Documente Academic

Documente Profesional

Documente Cultură

Unit 5 Hydro Electric Power Stations

Încărcat de

api-244568835Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Unit 5 Hydro Electric Power Stations

Încărcat de

api-244568835Drepturi de autor:

Formate disponibile

Unit 5 Hydroelectric Power Stations

Contents:

Elements of hydroelectric power station types concept of pumped storage plants storage requirements, mass curve (explanation only), estimation of power developed from a given catchment area; heads and efficiencies.

Ch. L. Mohan Kumar Asst. Professor Dept. Mechanical Engineering

Hydroelectric Power Stations

INTRODUCTION

Hydroelectric Power is a renewable resource of energy. Other renewable resources include geothermal, wave power, tidal power, wind power, and solar power. Hydroelectric power plants do not use up resources to create electricity nor do they pollute the air, land, or water, as other power plants may. Hydroelectric power comes from flowing water coming from winter and spring runoff from mountain streams and clear lakes. Water, when it is falling by the force of gravity, can be used to turn turbines and generators that produce electricity. In early days, hydroelectric plants supplied as much as 40 percent of the electric energy produced. Although the amount of energy produced by this means has steadily increased, the amount produced by other types of power plants has increased at a faster rate and hydroelectric power presently supplies about less percent of the electrical generating capacity of the Nation. Hydropower is an essential contributor in the national power grid because of its ability to respond quickly to rapidly varying loads or system disturbances, which base load plants with steam systems powered by combustion or nuclear processes cannot accommodate. Hydroelectric power plants are the most efficient means of producing electric energy. The efficiency of today's hydroelectric plant is about 90 percent. Hydroelectric plants do not create air pollution like the fuel, projects have long lives relative to other forms of energy generation, and hydroelectric generators respond quickly to changing system conditions. These favorable characteristics continue to make hydroelectric projects attractive sources of electric power.

5.1

Applications of Hydro Electric Plants

Earlier hydro-electric plants have been used as exclusive sources of power, but the trend is towards use of hydropower in an interconnected system with thermal stations. As a selfcontained and independent power source, a hydro-plant is most effective with adequate storage capacity otherwise the maximum load capacity of the station has to be based on minimum flow of stream and there is a great wastage of water over the dam for greater part of the year. This increases the, per unit cost of installation. By interconnecting hydropower system, a great deal of saving in cost can be effected due to: Reduction in necessary reserve capacity Diversity utilization factors on hydro plants Higher capacity factors on efficient steam plants. In an interconnected system the base load is supplied by hydropower when the maximum flow demand is less than the stream flow while the steam supplies the peak. When stream flow is lower than the maximum demand the hydro plant supplies the peak load and steam plant the base load. 5.1.1 Advantages of Hydroelectric Power Plants No fuel charges. A hydroelectric plant is highly reliable. Maintenance and operating charges are low. Running cost of the plant is less and the plant has no standby losses.

Ch. L Mohan Kumar, Asst. Professor Department of Mechanical Engineering, AITAM

Page 1

Hydroelectric Power Stations

The plant efficiency does not change with time. Less supervising staff is required. No fuel transportation and ash problems. Once a dam is constructed, electricity can be produced at a constant rate. If electricity is not needed, the sluice gates can be shut, stopping electricity generation. The water can be saved for use another time when electricity demand is high. Dams are designed to last many decades and so can contribute to the generation of electricity for many years / decades. The lake that forms behind the dam can be used for water sports and leisure / pleasure activities. Often large dams become tourist attractions in their own right. The lake's water can be used for irrigation purposes. The build-up of water in the lake means that energy can be stored until needed, When the water is released to produce electricity. When in use, electricity produced by dam systems does not produce greenhouse gases. They do not pollute the atmosphere. 5.1.2 Disadvantages of Hydroelectric Power Plants Dams are extremely expensive to build and must be built to a very high standard so initial cost is high. The high cost of dam construction means that they must operate for many decades to become profitable. The flooding of large areas of land means that the natural environment is destroyed. People living in villages and towns that are in the valley to be flooded, must move out. This means that they lose their farms and businesses. In some countries, people are forcibly removed so that hydro-power schemes can go ahead. The building of large dams can cause serious geological damage like earth quakes. Although modern planning and design of dams is good, in the past old dams have been known to be breached (the dam gives under the weight of water in the lake). This has led to deaths and flooding. Dams built blocking the progress of a river in one country usually means that the water supply from the same river in the following country is out of their control. This can lead to serious problems between neighbouring countries. Building a large dam alters the natural water table level. For example, the building of the Aswan Dam in Egypt has altered the level of the water table. This is slowly leading to damage of many of its ancient monuments as salts and destructive minerals are deposited in the stone work from rising damp caused by the changing water table level.

Ch. L Mohan Kumar, Asst. Professor Department of Mechanical Engineering, AITAM

Page 2

Hydroelectric Power Stations

5.1.3 Important Hydro Electric Plants in India The important hydroelectric power plants which were installed throughout in India according to the region are listed as:

Northern Region

Name of the plant Bhakra Beas Baira Siul (Himachal Pradesh) Lower Jhelum (J & K) Salal (J & K) Rana Pratap Sagar (Rajasthan) Jawahar Sagar (Rajasthan) Rihand (Uttar Pradesh) Chitla (Uttar Pradesh) Obra (Uttar Pradesh) Ramganga (Uttar Pradesh) Capacity Right 600 MW Left 450 MW Dehar 660 MW Pong 240 MW 120 MW 105 MW 70 MW 172 MW 99 MW 300 MW 108 MW 99 MW 198 MW Capacity 300 MW 115 MW 880 MW 276 MW Capacity 400 MW 130 MW 114.7 MW 210 MW 891 MW 270 MW 120 MW 390 MW 300 MW 535 MW 240 MW 140 MW 100 MW 95 MW

