Documente Academic

Documente Profesional

Documente Cultură

30420130403003

Încărcat de

IAEME PublicationDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

30420130403003

Încărcat de

IAEME PublicationDrepturi de autor:

Formate disponibile

International Journal of Industrial Engineering Research and Development (IJIERD), ISSN 0976 INTERNATIONAL JOURNAL OF INDUSTRIAL ENGINEERING 6979(Print),

, ISSN 0976 6987(Online) Volume 4, Issue 3, September - December (2013), IAEME RESEARCH AND DEVELOPMENT (IJIERD)

ISSN 0976 6979 (Print) ISSN 0976 6987 (Online) Volume 4, Issue 3, September - December (2013), pp. 30-49 IAEME: www.iaeme.com/ijierd.asp Journal Impact Factor (2013): 5.1283 (Calculated by GISI) www.jifactor.com

IJIERD

IAEME

AN AHP MODEL FOR MATCHING LEAGILE STRATEGIES FOR THE OFF-SITE MANUFACTURE IN AUSTRALIA

Sherif Mostafa1 and Jantanee Dumrak2

1

(PhD Candidate/Staff, School of Natural and Built Environments, University of South Australia, City East Campus, GPO Box 2471 Adelaide SA 5001, Australia) 2 (Lecturer, International Institute of Business and Information Technology (IIBIT), Federation University, Adelaide, South Australia 5000, Australia)

ABSTRACT Australian housing supply has not been responsive commensurately to the growing demand. The residential sector challenges this issue by actively developing and effectively using new materials, processes, and practices to strengthen their competitive advantage against other construction sectors. Three main factors affecting the housing supply and demand are house completion time, cost of finished house, and customer preferences. The best current solution could be introducing the lean and agile concepts to manage the off-site manufacture (OSM) house building supply chain. In this paper, four strategies are introduced to balance the trade-offs between the housing supply and demand. This study presents an example on matching the strategies with the imbalance factors in the Australian house building using Analytical Hierarchy Process (AHP). The AHP model was developed using Expert Choice software package. The results from the AHP model show the benefits of each strategy with respect to each factor tested. Keywords: Australian Housing; OSM; Leagile Strategies; Customer Order Decoupling Point, AHP. I. INTRODUCTION The construction industry is a key economic component of Australia. The productivity of the industry has been continuously expanding. It was accounted for 7.7 per cent of the countrys gross domestic product (GDP) with the gross value added (GVA) reached AUD

30

International Journal of Industrial Engineering Research and Development (IJIERD), ISSN 0976 6979(Print), ISSN 0976 6987(Online) Volume 4, Issue 3, September - December (2013), IAEME

102 billion in the financial year 2010-2011 [1]. Australian construction industry includes the private and public sectors that are engaged in three broad activities; residential building, nonresidential building, and engineering construction. In Australia, the residential building contributed significantly to the national economy with the overall production value as reported at AUD 47 billion in 2010 and 2011. The Australian residential sector involves many independent building organisations to construct separate houses and other residential buildings including semi-detached houses, townhouses, flats, units and apartments. Nevertheless, the values of work commenced in residential building are likely to be less responsive to the growth of other construction activities [1]. This situation may be influenced by housing supply and demand factors. The housing supply has been found not keeping in pace with the housing demand as reported by [2, 3]. Some studies have examined the shortage of housing supply situation [2,4,5,6]. These studies focus mainly on housing demand side rather than the housing supply challenges [7]. This paper, therefore, addresses the undersupply of the Australian housing from both housing supply and demand perspectives. The housing supply should be considered as a chain containing all house building stakeholders. Lack of coordination between the stakeholders and management of this chain may lead to housing shortage [8]. Three main factors contributing to the Australian housing supply and demand imbalance are been identified in this paper. The factors are house price, house completion time and house customisation. The off-site manufacture (OSM) is a modern method of construction which involves two working sites: off-site factory and onsite construction. Elnaas, Gidado, and Ashton [9] highlight the key themes of decision factors to OSM. Time, quality and cost were the highly important themes for adopting OSM in UK. Some studies in Australia focus on the OSM uptake in house building and develop new housing technologies in home building [10-13]. It has been revealed that the opportunities of OSM in Australia are centred on detached housing, high-density multi-residential complexes, and public facilities such as hospitals, schools, and prisons [14]. It is suggested that some manufacturing concepts such as lean and agile can and should to be transferred to house building production [15, 12]. Selecting an appropriate strategy to meet specific housing house supply and demand requires a systematic selection process. This study, additionally, associates four leagile strategies to manage the two working sites of the OSM supply chain. The suggested strategies are Make to Stock (MTS), Make to Order (ATO), Design to Order (DTO), and Self-building Houses (SBH). The strategies aim to improve the overall performance and competitiveness of the Australian housing sector. The aim of this article is to identify the main factors contributing the imbalance of housing supply and demand, and to match the four leagile strategies with housing supply factors to improve the house building performance in Australia. The analytic hierarchy process (AHP), a multiple-criterion decision making (MCDM) approach developed by Saaty[16], is employed to form the analysis and deliver the most suitable strategy from the obtained data. AHP serves as a framework for prioritising the four leagile house building strategies with respect to the studied three factors. This article is structured into seven consecutive sections. After the introduction, the second section reviews the related literature to Australian housing supply and demand, lean, agile and leagile concepts, and OSM house building supply chain. Section three explains the four leagile house building strategies and the related case studies. The fourth section summarises the research methodology. The fifth section introduces the proposed AHP model which is applied to study four strategies using data obtained from the five largest house builders in five Australian states. The sixth section discusses the results delivered by the AHP model. In the final section, the research conclusion is given with recommendations for further research.

31

International Journal of Industrial Engineering Research and Development (IJIERD), ISSN 0976 6979(Print), ISSN 0976 6987(Online) Volume 4, Issue 3, September - December (2013), IAEME

II. LITERATURE REVIEW II. I. FACTORS AFFECTING THE AUSTRALIAN HOUSING SUPPLY AND DEMAND The Australian housing supply does not respond adequately to the growing demand especially in capital cities [2]. This situation has been confirmed by the housing industry alliances such as the National Housing Supply council (NHSC), Housing Industry Association (HIA), and Master Builders ers Australia [17]. The latest report on Housing to 2020 produced by HIA [5], indicates the gaps between underlying demand and supply in housing over the periods until 2020 ranging from low-, low medium-, and high-build build rate scenarios as presented in Fig.1. It can be seen from all build rate scenarios that the gaps between demand and supply do exist. It is forecasted that in 2016 the difference between demand and supply will reach 543,300, 372,100 and 213,200 dwellings in low, medium and high build rate respect respectively. At the year 2020, the expected shortage of dwellings will be 808,900, 500,900, and 214,700 respectively. According to a report of NHSC [3], delivering capacity of the public sector in housing supply will sharply decline in the near future as the recent recent housing outputs evidently decrease from the units produced in the last decades. The Australian housing undersupply is influenced by both housing supply and demand factors. The three main factors include house price, house completion time, and house cus customisation.

