Documente Academic

Documente Profesional

Documente Cultură

Juvinall Eqs Ch16

Încărcat de

Hiresomannavar MahanteshDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Juvinall Eqs Ch16

Încărcat de

Hiresomannavar MahanteshDrepturi de autor:

Formate disponibile

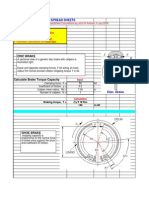

Chapter 16 Equations

Circular pitch of the gear (or pinion) in a plane normal to the teeth pn p cos tan n tan cos Diametral pitch in normal plane Pn P /cos Diameter of a helical gear (at pitch circle) d N / P N /(Pn cos ) Axial pitch pa p /tan Ne N /cos3 Transmitted force (English) Transmitted force (SI) Radial force component Fr Ft tan Axial force component Fa Ft tan Transverse normal force component Fb Ft /cos Helical-gear tooth force F Fb /cos n Ft /cos cos n Gear-tooth-bending stress (rened Lewis equation) Ft P Kv Ko(0.93Km) bJ (16.11) (16.10) (16.9) (16.8) . Ft 33,000W /V . Ft W /V (16.5) (16.6) (16.7) (16.7a) Equivalent number of teeth (formative or virtual number of teeth) (16.4) (16.3) (16.1) (16.2) Tangent of pressure angle measured in a plane normal to the teeth

Gear fatigue strength

(16.12)

CLCG CS kr kt kms Sn S n Surface (Hertz) fatigue stress cos K K (0.93K ) bd I 0.95 CR Ft

v o m p

(15.18)

H C p

(16.13)

(Chapter 16 Equations Continued)

Gear-tooth surface fatigue strength SH SfeCLiCR Shaft angle of crossed helical gears 1 2 Virtual number of teeth for pinion and gear (bevel gears) Np 2rbp p and N g 2rbg p (16.15) (16.14) (15.25)

Virtual number of teeth for pinion and gear (bevel gears) 2rbg P Np 2rbp P and N g Gear ratio Gear ratio Limit on face width b L 10 and b P 3 (L is dened in Figure 16.9) (16.17) p Ng d g tan g cot p g Np dp (16.16) (16.15a)

Average bevel gear diameter (feet) dav d b sin Average velocity (feet per minute) Vav davn Transmitted force (lb) . Ft 33,000W /Vav Vav davn Transmitted force (newtons) Bevel gear tooth force F Ft /cos Normal force (to pitch cone) component Fn F sin Ft tan Axial force component Fa Fn sin Ft tan sin (16.22) (f ) (16.21) . Ft W /Vav (16.19a) (16.18)

(16.20a) (16.19b)

Average velocity (meters per second)

(16.20b)

(Chapter 16 Equations Continued)

Radial force component Fr Fn cos Ft tan cos Axial force component (spiral bevel gear) Fa Ft (tan n sin sin cos ) cos Ft (tan n cos sin sin ) cos Ft P Kv Ko Km bJ (16.24) (16.23)

Radial force component (spiral bevel gear) Fr (16.25)

Bevel gear-tooth-bending stress

(15.17)

Bevel gear-tooth surface fatigue strength

H C p

Pitch diameter of worm gear

bd I K K K

Ft

v o p

(15.24)

dg N g p / Velocity ratio of worm gear set w Ng g Nw Guideline for worm gear set design Nw Ng 40 c 0.875 c 0.875 dw 3.0 1.7 Minimum diameter for shell worm dw 2.4p 1.1 (in.) Guideline for gear face width design b 0.5dw,out Worm lead angle tan L / dw Tangential force on worm gear Fgt Fwa Fn cos n cos f Fn sin

(15.2, modied)

(16.26)

(16.27)

Guideline for maximum power-transmitting capacity of worm gear set (16.28)

(16.29) (16.30)

(10.1, modied) (g)

(Chapter 16 Equations Continued)

