Documente Academic

Documente Profesional

Documente Cultură

1 CDI Advance 5080

Încărcat de

Diana BonanaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

1 CDI Advance 5080

Încărcat de

Diana BonanaDrepturi de autor:

Formate disponibile

Esko-Graphics CDI Advance 5080 Advancing digital flexo imaging

The Esko-Graphics Cyrel Digital Imager (CDI) is the first and most used laser imager for direct exposure on flexo plates. As a GATF and FTA Award Winner, it represents a great leap forward in digital flexography. CDI plates offer quality and printing stability that has so far only been achievable in offset or gravure. This provides business expansion from converting offset and gravure jobs to flexo. The Cyrel Digital Imager Advance addresses the highest quality flexo applications, primarily in the flexible packaging and folding carton markets, with inroads also in corrugated. Four productivity levels are available for the CDI Advance 5080: Optics 15 (1.5 m2/h), Optics 25 (2.5 m2/h) and Optics 40 (4.0 m2/h) and Optics 80 (8.0 m2/h). The CDI Advance 5080 Optics 80 addresses the highest throughput needs, imaging up to 8.0 m2 of digital plates per hour. In just 12 minutes, it images a full size 42 x 60 / 1067 x 1524 mm plate of arbitrary thickness. Optionally the CDI Advance 5080 comes with EasyClamp, to securely hold down flexo plates of any thickness on the vacuum drum.

The CDI images on Cyrel and other digital flexo plates.

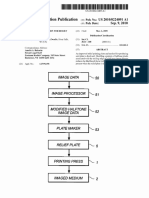

1 mask

layer

FIBER LASER

CDI imaging

Back exposure UV-A

Main exposure UV-A

4a

4b

Conventional solvent processing

Thermal processing

Drying

Post exposure UV-A

Finishing UV-C

The digital flexo plate has a mask layer sensitized to the CDIs laser light on top of its surface. After imaging, this mask takes the function of the traditional film negative. Through the integration of the image carrier, a digital flexo plate has sharper image definition and steeper relief shoulders than conventional plates produced with film. Image deterioration by UV light absorption and scattering in the traditional contacting through vacuum sheet and film is totally eliminated. CDI technology provides a major breakthrough in enhanced output quality and consistency, with reduced overall process cost.

Technical specifications Esko-Graphics CDI Advance 5080

Machine dimensions Width: 139.0 / 3530 mm Depth: 60.8 / 1545 mm Height: 41.4 / 1050 mm (cover closed) 52 / 1320 mm (cover open) Weight: 7500 lb. / 3400 kg

Type of imager External drum design Drum sizes: Drum 4260 and 4260 C (EasyClamp): max. plate format 42 x 60 (1067 x 1524 mm) or smaller Drum 5080 and 5080 C (EasyClamp): max. plate format 50 x 80 (1270 x 2032 mm) or smaller Sleeve capability: max. sleeve length up to 83 / 2110 mm Solid granite machine base High power Fiber laser source Class 1 laser equipment Image quality Screen rulings: up to 200 lpi, depending on imaging resolution Halftone 1-99%

Resolutions: fully variable from 2000 to 4000 ppi on job-to-job base Engine control Grapholas on Intel PC with Windows 2000. The input file format is LEN or TIFF, compatible with all CDI family members. Plates All digital photopolymer plates or ablative film Plate thickness: 0.030 to 0.255 / 0.76 mm to 6.35 mm Sizes up to: 42 x 60 / 1067 mm x 1524 mm (or smaller) 50 x 80 / 1270 mm x 2032 mm (or smaller)

Sleeves All digital sleeves (Seamless and Plate-On-Sleeve) Sizes up to: 83 / 2110 mm length, 50 / 1270 mm repeat Installation requirements 3x400V/N/PE, 50/60Hz, 6.5kVA No external compressed air supply needed No external water cooling is required

Productivity Imaging times for DuPont Cyrel digital flexo plates at 2000 ppi

Optics 15 (1.5 m2 /hour) Plate format Imaging time Sleeve format 600mm repeat x 1000mm length (0.6m2) Optics 25 (2.5 m2 /hour) Optics 40 (4 m2 /hour) Optics 80 (8 m2 /hour)

42 x 60 64 min.

50 x 80 100 min.

42 x 60 38 min.

50 x 80 60 min.

42 x 60 24 min.

50 x 80 38 min.

42 x 60 12 min.

50 x 80 19 min.

12 min. (50% SuperSkip zones)

7 min. 12 sec. (50% SuperSkip zones)

4 min. 30 sec. (50% SuperSkip zones)

2 min. 15 sec. (50% SuperSkip zones) www.esko-graphics.com

All specifications are subject to alteration.

