Documente Academic

Documente Profesional

Documente Cultură

1 s2.0 S2095311913605419 Main

Încărcat de

Sagar KumarDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

1 s2.0 S2095311913605419 Main

Încărcat de

Sagar KumarDrepturi de autor:

Formate disponibile

Journal of Integrative Agriculture

2013, 12(8): 1357-1362

August 2013

RESEARCH ARTICLE

The Development of a Renewable-Energy-Driven Reverse Osmosis System for Water Desalination and Aquaculture Production

Clark C K Liu

Department of Civil and Environmental Engineering, and Water Resources Research Center, University of Hawaii at Manoa, HI 96822, USA

Abstract

Water and energy are closely linked natural resources - the transportation, treatment, and distribution of water depends on low-cost energy; while power generation requires large volumes of water. Seawater desalination is a mature technology for increasing freshwater supply, but it is essentially a trade of energy for freshwater and is not a viable solution for regions where both water and energy are in short supply. This paper discusses the development and application of a renewable-energy-driven reverse osmosis (RO) system for water desalination and the treatment and reuse of aquaculture wastewater. The system consists of (1) a wind-driven pumping subsystem, (2) a pressure-driven RO membrane desalination subsystem, and (3) a solar-driven feedback control module. The results of the pilot experiments indicated that the system, operated under wind speeds of 3 m s-1 or higher, can be used for brackish water desalination by reducing the salinity of feedwater with total dissolved solids (TDS) of over 3 000 mg L-1 to product water or permeate with a TDS of 200 mg L-1 or less. Results of the pilot experiments also indicated that the system can remove up to 97% of the nitrogenous wastes from the fish pond effluent and can recover and reuse up to 56% of the freshwater supply for fish pond operation. Key words: renewable energy, desalination, pressure-driven membrane processes, aquaculture, fish pond

INTRODUCTION

Existing water desalination processes are based on either thermal or membrane technology. Because of rapid advancements of membrane technology, most water desalination plants built in the last 30 years in the USA used membrane technology such as reverse osmosis (RO), electrodialysis, and nanofiltration (Glueckstern 1995; Liu and Park 2008). A major problem associated with membrane desalination is high energy consumption. To address this problem, efforts have been made to develop cost-effective desalination systems that use brackish water instead of seawater as feedwater and use renewable

Received 17 October, 2012 Accepted 10 January, 2013 Correspondence Clark C K Liu, Tel: +1-808-9567658, E-mail: clarkliu@hawaii.edu

energy instead of electricity to power the system operation (Feron 1985; Robinson et al. 1992; Weiner et al. 2001; Kershman et al . 2002; Liu et al . 2002). The osmotic pressure of seawater at a total dissolved solids (TDS) concentration of 35 000 mg L-1 is about 2 700 kPa (395 psi). Use of brackish water as feedwater for the RO desalination process would provide a smaller osmotic pressure and thus, brackish water desalination would require smaller applied pressure than seawater desalination - the osmotic pressure of brackish water at a TDS concentration of 3 000 mg L-1 is approximately 230 kPa (30 psi). Another major problem associated with membrane desalination is membrane fouling. The fouling problem is caused by the plugging of membrane surfaces by

2013, CAAS. All rights reserved. Published by Elsevier Ltd. doi:10.1016/S2095-3119(13)60541-9