Western Region

Name of the plant Ukai (Gujarat) Gandhi Sagar (Maharashtra) Koyna (Maharashtra) Tota (Maharashtra)

Southern Region

Name of the plant Lower Sileru (Andhra Pradesh) Upper sileru (Andhra Pradesh) Machkund (Andhra Pradesh) Nagarjun Sagar (Andhra Pradesh) Sharavathy (Karnataka) Kalinadi (Karnataka) Jog (Karnataka) Idukki (Kerala) Sabarigiri (Kerala) Kundah (Tamilanadu) Mettur (Tamilanadu) Periyar (Tamilanadu) Kodayar (Tamilanadu) Solayar (Tamilanadu)

Ch. L Mohan Kumar, Asst. Professor Department of Mechanical Engineering, AITAM

Page 3

Hydroelectric Power Stations

Eastern Region

Name of the plant Subernarekha (Bihar) Damodar Valley Corporation Balimela (Orissa) Hirakund (Orissa) Capacity 130 MW 104 MW 360 MW 270 MW

5.2

Selection of Site for a Hydroelectric Power Plant

While selecting a suitable site, if a good system of natural storage lakes at high altitudes and with large catchment areas can be located, the plant will be comparatively economical. Anyhow the essential characteristics of a good site are: large catchment areas, high average rainfall and a favorable place for constructing the storage or reservoir. For this purpose, the geological, geographical and meteorological conditions of a site need careful investigation. The following factors should be given careful consideration while selecting a site for a hydroelectric power plant: 1. Water Available. To know the available energy from a given stream or river, the discharge flowing and its variation with time over a number of years must be known. Preferably, the estimates of the average quantity of water available should be prepared on the basis of actual measurements of stream or river flow. The recorded observation should be taken over a number of years to know within reasonable, limits the maximum and minimum variations from the average discharge. The river flow data should be based on daily, weekly, monthly and yearly flow ever a number of years. Then the curves or graphs can be plotted between tile river flow and time. These are known as hygrographs and flow duration curves. The plant capacity and the estimated output as well as the need for storage will be governed by the average flow. The primary or dependable power, which is available at, all times when energy is needed, will depend upon the minimum flow. Such conditions may also fix the capacity of the standby plant. The, maximum of flood flow governs the size of the headwords and dam to be built with adequate spillway. 2. Water-Storage. As already discussed, the output of a hydropower plant is not uniform due to wide variations of rainfall. To have a uniform power output, water storage is needed so that excess flow at certain times may be stored to make it available at the times of low flow. To select the site of the dam; careful study should be made of the geology and topography of the catchment area to see if the natural foundations could be found and put to the best use. 3. Head of Water. The level of water in the reservoir for a proposed plant should always be within limits throughout the year. 4. Distance from Load Center. Most of the time the electric power generated in a hydroelectric power plant has to be used some considerable distance from the site of plant. For this reason, to be economical on transmission of electric power, the routes and the distances should be carefully considered since the cost of erection of transmission lines and their maintenance will depend upon the route selected.

Ch. L Mohan Kumar, Asst. Professor Department of Mechanical Engineering, AITAM

Page 4

Hydroelectric Power Stations

5. Access to Site. It is always a desirable factor to have a good access to the site of the plant. This factor is very important if the electric power generated is to be utilized at or near the plant site. The transport facilities must also be given due consideration. 6. Type of the land of the site: The land to be selected for the site should be cheap and rocky. The ideal site will be one where the dam will have largest catchment area to store water at high head and will be economical in construction. The necessary requirements of the foundation rocks for a masonary dam are as follows: The rock should be strong enough to withstand the stresses transmitted from the dam structure as well as thrust of the water when reservoir is full. The rock in the foundation of the dam should be reasonably impervious. The rock should remain stable under all conditions.

5.3

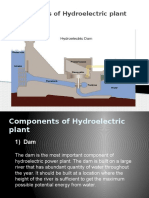

Essential Features of a Water Power Plant

A simplified flow sheet of a water power plant is shown in Figure 5.1. The essential features of a water power plant are as below: 1. Catchment area. 2. Reservoir. 3. Dam and intake house. 4. Inlet water way. Spillways Conduits Surge tanks 5. Power house. Prime movers Draft tubes 6. Tail race or outlet water way.

5.3.1 Catchment Area The catchment area of a hydro plant is the whole area behind the dam, draining into a stream or river across which the dam has been built at a suitable place.

Ch. L Mohan Kumar, Asst. Professor Department of Mechanical Engineering, AITAM Page 5

Hydroelectric Power Stations

5.3.2 Reservoir Whole of the water available from the catchment area is collected in a reservoir behind the dam. The purpose of the storing of water in the reservoir is to get a uniform power output throughout the year. A reservoir can be either natural or artificial. A natural reservoir is a lake in high mountains and an artificial reservoir is made by constructing a dam across the river. 5.3.3 Dam and Intake House A dam is built across a river for two functions: to impound the river water for storage and to create the head of water. Dams may be classified according to their structural materials such as: Timber, steel, earth, rock filled and masonary. Timber and steel are used for dams of height 6 m to 12 m only. Earth dams are built for larger heights, upto about 100 m. To protect the dam from the wave erosion, a protecting coat of rock, concrete or planking must be laid at the water line. The other exposed surfaces should be covered with grass or vegetation to protect the dam from rainfall erosion. Beas dam at Pong is a 126.5 m high earth core-gravel shell dam in earth dams; the base is quite large as compared to the height. Such dams are quite suitable for a pervious foundation because the wide base makes a long seepage path. The earth dams have got the following advantages: Suitable for relatively pervious foundation. Usually less costly than a masonary dam. If protected from erosion, this type of dam is the most permanent type of construction. It fits best in natural surroundings. The following are the disadvantages of earth dams: Greater seepage loss than other dams. The earth dam is not suitable for a spillway; therefore, a supplementary spillway is required. Danger of possible destruction or serious damage from erosion by water either seeping through it or overflowing the dam. The masonary dams are of three major classes: Solid gravity dam Buttress dam Arched dam.