Figure 1. Projected dwelling shortage at national level II.I.I. HOUSE PRICE The house price refers to residential construction costs, taxes on new housing and land release [7,3]. House price is a critical element determining the new housing housing construction [7]. In Australia, house prices have increased in all locations at similar rate of growth [2, 18]. According to the Australian Future Tax System (AFTS) report, the median house prices have risen from three times compared to the average household household income in 1990 to around five times in 2010 [19]. The house price includes land price and construction costs (material and labour costs) [7]. The Housing Supply and Affordability Reform (HSAR) states that the growth of house prices is driven by the increase crease in the prices of established houses [2]. However, AFTS [19] views that the construction costs are responsible for a higher proportion of the increase in

32

International Journal of Industrial Engineering Research and Development (IJIERD), ISSN 0976 6979(Print), ISSN 0976 6987(Online) Volume 4, Issue 3, September - December (2013), IAEME

house prices in some regions. The study of Liu and London [7] explore the relationship between new housing supply and construction costs in Australia. Their study concludes that construction costs are a key component of the poor performance of the Australian new housing supply. II. I. II. HOUSE CUSTOMISATION Customer preferences reflect customising the house design to suit house customer needs. The preferences may vary from person to person based on the residential desirability and acceptability. Customer preferences include the design and location of a house [20]. The house design includes the internal (floor area) and external (faade width) design for the house. The average floor area of the Australian dwellings has been increased. The average floor area of new detached houses increased from 162.4 square meters to 248.0 square meters from 1984 to 2009. Whereas, new other residential dwellings increased from 99.2 square meters to 140.8 square meters [21]. It is evident from an examination of volume builders that double-story houses and more complex street facing faades have increased [22]. II. I. III.HOUSE COMPLETION TIME The house completion time is a key factor indicating the quality of housing delivery to house customers. The house completion time can be defined as the time period between the first and last physical building activities to produce a house and make it ready for occupation [17]. The average Australian house completion time has increased while the production rate has been relatively stable [4]. The average Australian house completion time rose from 1.8 quarters to 2.4 quarters from 2000 to 2008 [23]. Dalton et al. [17] identify three factors that might explain the lengthening of house completion time. The first factor is the construction method to manage all activities within house building processes. It also includes coordination and scheduling between the stakeholders as house building is generally delivered through a chain of stakeholders Therefore, building a house needs a successful construction method for meeting the planned schedule to deliver the house. The second factor is concerned with the level of skilled labour which affects the quality of a finished house. Most of the house builders employ quality assurance systems. Nevertheless, they have undergone a poor quality record [17]. The construction managers and supervisors have to arrange with the contractors and subcontractors for remediate defects. The remediation extends the planned construction time of the house. The third factor is the number of houses under construction. The study of Gharaie, Wakefield, and Blismas [24] shows a positive correlation between the number of houses under construction and completion time. II.II. OFF-SITE MANUFACTURE Off-site manufacture (OSM) is a modern method of construction which has been adopted to improve the performance of house building industry [25]. It refers to the production of house components in an off-site factory as well as their subsequent activities in a construction site [26]. OSM provides several benefits to all stakeholders involved in the house building process [10]. It improves onsite safety by providing cleaner and tidier environment to the construction site as well as enhances quality of the house components under factory production. Moreover, OSM reduces environmental effects by reducing waste generation, shortening lead time and increasing the efficiency and productivity [27-29]. There are four categories of OSM based on the degree of off-site works including component manufacture and sub-assembly, non-volumetric pre-assembly, volumetric pre-assembly, and modular building [30,31] as shown in Table 1.

33

International Journal of Industrial Engineering Research and Development (IJIERD), ISSN 0976 6979(Print), ISSN 0976 6987(Online) Volume 4, Issue 3, September - December (2013), IAEME

Table 1. Four categories of OSM. Level Category Definition Component manufacture Items always made in a factory and never considered 1 and sub-assembly for onsite construction (e.g. door furniture, windows) Non-volumetric pre- Pre-assembled units which do not enclose usable space 2 assembly (e.g. cladding wall panels, structural frames) Pre-assembled units which enclose usable space and are typically fully factory finished internally, but do not 3 Volumetric pre-assembly form the buildings structure (e.g. toilet pods, shower rooms) Pre-assembled volumetric units which also form the 4 Modular building actual structure and fabric (e.g. prison blocks, motels) In Australia, some studies positively address the OSM. For instance, the Construction 2020 report suggested OSM as a key vision for improving the construction industry [11. Two research projects carried out by Blismas[10]and Manley, Mckell, and Rose [32] reveal the future of OSM in the Australian built environment. The findings of the two projects confirmed that OSM has capability to produce high-volume, high-quality houses based on the efficiencies of the manufacturing principles.In spite of the benefits of the OSM, the factory physical production has several forms of non-value added activities or wastes. Ohno[33] enumerate seven forms of waste commonly found in factories physical production are overproduction, waiting time, transportation, over-processing, excessive-inventories, defective products, and unnecessary movement. Moreover, the customisation of prefabricated house makes the design specifications become more complex. Such complexity leads to slower response to achieve customer requirements. Three emerging challenges for a construction organisation derive from the management of two working locations simultaneously. The first challenge is the broken junction between the off-site and on-site activities. The second is the jumbled on-site processes due to difference between the production flow at off-site factories and construction flow on-site. The third challenge is the vague demands from unclear customers [34]. Some attempts have been made to address the shortcomings of OSM house building by adopting successful concepts from the manufacturing industry to house building [13], particularly in lean and agile concepts [35-38]. Lean and agile can manage the OSM supply chain as it does in manufacturing [39]. The combination of lean and agile is known as leagile. In this paper, four leagile strategies are proposed to manage the OSM supply chain as discussed in section three. II. III. AHP FOR MATCHING LEAGILE STRATEGIES WITH IMBALANCE HOUSING FACTORS It is contended that the housing supply and demand factors mentioned in the prior sections influence on the shortage situation of Australian housing. Moreover, these factors impact on the selection of house building supply chain strategies. To identify the solutions that can improve the housing shortage situation, AHP is suggested. AHP is a suitable application where the goal and the set of potential criteria and alternatives are made available [40]. AHP is a multiple-criterion decision making (MCDM) developed by Saaty[16] which takes into account of qualitative and quantitative judgements. AHP can be applied by using Expert

34

International Journal of Industrial Engineering Research and Development (IJIERD), ISSN 0976 6979(Print), ISSN 0976 6987(Online) Volume 4, Issue 3, September - December (2013), IAEME

Choice software. The software has advantages including a user friendly environment, an evaluation of inconsistency index of assessments, and a sensitivity analysis of results. The AHP approach assists in evaluating and ranking the leagile strategies of OSM supply chain with respect to the factors. AHP has widely utilised in many multiple criteria situations including operations management decisions based on customer requirements, construction contractor selection, supplier selection process, improving construction productivity, identifying design development factors in Australian public-project-partnership projects, new product development and infrastructure projects with social impact [41- 47].AHP facilitates the decision making process by constructing a hierarchical model presenting the integrated levels of the problem from the goal to alternatives [48]. AHP includes two basic components. The first component contains pairwise comparisons among all elements (e.g. criteria, sub criteria, and alternatives) at all levels of the model to make decision on various alternatives. The second component is a synthesis and a ranking of the model elements in order to identify the key elements of the decision making problem [49]. AHP has been used in the construction and house building industry. For instance, Wang et al. [42] use AHP to weight the decision criteria for selecting the best value contractors of two construction projects in Taiwan. Doloi[44] uses AHP to examine the causes of the poor productivity of construction workers in some building construction projects in Melbourne. Wang and Pan [50] propose an AHP model for spotting the factors affecting using industrialised house in Wuhan cityin China. Their model comprised four factors government, enterprise, custom and market. However, the model was not included any strategy for overcoming the impacts caused by these factors. In this study, AHP is employed to match the four leagile strategies with the three main factors contribute to the Australian housing imbalance. The goal (selecting appropriate house building strategy) is stated and the set of criteria (housing supply and demand imbalance factors) and alternatives (four leagile strategies) are determined. The house building activities from commencing the house building until the house is completed and ready for occupation are in focus. It is because, in the Australian housing context; the number of dwellings completed is less than number of dwellings commenced [1, 51]. Therefore, this paper identified the main factors influence Australian housing imbalance situation and associates the factors with the four suggested strategies. III. LEAGILE STRATEGIES FOR OSM HOUSE BUILDING SUPPLY CHAIN Three approaches to operate a supply chain are lean, agile, and Leagile [52]. Lean approach was first developed in the Toyota production system (TPS). Lean is an integrated socio-technical system comprising of management practices that can be applied to eliminate the waste [53]. Lean thinking as an application into the construction environment was first discussed by Koskela in 1992 [54]. A transformation-flow-value concept of production has been developed as a new perspective to improve the construction performance [55]. According to the concept, the construction production consists of three corresponding processes: a transformation of materials into standing structures, a flow of the materials and information through various production processes and a value creation for customers through the elimination of value loss [56]. Agile concept, on the other hand, became popular in 1991. Sharifi and Zhang [57] state that new competitive environment is a key driver for changes in the manufacturing industry. The competition qualities are continuous improvement, rapid response and quality