AUG05 - G2558150_US

S-ar putea să vă placă și

- Hapa - in House Printing Solutions (Marcel Aeby)Document44 paginiHapa - in House Printing Solutions (Marcel Aeby)Yose RizalÎncă nu există evaluări

- Bobst PDFDocument52 paginiBobst PDFAbdul BasitÎncă nu există evaluări

- Lombardi Company PresentationDocument35 paginiLombardi Company PresentationPam Landi0% (1)

- 2015 BASF Flexible-Packaging-Inks Landscape ELDocument12 pagini2015 BASF Flexible-Packaging-Inks Landscape ELPongthip PesachpinankulÎncă nu există evaluări

- Flexo Vs OffsetDocument18 paginiFlexo Vs OffsetJavier Martinez CañalÎncă nu există evaluări

- US 20100224091A1 - Trailing Edge Pattern for Relief Plate FeatureDocument12 paginiUS 20100224091A1 - Trailing Edge Pattern for Relief Plate FeatureCikumunya ArsÎncă nu există evaluări

- Harper Anilox RollDocument88 paginiHarper Anilox Rollsuracheted0% (1)

- The Ink Room of TomorrowDocument4 paginiThe Ink Room of TomorrowQuý Đình Mai MaiÎncă nu există evaluări

- Flexography: The Process of Printing on Raised SurfacesDocument34 paginiFlexography: The Process of Printing on Raised Surfacesfajar ramadhanÎncă nu există evaluări

- Relationships Between The Surface Texture of Flexographic Printing Plates and The Printability of Kraft PaperDocument11 paginiRelationships Between The Surface Texture of Flexographic Printing Plates and The Printability of Kraft PaperQuý Đình Mai MaiÎncă nu există evaluări

- Materi PrintingDocument16 paginiMateri PrintingnuryadyÎncă nu există evaluări

- Anilox Rolls Selection GuideDocument4 paginiAnilox Rolls Selection GuideMismail EgypacÎncă nu există evaluări

- G7 How-ToDocument56 paginiG7 How-Tomythchenling100% (2)

- CHAPTER 3.0 - GravureDocument10 paginiCHAPTER 3.0 - GravureGiha Tardan100% (1)

- Pigments Training - Printing - Doman-ShotwellDocument18 paginiPigments Training - Printing - Doman-ShotwellHerbert AguilargonzalezÎncă nu există evaluări

- Ffta First 5.0 Design GuideDocument87 paginiFfta First 5.0 Design GuideSharlowÎncă nu există evaluări

- Flexographic Ctsa Vol1 PDFDocument390 paginiFlexographic Ctsa Vol1 PDFShrinil DesaiÎncă nu există evaluări

- OnPress 63Document22 paginiOnPress 63Carlos GrajalesÎncă nu există evaluări

- Doctor in PrintingDocument57 paginiDoctor in PrintingKeerthanaÎncă nu există evaluări

- Flexo Printing Machinery Catalog English UpdatedDocument8 paginiFlexo Printing Machinery Catalog English UpdatedOMAR JOSE LEALÎncă nu există evaluări

- Issue #9 Printing and Graphics Science Group NewsletterDe la EverandIssue #9 Printing and Graphics Science Group NewsletterÎncă nu există evaluări

- 30 77 High Speed Gravure ProoferDocument2 pagini30 77 High Speed Gravure ProoferCode 9Încă nu există evaluări

- G7 How To 2009Document68 paginiG7 How To 2009Peibol SotoÎncă nu există evaluări

- FIRST The Scoop: Mark R. Mazur Joe TuccittoDocument124 paginiFIRST The Scoop: Mark R. Mazur Joe TuccittoEso PappasÎncă nu există evaluări

- DuPont v1Document40 paginiDuPont v1Raluca SpitaÎncă nu există evaluări

- Anilox SelectionDocument2 paginiAnilox SelectionTanneru Hemanth KumarÎncă nu există evaluări

- Rodillos AniloxDocument2 paginiRodillos AniloxCarlos CardenasÎncă nu există evaluări

- Introduction To Radiation Curing Chemistry and TechnologyDocument61 paginiIntroduction To Radiation Curing Chemistry and TechnologyViky Gordon100% (1)

- Laminating Troubleshooting FinalDocument25 paginiLaminating Troubleshooting FinalHabteyes AbateÎncă nu există evaluări

- Reference Manual Printing and Converting PerformanceDocument74 paginiReference Manual Printing and Converting PerformanceAli HussnainÎncă nu există evaluări