Ch. L Mohan Kumar, Asst. Professor Department of Mechanical Engineering, AITAM

Page 6

Hydroelectric Power Stations

Fig. 5.2: Different types of Masonary Dams The buttress or deck dam has an inclined upstream face, so that water pressure creates a large downward force, which provides stability against overturning or sliding. An arch dam is preferable where a narrow canyon width is available. It can be anchored well and less concrete than will carry the water pressure against the arch with a straight gravity type. This dam has the inherent stability against sliding. The most commonly used dams are shown in Figure 5.2. Dams must be able to pass the flood water to avoid damage to them. This may be achieved by: spillways, conduits piercing the dam and the tunnels by passing the dam. The intake includes the head works, which are the structures at the intake of conduits, tunnels or flumes. These structures include booms, screens or trash racks, sluices for bypassing debris, and gates or valves for controlling the water flow. Booms prevent the ice and floating logs from going into the intake by diverting them to a bypass chute. Booms consist of logs tied end to end and form a floating chain. Screens or trash racks are fitted directly at the intake to prevent the debris from going into the intake. Debris cleaning devices should also be fitted on the trash racks. Gates and valves control the rate of water flow entering the intake. The different types of gates are radial gates, sluice gates, wheeled gates, plain sliding gates, crest gates, rolling or drum gates etc. The various types of valves are rotary, spherical, butterfly or needle valves. A typical intake house is shown in Fig. An air vent should be placed immediately below the gate and connected to the top of the penstock and taken to a level above the head water. When the head gates are closed and the water is drawn off through the turbines, air will enter into the penstock through the air vent and prevent the penstock vacuum which otherwise may cause collapsing of the pipe. A filler gate is also provided to balance the water pressure for opening the gate. 5.3.4 Inlet Water Ways Inlet water ways are the passages, through which the water is conveyed to the turbines from the dam. These may include tunnels, canals, flumes, forebays and penstocks and also surge tanks. A forebay is an enlarged passage for drawing the water from the reservoir or the river and giving it to the pipe lines or canals. Tunnels are of two types: Pressure type Non-pressure type. The pressure type enables the fall to be utilized for power production and these are usually lined with steel or concrete to prevent leakages and friction losses. The non-pressure

Ch. L Mohan Kumar, Asst. Professor Department of Mechanical Engineering, AITAM

Page 7

Hydroelectric Power Stations

type tunnel acts as a channel. The use of the surge tank is to avoid water hammer in the penstock. Water hammer is the sudden rise in pressure in the penstock due to the shutting off the water to the turbine. This sudden rise in pressure is rapidly destroyed by the rise of the water in the surge tank otherwise it may damage or burst the penstock. 5.5.5 Power House The power house is a building in which the turbines, alternators and the auxiliary plant are housed. 5.3.6 Tail Race or Outlet Water Way Tail race is a passage for discharging the water leaving the turbines, into the river and in certain cases; the water from the tail race can be pumped back into the original reservoir.

5.4

Classification of Hydroelectric Power Plants

In hydro-plants, water is collected behind the dam. This reservoir of water may be classified as either storage or pondage according to the amount of water flow regulation they can exert. The function of the storage is to impound excess river flow during the rainy season to supplement the low rates of flow during dry seasons. They can meet the demand of load fluctuations for six months or even for a year. Pondage involves in storing water during low loads so that this water can be utilized for carrying the peak loads during the week. They can meet the hourly or weekly fluctuations of load demand. With pondage, the water level always fluctuates during operations. It rises at the time of storing water, falls at the time off drawing water, remains constant when the load is constant. The hydro-power plants can be classified as below: 1. According to availability of head a) High head plants b) Low head plants c) Medium head plants. 2. According to the nature of load a) Base load plants b) Peak load plants 3. According to quantity of water available a) Run-of-river power plants without pondage b) Run-of-river power plants with pondage c) Storage type plants d) Pump storage power Plants e) Mini and micro hydel plants 5.4.1 According to the availability of Head These plants are usually base load plants. The hydro-plants cannot be classified directly on the basis of head alone as there is no clear line of demarcation between a high head and a medium head or between medium head and low head. The power plant can be classified on the basis of head roughly in the following manner: High head plants: About 100 m and above Medium head plants: About 30 to 500 m

Ch. L Mohan Kumar, Asst. Professor Department of Mechanical Engineering, AITAM

Page 8

Hydroelectric Power Stations

Low head plants: Upto about 50 m 5.4.1.1 High Head Plants Figure 5.3 shows the elevation of a high head plant. The water is taken from the reservoir through tunnels, which distribute the water to penstock through which the water is conveyed to the turbines. Alternately, the water from the reservoir can be taken to a smaller storage known as a forebay, by mans of tunnels. From the forebay, the water is then distributed to the penstocks. The function of the forebay is to distribute the water to penstocks leading to turbines.

The inflow to the forebay is so regulated that the level in the forebay remains nearly constant. The turbines will thus be fed with under a constant static head. Thus, the forebays help to regulate the demand for water according to the load on the turbines. Trash racks are fitted at the inlets of the tunnels to prevent the foreign matter from going into the tunnels. In places; where it in not possible to construct forebays, vertical constructions known as `surge tanks' are built. The surge tanks are provided before the valve house and after the tunnel from the head works. The function of the surge tank is to prevent a sudden pressure rise in the penstock when the load on the turbines decreases and the inlet valves to the turbines are suddenly closed. In the valve house, the butterfly valves or the sluice type valves control the water flow in the penstocks and these valves are electrically driven. Gate valves are also there in the powerhouse to control the water flow through the turbines. After flowing through tile turbines, the water is discharged to the tailrace. 5.4.1.2 Low Head Power Plants