35

International Journal of Industrial Engineering Research and Development (IJIERD), ISSN 0976 6979(Print), ISSN 0976 6987(Online) Volume 4, Issue 3, September - December (2013), IAEME

improvement. The initiative of agile construction was established in direct response to the Latham Report published in 1994 [58]. The report highlighted the UK construction industry requirement to reduce the construction cost by 30 per cent by the year 2000. To achieve this target, the whole industry needed to change. Benchmarking has been a method used to stimulate the required change in the construction practices [58]. Naim et al. [38] suggest the employment of agile principles in the construction supply chains to achieve profitable opportunities in dynamic markets. Agile construction exemplifies the characteristics of visibility, responsiveness, productivity and profitability [59]. The integration of lean and agile is the best solution to answer all the production issues in the world class market competition [60]. Combining lean and agile within the whole supply chain can be accomplished by using the decoupling point (DP). It is known as leagility. The leagility term was firstly introduced byNaylor, Naim, and Berry [61]. In general, the DP separates the leagile supply chain into lean in the upstream and agile in the downstream [62].For market competition, Christopher and Towill [52]emphasise that supply chains must be responsive to market demand changes which can be divided into three critical dimensions; variety, variability (or predictability) and volume. Lean concept is the best alternative where there are high volume, low variety, and low predictable change environment. On the contrary, agile concept is the best option where there are high variety, low volume, and high predictable change environment. The real demand visibility is limited in most supply chains. The supply chains may be lean prior to DP and agile beyond DP. There are two DPs in the leagile supply chains [52]. The first DP is the material DP which should ideally lie as far down stream as possible to be close to the final marketplace. The second DP is the information DP which should lie as far upstream as possible in the supply chain. Agility beyond the decoupling point is explained by the principle of postponement using a generic or modular inventory to postpone the final commitment whilst the final assembly or customisation depends on real demand. Leagile supply chain has capabilities to achieve the house customer value through different strategies in accordance with the DP positions. The leagile house building supply chain mainly focuses on waste removal and responsive mechanisms through applying the excellence lean and agile practices.The studies of Childerhouse et al. [53] and Naim and Barlow [15] focus on using the material DP in the UK house building supply chain. In this paper, the leagile house building supply chain employs the customer order decoupling point (CODP) or order penetration point which encompasses both information and materials. The material DP is the stocking point of finished house modules or components. The information DP is the point where the customer demand enters the value chain. The four strategies suggested for leagile house building supply chain are demonstrated in Fig.3. Two supermarkets have been included. The first supermarket stores the house elements and lies between supplier and off-site factory. The second supermarket holds the finished house modules and lies between the off-site factory and construction site. Kanban is used to smooth the flow of manufacturing and construction activities [63]. Kanban is an information and material movement system used to define the type and quantity of parts between processes [64]. The Withdrawal Kanban (WK) is used to authorise movement of material from the two supermarkets while the Production Order Kanban (POK) is used replenish the two supermarkets. Four alternative positions for the CODP which are proposed to be employed in Australian house building supply chain.

36

International Journal of Industrial Engineering Research and Development (IJIERD), ISSN 0976 6979(Print), ISSN 0976 6987(Online) Volume 4, Issue 3, September - December (2013), IAEME

Figure 3. Four leagile strategies of OSM house building supply chain

III. I. MAKE TO STOCK (MTS) STRATEGY In MTS strategy, CODP is located after the on-site construction activities and finished house building. This strategy is commonly known as specs. The houses are designed and built speculatively based on the builders catalogue [17, 38]. Customers have a choice selection from the available houses based on the location, cost, size, and design. It is found in Barlow and Ozaki [65] that 25 per cent of new houses in Japan are speculative houses. The house customers have less or no choice over the house specifications and designs. The market winner in this strategy is the lower finished house selling price. Panelised house building designed by Monarch Building Systems presented in Blismas [10] is another example of the MTS strategy. The house panels are produced and utilised as standard panels in the companys building projects. With the MTS strategy, the company can ensure its capacity to serving large-size accommodation projects within the contracted timeframe. Therefore, the activities before selling should be lean to fit the costs. Agile is located after the CODP to diminish the delivery time and to meet the customer satisfaction and the speed of return on investment (ROI) [35]. III. II. ASSEMBLE TO ORDER (ATO) STRATEGY In ATO strategy, CODP is positioned at the off-site factory. The customer houses are built according to the builders catalogues. A variety of house designs are included in the catalogues. Customers have a degree of customisation to select a combination of specs to match their demands. The customers can add extra features to their own kitchen, bathrooms, external living area, as well as upgrade standard items such as windows and doors[17]. The house builders, then, perform the construction activities on-site and assembles the selected modules to complete the house. Two examples of ATO demonstrated in a work of Hk and Stehn [37] are from Swedish construction companies. In the first example, the strategy has

37

International Journal of Industrial Engineering Research and Development (IJIERD), ISSN 0976 6979(Print), ISSN 0976 6987(Online) Volume 4, Issue 3, September - December (2013), IAEME

been employed in construction of official and commercial buildings. The second example targets at developing standard modules for multi-family dwelling and students lodgings. Both companies emphasise on encouraging their customers to select building designs within their existing catalogues. Another example of ATO strategy is given in Pan and Goodier [27] from the UK house builders. Classic private house builders are claimed offering their customers with an alteration in house configuration based on the site and geographical areas. The market winners in this strategy are the house pricing and designs of house modules, and the completion time. It is suggested for the ATO strategy to employ lean within the off-site factories. Agile should be employed in stages of shipments and on-site construction to ensure more responsiveness in delivering the houses. III. III. DESIGN TO ORDER (DTO) STRATEGY In the DTO strategy, the customer demand enters the value stream at the design stage. Therefore, customers have a relatively high degree of customisation. They can specify the design of their own house modules. They have the flexibility to change the predesigned modules to fit their needs. In Japan, about 75 per cent of new detached houses are built on the existing land owned by the house owners. These new houses are designed based on the standard floor plan, but provides the house owner with flexibility to any degree of customization [65]. An example of the DTO strategy comes from Australian experience demonstrated inBlismas [10]. The construction procedure assimilated to the DTO strategy was chosen to build Prep classrooms in the State of Queensland. The design team was obliged to deliver specific features to be incorporated to the modules. Thus, a mock-up and two prototypes were prepared prior to the module production. The modules were, then, produced according to the approved design. The market winner in this strategy is high customisation. Therefore, the house building stages require a combination of lean and agile. Lean is suitable for supplying the material and running the off-site factories whilst other related activities need to be more agile. III. IV. SELF-BUILDING HOUSE (SBH) STRATEGY The final strategy is SBH. This strategy is suitable for the self-building houses which a homeowner is intimately involved in every aspect of the house building. This strategy is developed on a similar concept of the house building and the personal computer assembly [15]. The Australian houses are built by small to large organisations. In 2009, the largest 100 builders commenced approximately 37 per cent of all residential dwellings [17]. Sixty-three per cent of all residential dwellings were constructed either by small builders or in the form of self-building houses. In Victoria State, the Department of Human Services [66] introduces group self-build initiative to support individuals to build their own houses. The group usually consists of 12 homes within or nearby area. Each group of participants receives a bridging loan from the director of housing to purchase land and build their houses. The customers are at their own responsibilities to hire an architect for house designing and builders to assist them with some onsite construction activities. Likewise, the self-building houses model has been adopted in the UK housing sector where approximately 20 per cent of total housing supply is delivered by the house owners with(out) an outsourcing contract for design and built (D&B) [67]. In this strategy, the key role of house building organisations is to supply the house modules and components to the suppliers. House building organisations should aim at making the house assembly as simple as possible. The organisations should provide variable designs to meet different types of house needs. Lean is suitable to run the house modules factory while agile is the best option for quick responses to demands of self-build house suppliers.