- Indian Printing Industry Profile 2010Document36 paginiIndian Printing Industry Profile 2010Anil YadavÎncă nu există evaluări

- Press: Flexible. Easy. Intelligent. Accurate Color On All Printing DevicesDocument4 paginiPress: Flexible. Easy. Intelligent. Accurate Color On All Printing DevicesmigueldemacrolabÎncă nu există evaluări

- Troubleshooting Guide: GravureDocument20 paginiTroubleshooting Guide: Gravureक्षितिजÎncă nu există evaluări

- Witcobond W 234Document1 paginăWitcobond W 234NashÎncă nu există evaluări

- Gravure - Cylinder Spes PDFDocument66 paginiGravure - Cylinder Spes PDFamit50% (2)

- Doctor Systems BrochureDocument8 paginiDoctor Systems BrochureMostafizur RahmanÎncă nu există evaluări

- FIRST 6.0: Flexographic Image Reproduction Specifications and TolerancesDe la EverandFIRST 6.0: Flexographic Image Reproduction Specifications and TolerancesÎncă nu există evaluări

- PC CatalogDocument28 paginiPC CatalogSeenivasagam SeenuÎncă nu există evaluări

- E0499 Fogra Softproof HandbookDocument43 paginiE0499 Fogra Softproof HandbookMarcus FX100% (1)

- Rupa FlexiPOLYDocument1 paginăRupa FlexiPOLYSaravvanan RajendranÎncă nu există evaluări

- Common finishing problems and solutions guideDocument16 paginiCommon finishing problems and solutions guideSyamlal Skaku100% (1)

- Iso News 23e PDFDocument5 paginiIso News 23e PDFThảo PhạmÎncă nu există evaluări

- Flint InksDocument24 paginiFlint InksshoanashokÎncă nu există evaluări

- Understanding Color Spaces and Color DifferencesDocument1 paginăUnderstanding Color Spaces and Color DifferencesSalvador GómezÎncă nu există evaluări

- MSDS Uv 2Document14 paginiMSDS Uv 2DewiÎncă nu există evaluări

- By Shrikant Athavale SPA Technical Advisor Pune Cell: +91 7588288204Document80 paginiBy Shrikant Athavale SPA Technical Advisor Pune Cell: +91 7588288204Avi Yusri100% (1)

- 7 9layerblownfilmlinesDocument6 pagini7 9layerblownfilmlinesductoan32Încă nu există evaluări

- Flexible Packaging: (Basic Films / Raw Materials For Converting)Document10 paginiFlexible Packaging: (Basic Films / Raw Materials For Converting)pandu krÎncă nu există evaluări

- Agfa Offset Printing Training on Inks and FountainsDocument24 paginiAgfa Offset Printing Training on Inks and FountainssmkazmiÎncă nu există evaluări

- Mimaki JV3-160 SP PDFDocument136 paginiMimaki JV3-160 SP PDFAlisson BrighentiÎncă nu există evaluări

- UV Flexo - Printing Unit - BG03Document64 paginiUV Flexo - Printing Unit - BG03DeniMestiWidianto100% (2)

- Proven UV Offset Printing Technology For High Quality LabelsDocument13 paginiProven UV Offset Printing Technology For High Quality LabelsJavier Martinez CañalÎncă nu există evaluări

- Traction Die Cutting BG 07Document41 paginiTraction Die Cutting BG 07DeniMestiWidiantoÎncă nu există evaluări

- Understanding Anilox Roller Engraving Angles and VolumesDocument16 paginiUnderstanding Anilox Roller Engraving Angles and VolumesJose Guerra100% (2)

- Ilfs Uv Coating QC SeminarDocument15 paginiIlfs Uv Coating QC SeminarHarshil BhadiyadraÎncă nu există evaluări

- Inkformation 4 en 02Document28 paginiInkformation 4 en 02MohammadAlAmeenÎncă nu există evaluări

- G7 Pre Qualification Checklist Sheetfed v1.3Document6 paginiG7 Pre Qualification Checklist Sheetfed v1.3Ganjar RukmaÎncă nu există evaluări

- Issue #13 Printing and Graphics Science Group NewsletterDe la EverandIssue #13 Printing and Graphics Science Group NewsletterÎncă nu există evaluări

- Metal Bearing Waste Streams: Minimizing, Recycling and TreatmentDe la EverandMetal Bearing Waste Streams: Minimizing, Recycling and TreatmentÎncă nu există evaluări

- Manual of Curatorship: A Guide To Museum PracticeDocument7 paginiManual of Curatorship: A Guide To Museum PracticeLuísa MenezesÎncă nu există evaluări