Tangential force on worm Fwt Fga Fn cos n sin f Fn cos Radial force on gear Fgr Fwr Fn sin n Ratio of tangential velocity of gear to tangential velocity of worm Vg / Vw tan Efciency of worm gear set e Sliding velocity Vs Vw /cos Vg /sin Worm gear set coefcient of friction condition for self-locking f cos n tan Dynamic load Fd Fgt Kv Fgt 1200 Vg 1200 (16.39) (16.36) (16.35) cos n f tan cos n f cot (16.34) (16.33) (i) (h)

Maximum allowable value of dynamic load (bending fatigue) Fs Sn bpy Maximum allowable value of dynamic load (surface fatigue) Fw dg bKw Rate of heat dissipation H CA(to ta) External area of conventional worm gear housing A 0.3c 1.7 (16.42) (13.13) (16.41) (16.40)

S-ar putea să vă placă și

- Engineering Vibroacoustic Analysis: Methods and ApplicationsDe la EverandEngineering Vibroacoustic Analysis: Methods and ApplicationsStephen A. HambricÎncă nu există evaluări

- Machine Design 2013Document44 paginiMachine Design 2013cooLkiD1412Încă nu există evaluări

- Case Study 14Document20 paginiCase Study 14Mohammad GalalÎncă nu există evaluări

- Problem #M5: Gear Kinematics:: Solution of The Machine Design-II ProblemsDocument5 paginiProblem #M5: Gear Kinematics:: Solution of The Machine Design-II ProblemsrheyÎncă nu există evaluări

- Solution Machine DesignDocument9 paginiSolution Machine DesignRaDaCa CabsÎncă nu există evaluări

- Belt Conveyor CalcsDocument3 paginiBelt Conveyor Calcsjnmanivannan100% (4)

- Vibration Analysis of Rotating MachineryDocument20 paginiVibration Analysis of Rotating MachineryFranjo ZovkoÎncă nu există evaluări

- Powering CalculationDocument11 paginiPowering CalculationIbrahim SameirÎncă nu există evaluări

- List of Symbols - 2009 - Railway Noise and VibrationDocument7 paginiList of Symbols - 2009 - Railway Noise and VibrationmcnortyÎncă nu există evaluări

- Machine Design IIDocument11 paginiMachine Design IIExequiel MedinaÎncă nu există evaluări

- The Influence of Pressure Angle of Spur Gears On Bending Stress Considering The Effect of Root Fillet RadiusDocument11 paginiThe Influence of Pressure Angle of Spur Gears On Bending Stress Considering The Effect of Root Fillet RadiushaceneÎncă nu există evaluări

- Qprop TheoryDocument14 paginiQprop TheoryLow CmÎncă nu există evaluări

- 17 BeltDrivesDocument41 pagini17 BeltDrivesmohammedelyoussefÎncă nu există evaluări

- Camshaft Precision Color, Florian Ion PETRESCUDocument88 paginiCamshaft Precision Color, Florian Ion PETRESCUPetrescu FlorianÎncă nu există evaluări

- Bevel GearDocument28 paginiBevel Gearmahesh kitturÎncă nu există evaluări

- Core Points - BLOCK1Document20 paginiCore Points - BLOCK1icedgoblinÎncă nu există evaluări

- For The First Shaft:: Torque RadiusDocument10 paginiFor The First Shaft:: Torque RadiusHammadÎncă nu există evaluări

- Belt Conveyor CalcsDocument3 paginiBelt Conveyor Calcspandu_chemengÎncă nu există evaluări

- ASME Code Case 2901Document2 paginiASME Code Case 2901sudokuÎncă nu există evaluări

- Belt Conveyor CalcsDocument3 paginiBelt Conveyor Calcswidyaditya8Încă nu există evaluări

- Brake Long Shoe EngDocument22 paginiBrake Long Shoe Eng07 Aprinaldo JennerÎncă nu există evaluări

- Dynamic Analysis of Slider Crank MechanismsDocument14 paginiDynamic Analysis of Slider Crank MechanismssenthilÎncă nu există evaluări