38

International Journal of Industrial Engineering Research and Development (IJIERD), ISSN 0976 6979(Print), ISSN 0976 6987(Online) Volume 4, Issue 3, September - December (2013), IAEME

IV. RESEARCH METHOD The use of AHP in this study was to design the model combining the suggested four leagile house building strategies and the key factors contributing to the housing undersupply in Australia. This included selecting and scrutinising a number of possible criteria. Data and information were collected from various resources related to the Australian housing including peer reviewed journals, references books, websites, and Australian housing authorities including National Housing Supply Council (NHSC), Housing Industry Association (HIA), Australian Bureau of Statistics (ABS), Australian Housing and Urban Research Institute (AHURI), and Council of Australian Governments (COAG). The collected materials were carefully examined and allocated reference number. After that, the possible factors (criteria and sub-criteria) affecting the imbalance between housing supply and demand in Australia were determined. After the AHP model constructed, pairwise comparisons were used to rate all child elements with respect to the parent element according to nine point scale developed by Saaty [16]. The validity of the pairwise comparisons process was performed using the AHP consistency test. This process was carried out through the determination of inconsistency index of the pairwise comparisons which could be calculated in the Expert Choice software. In general, the Consistency Ratio (CR) less than 0.1 indicates a satisfactory degree of consistency [68]. The new set of acceptable CR values has been modified by Saaty [69] where the values work in association to the size of the matrix. For a 33 matrix, 44 matrix and larger matrices the CR value should be 0.05, 0.08 and 0.10 respectively. Afterwards, the AHP priorities were generated using the Expert Choice software. The local priorities were synthesised from the goal while the overall priorities were calculated. The relative weights were used to identify the key factors (criteria and sub-criteria). Moreover, the overall rating of the four house building strategies was determined. After that, a series of sensitivity analyses were performed in the Expert Choice software to investigate the impact of changing the importance of the criteria on the overall rating of the four strategies. V. ILLUSTRATIVE EXAMPLE V. I. THE AHP MODEL The AHP approach began with constructing the model of the decision problem. The first level was set as the goal of the model. The second level consisted of the three selected criteria: (1) house completion time; (2) house price; and (3) house customisation. Each criterion was further subdivided into eight sub-criteria. The three sub-criteria under house completion time were number of houses under construction, shortage of skilled labour, and construction method. Whereas, two sub-criteria were located under house price construction material and labour costs. Three sub-criteria came under house customisation; house floor area, house location, and faade width. The four strategies were placed at the bottom level of the hierarchy as decision alternatives. After setting all elements of the AHP model, the model was developed usingExpert Choice as shown in Fig.4 V. II. FOUR LEAGILE STRATEGIES The imbalance between the housing supply and demand has occurred in all Australian states and territories (COAG, 2012; NHSC, 2012). The Housing 100 Report for 2013 presented the Australias the most active 100 builders (HIA, 2013). Their main housing activities contributed around 75 per cent of the housing supply for detached houses and multi39

International Journal of Industrial Engineering Research and Development (IJIERD), ISSN 0976 6979(Print), ISSN 0976 6987(Online) Volume 4, Issue 3, September - December (2013), IAEME

unit apartments. In this paper, the top five potential builders of supplying houses in five Australian States Western Australia (WA), South Australia (SA), New South Wales (NSW), Victoria (VIC), and Queensland (QLD) were analysed as shown in Table 2. The five selected potential builders were capable of adopting the four leagile strategies. This adopting capacity was enhanced by their house building work in the five states, market share, decision making and the future trends during the period of 2011-2013 [5, 22] (HIA, 2011, 2013). Selecting a strategy depends on the situations of house market in Australia. Demand of house customers shapes the housing market. Therefore, the builders can respond to house market changes by adopting the suitable strategy. For example, the builders might have to build small floor plan house, less customised and with medium price for the Australian low income groups (increase the housing affordability). This combination could lead to the employment of one or more strategies proposed in this paper. The Australian medium income groups might prefer to select house elements and design from the available designs in the builders catalogues. In this case, a suitable strategy for this situation must be carefully determined. The customers have ability to change the house design to fit their needs. Therefore, customers are likely to be involved in designing all house elements. Therefore, the four strategies proposed can cover different customers demands. The strategies allow house builders to make decision to tailor their house building activities. The weightings of the criteria and sub-criteria for each strategy were performed through a comparison when a builder employs each strategy. The weighting criteria and sub-criteria for the four strategies are demonstrated in Table 3. V. II. I. PAIRWISE COMPARISONS OF THE MODEL ELEMENTS Pairwise comparisons were performed to associate the relationships between all elements at all levels of the AHP model. The three criteria were compared with respect to their importance to the goal. Under each criterion, the sub-criteria were compared according to their importance to the criterion. All pairwise numerical comparisons were performed in the expert choice software. The Saatys scale allows to compare each two elements in the hierarchy using verbal or numerical judgments as equally (i.e., has a weight of 1), moderately (i.e., has a weight of 3), strongly (i.e., has a weight of 5), very strong (i.e., has a weight of 7), extremely (i.e., has a weight of 9). The intermediate values are used where appropriate as equally to moderately (i.e., has a weight of 2), moderately to strongly (i.e., has a weight of 4), strongly to very strongly (i.e., has a weight of 6), very strongly to extremely (i.e., has a weight of 8) [70, 16] (Armacost, Componation, Mullens, & Swart, 1994; Saaty, 1980). An example of pairwise comparison between MTS and ATO strategies respect of houses under construction is demonstrated in Fig.5. The data of each comparison is displayed in a matrix form (e.g. 44 matrix in Fig.5). The number of each cell in the matrix represents the relation between two compared elements with respect to the parent element. In Expert Choice, the black coloured numbers means that the criterion on the left hand side is relatively more important than the criterion on the right hand side. Whereas the red coloured numbers appears, it means the criterion on the right is relatively important than the criterion on the left. After completing the pairwise comparisons, all priorities of the AHP model were calculated as shown in Table 4.

