Aqua purificata

H

2

O M

r

18.02

DEFINITION

Water for the preparation of medicines other than those

that are required to be both sterile and apyrogenic, unless

otherwise justified and authorised.

Purified water in bulk

PRODUCTION

Purified water in bulk is prepared by distillation, by ion

exchange, by reverse osmosis or by any other suitable

method from water that complies with the regulations on

water intended for human consumption laid down by the

competent authority.

Purified water in bulk is stored and distributed in conditions

designed to prevent growth of micro-organisms and to avoid

any other contamination.

Microbiological monitoring. During production and

subsequent storage, appropriate measures are taken to

ensure that the microbial count is adequately controlled

and monitored. Appropriate alert and action levels are set

so as to detect adverse trends. Under normal conditions, an

appropriate action level is a microbial count of 100 CFU/ml,

determined by filtration through a membrane with a nominal

pore size not greater than 0.45 m, using R2A agar and

incubating at 30-35 C for not less than 5 days. The size of

the sample is to be chosen in relation to the expected result.

R2A agar

Yeast extract 0.5 g

Proteose peptone 0.5 g

Casein hydrolysate 0.5 g

Glucose 0.5 g

Starch 0.5 g

Dipotassium hydrogen phosphate 0.3 g

Magnesium sulphate, anhydrous 0.024 g

Sodium pyruvate 0.3 g

Agar 15.0 g

Purified water to 1000 ml

Adjust the pH so that after sterilisation it is 7.2 0.2.

Sterilise by heating in an autoclave at 121 C for 15 min.

Growth promotion of R2A agar

Preparation of test strains. Use standardised stable

suspensions of test strains or prepare them as stated

in Table 0008.-1. Seed lot culture maintenance

techniques (seed-lot systems) are used so that the viable

micro-organisms used for inoculation are not more than

5 passages removed from the original master seed-lot.

Grow each of the bacterial strains separately as described

in Table 0008.-1. Use buffered sodium chloride-peptone

solution pH 7.0 or phosphate buffer solution pH 7.2

to make test suspensions. Use the suspensions within

2 h, or within 24 h if stored at 2-8 C. As an alternative

to preparing and then diluting a fresh suspension

of vegetative cells of Bacillus subtilis, a stable spore

suspension is prepared and then an appropriate volume

of the spore suspension is used for test inoculation. The

stable spore suspension may be maintained at 2-8 C for

a validated period of time.

Growth promotion. Test each batch of ready-prepared

medium and each batch of medium, prepared either from

dehydrated medium or from the ingredients described.

Inoculate plates of R2A agar separately with a small

number (not more than 100 CFU) of the micro-organisms

indicated in Table 0008.-1. Incubate under the conditions

described in the table. Growth obtained must not differ

by a factor greater than 2 from the calculated value for a

standardised inoculum. For a freshly prepared inoculum,

growth of the micro-organisms must be comparable to

that obtained with a previously tested and approved batch

of medium.

Table 0008.-1. Growth promotion of R2A agar

Micro-organism Preparation of the test strain Growth promotion

Pseudomonas

aeruginosa

such as:

ATCC 9027

NCIMB 8626

CIP 82.118

NBRC 13275

Casein soyabean digest agar or

casein soyabean digest broth

30-35 C

18-24 h

R2A agar

100 CFU

30-35 C

3 days

Bacillus subtilis

such as:

ATCC 6633

NCIMB 8054

CIP 52.62

NBRC 3134

Casein soyabean digest agar or

casein soyabean digest broth

30-35 C

18-24 h

R2A agar

100 CFU

30-35 C

3 days

Total organic carbon or oxidisable substances. Carry out

the test for total organic carbon (2.2.44) with a limit of

0.5 mg/l or alternatively the following test for oxidisable

substances: to 100 ml add 10 ml of dilute sulphuric acid R

and 0.1 ml of 0.02 M potassium permanganate and boil for

5 min; the solution remains faintly pink.

Conductivity. Determine the conductivity off-line or in-line

under the following conditions.

EQUIPMENT

Conductivity cell :

electrodes of a suitable material such as stainless steel ;

cell constant : the cell constant is generally certified

by the supplier and is subsequently verified at suitable

intervals using a certified reference solution with a

conductivity less than 1500 Scm

1

or by comparison

with a cell having a certified cell constant ; the cell

constant is confirmed if the value found is within 2 per

cent of the certified value, otherwise re-calibration must

be performed.