1358

Clark C K Liu

organic and inorganic substances present in the feedwater. Methods of pretreatment and new fouling resistant membrane materials are being developed by studying the physicochemical and biological interactions between the membrane surface and foulants and anti-fouling agents (Mulder 1996; Liu and Park 2008). Aquaculture is the fastest growing food production industry because of significant increases in demand for fish and seafood throughout the world. Aquaculture is growing more rapidly than any other segment of the animal culture industry. In 2000, the total aquaculture production (including aquatic plants) was 45.7 million metric tons and valued at US$ 56.5 billion (FAO 2002). Concerns are evoked about the possible effects of aquaculture wastewater on both productivity in aquaculture ponds and on ambient aquatic ecosystem. Nitrogenous compounds are major contaminants in aquaculture wastewater. Ammonia is the principal nitrogenous waste produced by fishes. Short-term exposure of fishes to high concentration of ammonia causes increased gill ventilation, hyper excitability, loss of equilibrium, convulsions, and then death. Chronic exposure of fishes to a lesser concentration of ammonia include tissue damage, decrease in reproductive capacity (number of eggs produced, egg viability, delay in spawning), decrease in growth, and increase in susceptibility to disease (Thurston et al. 1986). Development of cost-effective technology for aquaculture wastewater treatment, especially nitrogen removal, is one of the most important factors for achieving a profitable and sustainable aquaculture industry in many parts of the world. Aquaculture wastewater can be treated by using biofilters, including trickling filters, submerged filters, rotating media filters, fluidized bed filters and lowdensity media filters (Jewell and Cummings 1990; Abeysinghe et al . 1996; Hargrove et al . 1996; Ng et al . 1996; Twarowska et al . 1997). There are, however, significant drawbacks of using biofilters to treat aquaculture wastewater, including excessive sludge production, unstable performance, and nitrate accumulation. In this study, after successfully testing the use of the renewable-energy-driven RO system for water desalination, the system was further modified and tested as a cost-effective and environment-friendly method for removing nitrogenous wastes from culture water of tilapia.

RESULTS AND DISCUSSION

System performance of wind energy conversion

The overall efficiency of a windmill/pump is defined as the ratio of energy delivered to the water to the available wind energy (Kiranoudis et al. 1997): (1) Where a=air density (kg m-3), A=rotor swept area (m2), and U=wind speed (m s-1), w=water density (kg m -3), g=acceleration of gravity (m s-2), Qw=water flow rate (m3 s-1), and H=hydraulic head (m). Fig. 1 shows the overall efficiency of wind energy conversion versus wind speed, based on field data collected by this study. The observed data (dots) are correlated well with a regression curve, which can be expressed by the following empirical equation: (2)

System performance and water desalination

System desalination performance is illustrated in Fig. 2. Fig. 2-A shows the flow rate and salinity of the permeate as a function of wind speed, with a constant feedwater salinity of 2 500 mg L-1 and a constant operating pressure of 621 kPa (90 psi). The system can be operated at a wind speed as low as 3 m s -1, a wind speed at which a permeate flow of 0.133 m3 h-1 with a

Fig. 1 Overall system efficiency of wind energy conversion versus wind speed.

2013, CAAS. All rights reserved. Published by Elsevier Ltd.

The Development of a Renewable-Energy-Driven Reverse Osmosis System for Water Desalination and Aquaculture

1359

Fig. 2 System performance in water desalination. A, wind speed and permeate flow and salinity. B, pressure and permeate flow and salinity.

salinity of 146 mg L-1 can be produced. Fig. 2-B shows the flow rate and salinity of permeate as a function of operating pressure, with a constant wind speed of 6 m s-1 and a feedwater salinity of 2 500 mg L-1. Under these conditions, a permeate flow of 0.10 m3 h-1 with a salinity of 175 mg L-1 can be produced under a pressure of 517 kPa (75 psi). By increasing the operating pressure to 862 kPa (125 psi), a permeate flow of 0.20 m3 h-1 with a salinity of 110 mg L-1 can be produced. Therefore, the system is relatively sensitive to the operating pressure. A pilot plant of renewable energy driven desalination, to be located on Ewa Beach, Oahu, Hawaii, was designed based on experimental data. The pilot plant of renewable energy-driven RO desalination was designed by scaling up the testing system, which can be achieved by using 20-ft (6.14-m) windmills and by arranging multi-units of windmill/pump and membrane processing in parallel and in series (Fig. 3). A cost-analysis indicated that the pilot plant can produce freshwater at a rate of 1 285 000 gallons per year, at a cost of US$ 5.40 per 1 000 gallons.

h, 4-h, and 6-h discharging periods underwent relatively faster increases with wind and had a tendency to approach the apparent maximum value. Among the three recovery rate curves, 2-h discharging period has a sharper slope than the others. There was no obvious difference on the slope changes between the 4-h and 6h recovery rate curves. There was an upper limit in increased water recovery rate in the system either by increasing the wind speed or by selecting alternatives for the concentrate

System performance of aquaculture wastewater treatment

The system performances under two categories of wind speed and discharging frequency are shown in Fig. 4. The high operation efficiency zone for water recovery rate in the system was determined. The recovery rate was below 65% for the 0-h discharging period that increased slowly with wind, which included very strong winds. In comparison, the water recovery rate for 2-

Fig. 3 Schematic of conceptual design of a renewable-energydriven RO desalination pilot plant.

