Documente Academic

Documente Profesional

Documente Cultură

177R0369 MCD500 FactSheet 1310 Redesign

Încărcat de

Javier AffifDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

177R0369 MCD500 FactSheet 1310 Redesign

Încărcat de

Javier AffifDrepturi de autor:

Formate disponibile

MAKING MODERN LIVING POSSIBLE

VLT Soft Starter MCD 500

VLT Soft Starter MCD 500 is a total motor starting solution. Current transformers measure motor current and provide feedback for controlled motor ramp profiles.

The Adaptive Acceleration Control (AAC) automatically employs the best starting and stopping profile for the application. Adaptive Acceleration Control means, that for each start and stop, the soft starter compares and adapts the process to the chosen profile fitting to the application. The VLT Soft Starter MCD 500 has a four line graphical display and a logic keypad making programming easy. Advanced setup is possible displaying operational status. Three menu systems: Quick Menu, Application Setup and Main Menu provide optimum programming approach. Features AAC Adaptive Acceleration Control Adjustable bus bars allow for both top

Power range and bottom entry (360-1600 Amps, 215-1140 HP) DC injection braking distributed evenly over three phases

Benefits Automatically adapts to the chosen

starting and stopping profile retrofitting the motor

Space saving, less cable cost and easy Less installation cost and less stress on Smaller soft starter can be selected for

the application

21 1600 A, 10 - 1140 HP (1600 HP inside Delta Connection) Versions for 200 690 VAC

Inside Delta (6-wire connection) Log menus, 99 events and trip log Auto Reset Jog (slow-speed operation) Second-order thermal model

provide information on events, trips and performance

Eases analysis of the application Less down-time Application flexibility Allows motors to be used to their

Perfect

match for:

- Pumps - Fans - Compressors - Mixers - Conveyors - Centrifuges - Mills - Saws - and many more

Internal bypass contactors

(21215 A, 10 - 150 HP)

Auto-start/stop clock Compact size amongst the smallest

in their class

4-line graphical display Multiple programming setup

full potential without damage from overloading Saves space and wiring compared to external bypass Very little heat dissipates when running. Eliminates costly external fans, wiring or bypass contactors Application flexibility

(Standard Menu, Extended Menu, Quick Set)

Saves space in cabinets and other

application setups

Multiple languages Serving the whole world

Optimum programming approach and

setup for viewing operational status holding to maximum flexibility

Simplifies the programming, but still

www.danfossdrives.com

Specifications Specications

AAC Proles

Fully featured Soft Starter for motors up to 850 kW Fully featured Soft Starter for motors up to Total motor starting solution 1140 HP Advanced start, stop and protection Total motor starting solution features Adaptive Acceleration Control Advanced start, stop and protection Inside Delta connection features 4-line graphical display Adaptive Acceleration Control Multiple programming setup menus Inside Delta connection Optional: 4-line graphical display Modules for serial communication: Multiple programming setup menus DeviceNet Optional: Probus Modules for serial communication: Modbus RTU DeviceNet USB Profibus Remote operator kit Modbus PC software: RTU USB WinMaster MCT10 Remote operator kit PC software:

WinMaster MCT10

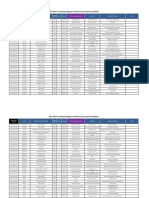

Supply Supply Mains voltage (L1, L2, L3) Mains voltage (L1, L2, L3) MCD5-xxxx-T5 200 VAC ~ 525 VAC ( 10%) MCD5-xxxx-T7 380 VAC ~ 690 VAC 10%) (earthed star supply system only) MCD5-xxxx-T5 200 VAC ~( 525 VAC ( 10%) MCD5-xxxx-T7 380 VAC ~ 600 VAC 10%) (inside delta connection) 380 VAC ~( 690 VAC ( 10%) MCD5-xxxx-T7 Control voltage (terminals A4, A5, A6) (earthed star supply system only) CV1 (A5, A6) 24 VAC/VDC 20%) MCD5-xxxx-T7 380 ( VAC ~ 600 VAC ( 10%) (inside delta connection) CV2 (A5, A6) 110~120 VAC (+ 10% / - 15%) Control voltage (terminals A4, A5, A6) CV2 (A4, A6) 220~240 VAC (+ 10% / - 15%) CV1 (A5, A6) Mains frequency 50/60 Hz24 VAC/VDC ( 20%) ( 10%) CV2 insulation (A5, A6) voltage to earth Rated 600 VAC 110~120 VAC (+ 10% / - 15%) Rated impulse withstand voltage 4 kV CV2 (A4, A6) 220~240 VAC (+ 10% / - 15%) Form designation Bypassed or continuous, semiconductor motor starter form 1 Mains frequency 50/60 Hz ( 10%) Short circuit capability Rated insulation voltage to earth 600 VAC Coordination with semiconductor fuses Type 2 4 kV Rated impulse withstand voltage Coordination with HRC fuses Type 1 Bypassed or continuous, semiconductor motor Form designation MCD500-0021B to 0215B Prospective current of starter form 1 65 kA MCD500-0245C Prospective current of 85 kA Short circuit capability MCD500-1200C to 1600C Prospective current of 100 kA Coordination with semiconductor fuses Type 2 Electromagnetic capability (compliant with EU Directive 89/336/EEC) Coordination with HRC fuses Type 1 EMC Emissions (Terminals 13 & 14) IEC 60947-4-2 Class B and Lloyds Marine No. 1 Specification MCD500-0021B to 0215B Prospective current of 65 kA EMC Immunity IEC 60947-4-2 MCD500-0245C Prospective current of 85 kA Outputs MCD500-1200C to 1600C Prospective current of 100 kAAC15 pf 0.3 Relay Outputs 10A @ 250 VAC resistive, 5A @ 250 VAC Programmable Outputs Electromagnetic capability (compliant with EU Directive 89/336/EEC) Relay A (13, 14) Normally open IEC 60947-4-2 Class B and Relay B (21, 22, 24) Changeover EMC Emissions (Terminals 13 & 14) Lloyds Marine No. 1 Specication Relay C (33, 34) Normally open EMC Immunity IEC 60947-4-2 Analog Output (07, 08) 0 20 mA or 4 20 mA ( selectable) Maximum load 600 (12 VDC @ 20 mA) (accuracy 5%) Outputs 24 VDC Output (16, 08) Maximum load 200 mA (accuracy VAC 10%) 10A @ 250 resistive, 5A Relay Outputs @ 250 VAC AC15 pf 0.3 Environmental Protection MCD5-0021B ~ MCD5-0105B IP 20 & NEMA, UL Indoor Type 1 Programmable Outputs Protection MCD5-0131B ~ MCD5-1600C IP 00, ULNormally Indoor Open Type Relay A (13, 14) open Operating temperature -10 C toChangeover 60 C, above 40 C with derating Relay B (21, 22, 24) Storage temperature - 25 C to + 60 C Relay C (33, 34) Normally open Operating Altitude 0 1000 m, above 1000 m with derating Analogue Output (07, 08) 0 20 mA or 4 20 mA ( selectable) Humidity 5% to 95% Relative Humidity Maximum load 600 (12 Pollution degree Pollution Degree 3VDC @ 20 mA) (accuracy 5%) 24 VDC Output (16, 08) Maximum load 200 mA (accuracy 10%) Heat Dissipation

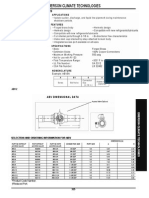

Control Panel VLT LCP 501

Same user interface as MCD500 Remote operation kit Start/stop, reset Plug & play with MCD500 LED for start, run, trip Copy paste of parameters Trip codes Multiple monitoring set-up Current display Door-mount kit 3m cable Motor temperature display 4 20 mA output IP65 (NEMA 12)