Ch. L Mohan Kumar, Asst. Professor Department of Mechanical Engineering, AITAM

Page 9

Hydroelectric Power Stations

These power plants are also known as Canal power plants. Such a plant is shown in Figure 5.4. A dam is built on the river and the water is diverted into a canal, which conveys the water into a forebay from where the water is allowed to flow through turbines. After this, the water is again discharged into the river through a tailrace. At the mouth of the canal, head gates are fitted to control the flow in the canal, before the water enters the turbines from the forebay. It is made to flow through screens or trash-racks so that no suspended matter goes into the turbines. If there is any excess water due to increased flow in the river or due to decrease of load on the plant, it will flow over the top of the dam or a waste weir can be constructed along the forebay so that the excess water flows over it into the river. For periodic cleaning and repair of the canal and the forebay, a drain gate is provided on the side of the waste weir. The head gate is closed and the drain gate is opened so that whole of the water is drawn from the forebay and the canal for their cleaning and repair. 5.4.1.3 Medium Head Plants If the head of water available is more than 50 m., then the water from the forebay is conveyed to the turbines through pen-stocks. Such a plant will then be named as a medium head plant as shown in the figure 5.5. In these plants, the river water is usually tapped off to a forebay on one bank of the river as in the case of a low head plant. From the forebay, the water is then led to the turbines through penstocks.

5.4.2 According to the Nature of Load 5.4.2.1 Base Load Plants The plants which cater to the base load of the system are called base load plants. These plants are required to supply a constant power when connected to the grid. Thus they run without stop and are often remote controlled with which least staff is required for such plants. Run-of-river plants without pondage may sometimes work as base load plant, but the firm capacity in such cases will be much less. 5.4.2.2 Peak Load Plants The plants which can supply the power during the peak loads are called peak load plants. Some of such plants supply the power during average load but also supply peak load as and when it is there; whereas other peak load plants are required to work during peak load hours only. The run-off-river plants may be made for the peak load by providing pondage.

Ch. L Mohan Kumar, Asst. Professor Department of Mechanical Engineering, AITAM Page 10

Hydroelectric Power Stations

5.4.3 According to the Quantity of Water Available 5.4.3.1 Run-of-river Power Plants without Pondage A run-of-river plant without pondage has no control over river flow and uses the water as it comes. There is no control of flow of water so that during high floods or low loads water is wasted while during low run off the plant capacity is considerably reduced. Due to nonuniformity of supply and lack of assistance from a firm capacity the utility of these plants is much less than those of other types. The head on which these plants work varies considerably. Such a plant can be made a great deal more useful by providing sufficient storage at the plant to take care of the hourly fluctuation in load. This lends some firm capacity to the plant. During good flow conditions these plants cater to the base load of the system, when flow reduces they may supply the peak demands. These plants usually supply peak load. During floods, the tail water level may become excessive rendering the plant inoperative. 5.4.3.2 Run-of-river Power Plants with Pondage A run-of-river plant with pondage may supply base load or peak load power. Pondage usually refers to the collection of water behind a dam at the plant and increases the stream capacity for a short period say a week. Storage means collection of water in upstream reservoirs and this increases the capacity of the stream over an extended period of several months. Storage plants may work satisfactorily as base load and peak load plants. At times of high water flow it may be base loaded and during dry seasons it may be peak loaded. This type of plant, as compared with that of without pondage, is more reliable and its generating capacity is less dependent on the flow rates of water available. 5.4.3.3 Pumped Storage Power Plants These plants supply the peak load for the base load power plants and pump all or a portion of their own water supply. The usual construction would be a tail water pond and a head water pond connected through a penstock. The generating pumping plant is at the lower end. During off peak hours, some of the surplus electric energy being generated by the base load plant is utilized to pump the water from tail water pond into the head water pond and this energy will be stored there. During times of peak load, this energy will be released by allowing the water to flow from the head water pond through the water turbine of the pumped storage plant. These plants can be used with hydro, steam and i.e. engine plants. This plant is nothing but a hydraulic accumulator system and is shown in Figure 5.6.

Ch. L Mohan Kumar, Asst. Professor Department of Mechanical Engineering, AITAM

Page 11

Hydroelectric Power Stations

These plants can have either vertical shaft arrangement or horizontal shaft arrangement. In the older plants, there were separate motor driven pumps and turbine driven generators. The improvement was the pump and turbine on the same shaft with the electrical element acting as either generator or motor. The latest design is to use a Francis turbine, which is just the reverse of centrifugal pump. When the water flows through it from the head water pond it will act as a turbine and rotate the generator. When rotated in the reverse direction by means of an electric motor, it will act as a pump to shunt the water from the tail water pond to the head water pond. The efficiency of such a plant is never 100 per cent. Some water may evaporate from the head water pond resulting in the reduction in the stored energy or there might be run off through the soil. 5.4.3.4 Mini and Micro hydel Plants In order to meet with the present day energy crisis partly, a solution is to develop mini (5 m to 20 m head) and micro (less than 5 m head) hydel potential in our country. The low head hydro potential is scattered in this country and estimated potential from such sites should be as much as 20,000 MW. By proper planning and implementation, it is possible to commission a small hydro-generating setup of 5MW with in a period of one and half year against a decade or two for large capacity power plants. Several such setups upto 1000kW each have been already installed in Himachal Pradesh, U.P., Arunachal Pradesh, West Bengal, and Bhutan. To reduce the cost of micro hydel stations than that of conventional installation the following considerations are kept in view: The civil engineering works needs to be kept to a minimum and designed to fit in with already existing structures e.g., irrigations, channels, locks, small dams etc. The machines need to be manufactured in a small range of sizes of simplified designs, allowing the use of unified tools and aimed at reducing the cost of manufacture. These installations must be automatically controlled to reduce the attending personnel. This equipment must be simple and robust, with easy accessibility to essential parts for maintenance. The units must be light and adequately sub-assembled for ease of handling and transport and to keep down erection and dismantling costs. Micro hydel plants (micro stations) make use of standardized bulb sets with unit output ranging from 100 to 1000 kW working under heads between 1.5 to 10 meters.