4344 See the information section on general monographs (cover pages)

EUROPEAN PHARMACOPOEIA 6.3 Water, purified

Conductometer: accuracy of 0.1 Scm

1

or better at the

lowest range.

System calibration (conductivity cell and conductometer) :

against one or more suitable certified reference solutions;

accuracy: within 3 per cent of the measured conductivity

plus 0.1 Scm

1

.

Conductometer calibration: calibration is carried out for

each range of measurement to be used, after disconnection

of the conductivity cell, using certified precision resistors

or equivalent devices with an uncertainty not greater than

0.1 per cent of the certified value.

If in-line conductivity cells cannot be dismantled, system

calibration may be performed against a calibrated

conductivity-measuring instrument with a conductivity cell

placed close to the cell to be calibrated in the water flow.

Temperature measurement : tolerance 2 C.

PROCEDURE

Measure the conductivity without temperature

compensation, recording simultaneously the temperature.

Temperature-compensated measurement may be performed

after suitable validation.

The water to be examined meets the requirements if the

measured conductivity at the recorded temperature is not

greater than the value in Table 0008.-2.

Table 0008.-2. Temperature and conductivity

requirements

Temperature

(C)

Conductivity

(Scm

1

)

0 2.4

10 3.6

20 4.3

25 5.1

30 5.4

40 6.5

50 7.1

60 8.1

70 9.1

75 9.7

80 9.7

90 9.7

100 10.2

For temperatures not listed in Table 0008.-2, calculate the

maximal permitted conductivity by interpolation between

the next lower and next higher data points in the table.

Heavy metals. If purified water in bulk complies with

the requirement for conductivity prescribed for Water for

injections (0169) in bulk , it is not necessary to carry out the

test for heavy metals prescribed below.

CHARACTERS

Appearance: clear and colourless liquid.

TESTS

Nitrates: maximum 0.2 ppm.

Place 5 ml in a test-tube immersed in iced water, add 0.4 ml

of a 100 g/l solution of potassium chloride R, 0.1 ml of

diphenylamine solution R and, dropwise with shaking,

5 ml of nitrogen-free sulphuric acid R. Transfer the tube

to a water-bath at 50 C. After 15 min, any blue colour in

the solution is not more intense than that in a reference

solution prepared at the same time in the same manner

using a mixture of 4.5 ml of nitrate-free water R and 0.5 ml

of nitrate standard solution (2 ppm NO

3

) R.

Aluminium (2.4.17) : maximum 10 ppb, if intended for use in

the manufacture of dialysis solutions.

Prescribed solution. To 400 ml of the water to be examined

add 10 ml of acetate buffer solution pH 6.0 R and 100 ml of

distilled water R.

Reference solution. Mix 2 ml of aluminium standard

solution (2 ppm Al) R, 10 ml of acetate buffer solution

pH 6.0 R and 98 ml of distilled water R.

Blank solution. Mix 10 ml of acetate buffer solution

pH 6.0 R and 100 ml of distilled water R.

Heavy metals (2.4.8) : maximum 0.1 ppm.

To 200 ml add 0.15 ml of 0.1 M nitric acid and heat in a

glass evaporating dish on a water-bath until the volume

is reduced to 20 ml. 12 ml of the concentrated solution

complies with test A. Prepare the reference solution using

10 ml of lead standard solution (1 ppm Pb) R and adding

0.075 ml of 0.1 M nitric acid. Prepare the blank solution

adding 0.075 ml of 0.1 M nitric acid.

Bacterial endotoxins (2.6.14) : less than 0.25 IU/ml, if

intended for use in the manufacture of dialysis solutions

without a further appropriate procedure for removal of

bacterial endotoxins.

LABELLING

The label states, where applicable, that the substance is

suitable for use in the manufacture of dialysis solutions.

Purified water in containers

DEFINITION

Purified water in bulk that has been filled and stored in

conditions designed to assure the required microbiological

quality. It is free from any added substances.

CHARACTERS

Appearance: clear and colourless liquid.

TESTS

It complies with the tests prescribed in the section on

Purified water in bulk and with the following additional tests.

Acidity or alkalinity. To 10 ml, freshly boiled and cooled in a

borosilicate glass flask, add 0.05 ml of methyl red solution R.

The solution is not coloured red.

To 10 ml add 0.1 ml of bromothymol blue solution R1. The

solution is not coloured blue.