During start 4.5 watts per ampere Environmental Protection MCD5-0021B ~ MCD5-0105B IP 20 & NEMA, UL Indoor Type 1 Dimensions Protection MCD5-0131B ~ MCD5-1600C IP 00, UL Indoor Open Type Current rating [AI] Weight (lbs) Height (inches) Width (inches) Depth (inches) Frame Size Operating temperature -10 C to 60 C, above 40 C with derating 21, 37, 43 and 53 9.25 Storage temperature - 25 C to + 60 C 7.2 68 9.92 11.61 5.90 G1 Operating Altitude 0 1000 m, above 1000 m with derating 84, 89 and 105 10.8 8.38 Humidity 5% to 95% Relative Humidity 131, 141, 195 and 215 32.8 17.24 10.82 9.84 G2 Pollution245 degree 52.6 18.11 Pollution Degree 15.35 3 10.98 G3 360, 380 and 428 Heat Dissipation 595, 619, 790 and 927 During start 1200, 1410 and 1600 77 100 264 27.12 16.92 4.5 watts per ampere 33.70 23.03 11.82 14.33 G4 G5

Danfoss VLT Drives

Dimensions

www.danfossdrives.com

Weight [kg] Height [mm] Width [mm] Depth [mm] 295 438 460 150 275 390 183 213 250 279 Frame size G1 G2 G3

4401 N. Bell School Road Loves Park, IL 61111, USA Phone: 1.800.432.6367 1.815.639.8600 FAX: 1.815.639.8000

Danfoss VLT Drives Current rating [A]

8800 W. Bradley Road 21, 37, 43 and 53 4.2 Milwaukee, 68 WI 53224, USA4.5 Phone: 1.800.621.8806 4.9 84, 89 and 105 1.414.355.8800 14.9 131, 141, 195 and 215 FAX: 1.414.355.6117 245 23.9

360, 380 and 428 35 Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves to alter its products without notice. This 689 the right 430 302 G4 also applies to products already on order provided that such alterations can be made without 595, 619, 790 and 927subsequential 45 changes being necessary in specifications already agreed. All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks A/S. All rights reserved. 1200, 1410 and 1600 120 of Danfoss 856 585 364 G5

Copyright 2011 by Danfoss 06/11 177R0369

S-ar putea să vă placă și

- 2021 GKS For Graduate Degrees Final Round Successful CandidatesDocument37 pagini2021 GKS For Graduate Degrees Final Round Successful CandidatesIrfan Muhamad Ramadon63% (19)

- Repeater Diagnostics and Control (RDAC) User Guide: November 2017Document150 paginiRepeater Diagnostics and Control (RDAC) User Guide: November 2017Cesar Del Castillo0% (1)

- Handbuch HYCOOL ENDocument39 paginiHandbuch HYCOOL ENJavier AffifÎncă nu există evaluări

- Graphics and Visual ComputingDocument16 paginiGraphics and Visual ComputingTopher HayagÎncă nu există evaluări

- 177R0369 MCD500 FactSheet 1310 RedesignDocument2 pagini177R0369 MCD500 FactSheet 1310 RedesignLuis Olmedo Castañeda GarcíaÎncă nu există evaluări

- Commander SE: Simple and EasyDocument8 paginiCommander SE: Simple and EasyRitesh SharmaÎncă nu există evaluări

- R1000 CatalogueDocument24 paginiR1000 CataloguemssurajÎncă nu există evaluări

- AC Invertor1000dsDocument20 paginiAC Invertor1000dsRonak PatelÎncă nu există evaluări

- 10 A 8 DDDocument7 pagini10 A 8 DDElectromateÎncă nu există evaluări

- Soft Starter - L&T PDFDocument24 paginiSoft Starter - L&T PDFrajpre1213100% (1)

- 8200 MotecDocument3 pagini8200 Motecyera1Încă nu există evaluări

- ABB Inverter SpecificationsDocument4 paginiABB Inverter SpecificationsPatanjali PamidighantamÎncă nu există evaluări

- lp11 924Document5 paginilp11 924api-170472102Încă nu există evaluări

- Advanced Motion Controls Dpcanir-060a400Document11 paginiAdvanced Motion Controls Dpcanir-060a400ElectromateÎncă nu există evaluări

- L&T Yaskawa AC DrivesDocument20 paginiL&T Yaskawa AC Drivesjunfa0% (1)

- C100 CatalogDocument20 paginiC100 CatalogMarcela RoneÎncă nu există evaluări

- Drive Systems A500 Series: Your Partner in Industrial Automation SystemsDocument4 paginiDrive Systems A500 Series: Your Partner in Industrial Automation SystemsFranklin DannyÎncă nu există evaluări

