Documente Academic

Documente Profesional

Documente Cultură

Knowledge Tree July 2012

Încărcat de

Praveen K.RDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Knowledge Tree July 2012

Încărcat de

Praveen K.RDrepturi de autor:

Formate disponibile

Contents...

Volume5

Issue 7

July 2012

ditors Note 2

osters . 3

opic .5

echtoon .9

uzzle10

inners11

International

Friendship day

24th July

Civil Engineering Magazine

D

ear Readers

We are much obliged with

your responses and happy to be a part of

this initiative.

India is a land of agriculture & the work

force we use in the construction feld most-

ly originates from here.

In construction industry we have many is-

sues that creates bottle necks in achieving

required productivity & Quality.

Some of them are

- Un educated & Un trained work force

- Non availability of same person

throughout the duration of the project

We in L&T have taken up major initiatives

in training & developing the rural workers

through Construction skill training insti-

tutes ( CSTI ).

Still there is a large gap in the demand Vs

Supply of the qualifed work force.

This gap cannot be fulflled easily in the

near future.

Meanwhile our works are sufering in Qual-

ity & productivity.

In order to tackle this issue , we have to ana-

lyse the problem & frame a system to tackle

the issue now!

Our problem is in front of us we can ensure

the self regulation.

We don't have trained skilled or experi-

enced skilled work force.

Many sites have taken up the issue & estab-

lished screening , training & encouraging

mechanisms.

Even if the worker is trained at site in par-

ticular activity say concreting or masonry ,

there is no guarantee that he will continue

for considerable amount of time.

Hence the site engineers & supervisors job

is getting compounded day be day and he is

spending major portion of his time in con-

trolling the work force & rectifying the de-

fects they generated through the work.

It is established fact that Awareness is the

key to Improvement .

PT&D ICCivil Engineering department

believes in this concept & had initiated frst

of its kind step to bring in awareness in the

workers on continuous basis.

Series of posters on workmanship require-

ments were prepared in English , Hindi &

other vernacular languages. This efort is

frst of its kind in construction industry .

Several day to day activities are made in to

Posters and simple language is used to ex-

TSR Bangar Raj u

K.Satish Varma

plain along with appropriate pictures.

As pictures are worth a million words .,

this concept is the foundation for this de-

velopment. These posters were deployed in

pilot project sites of PT&D and that the

same was well received by staf and workers.

These posters are displayed at prominent

places especially in the assembly area and

work spots.

Along with this , the efectiveness could be

multifold if PEPTALK is included on the

work methods on daily basis.

Few minutes with the workers in the begin-

ning of every day can bring dramatic

change in their ability to transform to a pro-

ductive workforce.

We have experienced the power of pep talk

in many walks of our life , right from the as-

sembly sessions in our school to safety pep

talks at our work place.

Hence this can bring a change in workers

mindset & prompt them to adhere to our

standards as time passes by.

This brings in a silent revolution on work-

manship improvement , workers develop-

ment & thus Nation building.

Let us join this movement & bring a change

in our work place.

We call this silent transformationbe a

part of it.

The posters are uploaded in the EIP -Vidya

website. Click on the link given on page4

for accessing.

You can download the same & print it to A

Zero size fex Boards and display them

where needed & easily seen by all.

We invite your suggestions to improve the

content. Please write to us at

bangartsr@lntecc.com for improvisation.

In this month, we have detailed on the ac-

ceptance criteria of concrete in its real

sense.

We hope this topic will be of immense use

to Quality Engineers & to all.

We regret for the delay in publishing the

Knowledge TreeJuly Issue.

This month is having few important events.

1

st

July is observed as Doctors day in India .

24

th

July is observed as Guru Purnima

30

th

July is observed as International

Friendship Day.

Pep Talks

Awareness

generation

Click Here

to Down load

the posters

C

oncrete is a versatile material of the 21st

century. It can be molded in to any

shape or size and can be made to suit to

requirements.

With the same ingredients and varying proportion

we can obtain diferent concrete grades. The grades

of concrete is designated as M 20 or 25 or 30 Etc.

The M-stands for Mix & the remaining part

stands for the strength of the concrete in N/mm2.

Concrete is stronger in Compression & weaker in

Tensionit is a known fact to all. But the strength

is obtained in concrete with

Careful selection of ingredients

Carrying Mix design for fxing the propor-

tions to suit to the sources.

Following strict Quality control measures

during production.

Ensuring proper sampling techniques

Careful curing of the member

Several Quality control measures have to be taken

for ensuring good Product which satisfes the stand-

ards or specifcations of the project.

Diferent countries have diferent criteria's for ac-

cepting concrete.

In India we follow

1. IS 4562000 with Amendment3 for deciding

the acceptance of concrete.