Oxidisable substances. To 100 ml add 10 ml of dilute

sulphuric acid R and 0.1 ml of 0.02 M potassium

permanganate and boil for 5 min. The solution remains

faintly pink.

Chlorides. To 10 ml add 1 ml of dilute nitric acid R and

0.2 ml of silver nitrate solution R2. The solution shows no

change in appearance for at least 15 min.

Sulphates. To 10 ml add 0.1 ml of dilute hydrochloric acid R

and 0.1 ml of barium chloride solution R1. The solution

shows no change in appearance for at least 1 h.

Ammonium: maximum 0.2 ppm.

To 20 ml add 1 ml of alkaline potassium tetraiodomercurate

solution R. After 5 min, examine the solution down the

vertical axis of the tube. The solution is not more intensely

coloured than a standard prepared at the same time by

adding 1 ml of alkaline potassium tetraiodomercurate

solution R to a mixture of 4 ml of ammonium standard

General Notices (1) apply to all monographs and other texts 4345

Wheat starch EUROPEAN PHARMACOPOEIA 6.3

solution (1 ppm NH

4

) R and 16 ml of ammonium-free

water R.

Calcium and magnesium. To 100 ml add 2 ml of ammonium

chloride buffer solution pH 10.0 R, 50 mg of mordant

black 11 triturate R and 0.5 ml of 0.01 M sodium edetate. A

pure blue colour is produced.

Residue on evaporation: maximum 0.001 per cent.

Evaporate 100 ml to dryness on a water-bath and dry in an

oven at 100-105 C. The residue weighs a maximum of 1 mg.

Microbial contamination

TAMC: acceptance criterion 10

2

CFU/ml (2.6.12). Use casein

soya bean digest agar.

LABELLING

The label states, where applicable, that the substance is

suitable for use in the manufacture of dialysis solutions.

01/2009:0359

WHEAT STARCH

Tritici amylum

DEFINITION

Wheat starch is obtained from the caryopsis of Triticum

aestivum L. (T. vulgare Vill.).

CHARACTERS

Appearance: very fine, white or almost white powder that

creaks when pressed between the fingers.

Solubility: practically insoluble in cold water and in ethanol

(96 per cent).

Wheat starch does not contain starch grains of any other

origin. It may contain a minute quantity, if any, of tissue

fragments of the original plant.

IDENTIFICATION

A. Examined under a microscope using equal volumes

of glycerol R and water R, it presents large and small

granules, and, very rarely, intermediate sizes. The large

granules, 10-60 m in diameter, are discoid or, more

rarely, reniform when seen face-on. The central hilum and

striations are invisible or barely visible and the granules

sometimes show cracks on the edges. Seen in profile,

the granules are elliptical and fusiform and the hilum

appears as a slit along the main axis. The small granules,

rounded or polyhedral, are 2-10 m in diameter. Between

orthogonally orientated polarising plates or prisms, the

granules show a distinct black cross intersecting at the

hilum.

B. Suspend 1 g in 50 ml of water R, boil for 1 min and cool.

A thin, cloudy mucilage is formed.

C. To 1 ml of the mucilage obtained in identification test B

add 0.05 ml of iodine solution R1. A dark blue colour is

produced, which disappears on heating.

TESTS

pH (2.2.3) : 4.5 to 7.0.

Shake 5.0 g with 25.0 ml of carbon dioxide-free water R for

60 s. Allow to stand for 15 min.

Foreign matter. Examined under a microscope using a

mixture of equal volumes of glycerol R and water R, not

more than traces of matter other than starch granules are

present. No starch grains of any other origin are present.

Total protein: maximum 0.3 per cent of total protein

(corresponding to 0.048 per cent N

2

, conversion factor:

6.25), determined on 6.0 g by sulphuric acid digestion (2.5.9)

modified as follows: wash any adhering particles from the

neck into the flask with 25 ml of sulphuric acid R; continue

the heating until a clear solution is obtained; add 45 ml of

strong sodium hydroxide solution R.

Oxidising substances (2.5.30) : maximum 20 ppm, calculated

as H

2

O

2

.

Sulphur dioxide (2.5.29) : maximum 50 ppm.

Iron (2.4.9) : maximum 10 ppm.

Shake 1.5 g with 15 ml of dilute hydrochloric acid R. Filter.

The filtrate complies with the test.