- NGR SizingDocument14 paginiNGR SizingSibolis Naburju0% (1)

- 76-4-Worm GearDocument7 pagini76-4-Worm Gearrip111176Încă nu există evaluări

- MD 2 (Me 424) FormulasDocument14 paginiMD 2 (Me 424) FormulasLancePacioÎncă nu există evaluări

- Trunnion Calculation SheetDocument3 paginiTrunnion Calculation SheetRafael SequeiraÎncă nu există evaluări

- Solution Machine DesignDocument9 paginiSolution Machine DesignRheymar MercadoÎncă nu există evaluări

- BevelDocument20 paginiBevelOmer NadeemÎncă nu există evaluări

- Machine Design: Bs Mechanical EngineeringDocument24 paginiMachine Design: Bs Mechanical EngineeringManilyn TumalaÎncă nu există evaluări

- Horizontal Alignment IDocument31 paginiHorizontal Alignment IAravind KumarÎncă nu există evaluări

- Milling - Cutting Data: Nomenclature and FormulaDocument1 paginăMilling - Cutting Data: Nomenclature and Formulastanalina00Încă nu există evaluări

- 198 PDFDocument1 pagină198 PDFstanalina00Încă nu există evaluări

- 198 PDFDocument1 pagină198 PDFJose Erley MTÎncă nu există evaluări

- Chapter 15 Spur Gears: Figure 15.1 (P. 591)Document28 paginiChapter 15 Spur Gears: Figure 15.1 (P. 591)vab88100% (1)

- Unit 1 Module 2 PDFDocument26 paginiUnit 1 Module 2 PDFKaradam Patel0% (1)

- Hydraulics and Water Resources (CEE 340) (Topic 2) : TurbineDocument12 paginiHydraulics and Water Resources (CEE 340) (Topic 2) : TurbineRachel YarasavichÎncă nu există evaluări

- White - 6th Ed - 3.54 PDFDocument1 paginăWhite - 6th Ed - 3.54 PDFMhwae Mhwae Kyaing KyaingÎncă nu există evaluări

- Ee 212 Ac Induction MotorsDocument9 paginiEe 212 Ac Induction MotorsabigabacÎncă nu există evaluări

- Brake Design and CalculationDocument2 paginiBrake Design and CalculationDavid Lambert89% (9)

- At 1500 RPM, A Motor Develops 3.6 LB-FT of Torque Per HPDocument4 paginiAt 1500 RPM, A Motor Develops 3.6 LB-FT of Torque Per HPkotireddybÎncă nu există evaluări

- Bearing Load CalculationDocument9 paginiBearing Load CalculationRakesh Nair AÎncă nu există evaluări

- Mark Z. Jacobson Department of Civil & Environmental Engineering Stanford University Stanford, CA 94305-4020 Jacobson@stanford - EduDocument50 paginiMark Z. Jacobson Department of Civil & Environmental Engineering Stanford University Stanford, CA 94305-4020 Jacobson@stanford - Eduataro91Încă nu există evaluări

- 5.1 Model of Synchronously Averaged VibrationDocument46 pagini5.1 Model of Synchronously Averaged VibrationmghgolÎncă nu există evaluări

- Lecture05 P1Document18 paginiLecture05 P1Cao Gia BảoÎncă nu există evaluări

- Hss Beam End Reaction (13 Edition) : W, Kip/ftDocument2 paginiHss Beam End Reaction (13 Edition) : W, Kip/ftrajedmaglinteÎncă nu există evaluări

- Roller Chain: 0: Chain of Usual Proportion 1: Light Weight Chain 5: Roller Less Chain: Replacement Chain PitchDocument12 paginiRoller Chain: 0: Chain of Usual Proportion 1: Light Weight Chain 5: Roller Less Chain: Replacement Chain PitchCarl Kristopher PeloniaÎncă nu există evaluări