2. Where specifcation demands we may have to

adopt those requirements. For example , for

railways Jobs we use RVNL(Rail Vikas Nigam

Limited ) specifcation criteria.

3. For National Highway / Road Jobs we use

MORTH ( Ministry of Road Transport & High-

ways ) specifcation.

Where as internationally many standard have their

own criteria's for the concrete acceptance.

British standard sets criteria in BS 8110 .

A

c

c

e

p

t

a

n

c

e

c

r

i

t

e

r

i

a

o

f

c

o

n

c

r

e

t

e

These criteria's are important in deciding the ac-

ceptability of concrete grade.

Many people believe & presume that when a cube is

failed the concrete is failed. But it is not so.

Many factors efects the concrete cube casting & the

subsequent test there on.

The following are the general issues that takes place

in concrete cube failure.

Inbuilt factors : ( Factors that afect concrete

quality & strength )

+ Incorrect selection of material for concrete use

+ Improper quality control mechanism adopted

for material tests.

+ Non adherence to Mix design requirements

+ Improper Batch plant which is out of calibration

& defective.

+ Un controlled addition of water

Factors that doesn't afect the concrete quality

but reduces the cube strength:

^ Sampling defects

^ Curing inadequacy of the cubes

^ Cube mould disfguring / out of size & Shape

^ Calibration defects of testing machine.

^ Technicians skill or training inadequacy

^ Incorrect placement of cubes in the machine &

loading defects

So Standard has set criteria for acceptance of con-

crete taking in to the above possible errors in to

consideration.

The errors that are inbuilt factors produce defective

concrete , where as for the other factors as men-

tioned above the concrete is not defective. But the

sampling , testing mechanism & methods are defec-

tive.

In order to know whether the concrete poured is

passing or failing the required grade we must not

rely on a single cube , rather on set of cubes that

represents the complete pour.

If one cube from a complete set gets less strength

than the required grade we must not label it as fail-

ure.

The following both criteria must be satisfed to ac-

cept the concrete grade.

Primarily the concrete can be accepted or rejected

based on the grade of it or as per Table2 of IS 456.

However to evaluate the concrete grade statistically

we must satisfy the following criteria from IS 456

2000section 16.1

A. The individual cube result shall not be less than

f

ck

3 N/mm

2

.

B. The average determined from any group of 4

consecutive non overlapping test results shall

not be less than f

ck

+3 N/mm

2

To understand better , let us consider the cube test

results of M25 grade concrete cast on a given day .

250 m

3

of concrete was cast at a site & 9 samples

were taken ( 3 specimens per sample )the results are

as given in the following table.

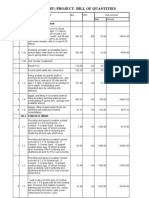

1. First check whether all the samples are having

strength more or equal to F

ck

In this case two

specimens found to have less than F

ck

value of 25

N/mm

2

.

Though the sample strength is less than specifed

grade ( 25 N/mm2 ) we cant reject the concrete

right away. But we need to verify the Acceptance

criteria per Section 16.1.

2. Second check whether the individual specimen

difers from average of the 3 specimens in the

sample. If there is a variation more than 15%

then that sample shall be rejected or not to be

taken in to consideration for acceptance criteria.

( it doesn't mean that the concrete representing

the sample is rejected )

3. Check whether any individual specimen is less

than F

ck

3. In our illustration, none of them are

less than the same.

4. Then arrange the samples ( average of 3 speci-

mens ) in groups of 4 ( with out using the same

sample again ).

5. Take the average of the 4 samples. (consecutive

non overlapping sample results ). Out of the ver-

ifcation , even if any one sample passes the F

ck

+3 requirement along with check on step4 ,

the concrete grade is accepted.

Final Result : As both the criteria's are met , the

grade is accepted.

For all the above purposes the frequency of concrete

cube casting as mentioned in IS 456Section 15.2.2

must be followed.

In case the frequency of sampling is not mentioned

in the specifcation or in tender , then the maxi-

mum concrete that 4 consecutive test results repre-

sents must be limited to 60m

3

.

This means when concrete is carried in small batch-

es , then to evaluate the grade of concrete , the total

quantity of all such concretes must not exceed

60m

3

. ( this concrete may be carried in same day or

in 2 or 3 days ).

In order to ensure that such low strength doesn't

arise , we need to check the sampling methods

adopted & correct them where necessary.