40

International Journal of Industrial Engineering Research and Development (IJIERD), ISSN 0976 6979(Print), ISSN 0976 6987(Online) Volume 4, Issue 3, September - December (2013), IAEME

Figure 4. proposed AHP model for selecting OSM house building strategy

Table 2. Top five Australian house builders attribute [22] (HIA, 2013)

Builder A HIA top 100 2012/2013 States House building activity Houses starts during 2013 House market share Number of models 1

st

Builder B 2

nd

Builder C 3

rd

Builder D 4

th

Builder E 5th VIC, SA, QLD Builder 1692 6.4% 36

WA Builder 3443 13% 224

WA,VIC Builder and developer 3199 12% 102

SA, VIC, NSW, QLD builder 2837 10.7% 60

QLD,VIC, SA Builder and developer 2432 9.2% 56

41

International Journal of Industrial Engineering Research and Development (IJIERD), ISSN 0976 6979(Print), ISSN 0976 6987(Online) Volume 4, Issue 3, September - December (2013), IAEME

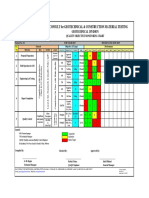

Table 3. Leagile strategies weighting in each criterion and sub-criteria

A1: MTS C1: House customisation Low Small floor area Fixed location Limited Low price range Low Low Short under Few Favourable Medium labour intensive Moderate Favourable Medium to High labour intensive Many Neutral Medium to High labour intensive Few Very favourable Requires less labour force A2: ATO Moderate Small floor area Flexible location Medium Moderate range Medium Medium Moderate A3: DTO Very high Larger floor area More flexible Large High range High High Long A4: SBH High Suitable for any floor area Highly flexible ModerateHigh LowModerate range low low ModerateShort

C1.1: C1.2: C1.3:

House floor area House location Faade options C2: House price

C2.1: C2.2:

Construction material cost Labour cost C3: House completion time Number of houses construction Construction method Level of skilled labour

C3.1: C3:2 C3:3

Figure 5. Example of pairwise comparison of two strategies

42

International Journal of Industrial Engineering Research and Development (IJIERD), ISSN 0976 6979(Print), ISSN 0976 6987(Online) Volume 4, Issue 3, September - December (2013), IAEME

Table 4. Weighting of the criteria, sub-criteria and alternatives

Alternatives (strategies) Criteria Sub-criteria Construction method (0.333) Level of skilled labour (0.333) Number of houses construction (0.333) under ATO 0.011 0.008 0.009 0.028 0.012 0.032 0.016 0.06 0.013 0.05 0.063 0.151 DTO 0.006 0.005 0.005 0.016 0.034 0.016 0.035 0.085 0.012 0.022 0.034 0.135 MTS 0.011 0.017 0.022 0.05 0.009 0.078 0.008 0.095 0.039 0.122 0.161 0.306 SBH 0.039 0.036 0.03 0.105 0.049 0.039 0.073 0.161 0.069 0.073 0.142 0.408 Total Priority of criteria and subcriteria 0.067 0.066 0.066 0.199 0.104 0.165 0.132 0.401 0.133 0.267 0.400

House completion time

House completion time (Total Priority) Faade width (0.260) House customisation House floor area (0.413) House location (0.327) House customisation (Total Priority) House price Labour costs (0.333) Material costs (0.667)

House price (Total Priority) Total Priority of alternatives

For the house completion time criterion, the sub-criteria had the same priority of 0.333. The house customisation sub-criteria priorities were 0.26 for faade width, 0.413 for house floor area and 0.327 for house location. The house price sub-criteria were rating as 0.333 for the labour costs and 0.667 for the material costs. The priorities of the criteria with respect to the goal were calculated. House customisation received the highest priority with 0.401, followed by house price with 0.400 and house completion time with 0.199. The inconsistency index of the judgements was checked to ensure that it is lower than or equal 0.1. Finally, the ranking of the four strategies were calculated with respect to the sub-criteria under each criterion. The weightings of the sub-criteria in each strategy were decided on each strategy adopted by the five builders (see Table 3). V. II. II. SYNTHESISING THE RESULTS After pairwise comparisons, the local priorities were synthesised from the goal while the overall priorities were calculated. The overall priorities of the four house building strategies are displayed in Fig.6. The distributive mode was selected. From the test results, the SBH strategy was considered as the best alternative which received the highest rating of 0.407. The second best strategy was MTS which scored 0.306, followed by ATO with a score 0.151. The last one was the DTO strategy with a score of 0.136.

43

International Journal of Industrial Engineering Research and Development (IJIERD), ISSN 0976 6979(Print), ISSN 0976 6987(Online) Volume 4, Issue 3, September - December (2013), IAEME

Figure 6. Overall priorities of alternatives in distributive mode VI. RESULTS AND DISCUSSION The sensitivity analysis was performed to examine the change results occurred in the priorities of the criteria. A performance summary of each house building strategy interacting with the three factors is shown in Fig.7. Overall, it is projected that the self-build housing (SBH) strategy was considered as the best strategy. However, SBH did not perform as the best strategy on individual criteria. It can be seen from Fig.7 that SBH strategy performed its best in house customisation and house completion time factors while it ranked the second on house price factor. On the other hand, the MTS strategy individually performed its best in house price.

Figure 7. Performance sensitivity graph of house building supply chain strategies

44

International Journal of Industrial Engineering Research and Development (IJIERD), ISSN 0976 6979(Print), ISSN 0976 6987(Online) Volume 4, Issue 3, September - December (2013), IAEME

VI. I. THE MAIN CRITERIA FOR STRATEGY SELECTION The priorities of importance for criteria and sub-criteria under each strategy are presented in Table 4. The house customisation criterion which consisted of sub-criteria, faade width, house floor area, and house location, obtained the highest score of importance (0.401). The second most important criterion was the house price with the score of 0.4. House price contained labour costs (0.133) and material costs (0.267) sub-criteria respectively. On the other hand, house completion time projected as the third important criterion with the score of 0.199. Under this criterion, construction methods (0.067), level of skilled labour (0.066) and number of houses under construction (0.066) were tested. It can be concluded that house customisation and house price were the most significant criteria for strategy selection according to data obtained in this research from five major builders in Australia. The results provided a clear-sighted on the factors affecting the Australian housing delivery which could lead to the implications and decision making of the house builders based on house customers demand. The house completion time, house customisation, and house price are directly affected by the builder strategy to complete a house. The adoption of the leagile strategies will support the uptake of OSM and enhance the house deliver. VI. II. IMPLICATIONS OF THE MODEL FOR HOUSE BUILDING DECISION The results from the examination of the proposed AHP model indicated that SBH strategy performed most effectively along the three factors. The SBH strategy could be suggested to the Australian house builders based on the research results that the strategy was the most suitable for the different combinations of the three factors. Furthermore, the results of scenarios demonstration is supported by the AHURI report undertaken by Dalton et al. [17] that 63 per cent of the Australian residential dwellings in 2009 were constructed by small builders or in the form of self-building houses. According to the case study of the state of Victoria presented earlier, a group self-build initiative was introduced to support individuals building their own houses. A key role of OSM in Australia is to supply variety of house modules and components to house-module suppliers so that OSM could meet the different types of house needs. The SBH strategy is the best in achieving minimum house cost which enhances the house affordability for the low- and medium-income Australians. According to the research results, the MTS strategy ranked the second from overall alternatives. This strategy could be used for mass house building projects where the builders may have to complete the project within the contract timeframe. Nevertheless, this research showed that the MTS strategy was the last alternative for house customisation in the model. A major drawback of the MTS strategy derives from low/none house customisations. The strategy may be suitable only for the construction of standard house designs. VII. CONCLUSIONS The Australian house building sector has experienced continuous growth and unmet housing demand. The house customisation, house cost and completion time add more complexities to the design specifications. Furthermore, customer demands are ambiguous and dynamically changed. The four strategies have been proposed in this paper to answer the different situations of demand and balance the trade-off between house builders and customers. This study was carried out using the AHP model to facilitate the selection of the OSM strategies with respect to the three main factors contributing to the imbalance of housing supply and demand in Australia.