Loss on drying (2.2.32) : maximum 15.0 per cent, determined

on 1.000 g by drying in an oven at 130 C for 90 min.

Sulphated ash (2.4.14) : maximum 0.6 per cent, determined

on 1.0 g.

Microbial contamination

TAMC: acceptance criterion 10

3

CFU/g (2.6.12).

TYMC: acceptance criterion 10

2

CFU/g (2.6.12).

Absence of Escherichia coli (2.6.13).

Absence of Salmonella (2.6.13).

4346 See the information section on general monographs (cover pages)

S-ar putea să vă placă și

- Tablet Press Operation: Weight HardnessDocument5 paginiTablet Press Operation: Weight HardnessMichael TouseyÎncă nu există evaluări

- British Pharmacopoeia purified water standardDocument4 paginiBritish Pharmacopoeia purified water standardmariashidalgoÎncă nu există evaluări

- A WHO GuideDocument100 paginiA WHO Guidej.k.kumar92% (13)

- Tablet Coating BasicsDocument4 paginiTablet Coating BasicsTahir KhanÎncă nu există evaluări

- Environmental Monitoring in Pharmaceutical FacilitiesDocument40 paginiEnvironmental Monitoring in Pharmaceutical Facilitiesananth100% (3)

- Sterility Testing - Pics PDFDocument15 paginiSterility Testing - Pics PDFdepardieu1973100% (2)

- Commissioning and Qualification ASTM ApproachDocument0 paginiCommissioning and Qualification ASTM Approachvenki_beeÎncă nu există evaluări

- Capsule Filling Machine OQDocument37 paginiCapsule Filling Machine OQvenki_bee76% (21)

- Who TRS 970 Anexo 2 PDFDocument23 paginiWho TRS 970 Anexo 2 PDFAnonymous guhSjjNWdP100% (1)

- Cleaning Validation Guidelines - A Complete ListDocument11 paginiCleaning Validation Guidelines - A Complete ListSanjay SharmaÎncă nu există evaluări

- In Process Quality Control Tests (IPQC) For Solid Dosage FromDocument28 paginiIn Process Quality Control Tests (IPQC) For Solid Dosage FromSagar kishor savale75% (8)

- BioBall Verification Protocol Iss 3Document16 paginiBioBall Verification Protocol Iss 3Michelle Morgan LongstrethÎncă nu există evaluări

- Tle - Afa-Fp: Quarter 4 - Module 1Document15 paginiTle - Afa-Fp: Quarter 4 - Module 1Erl CasiñoÎncă nu există evaluări

- Compressed Air in Pharmaceutical IndustryDocument26 paginiCompressed Air in Pharmaceutical IndustryPaulus Gunawan94% (17)

- Risk Assessment in Automated Manufacturing Practices 2Document0 paginiRisk Assessment in Automated Manufacturing Practices 2venki_beeÎncă nu există evaluări

- Risk Assessment Example For CSV - EDMSDocument2 paginiRisk Assessment Example For CSV - EDMSvenki_bee100% (2)

- URS 01 - Rotary Press Tablet Machine SPLDocument18 paginiURS 01 - Rotary Press Tablet Machine SPLrosy0171057% (7)

- Commissioning and Qualification 2Document0 paginiCommissioning and Qualification 2venki_beeÎncă nu există evaluări

- Active Pharmaceutical Ingredients Committee (APIC)Document12 paginiActive Pharmaceutical Ingredients Committee (APIC)Ngoc Sang Huynh100% (1)

- Risk Assessment For Automated Manufacturing Process - 1Document0 paginiRisk Assessment For Automated Manufacturing Process - 1venki_beeÎncă nu există evaluări

- PHSS Control Strategy White PaperDocument13 paginiPHSS Control Strategy White PaperAkuWilliams100% (1)

- British Pharmacopoeia Volume IIIDocument2 paginiBritish Pharmacopoeia Volume IIIQonita NitaÎncă nu există evaluări

- Guidelines Packaging Pharmaceutical Products TRS902 Annex 9Document38 paginiGuidelines Packaging Pharmaceutical Products TRS902 Annex 9Shuhash100% (1)

- Design Manual - PharmaDocument150 paginiDesign Manual - PharmaArun CherianÎncă nu există evaluări

- Calcium Gluconate USP MonographDocument4 paginiCalcium Gluconate USP Monographthe docsproviderÎncă nu există evaluări