2013, CAAS. All rights reserved. Published by Elsevier Ltd.

1360

Clark C K Liu

Fig. 4 System performance in aquaculture wastewater treatment under varying wind speeds and effluent discharge periods.

discharging periods. The water recovery rate for the 4-h and 6-h modes seemed to reach more than 90%; after approximately 93% water recovery, the system stabilized with no further recovery rate expected. However, for the 2-h mode, 85% water recovery was difficult to attain. Although the 6-h and 4-h modes had similar performances in the high efficient zone (wind speed >5 m s-1), the 6-h functioned at a slightly higher efficiency. This was one of the factors why the 6-h discharging mode was selected as the operation mode.

CONCLUSION

In this study, a brackish water desalination system was developed and tested. The system was driven entirely by renewable energy, which used wind energy to drive the RO desalination process and used solar energy to drive the system operating control module. With a twostage wind-driven pumping mechanism, the system can generate and maintain two different levels of operating water pressure for the pretreatment process and the RO process. The control module operated the system and allowed continuous operation under varying wind speeds and feedwater salinity. The system can produce freshwater at a total dissolved solids (TDS) of less than 200 mg L -1 from brackish feedwater with a TDS greater than 3 000 mg L-1. Data collected in field experiments showed that the system can be operated under mild wind speeds of 3.0 m s-1 or higher, with an average rejection rate

of 94%, and an average recovery ratio of 25%. A cost analysis for a pilot plant indicated that brackish water desalination was a viable water supply alternative for the Pacific Islands and other remote communities. This study also showed that the renewable-energydriven RO system was a technically feasible and environment friendly method of wastewater treatment and reuse in aquaculture production. The system can be operated at the average wind speed as low as 3.0 m s-1. With an average wind speed of 5.0 m s-1 or more, the system worked continuously. It can generate and recycle freshwater at a flow rate ranging from 227.8 to 366.5 L h-1, depending on the wind speed. Approximately 70 to 84% of aquaculture wastewater can be recycled. The system was capable of removing 90 to 97% of nitrogenous waste present in the tilapia culture effluents, while the average recovery rate was about 40 to 56%. Agricultural irrigation water use is often associated with the problems of (1) the high rate of energy consumption, especially when long distance water transport or deep groundwater pumping is involved; and (2) the excessive salt content in source water. The renewable-energy-driven RO system developed by this study was also useful in certain areas where the surface freshwater was limited, but agricultural and food productions were necessary. This system was evaluated as part of an irrigation project in South Kona, Hawaii to reduce the salt content in source water and to reduce the pumping cost (Liu 2012). The project feasibility analysis indicated that this system can pump 3 million gallons per day (mgd) of freshwater from a coastal aquifer to irrigate 1 300 acres of coffee and other crops in the project area.

SYSTEM DEVELOPMENT

System development for water desalination

The prototype renewable-energy-driven RO desalination system developed by the University of Hawaii, USA, on Coconut Island consisted of two subsystems: 1) a wind-energy conversion subsystem, and 2) an RO process subsystem (Fig. 5). In the wind-energy conversion subsystem, a pump coupled with a multi-blade

2013, CAAS. All rights reserved. Published by Elsevier Ltd.

The Development of a Renewable-Energy-Driven Reverse Osmosis System for Water Desalination and Aquaculture

1361

windmill pressurized the feedwater. The overall system inputs were wind and feedwater, and the system outputs were permeate and brine. A control module data, which consisted of several acquisition and feedback control devices, was developed (Liu 2009). Feedwater, which was pressurized by a wind pump, flows into a pressure stabilizer that reduced large fluctuations of pressure and flow rate. The relatively stable feedwater flowed out of the stabilizer and then passed through a pretreatment unit before entering the RO membrane. A 4.3-m (14-ft) diameter multi-blade windmill installed on a 9-m-tall tower drives a piston pump with a 275-mm (11-inch) stroke and 980-cm 3 effective displacement. Both the windmill and piston pump were manufactured by Dempster Inc. A stabilizer was used to maintain a steady feedwater flow by reducing excessive fluctuastion of the pressure and the flow rate. The stabilizer developed by the University of Hawaii was similar to hydro-pneumatic pressure tank with a 0.3-m3 inner volume; it yielded a mean hydraulic detention time of about 30 min, under design conditions. An ultra low-pressure RO

membrane (M-T4040ULP), manufactured by Applied Membrane Inc., was used. The effective surface area of a single RO unit was 7.40 m 2 (80 ft 2). This system can provide dual water pressure for pretreatment at 172-374 kPa (20-50 psi) and for RO processing at 517-724 kPa (75-105 psi).