45

International Journal of Industrial Engineering Research and Development (IJIERD), ISSN 0976 6979(Print), ISSN 0976 6987(Online) Volume 4, Issue 3, September - December (2013), IAEME

For future research, more house builders and housing undersupply factors can be added to the current study. This may include other factors such as coordination and scheduling among the stake holders, land supply, and demographic factors (e.g. economic circumstances of household, number of overseas migrations). It is important to understand the effects caused by these factors in order to improve the housing delivering system. These nominated criteria have been addressed in the Australian housing supply and demand literature. Therefore, the future study could conduct surveys with the Australian house building experts (e.g. house builders, residential developers, architects, and house owners) in order to verify or to refine the model. Questionnaire and interview surveys may need to be designed using the proposed AHP model. REFERENCES [1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] ABS, 2012 Year Book Australia. Canberra, ACT: Australian Bureau of Statistics, 2012. COAG, Housing Supply and Affordability Reform. Canberra ACT, Australia: Council of Australian Governements, 2012. NHSC, Housing Supply and Affordability: Key Indicators, Canberra ACT, Australia: National Housing Supply Counci, 2012. E.Gharaie, House Completion Time in Australia: Workflow Planning Approach. (Doctor of Philosophy), RMIT University, Melbourne, Australia, 2011. HIA, Housing to 2020 : The states of Australian housing to the year 2020, Campbell ACT, Australia, Housing Industry Association Economics Group, 2011. NHSC, Housing supply and affordability issues 2012-13. Canberra, National Housing Supply Council,2013. J. Liu, and K. London, Analysing the Relationship between New Housing Supply and Residential Construction Costs with Regional Heterogeneities,Australasian Journal of Construction Economics and Building, 11(3),2011, 58-67. K. London, and J. Siva, Housing Supply Chain Model for Innovation Research Report. Melbourne, Victoria: Australian Housing Supply Chain Alliance members, 2011. H. Elnaas, K. Gidado and P. Ashton, Factors and Drivers Effecting the Decision of Using Off-Site Manufacturing (OSM) Systems in House Building Industry, Journal of Engineering, Project, and Production Management, 4(1), 2014, 51-58. N. Blismas, Off-site manufacture in Australia: Current state and future directions. Brisbane, QLD: Cooperative Research Centre for Construction Innovation, 2007. K. D.Hampson, and P. Brandon, Construction 2020-A Vision For Australia's Property And Construction Industry. Brisbane, QLD: CRC Construction Innovation, 2004. PATH, Technology roadmap: whole house and building process redesign, one year progress report, In Prepared for US Department of Housing and Urban Development (Ed.), Partenership for Advanced Technology in Housing. Washington DC, USA: Office of Policy Development and Research, 2002. PATH. (2003). Technology roadmap for manufactured housing, In Prepared for US Department of Housing and Urban Development, Partenership for Advanced Technology in Housing, New York, USA: Office of Policy Development and Research, 2003.

46

[13]

International Journal of Industrial Engineering Research and Development (IJIERD), ISSN 0976 6979(Print), ISSN 0976 6987(Online) Volume 4, Issue 3, September - December (2013), IAEME

[14] N. Blismas, and R. Wakefield, Drivers, constraints and the future of offsite manufacture in Australia,Construction Innovation: Information, Process, Management, 9(1), 2009, 72-83. [15] M. Naim, and J. Barlow, An innovative supply chain strategy for customized housing. Construction Management and Economics, 21(6), 2003, 593-602. doi: 10.1080/0144619032000134129. [16] T. L. Saaty, The analytic hierarchy process : planning, priority setting, resource allocation. (London McGraw-Hill International Book Co., 1980). [17] T. Dalton, R. Wakefield, and R. Horne, Australian suburban house building: industry organisation, practices and constraints, Australian Housing and Urban Research Institute Positioning Paper Series, 2011, 1-56. [18] R. Fox, R., andR. Finlay, Dwelling Prices and Household Income, In Reserve Bank of Australia , Sydney, Australia, 2013. [19] AFTS, Australias future tax system: Report to the Treasurer, Attorney-Generals Department,Barton ACT, Australia,2010. [20] NHSC, Key findings of the 2011 State of supply report, Canberra ACT, National Housing Supply Council, 2011. [21] ABS, Building Approvals, Australia. Canberra ACT, Australian Bureau of Statistics, 2010. [22] HIA, Housing 100 : Australias Largest Homebuilders and Residential Developers 2012/2013, Campbell ACT, Housing Industry Association, 2013. [23] ABS, Average quarterly completion times for new houses, Building Approvals, Australia, Canberra ACT, Australian Bureau of Statistics, 2008. [24] E. Gharaie, R. Wakefield, and N. Blismas, Explaining the Increase in the Australian Average House Completion Time:Activity-based versus Workflow-based Approach, Australasian Journal of Construction Economics and Building, 10(4), 2010, 34-49. [25] W. Nadim, W., Modern Methods of Construction, In A. G. Akintoye, Jack.; Zawdie, Girm (Ed.), Construction innovation and process improvement (Chichester, West Sussex, U.K. : Wiley-Blackwell, 2012) 209-233. [26] K. Russell, S. Kanjanabootra, C. Ouyang, and M.T. Wynn, Procuring OSM: base-line models of off-site manufacture business processes in Australia, 16th Pacific Association of Quantity Surveyors Congress-Innovation and Sustaining: Challenges and Opportunities, Darussalam, Brunei, 2012. [27] W. Pan, and C. Goodier, House-building business models and off-site construction take-up,Journal of Architectural Engineering, 18(2), 2011, 84-93. [28] V. W. Y. Tam, C. Tam,and W. C. Y. Ng, On prefabrication implementation for different project types and procurement methods in Hong Kong,Journal of Engineering, Design and Technology, 5(1), 2007, 68-80. [29] X. Zhai, R. Reed, and A. Mills, Factors impeding the offsite production of housing construction in China: an investigation of current practice, Construction Management and Economics, 2013, 1-13. [30] A. Gibb, and F. Isack, (2003), Re-engineering through pre-assembly: client expectations and drivers. Building Research & Information, 31(2), 2003, 146-160. [31] A. Gibb, Off-site fabrication: prefabrication, pre-assembly and modularisation (Latheronwheel, Whittles, 1999). [32] K. Manley, S. Mckell, and T. Rose, Innovative Practices in the Australian Built Environment Sector: An Information Resource for Industry, Brisbane, Australia, 2009.