- Butler Presentation PDFDocument25 paginiButler Presentation PDFMuhammad Mazharul IslamÎncă nu există evaluări

- - Published on 16 Sep 15: ANSWER: Blade loading coefficient (Ψ) decreasesDocument7 pagini- Published on 16 Sep 15: ANSWER: Blade loading coefficient (Ψ) decreasesSaurabh ChaudhariÎncă nu există evaluări

- Beam To Beam Web - Shear ConnectionDocument2 paginiBeam To Beam Web - Shear ConnectionGautam SharmaÎncă nu există evaluări

- 22 PDFDocument25 pagini22 PDFgavin kennedyÎncă nu există evaluări

- FormulasDocument18 paginiFormulasElisif DeFairÎncă nu există evaluări

- Structural Analysis Chapter 1Document129 paginiStructural Analysis Chapter 1dash1991Încă nu există evaluări

- A New Trackdesign For Safer Greyhound RacingDocument10 paginiA New Trackdesign For Safer Greyhound RacingJadeÎncă nu există evaluări

- Gears Types: Example: Car Differential Example: Car DifferentialDocument11 paginiGears Types: Example: Car Differential Example: Car DifferentialAmal RadhakrishnanÎncă nu există evaluări

- Saddle 4Document2 paginiSaddle 4RUDHRA DHANASEKARÎncă nu există evaluări

- Compound Epicyclic Gear TrainsDocument5 paginiCompound Epicyclic Gear TrainsSezgin BayrakÎncă nu există evaluări

- Slab On Grade DesignDocument1 paginăSlab On Grade DesignManoj JaiswalÎncă nu există evaluări

- Tunnel Field-effect Transistors (TFET): Modelling and SimulationDe la EverandTunnel Field-effect Transistors (TFET): Modelling and SimulationÎncă nu există evaluări

- Roller Bearing Supported Mills FINAL LRDocument8 paginiRoller Bearing Supported Mills FINAL LRHiresomannavar MahanteshÎncă nu există evaluări

- 12 Pages Book LetDocument12 pagini12 Pages Book LetHiresomannavar MahanteshÎncă nu există evaluări

- Chapter 15: Helical, Bevel and Worm Gears: The Main Object of Science Is The Freedom and Happiness of ManDocument32 paginiChapter 15: Helical, Bevel and Worm Gears: The Main Object of Science Is The Freedom and Happiness of ManHiresomannavar MahanteshÎncă nu există evaluări

- BwiDocument8 paginiBwiHiresomannavar MahanteshÎncă nu există evaluări

- OK Vertical Roller MillDocument8 paginiOK Vertical Roller MillHiresomannavar Mahantesh100% (2)

- OK Vertical Roller MillDocument8 paginiOK Vertical Roller MillHiresomannavar Mahantesh100% (2)

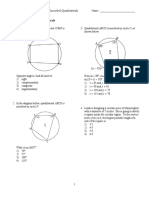

- Class 10 Maths Previous Year Solved PapersDocument121 paginiClass 10 Maths Previous Year Solved Papersjaswanthbalu2006Încă nu există evaluări

- Stage 8 Paper 1 2024Document14 paginiStage 8 Paper 1 2024tayoakere3100% (3)

- 01a Igcse Maths 4ma1 1fr November 2020 Examination PaperDocument24 pagini01a Igcse Maths 4ma1 1fr November 2020 Examination PaperMaedot HaddisÎncă nu există evaluări

- Chap3.3 HexCrystal DirectionsDocument6 paginiChap3.3 HexCrystal DirectionsJeonghun LeeÎncă nu există evaluări

- Geometry Chapter 6 WorksheetsDocument6 paginiGeometry Chapter 6 Worksheetsapi-3067202130% (1)

- Tracing Shapes BookletDocument9 paginiTracing Shapes Bookletnorshahidah5348Încă nu există evaluări

- Math8 Q4 SLM WK4Document11 paginiMath8 Q4 SLM WK4Juvelyn Teves MunalemÎncă nu există evaluări