- PTS 60.3302 Monitoring of Air Quality & Atmospheric EmissionsDocument37 paginiPTS 60.3302 Monitoring of Air Quality & Atmospheric EmissionsArifin MustafaÎncă nu există evaluări

- Maintenance of Purified Water System (Pretreatment)Document2 paginiMaintenance of Purified Water System (Pretreatment)venki_beeÎncă nu există evaluări

- API 原料药的验证 PDFDocument609 paginiAPI 原料药的验证 PDFflongÎncă nu există evaluări

- ASTM D 3155 - 98 Lime Content of Uncured Soil-Lime MixturesDocument4 paginiASTM D 3155 - 98 Lime Content of Uncured Soil-Lime Mixturesalin2005Încă nu există evaluări

- Pharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersDe la EverandPharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersÎncă nu există evaluări

- 5.redundant Sterilizing Filtration - MR - SomDocument34 pagini5.redundant Sterilizing Filtration - MR - SomTaÎncă nu există evaluări

- Pharmaceutical CGMP Guidelines Water TestingDocument24 paginiPharmaceutical CGMP Guidelines Water TestingloisetapiceriaÎncă nu există evaluări

- IQ-PQ-EQ Documents For FDC - IRN75Document12 paginiIQ-PQ-EQ Documents For FDC - IRN75Doan Chi ThienÎncă nu există evaluări

- WHO Guideline For Sterile Pharmaceutical Product PDFDocument24 paginiWHO Guideline For Sterile Pharmaceutical Product PDFNova Alvia LodiÎncă nu există evaluări

- From Start To Finish: Pharmaceutical Grade WaterDocument6 paginiFrom Start To Finish: Pharmaceutical Grade Watervenki_bee100% (1)

- JETT AutoclaveURSDocument29 paginiJETT AutoclaveURSBadar RizwanÎncă nu există evaluări

- Stability Studies of Pharmaceutical & Cosmetic ProductsDe la EverandStability Studies of Pharmaceutical & Cosmetic ProductsÎncă nu există evaluări

- Hvac and Environment GuideDocument185 paginiHvac and Environment GuiderejithkmÎncă nu există evaluări

- GMP Inspection East AfricaDocument336 paginiGMP Inspection East AfricaTuan NguyenÎncă nu există evaluări

- Techno Drugs Raw Material Test ProcedureDocument9 paginiTechno Drugs Raw Material Test ProcedureMd. Moniruzzaman0% (1)

- HTM2010 Parts1-6 PDFDocument724 paginiHTM2010 Parts1-6 PDFJUAN CARLOS RiveraÎncă nu există evaluări

- cGMP Current Good Manufacturing Practices for PharmaceuticalsDe la EverandcGMP Current Good Manufacturing Practices for PharmaceuticalsEvaluare: 1 din 5 stele1/5 (2)

- ANVISA - Brazil Released A New Guidance On Nitrosamines - VinaGMPDocument32 paginiANVISA - Brazil Released A New Guidance On Nitrosamines - VinaGMPThắng Vũ Đức100% (1)

- USP General Chapter <795> Nonsterile Compounding GuideDocument13 paginiUSP General Chapter <795> Nonsterile Compounding GuideangelÎncă nu există evaluări

- European Pharmacopoeia 8.2 - 2014 - IndexDocument53 paginiEuropean Pharmacopoeia 8.2 - 2014 - IndexRoger (Sisfarma)100% (3)

- Cleaning in Place (CIP) in Food Processing: December 2013Document55 paginiCleaning in Place (CIP) in Food Processing: December 2013Đivềphía Mặt TrờiÎncă nu există evaluări

- ISPE Cleaningvalidation PDFDocument42 paginiISPE Cleaningvalidation PDFAjay KumarÎncă nu există evaluări

- Cleaning Validation PresDocument25 paginiCleaning Validation Presyazantm100% (1)

- A Practical Guide To Construction, Commissioning and Qualification Documentation - and Its Critical Role in Achieving ComplianceDocument8 paginiA Practical Guide To Construction, Commissioning and Qualification Documentation - and Its Critical Role in Achieving ComplianceModÎncă nu există evaluări

- Qualification of Purified Water Systems PDFDocument12 paginiQualification of Purified Water Systems PDFMario Vazquez B100% (1)

- Production of Plasma Proteins for Therapeutic UseDe la EverandProduction of Plasma Proteins for Therapeutic UseEvaluare: 3 din 5 stele3/5 (5)