5.5

Run Off

Rain fall or precipitation may be defined as the total condensation of moisture that reaches the earth in any form. It includes all forms of rains, ice, snow, hail or sleet etc. Evaporation represents practically that entire portion of the rainfall that does not reach the point of ultimate use as stream flow. So, evaporation includes all the rainfall that is returned to the atmosphere from land and water surfaces. Thus total evaporation is: Evaporation from land and water surfaces.

Ch. L Mohan Kumar, Asst. Professor Department of Mechanical Engineering, AITAM

Page 12

Hydroelectric Power Stations

Evaporation by transpiration which is the vaporization of water from the breathing pores of vegetable matter. Atmospheric evaporation (evaporation while precipitation is falling). Rain-fall is measured in terms of centimeters of water over a given area and over a given period (usually one year). The portion of the total precipitation that flows through the catchment area is known as Run-off. The catchment area of a hydro-site is the total area behind the dam, draining water into the reservoir. Thus, Run-off = Total precipitation Total evaporation. Part of the precipitation is absorbed by the soil and seeps or percolates into ground and will ultimately reach the catchment area through the underground channels. Thus, Total run-off = Direct run off over the land surface + Run-off through seepage. The units of run-off are m3/s or day-second meter. Day-second meter = Discharge collected in the catchment area at the rate of 1m3/s, for one day = 1 24 3600 = 86400 m3/day. The flow of run-off can also be expressed in cm of water on the drainage area feeding the river site for a stated period, or km, cm of water per unit of time. 5.5.1 Factors Affecting Runoff 1. Nature of Precipitation. Short, hard showers may produce relatively little run-off. A rain lasting a longer time results in larger run-off. The soil tends to become saturated and the rate of seepage decreases. Also, the humid atmosphere lowers evaporation, resulting in increased run-off. 2. Topography of Catchments Area. Steep, impervious areas will produce large percentage of total run-off. The water will flow quickly and absorption and evaporation losses will be small. 3. Geology of Area. The run-off is very much affected by the types of surface soil and subsoil, type of rocks etc. Rocky areas will give more run-off while pervious soil and subsoil and soft and sandy area will give lesser run-off. 4. Meteorology. Evaporation varies with temperature, wind velocity and relative humidity. Runoff increases with low temperature, low wind velocity and high relative humidity and vice versa. 5. Vegetation. Evaporation and seepage are increased by cultivation. Cultivation opens and roughens the hard, smooth surface and promotes seepage. Thick vegetation like forests consumes a portion of the rain fall and also acts as obstruction for run-off. 6. Size and Shape of Area. Large areas will give more run-off. A wide area like a fan will give greater run-off whereas; a narrow area like a leaf will give lesser run-off. In an area whose length is more than its width, the flow along its width will give more run-off than if the flow is along its length, since in the former case, seepage and evaporation will be less. 5.5.2 Measurement of Run-Off or Flow The run-off or stream flow can be determined with the help of three methods: 1. From Rain-Fall Records. The run-off can be estimated from rain-fall records by multiplying the rain fall with run-off coefficient for the drainage area. The run-off

Ch. L Mohan Kumar, Asst. Professor Department of Mechanical Engineering, AITAM Page 13

Hydroelectric Power Stations

coefficient takes into account the various losses and will depend upon the nature of the catchment area Then, Run-off = Rain fall run-off co-efficient This is not an accurate method of measuring run-off since the estimation of run-off coefficient cannot be very accurate. 2. Empirical Formulas. Empirical relations to determine the stream flow relate only to a particular site and cannot be relied upon for general use. 3. Actual Measurement. Direct measurement by stream gauging at a given site for a long period is the only precise method of evaluation of stream flow. The flow is measured by selecting a channel of fixed cross-section and measuring the water velocity at regular intervals, at enough points in the cross-section for different water levels. The velocity of flow can be measured with the help of current meter or float method. By integrating the velocities over the cross-section for each stage, the total flow for each stage can be calculated.

5.6

Mass Curve

The use of the mass curve is to compute the capacity of the reservoir for a hydro-site. The mass curve indicates the total volume of run-off in second meter-months or other convenient units, during a given period. The mass curve is obtained by plotting cumulative volume of flow as ordinate and time (days, weeks by months) as abscissa. Fig. shows a mass curve for a typical river for which flow data is given in Table.

The monthly flow is only the mean flow and is correct only at the beginning and end of the months. The variation of flow during each month is not considered. Cumulative daily flows, instead of monthly flows, will give a more accurate mass curve, but this involves an excessive amount of work. The slope of the curve at any point gives the flow rate in second-meter. Let us join two points X and Y on the curve. The slope of this line gives the average rate of flow during the period between X and Y. This will be = (Flow at Y Flow at X)/Time Span Let the flow demand be, 3000 sec-meter. Then the line X-Y may be called as `demand line' or Use line. If during a particular period, the slope of the mass Curve is greater than that of the demand line, it means more water is flowing into the reservoir than is being utilized, so the level of water in the reservoir will be increasing during that period and vice versa. Upto point X and beyond point Y the reservoir will be overflowing. Being full at both X and Y.

Ch. L Mohan Kumar, Asst. Professor Department of Mechanical Engineering, AITAM

Page 14

Hydroelectric Power Stations

The capacity of the reservoir is given by the maximum ordinate between the mass curve and the demand line. For the portion of mass curve between point X and Y, the storage capacity is about 4600 sec-meter-month. However, considering the entire mass curve, storage capacity will be about 15,400 sec-meter-months.