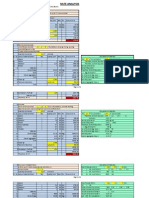

If the result doesn't satisfy the above requirements

27 4%

Sample -1 28 26.00 8%

23 -12%

29 1%

Sample -2 27 28.67 -6%

30 5%

28.42

29 -1%

Sample -3 30 29.33 2%

29 -1%

28 -6%

Sample -4 29 29.67 -2%

32 8%

30 7%

Sample -5 29 28.00 4%

25 -11%

25 -7%

Sample -6 29 27.00 7%

27 0%

28.83

29 -1%

Sample -7 29 29.33 -1%

30 2%

31 0%

Sample -8 33 31.00 6%

29 -6%

22 -21%

Sample -9 30 28.00 7%

32 14%

This result is higher

than 15% hence

invalid

Criteria -1

Mean of 4

consecutiv

e non

overlappin

g test

results >

25 + 3 =

28

No

individual

test

specimen

shall be

less than

25 - 3 = 22

Deviation

from Mean

Average

Mean of 4

consecutive

samples

Strength

in N/mm2

Sample results Evaluation

for Concrete

then further investigation need to be carried using

NDT techniques .

For the railway projects in India the acceptance

criteria is applied as below:

For the frst 5 sets

A. The average strength determined from any

group of the three consecutive test cubes ex-

ceeds the specifed characteristic strength +o.6X

current margin

B. Only one individual test cube in any set may be

below 0.95X specifed characteristic strength

After 5 sets

The average strength of any 15 consecutive cubes

exceeds the specifc characteristic cube strength +

0.9 X current margin

All the subsequent results are accepted if

A. The average strength of any group of three con-

secutive test cubes exceeds the specifed charac-

teristic strength + 0.6 X current margin.

B. Only one individual cube test result in any set

may fail below the specifed characteristic

strength provided that his value is not less than

0.9 X characteristic strength.

Current margin for all grades is 9.

As per MORTH specifcation , concrete grade is

accepted only when both the conditions are

met.

A. The mean strength determined from any group

of four consecutive samples exceed specifed

characteristic strength

B. Strength of any sample is not less than the speci-

fed characteristic compressive strength3 N/

mm

2

.

Across

3. CARRIED TO PROMOTE HYDRATION OF

CEMENT

5. VERSATILE MATERIAL IN CONSTRUC-

TION

8. ENSURES REPRESENTETIVE IS EQUAL

TO BULK

9. LOSING SHAPE OR SIZE

10. STANDS FOR M IN GRADE OF CON-

CRETE

Down

1. INHERENT CHARECTER OF THE MATE-

RIAL

2. ONE OF THE INGREDIENT IN CON-

CRETE THAT IS NON REACTIVE

4. NEEDED TO USE A MACHINE OR CARRY

A TEST

5. BINDING MATERIAL IN CONCRETE

6. NATIONAL HIGHWAY AUTHORITY OF

INDIA

7. CARRIED TO CHECK EQUIPMENTS AC-

CURACY/ DEPENDENCY

Find the

words

Mail to

bangartsr@lntecc.com

July

Jewel

Disclaimer : No part of this publication shall be reproduced without the written permission from the Editors. The views

expressed here need not be the views of the L&TConstruction . L&T doesn't take any responsibility of what so ever for the views expressed by the Editors / Authors. This is for the

S.Manikandan

S Ramya Sri

Sankaran

Roshan

G Anitha Nivashini

D Pavan

Choudary K

Rajith Kumar

K Praveen

Bharat T

Ujwal Kumar

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Examples For Ductile Detailing RCC BuildingsDocument72 paginiExamples For Ductile Detailing RCC BuildingsVaidyanathan SivasubramanianÎncă nu există evaluări

- Fly Ash Silica Fume in ConcreteDocument16 paginiFly Ash Silica Fume in ConcreteMax KopÎncă nu există evaluări

- C 5Document17 paginiC 5jjrelucio3748Încă nu există evaluări

- How To Execute A Post-Fire Rebuild PDFDocument2 paginiHow To Execute A Post-Fire Rebuild PDFPraveen K.RÎncă nu există evaluări

- Aniket Bhondve: ObjectiveDocument2 paginiAniket Bhondve: ObjectivePraveen K.RÎncă nu există evaluări

- Aniket Bhondve: ObjectiveDocument2 paginiAniket Bhondve: ObjectivePraveen K.RÎncă nu există evaluări

- Rate AnalysisDocument6 paginiRate AnalysisKrunal Joshi100% (1)

- TDS - Glenium Sky 504Document2 paginiTDS - Glenium Sky 504Praveen K.RÎncă nu există evaluări

- Rebar Steel RecievedDocument1 paginăRebar Steel RecievedPraveen K.RÎncă nu există evaluări

- Rate Analysis and Abstract BOQDocument37 paginiRate Analysis and Abstract BOQThota Revanth78% (41)