System development for treatment and reuse of aquaculture wastewater

Aquaculture wastewater passing through the RO membrane was separated into permeates (freshwater) and brine (concentrated wastewater). The permeate was re-circulated to the fish tank while the brine is diverted to a duckweed pond for further treatment and reuse Fig. 6. The system can generate and recycle freshwater at a flow rate that ranged from 227.8 to 366.5 L h-1, depending on the wind speed. The nitrogen removal rate ranged from 90 to 97% and the recovery rate of the RO membrane was about 40 to 56%. Further study will focus on increasing the system capacity while reducing the unit cost making the new technology more affordable.

Fig. 5 Schematic of renewable-energy-driven RO system for water desalination.

2013, CAAS. All rights reserved. Published by Elsevier Ltd.

1362

Clark C K Liu

Fig. 6 Schematic of renewable-energy-driven RO system for aquaculture wastewater treatment and reuse.

Acknowledgements

This study was supported in part by the U.S. Department of the Interior Bureau of Reclamation (USBR) through a research grant (04-FG-81-1062). This is contributed paper WRRC-CP-2013-07 of the Water Resources Research Center, University of Hawaii at Manoa, Honolulu. Any opinions, findings, and conclusions in this publication are those of the authors and do not necessarily reflect the view and policies of the USBR.

References

Abeysinghe D H, Shanableh A, Rigden B. 1996. Biofilters for water reuse in aquaculture. Water Science and Technology, 34, 253-260. FAO (Food and Agriculture Organizations of the United Nations). 2002. The State of World Fisheries and Aquaculture 2002. FAO Fisheries Department, Rome. Feron P. 1985. The use of wind-power in autonomous r e v e r s e o s m o s i s s e a w a t e r d e s a l i n a t i o n . Wind Engineering, 9, 180-199. Glueckstern P, Menahem P, Thoma A, Gelman Y. 2000. Desalination of brackish fish pond effluents - pilot testing and comparative economic evaluation of integrated UF-RO system vs . conventional systems. Desalination , 132, 55-64. Hargrove L L, Westerman P W, Losordo T M. 1996. Nitrification in three-stage and single-stage floating bead biofilters in a laboratory-scale recirculating aquaculture system. Aquaculture Engineering, 15, 67-80. Jewell W J, Cummings R J. 1990. Expanded bed treatment of complete recycle aquaculture systems. Water Science and Technology, 22, 443-450. Kershman S A, Rheinlander J, Gabler H. 2002. Seawater reverse osmosis powered from renewable energy sources - hybrid wind/photovoltaic/grid power supply for smallscale desalination in Libya. Desalination, 153, 17-23.

Kiranoudis C T, Voros N G, Maroulis Z B. 1997. Wind energy exploitation for reverse osmosis desalination plants. Desalination, 109, 195-209. Liu C C K, Park J W, Migita J, Qing G. 2002. Experiments of a prototype wind-driven reverse osmosis desalination system with feedback control. Desalination, 150, 277-287. Liu C C K, Park J W. 2008. Water Desalination . AccessScience, McGraw-Hill Companies, New York. Liu C C K. 2009. Wind-powered reverse osmosis water desalination for Pacific islands and remote coastal communities. In: Desalination and Water Purification Research and Development Program Report No. 128. U.S. Department of the Interior, Bureau of Reclamation, Denver, Colorado. Liu C C K. 2012. Feasibility study of renewable-energy for the South Kona watershed irrigation project. In: Project Report for Belt Collins Hawaii, LLC. Mulder M. 1996. Basic Principles of Membrane Technology. 2nd ed. Kluwer Academic, Dordrecht. Ng W J, Koh K, Ong S L, Sim T S, Ho J M. 1996. Ammonia removal from aquaculture water by means of fluidized technology. Aquaculture, 139 , 55-62. Robinson R, Ho G, Mathew K. 1992. Development of a reliable low-cost reverse osmosis desalination unit for remote communities. Desalination, 6, 9-26. Thurston R V, Russo R C, Meyn E L, Zajdel R K. 1986. Chronic toxicity of ammonia to fathead minnows. Transactions of the American Fisheries Society, 115, 196-207. Twarowaska J G, Westerman P W, Losordo T M. 1997. Water treatment and waste characterization evaluation of an intensive recirculating fish production system. Aquaculture Engineering, 16, 133-147. Weiner D, Fisher D, Moses E J, Katz B, Meron G. 2001. Operation experience of a solar- and wind-powered desalination demonstration plant. Desalination, 137, 7-13. (Managing editor SUN Lu-juan)