- 1 SM PDFDocument14 pagini1 SM PDFSiti HamsyiahÎncă nu există evaluări

- Dental Radiographs and Photographs in Human Forensic IdentificationDocument8 paginiDental Radiographs and Photographs in Human Forensic IdentificationBudi PurnomoÎncă nu există evaluări

- Dokumen - Tips - Astm A535 9 Percent NickelDocument5 paginiDokumen - Tips - Astm A535 9 Percent NickelJeovanne CabralÎncă nu există evaluări

- Lession Plan - MIDocument21 paginiLession Plan - MINithya SannidhiÎncă nu există evaluări

- 1830PSS R36 QuickReferenceGuide 8DG60888JAAADocument66 pagini1830PSS R36 QuickReferenceGuide 8DG60888JAAAFelippe CanatoÎncă nu există evaluări

- List of Computer Networking DevicesDocument1 paginăList of Computer Networking Deviceskamit17102900100% (1)

- Shariff NDocument4 paginiShariff NKruu ChinnuÎncă nu există evaluări

- 3.1 From Algae To Terrestrial Plants-Student SheetDocument2 pagini3.1 From Algae To Terrestrial Plants-Student Sheeteshaaljamal27Încă nu există evaluări

- ABYIPDocument18 paginiABYIP千住 マリエルÎncă nu există evaluări

- KTS - Sarao.bakus Temple of Eternal FiireDocument176 paginiKTS - Sarao.bakus Temple of Eternal FiireK.T.S. SaraoÎncă nu există evaluări

- Difference Between AerospaceDocument2 paginiDifference Between AerospaceSyawalMaulanaÎncă nu există evaluări

- Secretary Birds: Fascinating Hunters of the African SavannahDocument32 paginiSecretary Birds: Fascinating Hunters of the African Savannahpwint phyu kyawÎncă nu există evaluări

- Fundamentals of VolleyballDocument2 paginiFundamentals of VolleyballLawrence CezarÎncă nu există evaluări

- Design of Steel BeamsDocument4 paginiDesign of Steel BeamsSankalp LamaÎncă nu există evaluări

- Fodor Hungary Between East and WestDocument22 paginiFodor Hungary Between East and WestFatih YucelÎncă nu există evaluări

- Borneo SporenburgDocument2 paginiBorneo SporenburgDorin TecuceanuÎncă nu există evaluări

- Total Tattoo-June 2021Document114 paginiTotal Tattoo-June 2021Comicgek100% (2)

- Biology Practical NotebookDocument38 paginiBiology Practical Notebookabdulmalik saniÎncă nu există evaluări

- Steel PropertiesDocument26 paginiSteel PropertiesLutfy AzanÎncă nu există evaluări

- Baby NamesDocument9 paginiBaby Namesppremamca_617705407Încă nu există evaluări

- MR-JE - A SERVO AMPLIFIER INSTRUCTION MANUAL (Modbus RTU Protocol)Document114 paginiMR-JE - A SERVO AMPLIFIER INSTRUCTION MANUAL (Modbus RTU Protocol)Aung Naing OoÎncă nu există evaluări

- Vapour Bar Exchange IMFL PackageDocument4 paginiVapour Bar Exchange IMFL PackageNishank AgarwalÎncă nu există evaluări

- History of Cancer ChemotherapyDocument9 paginiHistory of Cancer ChemotherapyJoydeep MajumdarÎncă nu există evaluări

- Hobby 01: COD. 9942062.01 REV. 00Document9 paginiHobby 01: COD. 9942062.01 REV. 00Alexander SharamiginÎncă nu există evaluări

- M. Valerio Assignment 6.1Document1 paginăM. Valerio Assignment 6.1Mark Kristian ValerioÎncă nu există evaluări

- 2021 ESC Guidelines For The Diagnosis and Treatment of Acute and Chronic Heart FailureDocument137 pagini2021 ESC Guidelines For The Diagnosis and Treatment of Acute and Chronic Heart FailuredianÎncă nu există evaluări

- Infinera Product BrochureDocument4 paginiInfinera Product Brochurebarry_fieldÎncă nu există evaluări

- Reconsilation of Major Materials Steel SDA Lattice Ribs Rockbolts Admixture Etc.Document99 paginiReconsilation of Major Materials Steel SDA Lattice Ribs Rockbolts Admixture Etc.Rajat SharmaÎncă nu există evaluări

- CEFIC Guidelines Transport Equipment Packed Cargo (2010)Document7 paginiCEFIC Guidelines Transport Equipment Packed Cargo (2010)sl1828Încă nu există evaluări