- Danfoss MCD3000 BrosuraDocument2 paginiDanfoss MCD3000 BrosurazvekoslavÎncă nu există evaluări

- ABB ACS550 Drives CatalogueDocument16 paginiABB ACS550 Drives CatalogueAnonymous hXUhpe7S100% (1)

- Advanced Motion Controls Dprahie-015n400Document10 paginiAdvanced Motion Controls Dprahie-015n400ElectromateÎncă nu există evaluări

- Dse7310 20 Data SheetDocument2 paginiDse7310 20 Data SheetRICKYBLACKÎncă nu există evaluări

- Advanced Motion Controls Dpcanie-015n400Document10 paginiAdvanced Motion Controls Dpcanie-015n400ElectromateÎncă nu există evaluări

- STPTL Us12 24exp Dus132533wDocument4 paginiSTPTL Us12 24exp Dus132533wHector RomeroÎncă nu există evaluări

- Variador Yaskawa Pl.a1000.01Document76 paginiVariador Yaskawa Pl.a1000.01Tomas Enrique Ramirez GomezÎncă nu există evaluări

- Technical App Notes For DC590+ Series DC DriveDocument16 paginiTechnical App Notes For DC590+ Series DC DriveAnang Widhi PrasetiaÎncă nu există evaluări

- Manual iG5A - E - 0425Document32 paginiManual iG5A - E - 0425my27100% (1)

- Description Power Range: Analog Servo DriveDocument8 paginiDescription Power Range: Analog Servo DriveElectromateÎncă nu există evaluări

- Diesel Generator Set KTA19 Series Engine: 576kVA - 650kVA 50Hz 501kW 60HzDocument4 paginiDiesel Generator Set KTA19 Series Engine: 576kVA - 650kVA 50Hz 501kW 60HzSandro MunizÎncă nu există evaluări

- Advanced Motion Controls Dzxcante-008l080Document7 paginiAdvanced Motion Controls Dzxcante-008l080ElectromateÎncă nu există evaluări

- Advanced Motion Controls Dpcanis-100a400Document11 paginiAdvanced Motion Controls Dpcanis-100a400ElectromateÎncă nu există evaluări

- Minas A DriverDocument14 paginiMinas A DriverPham Long100% (1)

- Advanced Motion Controls Dpcania-060a400Document11 paginiAdvanced Motion Controls Dpcania-060a400ElectromateÎncă nu există evaluări

- Description Power Range: Analog Servo DriveDocument7 paginiDescription Power Range: Analog Servo DriveElectromateÎncă nu există evaluări

- Advanced Motion Controls Dpcania-100a400Document11 paginiAdvanced Motion Controls Dpcania-100a400ElectromateÎncă nu există evaluări

- A1000Document8 paginiA1000monikaÎncă nu există evaluări

- Variador Sumitomo PDFDocument8 paginiVariador Sumitomo PDFGera Ortiz MartinezÎncă nu există evaluări

- Gsx600uk 5Document20 paginiGsx600uk 5СДММ ГЕВГЕЛИЈАÎncă nu există evaluări

- 3gen 400-600Document4 pagini3gen 400-600Alexandre BatistaÎncă nu există evaluări

- Advanced Motion Controls Dpcanie-060a400Document11 paginiAdvanced Motion Controls Dpcanie-060a400ElectromateÎncă nu există evaluări

- VLT® Soft Starter MCD 500: PerfectDocument2 paginiVLT® Soft Starter MCD 500: PerfectserginÎncă nu există evaluări

- iG5A E (2012.01)Document44 paginiiG5A E (2012.01)ao0511Încă nu există evaluări

- Advanced Motion Controls Dprahir-060a400Document11 paginiAdvanced Motion Controls Dprahir-060a400ElectromateÎncă nu există evaluări

- Vi P10X XXX PDFDocument4 paginiVi P10X XXX PDFAdyPajuraÎncă nu există evaluări

- DSE 6010 DatasheetDocument2 paginiDSE 6010 DatasheetRabih MradÎncă nu există evaluări