2013, CAAS. All rights reserved. Published by Elsevier Ltd.

S-ar putea să vă placă și

- Reynold's Experiment Lab ReportDocument10 paginiReynold's Experiment Lab ReportCristen Alvarez100% (2)

- Oce421 Lect19Document20 paginiOce421 Lect19Nyi NyiÎncă nu există evaluări

- Modeling and Analysis of Hybrid Solar Water Desalination System For Different Scenarios in IndonesiaDocument17 paginiModeling and Analysis of Hybrid Solar Water Desalination System For Different Scenarios in IndonesiagiovanaÎncă nu există evaluări

- Unesco - Eolss Sample ChaptersDocument14 paginiUnesco - Eolss Sample ChaptersAl Musabbir LeeonÎncă nu există evaluări

- Enhancing The Performance of A Solar Driven Hybrid Solar StillDocument15 paginiEnhancing The Performance of A Solar Driven Hybrid Solar StillMohammad AkramÎncă nu există evaluări

- Desalination of WaterDocument13 paginiDesalination of WaterRAJANÎncă nu există evaluări

- Desalination by Renewable Energy: A Mini Review of The Recent PatentsDocument11 paginiDesalination by Renewable Energy: A Mini Review of The Recent PatentsAriel SialongoÎncă nu există evaluări

- Desalination in Arid LandsDocument48 paginiDesalination in Arid LandsHassanKMÎncă nu există evaluări

- Cost-Effective Seawater Purification System Using Solar PhotovoltaicDocument4 paginiCost-Effective Seawater Purification System Using Solar PhotovoltaicTajbia HossainÎncă nu există evaluări

- DRM Clima2012 Fcul 1 2jun2012Document7 paginiDRM Clima2012 Fcul 1 2jun2012Rita SousaÎncă nu există evaluări

- 1 s2.0 S0011916421003556 MainDocument9 pagini1 s2.0 S0011916421003556 Mainagus sutiawanÎncă nu există evaluări

- Flux Enhancement of RO Desalination ProcessesDocument5 paginiFlux Enhancement of RO Desalination ProcessesMohammed A. HelalÎncă nu există evaluări

- HumidityDocument18 paginiHumiditycinemastar2024Încă nu există evaluări

- A Review of Solar Thermal Energy Driven MembraneDocument17 paginiA Review of Solar Thermal Energy Driven MembraneputriÎncă nu există evaluări

- Sea Water DesalinationDocument7 paginiSea Water DesalinationBrianÎncă nu există evaluări

- Ch2+OPTIMIZATION OF CONCENTRIC-TUBULAR CPC WATER DESALINATION SYSTEM WITH PAHSE CHANGE MATERIALDocument43 paginiCh2+OPTIMIZATION OF CONCENTRIC-TUBULAR CPC WATER DESALINATION SYSTEM WITH PAHSE CHANGE MATERIALEmoo jazzÎncă nu există evaluări

- Energy Recovery in The Water & Waste Water Industry Using Micro-Hydropower: A ReviewDocument7 paginiEnergy Recovery in The Water & Waste Water Industry Using Micro-Hydropower: A ReviewjamesÎncă nu există evaluări

- Sustaining Water Resources: Environmental and Economic ImpactDocument18 paginiSustaining Water Resources: Environmental and Economic ImpactSOPHIAÎncă nu există evaluări

- 2014 EGYPT HDH 1-s2.0-S001191641400109X-mainDocument11 pagini2014 EGYPT HDH 1-s2.0-S001191641400109X-mainAicha Chorak Franky TissoukiÎncă nu există evaluări