Note: The amount of water to be stored in a reservoir can also be determined with the help of hydrograph. A horizontal line giving the average flow demand is drawn. The portion of the curve above this line will indicate the amount of water that should be stored in the reservoir to be used during lean months. But, hydrograph for one year varies from year to year, the storage capacity should be determined with the help of the mass curve.

5.7

Calculations of Water Power Plants

These calculations are concerned with the river or stream flow and the available head through which the water falls to generate the electric power. Water in motion possesses three forms of energy; kinetic energy due to its velocity, pressure energy due to its pressure and potential energy due to its height. Kinetic energy Pressure energy =

V

2

2 P

, Nm per kg of water.

= , Nm per kg of water.

Potential energy = gH Nm per kg of water. Where V = velocity of flow in m/s, p = pressure in N/m2, = density of water kg/m3 and H = the height of the level of water above some datum level. Theoretical power available from water = WQH watts Where Q = Water flow in cumecs H = Net head available in m. = (Total head the frictional losses) If the turbine has an efficiency t, then the B.P. at turbine shaft

Ch. L Mohan Kumar, Asst. Professor Department of Mechanical Engineering, AITAM

Page 15

Hydroelectric Power Stations

= W.Q.H.t watts It the efficiency of the electric generator is g, then the effective power at switch board = W.Q.H. tg watts In the above calculations, the following relations can be used to calculate the discharge.

5.8

(i)

Heads and efficiencies of Turbines

Gross Head (HG): Gross head HG is shown in Fig., is difference between the head race and tail race. (ii) Net or effective head (H) = HG - hf Where hf is the head loss due to friction, i.e.

hf 4 fLV 2 2 gD

, D is the diameter of the conduit.

Elements of common hydroelectric plants with plan and sectional views

(iii)

Efficiencies (a) Hydraulic efficiency (h): It is the ratio of the power given by the water to the runner to the power supplied by water at the inlet of the turbine, i.e.

Power delivered to the runner power supplied at inlet

(b) Mechanical efficiencies (m): Some mechanical losses occur when power delivered by water to the runner is transmitted to the shaft of the turbine and hence

Power at the shaft of turbine power delivered by water to the runner

Page 16

Ch. L Mohan Kumar, Asst. Professor Department of Mechanical Engineering, AITAM

Hydroelectric Power Stations

(c) Volumetric efficiencies (v): The volume of water striking the runner of the turbine is slightly less than the volume supplied to the turbine. A small amount of water escapes to the tail race without striking the runner. Hence

Volume of water actually striking the runner Volume of water supplied to the turbines

o

shaft power h m water power

(d) Overall efficiencies (o):

Ch. L Mohan Kumar, Asst. Professor Department of Mechanical Engineering, AITAM

Page 17

S-ar putea să vă placă și

- Differential Transformation Method for Mechanical Engineering ProblemsDe la EverandDifferential Transformation Method for Mechanical Engineering ProblemsÎncă nu există evaluări

- Renewable Energy Sources: Presented ByDocument56 paginiRenewable Energy Sources: Presented Byjkl417Încă nu există evaluări

- BITS Pilani: Engineering Materials: ENGG ZC 232Document49 paginiBITS Pilani: Engineering Materials: ENGG ZC 232Amit SinghÎncă nu există evaluări

- PDF ViscosityDocument18 paginiPDF ViscosityTobyBorlandÎncă nu există evaluări

- Engineering Materials by McalisterDocument17 paginiEngineering Materials by McalisterHamza KhalidÎncă nu există evaluări

- Beam Deflection AssignmentDocument4 paginiBeam Deflection AssignmentTalha KhanÎncă nu există evaluări

- 1/27/2014 Hareesha N Gowda, Asst. Prof, Dsce, Blore-78 1Document25 pagini1/27/2014 Hareesha N Gowda, Asst. Prof, Dsce, Blore-78 1Sameer SonuÎncă nu există evaluări

- FrictionDocument9 paginiFrictionjarvis007Încă nu există evaluări

- Quality Within Higher Education 2017 Summary ReportDocument52 paginiQuality Within Higher Education 2017 Summary ReportCentras CentrasÎncă nu există evaluări

- Shear Modulus (With Torsiometer)Document19 paginiShear Modulus (With Torsiometer)Irvin IrawanÎncă nu există evaluări

- Gear Trains - Lecture 10Document22 paginiGear Trains - Lecture 10priyankar007Încă nu există evaluări

- Couplings in MechatronicsDocument23 paginiCouplings in MechatronicsRavindra MahadeokarÎncă nu există evaluări

- Parilla x30 Overhaul ManualDocument38 paginiParilla x30 Overhaul ManualCarolina MatosÎncă nu există evaluări

- Unit V: - TurbinesDocument56 paginiUnit V: - TurbinesparthibankÎncă nu există evaluări

- CHP 29Document13 paginiCHP 29Abhiram Reddy100% (1)

- CHAPTER 6 Flow in Pipes FinalDocument22 paginiCHAPTER 6 Flow in Pipes FinalSyaiful Akmal AzizÎncă nu există evaluări

- Destructive and Non-Destructive TestingDocument17 paginiDestructive and Non-Destructive TestingBhargav ChaitanyaÎncă nu există evaluări

- Components of Hydroelectric PlantDocument13 paginiComponents of Hydroelectric PlantHarun Rasul100% (1)

- National Skill Training Institute, Mumbai: Draughtsman Mechanical, CitsDocument24 paginiNational Skill Training Institute, Mumbai: Draughtsman Mechanical, CitsNitin B maskeÎncă nu există evaluări

- Couplings and ClutchesDocument14 paginiCouplings and ClutchesBhotka BhutkiÎncă nu există evaluări

- Activity 1.1.5b Circuit Theory: SimulationDocument4 paginiActivity 1.1.5b Circuit Theory: SimulationParkerÎncă nu există evaluări

- Navier Stokes EquationDocument3 paginiNavier Stokes Equationvinay kumarÎncă nu există evaluări