- Connections Joints ADAMSDocument8 paginiConnections Joints ADAMSSantiago MolinaÎncă nu există evaluări

- Soalan Pat Tingkatan 1 2019 EditDocument24 paginiSoalan Pat Tingkatan 1 2019 Edithafiezphoto companyÎncă nu există evaluări

- Group 6: Submitted To: Ma'Am Karen PaduaDocument11 paginiGroup 6: Submitted To: Ma'Am Karen PaduaRolly Fallorina SenangeloÎncă nu există evaluări

- GMAT Quantitative Summary NotesDocument52 paginiGMAT Quantitative Summary Notes908yhjknÎncă nu există evaluări

- Space, Number, and Geometry: From Helmholtz To CassirerDocument258 paginiSpace, Number, and Geometry: From Helmholtz To CassirerJuan Felipe Bravo100% (3)

- G C A 3 InscribedQuadrilateralsDocument3 paginiG C A 3 InscribedQuadrilateralsLala JafarovaÎncă nu există evaluări

- Class 9 MCQ QUADRILATERALSDocument4 paginiClass 9 MCQ QUADRILATERALSRakeshÎncă nu există evaluări

- CBSE Class 5 Mathematics Worksheet - Area and PerimeterDocument5 paginiCBSE Class 5 Mathematics Worksheet - Area and PerimeterShilpi Sandeep Trips67% (18)

- Trigonometry & Solid Mensuration - SolutionDocument34 paginiTrigonometry & Solid Mensuration - SolutionLudy Dela Cruz89% (9)

- Trig Identities and Ratio Wts PDFDocument9 paginiTrig Identities and Ratio Wts PDFAshwin JambhulkarÎncă nu există evaluări

- 154 Top Theory of Machines MCQDocument26 pagini154 Top Theory of Machines MCQRajpalsinh JadejaÎncă nu există evaluări

- Solid State 1 B TechDocument54 paginiSolid State 1 B TechIshan MahtoÎncă nu există evaluări

- Worksheet Pack Constructions Triangles and HexagonsDocument5 paginiWorksheet Pack Constructions Triangles and HexagonsMahboob RiazÎncă nu există evaluări

- MATH 8 SLHT, Q3, Wk3&4 M8GE-IIId-1 & M8GE-IIId-e-1Document12 paginiMATH 8 SLHT, Q3, Wk3&4 M8GE-IIId-1 & M8GE-IIId-e-1Zia Belle Bedro - Luardo100% (1)

- 6 - 4 Triangle Inequalities - NEW - NotesDocument2 pagini6 - 4 Triangle Inequalities - NEW - NotesPrincess Tin PalerÎncă nu există evaluări

- Gen Ed Math 2 PnuDocument62 paginiGen Ed Math 2 PnuFobe Lpt NudaloÎncă nu există evaluări

- The Identification of Lattice PlanesDocument4 paginiThe Identification of Lattice PlanesMahr UdiÎncă nu există evaluări

- Math 4 - Quarter 4 Week 2 Module 2Document17 paginiMath 4 - Quarter 4 Week 2 Module 2Mm NoonaÎncă nu există evaluări

- LeaP - Math 5 Week 3 Q3Document9 paginiLeaP - Math 5 Week 3 Q3Roel SaturosÎncă nu există evaluări

- ParabolaDocument3 paginiParabolaSuresh ChÎncă nu există evaluări

- Arc To Chord RatioDocument3 paginiArc To Chord RatioReza MohammadianÎncă nu există evaluări

- HC Verma Solutions Class 11 Chapter 2 - Physics and MathematicsDocument6 paginiHC Verma Solutions Class 11 Chapter 2 - Physics and Mathematicsbrarbalwinder047Încă nu există evaluări

- Triangle: (Classifying Triangles)Document15 paginiTriangle: (Classifying Triangles)Nezir M AliÎncă nu există evaluări