- Procedurefor Cleaning ValidationDocument21 paginiProcedurefor Cleaning ValidationQ CÎncă nu există evaluări

- TOT Water For Pharmaceutical Use - Part 1Document132 paginiTOT Water For Pharmaceutical Use - Part 1Delly AnakAfternoonyesterdays0% (1)

- HTM 2031 Clean Steam For Sterilization PDFDocument72 paginiHTM 2031 Clean Steam For Sterilization PDFJOHN CAROÎncă nu există evaluări

- Purified Water Conductivity LimitsDocument3 paginiPurified Water Conductivity Limitsssnoorm100% (3)

- European Pharmacopoeia 7th Edition PDFDocument2 paginiEuropean Pharmacopoeia 7th Edition PDFCallie0% (1)

- Purified Water Specification From European Pharmacopoeia Edition 8Document3 paginiPurified Water Specification From European Pharmacopoeia Edition 8puut100% (1)

- Pub PHEUR-SE04 PDFDocument357 paginiPub PHEUR-SE04 PDFSantiago IbañezÎncă nu există evaluări

- Wfi UrsDocument44 paginiWfi UrsUroš ČampragÎncă nu există evaluări

- Biocontamination Control Techniques For Purified Water SystemDocument4 paginiBiocontamination Control Techniques For Purified Water SystemAli KureishiÎncă nu există evaluări

- Dissolution WHO PresentationDocument64 paginiDissolution WHO PresentationnkszoneÎncă nu există evaluări

- 3.BatchRecordsF10sm 000Document22 pagini3.BatchRecordsF10sm 000abdelaziz_ismail685662Încă nu există evaluări

- Japanese Pharmacopoeia XV - JP17Document1.802 paginiJapanese Pharmacopoeia XV - JP17333cubi3330% (1)

- PH Eur 2.8.20. Herbal Drugs - Sampling and Sample PreparationDocument2 paginiPH Eur 2.8.20. Herbal Drugs - Sampling and Sample PreparationLuisSanabriaSaavedraÎncă nu există evaluări

- Water For InjectionsDocument11 paginiWater For InjectionsRphNaeemMalikÎncă nu există evaluări

- Agua BPDocument3 paginiAgua BPEdgar Condori MendozaÎncă nu există evaluări

- Water For InjectionsDocument4 paginiWater For InjectionsAlvina Arum PuspitasariÎncă nu există evaluări

- EPA Method 9014Document7 paginiEPA Method 9014Joan MuñozÎncă nu există evaluări

- 2.4.18 Free FormaldehydeDocument2 pagini2.4.18 Free FormaldehydeMulayam Singh YadavÎncă nu există evaluări

- DEA & ACT-1 in Benfield Solution by Ion ChromatographyDocument9 paginiDEA & ACT-1 in Benfield Solution by Ion ChromatographyFauzan Azim EdhochenkoÎncă nu există evaluări

- Organic Carbon Total HR TNT 10128Document8 paginiOrganic Carbon Total HR TNT 10128okgnosasÎncă nu există evaluări

- Total Nitrogen by Kjeldahl MethodDocument7 paginiTotal Nitrogen by Kjeldahl Methodlinhpic99Încă nu există evaluări

- Preparation of 2% Lidocaine GelDocument12 paginiPreparation of 2% Lidocaine Gelmarker ilearniteasyÎncă nu există evaluări

- DR 4000 Chemical Oxygen Demand (0-15,000 MGL) Method 8000Document8 paginiDR 4000 Chemical Oxygen Demand (0-15,000 MGL) Method 8000Özgüll ClÎncă nu există evaluări

- 3 Steps To USP SucessDocument7 pagini3 Steps To USP Sucessvenki_bee100% (1)

- Granulation ProcessDocument5 paginiGranulation ProcessobrossaÎncă nu există evaluări

- Common Defects Observed During TabletingDocument9 paginiCommon Defects Observed During Tabletingvenki_bee100% (1)

- DQ Challenges and ConsiderationsDocument6 paginiDQ Challenges and ConsiderationsВладимир ВидиборскийÎncă nu există evaluări

- Pharmaceutical EngineeringDocument5 paginiPharmaceutical EngineeringIzzat EzmanÎncă nu există evaluări

- Membrane Contactors - An Introduction To The TechnologyDocument5 paginiMembrane Contactors - An Introduction To The Technologyvenki_beeÎncă nu există evaluări