- Stream Function Solution of Navier Stokes EquationsDocument16 paginiStream Function Solution of Navier Stokes EquationsSteven GoddardÎncă nu există evaluări

- Gearboxes: Gearbox ApplicationDocument8 paginiGearboxes: Gearbox Applicationrizviabbas2012Încă nu există evaluări

- MagnetismDocument17 paginiMagnetismOtenciano MautganonÎncă nu există evaluări

- Strength of Materials 2016 by S K Mondal PDFDocument472 paginiStrength of Materials 2016 by S K Mondal PDFrobinÎncă nu există evaluări

- Study and Explain Different Types of Turbines and Their Applications in Various FieldDocument22 paginiStudy and Explain Different Types of Turbines and Their Applications in Various Fieldcontactmahtab78675% (8)

- Problems On Beams PDFDocument16 paginiProblems On Beams PDFC j50% (6)

- Fixed BeamsDocument14 paginiFixed BeamsArun SunnyÎncă nu există evaluări

- Pte Mag PDFDocument68 paginiPte Mag PDFhollowÎncă nu există evaluări

- Bearing IntroductionDocument62 paginiBearing IntroductionsbkulkÎncă nu există evaluări

- ManometerDocument21 paginiManometerShiela Mae Pacampara GonzalesÎncă nu există evaluări

- Linear Equation in One Variable Part 1 AssignmentDocument3 paginiLinear Equation in One Variable Part 1 Assignmentgobinda prasad barmanÎncă nu există evaluări

- Assignment 1Document19 paginiAssignment 1NazriÎncă nu există evaluări

- Flywheel 2Document6 paginiFlywheel 2LegendaryNÎncă nu există evaluări

- Hydrostatic Force On A Submerged SurfaceDocument4 paginiHydrostatic Force On A Submerged SurfaceBenson James ChanÎncă nu există evaluări

- E. Surface Area of 3D ShapesDocument19 paginiE. Surface Area of 3D ShapesanjanamenonÎncă nu există evaluări

- Measurement of Screw ThreadsDocument21 paginiMeasurement of Screw ThreadsAnthony LopesÎncă nu există evaluări

- Chap 27 Advanced Machining PPT MFG Chapter27 FinalDocument42 paginiChap 27 Advanced Machining PPT MFG Chapter27 FinalnguyenhoanÎncă nu există evaluări

- The Effect of Task Based Language Teachi PDFDocument19 paginiThe Effect of Task Based Language Teachi PDFKhoangoaingu KhoangoainguÎncă nu există evaluări

- Chapter 2 Pelton TurbineDocument17 paginiChapter 2 Pelton TurbineSachin MohalÎncă nu există evaluări

- 1.2 Hydraulic PrinciplesDocument48 pagini1.2 Hydraulic PrinciplesAndikaÎncă nu există evaluări

- 2 Engineering MaterialsDocument14 pagini2 Engineering MaterialsPRASAD326100% (1)

- Practice Exam2 - SolutionsDocument10 paginiPractice Exam2 - SolutionsRyan KellyÎncă nu există evaluări

- Hydraulic TurbinesDocument18 paginiHydraulic TurbinesSatanapong ChantanakomÎncă nu există evaluări

- Mechanical PrinciplesDocument34 paginiMechanical PrinciplesJo okÎncă nu există evaluări

- On HydropowerDocument30 paginiOn HydropowerSushil Himanshu25% (4)

- 08 SchedulingDocument64 pagini08 SchedulingAkhil KalraÎncă nu există evaluări

- Properties and Characteristics of MaterialsDocument17 paginiProperties and Characteristics of MaterialsBensoy YambaÎncă nu există evaluări

- Module-II 2.gear DrivesDocument36 paginiModule-II 2.gear Drivesvanishree n100% (1)

- Basics of Belt DrivesDocument12 paginiBasics of Belt DrivesSrinivasan Ravi100% (1)

- Solve Linear EquationsDocument10 paginiSolve Linear EquationsGear Arellano IIÎncă nu există evaluări

- ARG FMA-EMPDevelopment WhitePaperDocument25 paginiARG FMA-EMPDevelopment WhitePaperJose AlfredoÎncă nu există evaluări

- Topic 4: Indices and Logarithms: Jacques Text Book (Edition 4) : Section 2.3 & 2.4Document22 paginiTopic 4: Indices and Logarithms: Jacques Text Book (Edition 4) : Section 2.3 & 2.4Ateef HatifaÎncă nu există evaluări

- Hydrostatic Force and Center of PressureDocument7 paginiHydrostatic Force and Center of PressureIsraafil Ahmad0% (1)

- Lecture Notes Mech Power Plant Engineering .Document49 paginiLecture Notes Mech Power Plant Engineering .Fazil KhanÎncă nu există evaluări

- Fluid Power Engineering PDFDocument164 paginiFluid Power Engineering PDFAkki100% (1)

- Hydroelectric EnergyDocument7 paginiHydroelectric EnergygigilzbeybeÎncă nu există evaluări

- Synopsis MDDocument8 paginiSynopsis MDKotagi Net CenterÎncă nu există evaluări

- Report of Project PGS 2Document16 paginiReport of Project PGS 2Safdar ali AlmaniÎncă nu există evaluări

- Maintenance Memo ATA 49-01Document2 paginiMaintenance Memo ATA 49-01amane72Încă nu există evaluări

- IALA Maritime Buoyage System 2010Document24 paginiIALA Maritime Buoyage System 2010emile jobity100% (1)

- P Ja 51687 Av TF32 VDDocument3 paginiP Ja 51687 Av TF32 VDrabreyÎncă nu există evaluări

- Sindbad: The Travels ofDocument2 paginiSindbad: The Travels ofSon PhamÎncă nu există evaluări

- Despiece Estanque CombustibleDocument3 paginiDespiece Estanque CombustibleRicardo HarringtonÎncă nu există evaluări