- Optimization of Seawater RO Systems Design: DesalinationDocument8 paginiOptimization of Seawater RO Systems Design: DesalinationRavi PrasadÎncă nu există evaluări

- Living With Dams Managing The Environmental ImpactsDocument20 paginiLiving With Dams Managing The Environmental ImpactsauliaÎncă nu există evaluări

- Enhanced Solar Evaporation Using A Photo-Thermal Umbrella: Towards Zero Liquid Discharge Wastewater ManagementDocument26 paginiEnhanced Solar Evaporation Using A Photo-Thermal Umbrella: Towards Zero Liquid Discharge Wastewater Managementgovinda reddyÎncă nu există evaluări

- 2 EnergyDocument12 pagini2 Energymohammad aboaıshaÎncă nu există evaluări

- Desalination: Keirrstian Roque C. AlvaradoDocument8 paginiDesalination: Keirrstian Roque C. AlvaradoJuvelyn DaculaÎncă nu există evaluări

- Desalination: Keirrstian Roque C. AlvaradoDocument8 paginiDesalination: Keirrstian Roque C. AlvaradoJuvelyn DaculaÎncă nu există evaluări

- Flow Energy Analysis of Reverse Osmosis Unit in Seawater Desalination Plant With Energy Recovery DeviceDocument8 paginiFlow Energy Analysis of Reverse Osmosis Unit in Seawater Desalination Plant With Energy Recovery DeviceIJAR JOURNALÎncă nu există evaluări

- HDH Desalination PDFDocument20 paginiHDH Desalination PDFDianita Citra Dewi100% (1)

- Dow Chemical. Materials Science Contributions To Membrane ProductionDocument39 paginiDow Chemical. Materials Science Contributions To Membrane ProductionJafar EhsaniÎncă nu există evaluări

- Energy Efficient Reverse Osmosis Desalination Process: Reza Dashtpour and Sarim N. Al-ZubaidyDocument7 paginiEnergy Efficient Reverse Osmosis Desalination Process: Reza Dashtpour and Sarim N. Al-ZubaidyRavi PrasadÎncă nu există evaluări

- Comparison Between Energy and Exergy Efficiencies in A Weir TypeDocument9 paginiComparison Between Energy and Exergy Efficiencies in A Weir TypeLizeth RuizÎncă nu există evaluări

- Aquavoltaics Synergies For Dual Use of WDocument30 paginiAquavoltaics Synergies For Dual Use of Wshinta theresiaÎncă nu există evaluări

- Water and Wastewater Minimization in Dairy Plants Using Water Pinch TechnologyDocument9 paginiWater and Wastewater Minimization in Dairy Plants Using Water Pinch TechnologykrazylionÎncă nu există evaluări

- Economic and Technical Analysis of Reverse OsmosisDocument13 paginiEconomic and Technical Analysis of Reverse OsmosisYoussefÎncă nu există evaluări

- Water DesalinatorDocument34 paginiWater DesalinatorFour WheelsÎncă nu există evaluări

- CCRO Pilot Recover Concentrate Potable Reuse Ad 45 D03759 enDocument14 paginiCCRO Pilot Recover Concentrate Potable Reuse Ad 45 D03759 enAbraham GarciaÎncă nu există evaluări

- Qu 2017 IOP Conf. Ser. Earth Environ. Sci. 67 012028Document8 paginiQu 2017 IOP Conf. Ser. Earth Environ. Sci. 67 012028parma coolÎncă nu există evaluări

- UAE's Water Problem: Why Waste, Waste Water?Document4 paginiUAE's Water Problem: Why Waste, Waste Water?Sara MostofiÎncă nu există evaluări

- Null DikonversiDocument17 paginiNull DikonversiBayu PratamaÎncă nu există evaluări

- Novel Design and Modeling of A Photovoltaic Hydro Electromagnetic Reverse Osmosis (PV-HEMRO) Desalination SystemDocument7 paginiNovel Design and Modeling of A Photovoltaic Hydro Electromagnetic Reverse Osmosis (PV-HEMRO) Desalination Systemali shahrouzianÎncă nu există evaluări

- Jurnal Desalinasi BasingDocument4 paginiJurnal Desalinasi BasingAlika Rara OkalistaÎncă nu există evaluări