47

International Journal of Industrial Engineering Research and Development (IJIERD), ISSN 0976 6979(Print), ISSN 0976 6987(Online) Volume 4, Issue 3, September - December (2013), IAEME

[33] [34] [35] [36] [37] [38] [39] [40] [41] [42] [43] [44] [45] [46] [47] [48] [49] [50] [51]

T. Ohno, T., Toyota production system: beyond large-scale production (Portland, OR: Productivity Press, 1988). A.S. Chang, and K.P. Lee, Nature of construction technology, Proceedings of the 12th Annual Conference of the IGLC, Copenhagen, Denmark, 2004. P. Childerhouse, S.M. Hong-Minh, and M.M. Naim, House building supply chain strategies: selecting the right strategy to meet customer requirements, Proceedings of the 8th Annual conference of the IGLC, Brighton, UK, 2000. S.D. Green, S. Fernie, and S. Weller, Making sense of supply chain management: a comparative study of aerospace and construction, Construction Management and Economics, 23(6), 2005, 579-593. M. Hk, and L. Stehn, Applicability of lean principles and practices in industrialized housing production, Construction Management and Economics, 26(10), 2008, 1091-1100. M. Naim, J. Naylor, and J. Barlow, Developing lean and agile supply chains in the UK housebuilding industry, proceedings of the 7th Annual Conference of the IGLC, Berkeley, 1999. C. Vidalakis, J.E. Tookey, and J. Sommerville, Demand uncertainty in construction supply chains: a discrete event simulation study, Journal of the Operational Research Society, 64(6), 2013, 1-11. O. Bayazit, Use of AHP in decision-making for flexible manufacturing systems, Journal of Manufacturing Technology Management, 16(7), 2005, 808-819. E. Hofmann, and S. Knbel, Alignment of manufacturing strategies to customer requirements using analytical hierarchy process,Production & Manufacturing Research, 1(1), 2013,19-43. W. C. Wang, W. D. Yu, I. T. Yang, , C. C. Lin, , M. T. Lee, and Y. Y. Cheng, Applying the AHP to support the best-value contractor selection lessons learned from two case studies in Taiwan, Journal of Civil Engineering and Management, 19(1), 2013 24-36. F. T. S. Chan, Interactive selection model for supplier selection process: an analytical hierarchy process approach, International Journal of Production Research, 41(15), 2003, 3549-3579. H. Doloi, Application of AHP in improving construction productivity from a management perspective, Construction Management and Economics, 26(8), 2008 841-854. P. Raisbeck, , and L. C. M. Tang, Identifying design development factors in Australian PPP projects using an AHP framework, Construction Management and Economics, 31(1), 2012, 20-39. F. Steinberg, and R. Woll, Application of analytical hierarchy process to support selection of difficult-to-quantify characteristics in new product development, Total Quality Management & Business Excellence, 24(7-8), 2013, 797-810. M. lvarez, A. Moreno, and C. Mataix, The analytic hierarchy process to support decision-making processes in infrastructure projects with social impact, Total Quality Management & Business Excellence, 24(5-6), 2012, 596-606. A. B., Borade,G. Kannan, and S. V. Bansod, Analytical hierarchy process-based framework for VMI adoption, International Journal of Production Research, 51(4), 2012, 963-978. Chan, H. K., & Wang, X., Fuzzy Hierarchical Model for Risk Assessment (Springer London, 2013). Q. Wang, and S. Pan, On Influence Factors of Wuhan Housing Industry Based on the AHP. Systems Engineering Procedia, 3(0), 2012 158-165. ABS, Building Activity, Australia, Jun 2013, Building Activity, Australian Bureau of Statistics, Canberra, Australia, 2013.

48

International Journal of Industrial Engineering Research and Development (IJIERD), ISSN 0976 6979(Print), ISSN 0976 6987(Online) Volume 4, Issue 3, September - December (2013), IAEME

[52] [53] [54] [55] [56] [57] [58] [59] [60] [61] [62] [63] [64] [65] [66]

[67] [68] [69] [70]

M. Christopher, and D. R. Towill, Supply chain migration from lean and functional to agile and customised. Supply Chain Management: An International Journal, 5(4), 2000, 206-213. R. Shah, A. Chandrasekaran, andK. Linderman, In pursuit of implementation patterns: the context of Lean and Six Sigma,International Journal of Production Research, 46(23), 2008, 6679-6699. A. Mossman, Why isnt the UK construction industry going lean with gusto? Lean Construction Journal, 5(1), 2009, 24-36. L. Koskela, Application of the New Production Philosophy to Construction, CIFE, Stanford University, Stanford, CA, 1992. S. Bertelsen, Bridging the gaptowards a comprehensive understanding of lean construction, Proceedings of the 10th Annual Conference of the IGLC, Gramado, Brazil, 2002. H. Sharifi, and Z. Zhang, A methodology for achieving agility in manufacturing organisations: An introduction. International Journal of Production Economics, 62(1), 1999, 7-22. S. Lee, The Agile Peformance Improvement Databse: A tool to improve construction performance, School of Management, University of Bath, 2003. P. Daneshgari, Agile Construction : Impact of Project Resource Management on Profits, IEC Insights, 2009, 10-12. A. Agarwal, R. Shankar, and M.K. Tiwari, Modeling the metrics of lean, agile and leagile supply chain: An ANP-based approach., European Journal of Operational Research, 173(1), 2006, 211-225. B. J. Naylor, M. Naim, and D. Berry, Leagility: Integrating the lean and agile manufacturing paradigms in the total supply chain, International Journal of Production Economics, 62(12), 1999, 107-118. R. Mason-Jones, and D. R. Towill, Total cycle time compression and the agile supply chain, International Journal of Production Economics, 62(1), 1999, 61-73. R. Arbulu, G. Ballard, and N. Harper, Kanban in construction, Proceedings of the 11th Annual Conference of the IGLC, Blacksburgh, VA, 2003. L. H.Forbes, and S. M. Ahmed, Modern construction: lean project delivery and integrated practices ( Boca Raton, FL: CRC Press, 2011). J. Barlow, and R. Ozaki, Building mass customised housing through innovation in the production system: lessons from Japan, Environment and Planning A, 37(1), 2005, 9-20. Department of Human Services, Group Self Build, Housing and Community Building, Housing & Community Building: Finance & Business Services.Retrieved 1/2/2013, 2013, from http://www.dhs.vic.gov.au/for-individuals/housing-and-accommodation/home-ownersupport/group-self-build, 2011. D. Marshall, D. Worthing, N. Dann, and R. Heath, The construction of houses (5th Edition edn. Oxon: Routledge, 2013). T. L. Saaty, How to make a decision: The analytic hierarchy process, European Journal of Operational Research, 48(1), 1990, 9-26. T. L. Saaty, How to Make a Decision: The Analytic Hierarchy Process, Interfaces, 24(6), 1994, 19-43. R. L. Armacost, P. J.Componation, M. A.Mullens, and W. W. Swart, An AHP framework for prioritizing customer requirements in QFD: an industrialized housing, IIE Transactions, 26(4), 1994, 72-79.

49

S-ar putea să vă placă și

- Impact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesDocument10 paginiImpact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesIAEME PublicationÎncă nu există evaluări

- A Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurDocument7 paginiA Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurIAEME PublicationÎncă nu există evaluări

- Modeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyDocument14 paginiModeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyIAEME PublicationÎncă nu există evaluări

- Broad Unexposed Skills of Transgender EntrepreneursDocument8 paginiBroad Unexposed Skills of Transgender EntrepreneursIAEME PublicationÎncă nu există evaluări

- Voice Based Atm For Visually Impaired Using ArduinoDocument7 paginiVoice Based Atm For Visually Impaired Using ArduinoIAEME PublicationÎncă nu există evaluări

- A Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiDocument16 paginiA Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiIAEME PublicationÎncă nu există evaluări

- A Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaDocument9 paginiA Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaIAEME PublicationÎncă nu există evaluări

- Dealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsDocument8 paginiDealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsIAEME PublicationÎncă nu există evaluări

- Influence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiDocument16 paginiInfluence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiIAEME PublicationÎncă nu există evaluări

- Attrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesDocument15 paginiAttrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesIAEME PublicationÎncă nu există evaluări

- Role of Social Entrepreneurship in Rural Development of India - Problems and ChallengesDocument18 paginiRole of Social Entrepreneurship in Rural Development of India - Problems and ChallengesIAEME PublicationÎncă nu există evaluări