- Catalog: General Purpose Plug-In RelaysDocument12 paginiCatalog: General Purpose Plug-In Relaysmicaziv4786Încă nu există evaluări

- Description Power Range: Analog Servo DriveDocument7 paginiDescription Power Range: Analog Servo DriveElectromateÎncă nu există evaluări

- Description Power Range: Analog Servo DriveDocument7 paginiDescription Power Range: Analog Servo DriveElectromateÎncă nu există evaluări

- Frenic LiftDocument8 paginiFrenic LiftĐộc Thiên ThanhÎncă nu există evaluări

- Automatic Transfer SwitchesDocument20 paginiAutomatic Transfer SwitchesgianmantÎncă nu există evaluări

- Advanced Motion Controls Dpcanir-015a400Document11 paginiAdvanced Motion Controls Dpcanir-015a400ElectromateÎncă nu există evaluări

- Description Power Range: Analog Servo DriveDocument7 paginiDescription Power Range: Analog Servo DriveElectromateÎncă nu există evaluări

- Advanced Motion Controls Dprahis-060a400Document11 paginiAdvanced Motion Controls Dprahis-060a400ElectromateÎncă nu există evaluări

- ACPL312TDocument18 paginiACPL312Tcms_saÎncă nu există evaluări

- CET Power - Datasheet BRAVO 230vac - 2014 v1Document2 paginiCET Power - Datasheet BRAVO 230vac - 2014 v1Micah WilsonÎncă nu există evaluări

- Manual Kholer 2250reozddDocument4 paginiManual Kholer 2250reozddVictorÎncă nu există evaluări

- Description Power Range: Analog Servo DriveDocument8 paginiDescription Power Range: Analog Servo DriveElectromateÎncă nu există evaluări

- Advanced Motion Controls Dpqnnie-100a400Document11 paginiAdvanced Motion Controls Dpqnnie-100a400ElectromateÎncă nu există evaluări

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsDe la EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsEvaluare: 3.5 din 5 stele3.5/5 (6)

- Digital Power Electronics and ApplicationsDe la EverandDigital Power Electronics and ApplicationsEvaluare: 3.5 din 5 stele3.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1De la EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Evaluare: 2.5 din 5 stele2.5/5 (3)

- Gases Nuevos de Bajo Efecto InvernaderoDocument82 paginiGases Nuevos de Bajo Efecto InvernaderoJavier AffifÎncă nu există evaluări

- Cooling Tower Controllers: Ensures Optimal Performance and Maximum EfficiencyDocument4 paginiCooling Tower Controllers: Ensures Optimal Performance and Maximum EfficiencyJavier AffifÎncă nu există evaluări

- Piston / Valve Design General Characteristics: Flow Switch 1.1. NovafixDocument2 paginiPiston / Valve Design General Characteristics: Flow Switch 1.1. NovafixJavier AffifÎncă nu există evaluări

- PVL Now Has Britain's Largest Range of Flow Switches, Manufactured by Honsberg of Germany & Kelco of AustraliaDocument14 paginiPVL Now Has Britain's Largest Range of Flow Switches, Manufactured by Honsberg of Germany & Kelco of AustraliaJavier AffifÎncă nu există evaluări

- C15 & C20 Series Inline Flow Switch: FeaturesDocument2 paginiC15 & C20 Series Inline Flow Switch: FeaturesJavier AffifÎncă nu există evaluări

- Ameritrol Electronic Thermal Flow SensorDocument2 paginiAmeritrol Electronic Thermal Flow SensorJavier AffifÎncă nu există evaluări

- Type SSM Medium Voltage 2300 - 13,800V: SoftstartersDocument5 paginiType SSM Medium Voltage 2300 - 13,800V: SoftstartersJavier AffifÎncă nu există evaluări

- Abv Refrigeration Ball Valves: Product Code Number. Reduced PortDocument1 paginăAbv Refrigeration Ball Valves: Product Code Number. Reduced PortJavier AffifÎncă nu există evaluări

- ACS350 Flyer EN Revc LRDocument2 paginiACS350 Flyer EN Revc LRJavier AffifÎncă nu există evaluări