- Wind Power Reduces Environmental Impacts of Desalination PlantsDocument1 paginăWind Power Reduces Environmental Impacts of Desalination PlantsAndreea FieraruÎncă nu există evaluări

- Articulo 16Document9 paginiArticulo 16CAMILO LINDARTEÎncă nu există evaluări

- Energy Consumption, GHG Emission, and Cost of Seawater Desalination in ChinaDocument16 paginiEnergy Consumption, GHG Emission, and Cost of Seawater Desalination in ChinaAquaEnergyMexÎncă nu există evaluări

- Water Climate and EnergyDocument5 paginiWater Climate and EnergyInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- Design and Evaluation of A Novel Ultrasonic Desalination System by Response Surface MethodologyDocument13 paginiDesign and Evaluation of A Novel Ultrasonic Desalination System by Response Surface Methodologypranavparamesh2004Încă nu există evaluări

- AgrivoltaicosDocument9 paginiAgrivoltaicosCARLOSÎncă nu există evaluări

- Desalination: SciencedirectDocument12 paginiDesalination: Sciencedirectarna silmaÎncă nu există evaluări

- Seawater Desalination Power ConsumptionDocument17 paginiSeawater Desalination Power ConsumptionPulkit GururaniÎncă nu există evaluări

- 1 s2.0 S2212371717300744 MainextDocument9 pagini1 s2.0 S2212371717300744 MainextHisham Bin TabassumÎncă nu există evaluări

- Water 07 01149Document15 paginiWater 07 01149Reed FisherÎncă nu există evaluări

- Alternative Solids Removal For Warm Water Recirculating RaftDocument10 paginiAlternative Solids Removal For Warm Water Recirculating RaftJesus Jimenez SaenzÎncă nu există evaluări

- Solar DistillDocument7 paginiSolar DistillPUBG SORRYÎncă nu există evaluări

- 1 s2.0 S2095311913605535 MainDocument7 pagini1 s2.0 S2095311913605535 MainAshutosh ChowdhuryÎncă nu există evaluări

- Lowcost Biofilters PDFDocument11 paginiLowcost Biofilters PDFOndos SaragihÎncă nu există evaluări

- S I W M S K: Ustainable Ntegrated Ater Anagement Tate of The NowledgeDocument19 paginiS I W M S K: Ustainable Ntegrated Ater Anagement Tate of The NowledgeMashaelÎncă nu există evaluări

- Comparing The Life Cycle Energy ConsumptDocument21 paginiComparing The Life Cycle Energy ConsumptOzPaper HelpÎncă nu există evaluări

- Research Report: The New Era of Water Resources Management: From "Dry" To "Wet" Water SavingsDocument23 paginiResearch Report: The New Era of Water Resources Management: From "Dry" To "Wet" Water SavingsauprscribdÎncă nu există evaluări

- Minimum Produced Water From Oil Wells With Water-Coning Control and Water-Loop InstallationsDocument18 paginiMinimum Produced Water From Oil Wells With Water-Coning Control and Water-Loop InstallationsAndré RochaÎncă nu există evaluări

- A Review of Membrane Processes and Renewable Energies For DesalinationDocument18 paginiA Review of Membrane Processes and Renewable Energies For DesalinationThipsuree KornboonraksaÎncă nu există evaluări

- SWRO Energy CunsumptionDocument16 paginiSWRO Energy CunsumptionmorjafÎncă nu există evaluări

- Desalination CounterplansDocument67 paginiDesalination CounterplansscolarokÎncă nu există evaluări

- Ecohydrology: Vegetation Function, Water and Resource ManagementDe la EverandEcohydrology: Vegetation Function, Water and Resource ManagementÎncă nu există evaluări

- Me6301 Engineering Thermodynamics - Uq - May June 2016Document4 paginiMe6301 Engineering Thermodynamics - Uq - May June 2016BIBIN CHIDAMBARANATHANÎncă nu există evaluări

- Argos Sequencing Batch Reactor: Aire-O Triton Aerator(s)Document2 paginiArgos Sequencing Batch Reactor: Aire-O Triton Aerator(s)Al Patrick Dela CalzadaÎncă nu există evaluări

- Wing Simulation in The Comsol 20-01-2015Document68 paginiWing Simulation in The Comsol 20-01-2015AndrijaMAÎncă nu există evaluări