- A Multiple - Channel Queuing Models On Fuzzy EnvironmentDocument13 paginiA Multiple - Channel Queuing Models On Fuzzy EnvironmentIAEME PublicationÎncă nu există evaluări

- EXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESDocument9 paginiEXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESIAEME PublicationÎncă nu există evaluări

- Application of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDDocument19 paginiApplication of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDIAEME PublicationÎncă nu există evaluări

- Various Fuzzy Numbers and Their Various Ranking ApproachesDocument10 paginiVarious Fuzzy Numbers and Their Various Ranking ApproachesIAEME PublicationÎncă nu există evaluări

- A Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksDocument10 paginiA Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksIAEME PublicationÎncă nu există evaluări

- Optimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsDocument13 paginiOptimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsIAEME PublicationÎncă nu există evaluări

- Knowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentDocument8 paginiKnowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentIAEME PublicationÎncă nu există evaluări

- Quality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceDocument7 paginiQuality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceIAEME PublicationÎncă nu există evaluări

- Analysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsDocument13 paginiAnalysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsIAEME PublicationÎncă nu există evaluări

- A Overview of The Rankin Cycle-Based Heat Exchanger Used in Internal Combustion Engines To Enhance Engine PerformanceDocument5 paginiA Overview of The Rankin Cycle-Based Heat Exchanger Used in Internal Combustion Engines To Enhance Engine PerformanceIAEME PublicationÎncă nu există evaluări

- Sentiment Analysis Approach in Natural Language Processing For Data ExtractionDocument6 paginiSentiment Analysis Approach in Natural Language Processing For Data ExtractionIAEME PublicationÎncă nu există evaluări

- Prediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsDocument13 paginiPrediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsIAEME PublicationÎncă nu există evaluări

- Financial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelDocument9 paginiFinancial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelIAEME PublicationÎncă nu există evaluări

- Moderating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorDocument7 paginiModerating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorIAEME PublicationÎncă nu există evaluări

- Formulation of The Problem of Mathematical Analysis of Cellular Communication Basic Stations in Residential Areas For Students of It-PreparationDocument7 paginiFormulation of The Problem of Mathematical Analysis of Cellular Communication Basic Stations in Residential Areas For Students of It-PreparationIAEME PublicationÎncă nu există evaluări

- Ion Beams' Hydrodynamic Approach To The Generation of Surface PatternsDocument10 paginiIon Beams' Hydrodynamic Approach To The Generation of Surface PatternsIAEME PublicationÎncă nu există evaluări

- Analysis On Machine Cell Recognition and Detaching From Neural SystemsDocument9 paginiAnalysis On Machine Cell Recognition and Detaching From Neural SystemsIAEME PublicationÎncă nu există evaluări

- A Review of Particle Swarm Optimization (Pso) AlgorithmDocument26 paginiA Review of Particle Swarm Optimization (Pso) AlgorithmIAEME PublicationÎncă nu există evaluări

- Evaluation of The Concept of Human Resource Management Regarding The Employee's Performance For Obtaining Aim of EnterprisesDocument6 paginiEvaluation of The Concept of Human Resource Management Regarding The Employee's Performance For Obtaining Aim of EnterprisesIAEME PublicationÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Hanson Cem 1 Portland Cement Data SheetDocument2 paginiHanson Cem 1 Portland Cement Data SheetStacey HarperÎncă nu există evaluări

- 193 Gmaw Zug Asme (Andhika Rolando 3g) WPQDocument1 pagină193 Gmaw Zug Asme (Andhika Rolando 3g) WPQMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- Surface Grinder ManualDocument11 paginiSurface Grinder ManualRandyWilsonÎncă nu există evaluări

- Dot - 39Document19 paginiDot - 39koshke100% (1)

- Rehabilitation of Concrete Tank Using Epoxy and FRP LiningDocument5 paginiRehabilitation of Concrete Tank Using Epoxy and FRP LiningChaitanya ShahÎncă nu există evaluări

- Lauffer Broschuere LCL AnsichtDocument4 paginiLauffer Broschuere LCL AnsichtRaul CostiniucÎncă nu există evaluări

- Auto Comp ReportDocument167 paginiAuto Comp ReportnilekaniÎncă nu există evaluări

- HA AlphasetDocument3 paginiHA AlphasetIonut Cornel PopaÎncă nu există evaluări

- SRB BlindadosDocument28 paginiSRB BlindadosLuisSilvaÎncă nu există evaluări

- Domestic Product Failures - Case Studies: C. GaggDocument24 paginiDomestic Product Failures - Case Studies: C. GaggAdam HolmesÎncă nu există evaluări

- Supplier Responsibilities: Section IIDocument2 paginiSupplier Responsibilities: Section IImehdi810Încă nu există evaluări

- Brochure Catalogue General en PDFDocument108 paginiBrochure Catalogue General en PDFLUIS XVÎncă nu există evaluări

- Jit-Just in TimeDocument90 paginiJit-Just in Timearvind ronÎncă nu există evaluări

- Lecture Notes BricksDocument8 paginiLecture Notes BricksMurtaza KolsawalaÎncă nu există evaluări

- CURA andDocument36 paginiCURA andEhsanul AzimÎncă nu există evaluări

- Neutralite DatasheetDocument4 paginiNeutralite DatasheetalvarikokexÎncă nu există evaluări

- Forwarding AgentDocument4 paginiForwarding AgentFakhrul HisyamÎncă nu există evaluări

- Engineers in Society (Project Report)Document61 paginiEngineers in Society (Project Report)Syafiq Fauzi50% (2)

- Astm A123 2013 PDFDocument8 paginiAstm A123 2013 PDFjoao carlos protz100% (2)

- Bose Corporation Solution 1,2,3Document6 paginiBose Corporation Solution 1,2,3aliya altaf100% (1)

- Operations Management Assignment 2Document3 paginiOperations Management Assignment 2Ahmed NadeemÎncă nu există evaluări

- Parts List OverlockDocument8 paginiParts List OverlockJohnChingateÎncă nu există evaluări

- Grinding FundamentalsDocument49 paginiGrinding FundamentalsanruloÎncă nu există evaluări

- 00-Quality Objective Monitoring Chart Fof Geotech Div-2Document1 pagină00-Quality Objective Monitoring Chart Fof Geotech Div-2Adly Al-SaafinÎncă nu există evaluări

- Section 3 - Corrosion - ProtectionDocument44 paginiSection 3 - Corrosion - ProtectionChris MedeirosÎncă nu există evaluări

- Lecture 19 Rapid Prototyping Concept, Advantages PDFDocument15 paginiLecture 19 Rapid Prototyping Concept, Advantages PDFRishabh MendirattaÎncă nu există evaluări

- Example Calculations: Example Calculation For A Single Strong-Bolt 2 Anchor Using SDDocument2 paginiExample Calculations: Example Calculation For A Single Strong-Bolt 2 Anchor Using SDmordidomiÎncă nu există evaluări

- Chapter 7 Pulverisers PlantDocument11 paginiChapter 7 Pulverisers PlantBineet Kumar VarmaÎncă nu există evaluări

- A S M GL4110 & GL4910 P R P: Utomatic Prinklers Odel Endent Ecessed EndentDocument2 paginiA S M GL4110 & GL4910 P R P: Utomatic Prinklers Odel Endent Ecessed EndentAnwar SyedÎncă nu există evaluări

- Токарный инструмент IscarDocument250 paginiТокарный инструмент IscarstctoolÎncă nu există evaluări