- SP-34-1987 Handbook On Reinforcement and DetailingDocument1 paginăSP-34-1987 Handbook On Reinforcement and DetailingPraveen K.RÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Wifer Quick Start Guide en NHA24030 00Document2 paginiWifer Quick Start Guide en NHA24030 00Jose Rene Salinas CantonÎncă nu există evaluări

- IS 2379 (1990) - Colour Code For Identification of Pipe Lines PDFDocument14 paginiIS 2379 (1990) - Colour Code For Identification of Pipe Lines PDFRajendar Reddy100% (1)

- Demagnetizing Coils BrochureDocument2 paginiDemagnetizing Coils BrochureVFUENTEALBA01Încă nu există evaluări

- UAN Routing PresentationDocument15 paginiUAN Routing PresentationmumerbuttÎncă nu există evaluări

- Mongolian Unicode Converter For Word (Extended)Document106 paginiMongolian Unicode Converter For Word (Extended)Shinekhuu990% (1)

- Chapter 2. - Activity Based Costing PPT Dec 2011Document5 paginiChapter 2. - Activity Based Costing PPT Dec 2011shemidaÎncă nu există evaluări

- CompactcvsDocument25 paginiCompactcvsanurag12345Încă nu există evaluări

- NEBOSH HSE Certificate in Process Safety Management - NEBOSHDocument8 paginiNEBOSH HSE Certificate in Process Safety Management - NEBOSHamra_41Încă nu există evaluări

- Pioneer pdp-503cmx Mxe PDFDocument167 paginiPioneer pdp-503cmx Mxe PDFTheojt100% (1)

- CIP-005 Pa - Stand - Reliability PDFDocument67 paginiCIP-005 Pa - Stand - Reliability PDFJoao MartinsÎncă nu există evaluări

- Man Edc7 c32Document12 paginiMan Edc7 c32Adam92% (13)

- Windows SecurityDocument136 paginiWindows SecuritymollaÎncă nu există evaluări

- ISAM ProtocolsDocument167 paginiISAM ProtocolsQuocKhanh PhạmÎncă nu există evaluări

- Now Sms 2011Document425 paginiNow Sms 2011Iguodala OwieÎncă nu există evaluări

- Allengers 325 RF - Installation and Service ManualDocument63 paginiAllengers 325 RF - Installation and Service Manualleopa7880% (20)

- Cs Fallback Brochure Final-NSNDocument4 paginiCs Fallback Brochure Final-NSNlouie mabiniÎncă nu există evaluări

- Reactjs TestingDocument35 paginiReactjs TestingAmit SharmaÎncă nu există evaluări

- SAAB Tank Rada G3 Service Manual Part 2Document30 paginiSAAB Tank Rada G3 Service Manual Part 2whitefreeizeÎncă nu există evaluări

- Calibration of Defibrillator Analyzer by Voltage Square MethodDocument8 paginiCalibration of Defibrillator Analyzer by Voltage Square MethodMIlham HafizÎncă nu există evaluări

- Asterisk + FreePBX + Raspberry Pi 2 VoIP Sip Server PDFDocument15 paginiAsterisk + FreePBX + Raspberry Pi 2 VoIP Sip Server PDFDAGNUXÎncă nu există evaluări

- Actuator MANDocument30 paginiActuator MANsinamicsÎncă nu există evaluări

- Solenoid Coils: Data SheetDocument23 paginiSolenoid Coils: Data SheetJohn BarrowÎncă nu există evaluări

- Veqaura (Meanua) Bible Papua New GuineaDocument52 paginiVeqaura (Meanua) Bible Papua New GuineaAsia BiblesÎncă nu există evaluări

- PDF Free Download Here Pdfsdocuments2com PDFDocument2 paginiPDF Free Download Here Pdfsdocuments2com PDFAngelo TabbayÎncă nu există evaluări

- Creating Security Standards - Context, Structure and Must-Have ContentDocument59 paginiCreating Security Standards - Context, Structure and Must-Have ContentBrayanÎncă nu există evaluări

- Lenel Prox LPSR-2400-GRMP/ BMP: ReaderDocument2 paginiLenel Prox LPSR-2400-GRMP/ BMP: ReaderDaniela OrozcoÎncă nu există evaluări

- Prodeco Genesis 500 Manual PRO.12V1.GEN .369.500Document44 paginiProdeco Genesis 500 Manual PRO.12V1.GEN .369.500danielÎncă nu există evaluări

- Concentric-Lay-Stranded Aluminum 1350 Conductors: Standard Specification ForDocument11 paginiConcentric-Lay-Stranded Aluminum 1350 Conductors: Standard Specification ForAlexis AguillonÎncă nu există evaluări

- Fire Protection and Safety FacilitiesDocument41 paginiFire Protection and Safety Facilitiesonur gunesÎncă nu există evaluări