- PT 66 - 1395-1397Document3 paginiPT 66 - 1395-1397Vemulapalli SaibabuÎncă nu există evaluări

- CHMTDocument55 paginiCHMTdaudpaperÎncă nu există evaluări

- SUBTOPIC 1 - Definition and Principle of InstrumentationDocument21 paginiSUBTOPIC 1 - Definition and Principle of InstrumentationJASPER PAYAPAYAÎncă nu există evaluări

- Develop Suppliers and Meet Quality StandardsDocument41 paginiDevelop Suppliers and Meet Quality StandardsBalavignesh VenugopalÎncă nu există evaluări

- Multi-Function Measuring Instrument: Testo 435 - The Allrounder For Ventilation and Indoor Air QualityDocument8 paginiMulti-Function Measuring Instrument: Testo 435 - The Allrounder For Ventilation and Indoor Air Qualityzivkovic brankoÎncă nu există evaluări

- TD213-0-ENG (Digital Thickness Gauge)Document8 paginiTD213-0-ENG (Digital Thickness Gauge)Yeisson Beltran AquinoÎncă nu există evaluări

- Deltacal Manual 2.0.0Document25 paginiDeltacal Manual 2.0.0Camilo RamirezÎncă nu există evaluări

- Thermo Chloride Ise ManualDocument39 paginiThermo Chloride Ise Manualwiroch6kayanhaÎncă nu există evaluări

- lb565 eDocument4 paginilb565 eMohan RajÎncă nu există evaluări

- The Punjab Factories RulesDocument430 paginiThe Punjab Factories RulesTspl HRÎncă nu există evaluări

- Arc Sensors - BrochureDocument12 paginiArc Sensors - BrochureJuan PiñerosÎncă nu există evaluări

- LSS Six Sigma Exam 1 StudyDocument22 paginiLSS Six Sigma Exam 1 StudyPriyaprasad PandaÎncă nu există evaluări

- Bmts-Cp-003a CBR Mould BsDocument2 paginiBmts-Cp-003a CBR Mould BsvirajÎncă nu există evaluări

- Medidor de PH PDFDocument8 paginiMedidor de PH PDFthiagofilipiniÎncă nu există evaluări

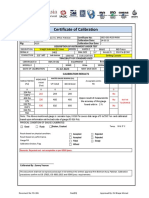

- Calibration Certificate of Weight IndicatorDocument1 paginăCalibration Certificate of Weight IndicatorHaseeb ManzoorÎncă nu există evaluări

- Acuan Normatif 6 How To Optimize Industrial Process Conditions by Measuring VaisalaDocument189 paginiAcuan Normatif 6 How To Optimize Industrial Process Conditions by Measuring VaisalaFiry TriÎncă nu există evaluări

- Gasboard 3100P User ManualDocument18 paginiGasboard 3100P User ManualhaisamdoÎncă nu există evaluări

- Jan 18 - WebDocument44 paginiJan 18 - WebNizar AlifÎncă nu există evaluări

- ISO 9001 Quality ManagementDocument9 paginiISO 9001 Quality Managementsiti sarahÎncă nu există evaluări

- Digital Manometer PM 9100HA (Lutron)Document2 paginiDigital Manometer PM 9100HA (Lutron)Sunil SainiÎncă nu există evaluări

- Cqi 9Document39 paginiCqi 9korray1100% (1)

- 0708 Control of Manitoring and Measuring DevicesDocument4 pagini0708 Control of Manitoring and Measuring DevicesSundara Rajan RamakrishnanÎncă nu există evaluări

- Digipump Ip88X Operator'S Manual: Please Read This Manual Completely Prior To Using The Device!Document33 paginiDigipump Ip88X Operator'S Manual: Please Read This Manual Completely Prior To Using The Device!DanielaÎncă nu există evaluări

- 89145000ENDocument3 pagini89145000ENAya HalimÎncă nu există evaluări

- Celdas de CargasDocument120 paginiCeldas de CargasRafael RogelÎncă nu există evaluări

- Preventative Maintenance V1.1Document6 paginiPreventative Maintenance V1.1Amin EslamiÎncă nu există evaluări

- Calibrate Ammeter Using Ohm's LawDocument3 paginiCalibrate Ammeter Using Ohm's LawKEREN EVANGELINE I (RA1913011011002)Încă nu există evaluări