- ZB Scroll Compressors ManualDocument70 paginiZB Scroll Compressors ManualJavier AffifÎncă nu există evaluări

- Whirlpool 7mwt9601ww0 Manual de UsuarioDocument12 paginiWhirlpool 7mwt9601ww0 Manual de UsuarioMARTIN CABRERAÎncă nu există evaluări

- Managed IT Services RFP TemplateDocument11 paginiManaged IT Services RFP Templateedpaala67% (3)

- CorrespondenceDocument4 paginiCorrespondenceBec HindleÎncă nu există evaluări

- Preparing - Your - Lab - D-6660 July 2002Document11 paginiPreparing - Your - Lab - D-6660 July 2002Navi MoralesÎncă nu există evaluări

- Workshop Solution For Bulk ProcessingDocument20 paginiWorkshop Solution For Bulk Processingmuruganandhan100% (2)

- Biases Used in EdTechDocument3 paginiBiases Used in EdTechRahul GargÎncă nu există evaluări

- Public Key Cryptography - Chapter 9Document109 paginiPublic Key Cryptography - Chapter 9sonyÎncă nu există evaluări

- Oracle Process ExecutionDocument552 paginiOracle Process ExecutionVineethÎncă nu există evaluări

- Narrative Profile - BEED LibraryDocument51 paginiNarrative Profile - BEED LibraryJUNNARIEÎncă nu există evaluări

- Gjse CP 05Document4 paginiGjse CP 05abci jorginÎncă nu există evaluări

- Datascience One WordDocument30 paginiDatascience One WordShradha GaikwadÎncă nu există evaluări

- Finance Manager / Accounting Manager: Personal InformationDocument3 paginiFinance Manager / Accounting Manager: Personal InformationHarshwardhan PathakÎncă nu există evaluări

- DariaDocument1 paginăDariaBojan DimishkovskiÎncă nu există evaluări

- Mn00224e-ALPlus2 - ALCPlus2 - ALCPlus2eDocument388 paginiMn00224e-ALPlus2 - ALCPlus2 - ALCPlus2eAlberto Rodrigues de SouzaÎncă nu există evaluări

- Launchpad YOP22 - V1.3Document4 paginiLaunchpad YOP22 - V1.3Sambhu LalÎncă nu există evaluări

- Carrier Water Cooled Package Unit - tcm177-85755Document9 paginiCarrier Water Cooled Package Unit - tcm177-85755Ravindra JadhavÎncă nu există evaluări

- Principles of Management Assignment by 20191bbl0061 Mohammed RohinDocument4 paginiPrinciples of Management Assignment by 20191bbl0061 Mohammed RohinRohin Bin RafiÎncă nu există evaluări

- Running Head: Workrite Lock-In Project 1Document10 paginiRunning Head: Workrite Lock-In Project 1Caroline WanjaÎncă nu există evaluări

- Samsung Introduction of New 40T v3Document15 paginiSamsung Introduction of New 40T v3costel cracanaÎncă nu există evaluări

- Cryptocurrency From Shari'ah PerspectiveDocument18 paginiCryptocurrency From Shari'ah PerspectiveAna FienaÎncă nu există evaluări

- Icon Line Trimmer - ICPLT26 Operator ManualDocument10 paginiIcon Line Trimmer - ICPLT26 Operator ManualAnirudh Merugu67% (3)

- HP 3070 Unix InstallationDocument18 paginiHP 3070 Unix InstallationpvvsczÎncă nu există evaluări

- Zeiss AI EbookDocument56 paginiZeiss AI EbookRaylson De SÁ Melo UFCÎncă nu există evaluări

- Upstream Upper-IntermediateDocument268 paginiUpstream Upper-IntermediateEsteraÎncă nu există evaluări

- REFERENCESDocument2 paginiREFERENCESMichael MontemayorÎncă nu există evaluări

- Boot AnimationDocument27 paginiBoot AnimationAbhishek100% (1)

- Manual de Usuario Ecografo DC40 PDFDocument291 paginiManual de Usuario Ecografo DC40 PDFFederico Rodriguez MonsalveÎncă nu există evaluări