- Alam Jaya IIDocument2 paginiAlam Jaya IIStephanie LambertÎncă nu există evaluări

- Tijuana A MexicoDocument1 paginăTijuana A MexicoLance LamperougeÎncă nu există evaluări

- Ford Trucks 3242S HR: Basic FeaturesDocument2 paginiFord Trucks 3242S HR: Basic FeaturesDaniela DascaluÎncă nu există evaluări

- When Jeepney Meets Technology - A ReflectionDocument3 paginiWhen Jeepney Meets Technology - A ReflectionAlden MiradorÎncă nu există evaluări

- Rural Road DesignDocument151 paginiRural Road DesignBerlin100% (1)

- Acronyms and AbbreviationsDocument422 paginiAcronyms and AbbreviationsvanmurthyÎncă nu există evaluări

- TE 250 USA 2012: Spare Parts Manual: ChassisDocument32 paginiTE 250 USA 2012: Spare Parts Manual: ChassisAna CiocanÎncă nu există evaluări

- 615 For HatfieldDocument4 pagini615 For HatfieldMichele CarrieroÎncă nu există evaluări

- QRF HD785-5Document2 paginiQRF HD785-5Ralf MaurerÎncă nu există evaluări

- National Cranberry CooperativeDocument11 paginiNational Cranberry CooperativeFabiola SE100% (2)

- BooksDocument16 paginiBooksshakthi jayanthÎncă nu există evaluări

- @magazinesy Autocar UK - 6 April 2022Document84 pagini@magazinesy Autocar UK - 6 April 2022Wndah CahyaniÎncă nu există evaluări

- enDocument291 paginienAlezNgÎncă nu există evaluări

- Suspension Systems and ComponentsDocument90 paginiSuspension Systems and Componentsmaheshgarg81100% (2)

- Exhibit 9 To MFS - FedEx Delivery Notification May 26, 2017 LTR, May 30, 2017Document2 paginiExhibit 9 To MFS - FedEx Delivery Notification May 26, 2017 LTR, May 30, 2017larry-612445Încă nu există evaluări

- IndexDocument10 paginiIndexvictorbirlanÎncă nu există evaluări

- Lucas Tvs Report 1Document71 paginiLucas Tvs Report 1fathima100% (4)

- Bridgeport Crossroads Transportation & Land Use StudyDocument95 paginiBridgeport Crossroads Transportation & Land Use StudyLancasterOnlineÎncă nu există evaluări

- Technical Standards For Marine EquipmentDocument23 paginiTechnical Standards For Marine EquipmentYashashree MuduliÎncă nu există evaluări

- LOI For Buyers (Blank)Document3 paginiLOI For Buyers (Blank)Vikram Sathish AsokanÎncă nu există evaluări

- Design Sarojini NagarDocument11 paginiDesign Sarojini NagarTanuj Bhardwaj75% (4)

- UttarakhandDocument2 paginiUttarakhandfaisal begÎncă nu există evaluări

- Technical Specification 37000dwt Tank Reve 23-12-2004Document166 paginiTechnical Specification 37000dwt Tank Reve 23-12-2004Mic UtuÎncă nu există evaluări

- Self Propelled Scissor LiftDocument10 paginiSelf Propelled Scissor LiftDIBNESH PANDITAÎncă nu există evaluări

- The Cyanide Canary: A True Story of InjusticeDe la EverandThe Cyanide Canary: A True Story of InjusticeEvaluare: 4 din 5 stele4/5 (52)

- To Engineer Is Human: The Role of Failure in Successful DesignDe la EverandTo Engineer Is Human: The Role of Failure in Successful DesignEvaluare: 4 din 5 stele4/5 (138)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDe la EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansÎncă nu există evaluări

- Waste: One Woman’s Fight Against America’s Dirty SecretDe la EverandWaste: One Woman’s Fight Against America’s Dirty SecretEvaluare: 5 din 5 stele5/5 (1)

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsDe la EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsÎncă nu există evaluări

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionDe la EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionEvaluare: 3 din 5 stele3/5 (1)

- Structural Cross Sections: Analysis and DesignDe la EverandStructural Cross Sections: Analysis and DesignEvaluare: 4.5 din 5 stele4.5/5 (19)

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesDe la EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesÎncă nu există evaluări

- Rocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyDe la EverandRocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyEvaluare: 4.5 din 5 stele4.5/5 (5)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDe la EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansEvaluare: 4.5 din 5 stele4.5/5 (21)

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetDe la EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetEvaluare: 4.5 din 5 stele4.5/5 (10)

- Troubleshooting and Repair of Diesel EnginesDe la EverandTroubleshooting and Repair of Diesel EnginesEvaluare: 1.5 din 5 stele1.5/5 (2)

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeDe la EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeEvaluare: 4.5 din 5 stele4.5/5 (59)

- The Finite Element Method: Linear Static and Dynamic Finite Element AnalysisDe la EverandThe Finite Element Method: Linear Static and Dynamic Finite Element AnalysisEvaluare: 5 din 5 stele5/5 (3)

- Geotechnical Engineering Calculations and Rules of ThumbDe la EverandGeotechnical Engineering Calculations and Rules of ThumbEvaluare: 4 din 5 stele4/5 (17)

- Construction Innovation and Process ImprovementDe la EverandConstruction Innovation and Process ImprovementAkintola AkintoyeÎncă nu există evaluări

- CAREC Road Safety Engineering Manual 3: Roadside Hazard ManagementDe la EverandCAREC Road Safety Engineering Manual 3: Roadside Hazard ManagementÎncă nu există evaluări

- Predicting Lifetime for Concrete StructureDe la EverandPredicting Lifetime for Concrete StructureÎncă nu există evaluări

- Summary of Neil Postman's Amusing Ourselves to DeathDe la EverandSummary of Neil Postman's Amusing Ourselves to DeathEvaluare: 4 din 5 stele4/5 (2)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)