- Temperature Distribution in Aluminum Extrusion BilletsDocument28 paginiTemperature Distribution in Aluminum Extrusion BilletsrobadvancedautomatioÎncă nu există evaluări

- The Kinetics of Gasification and Reactor TheoryDocument12 paginiThe Kinetics of Gasification and Reactor TheoryJose Luiz QueirozÎncă nu există evaluări

- LUNARIA FR 32 - 46 - 68 - 100 - 150: ApplicationsDocument1 paginăLUNARIA FR 32 - 46 - 68 - 100 - 150: Applicationsjean-sebastien CordierÎncă nu există evaluări

- Wastewater Constituents: Instructor DR Sher Jamal KhanDocument23 paginiWastewater Constituents: Instructor DR Sher Jamal KhanZahid FarooqÎncă nu există evaluări

- Acn PDFDocument2 paginiAcn PDFMarnel Roy MayorÎncă nu există evaluări

- Double PipeDocument8 paginiDouble PipeGURUDATT H MÎncă nu există evaluări

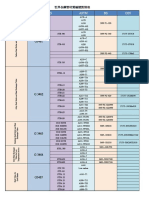

- 世界鋼管材質對照表Document2 pagini世界鋼管材質對照表ChunJung ChenÎncă nu există evaluări

- Q8 Heller 22 - Pds - HVLP - En.Document1 paginăQ8 Heller 22 - Pds - HVLP - En.MaxÎncă nu există evaluări

- Dupont Vespel Cr-6100: Application and Installation Guide For Centrifugal Pump Stationary Wear PartsDocument12 paginiDupont Vespel Cr-6100: Application and Installation Guide For Centrifugal Pump Stationary Wear PartsMagali OsorioÎncă nu există evaluări

- Lubrication, BearingDocument25 paginiLubrication, Bearinggaurav tiwariÎncă nu există evaluări

- Duct Sizing - Circular DuctDocument18 paginiDuct Sizing - Circular DuctbalaÎncă nu există evaluări

- CS2500Document528 paginiCS2500David Muñoz CastroÎncă nu există evaluări

- Directional Variation of Permeabiltiy: V H V HDocument7 paginiDirectional Variation of Permeabiltiy: V H V HLorraine TalattadÎncă nu există evaluări

- Rajiv Gandhi University of Knowledge Technologies (RGUKT), Hyderabad B.tech Chemical Engineering PDFDocument24 paginiRajiv Gandhi University of Knowledge Technologies (RGUKT), Hyderabad B.tech Chemical Engineering PDFAxit PatelÎncă nu există evaluări

- Impact of Flowfield-Radiation Coupling On AeroheatingDocument11 paginiImpact of Flowfield-Radiation Coupling On Aeroheatingmiquelbs2001Încă nu există evaluări

- Charging Kit - PCMDocument2 paginiCharging Kit - PCMSrikanth ReddyÎncă nu există evaluări

- (Kim Et Al., 2017)Document74 pagini(Kim Et Al., 2017)Gabriel DiazÎncă nu există evaluări

- Prasad 2017 IOP Conf. Ser.3A Mater. Sci. Eng. 197 012076Document8 paginiPrasad 2017 IOP Conf. Ser.3A Mater. Sci. Eng. 197 012076Shah TufailÎncă nu există evaluări

- GPD Ultra FiltrationDocument9 paginiGPD Ultra FiltrationArfeen HussainÎncă nu există evaluări

- How To Calculate External Static Pressure in HVACDocument4 paginiHow To Calculate External Static Pressure in HVACEntertain EveryoneÎncă nu există evaluări

- Ep CorDocument3 paginiEp CorNathanÎncă nu există evaluări

- Module VI - ME205Document20 paginiModule VI - ME205Hari650Încă nu există evaluări

- Plastic Pipe: For Drainage & Pressure ApplicationsDocument20 paginiPlastic Pipe: For Drainage & Pressure Applicationsrasputin0780803494Încă nu există evaluări

- Wind Tunnel Velocity Profiles Generated by Differentially-Spaced Flat PlatesDocument10 paginiWind Tunnel Velocity Profiles Generated by Differentially-Spaced Flat PlatesMario AlemanÎncă nu există evaluări

- Flutec High Pressure Ball ValveDocument2 paginiFlutec High Pressure Ball ValvefahazumeeÎncă nu există evaluări